Académique Documents

Professionnel Documents

Culture Documents

ChE 471 EXAM 2 2004

Transféré par

HungDoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ChE 471 EXAM 2 2004

Transféré par

HungDoDroits d'auteur :

Formats disponibles

CHE 471

FALL 2004

EXAM 2

(Closed Book, Closed Notes)

(2 Crib Sheets Allowed)

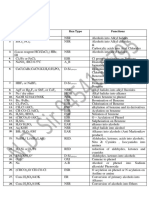

PROBLEM #1

Consider the following competitive reactions:

RP 1 mol L hr

P

A

RR 2 C A mol L hr

RS 1 C A2 mol L hr

The feed concentration is C Ao 5 mol L . For this reaction system and feed concentration

your task is to optimize (maximize) the concentration of P, C p .

a)

What reactor type (or reactor combination) do you recommend and why? Clearly explain

your answer and illustrate it graphically.

b)

What is the maximum achievable C p ?

c)

What is the volume of the reactor(s) required if you are processing 10,000 (L/h) of the feed?

Hint: Examine the point yield y R p

R A as a function of

CA .

PROBLEM #2

Consider a system of consecutive first order reactions

A k1 R k2 S

with k1 k 2 0.01 min 1 . You are asked to maximize the concentration of the intermediate

R and have two equal size stirred tank reactors (CSTRs) at your disposal V1 V2 .

a)

In order to maximize C R do you want to operate the two CSTRs in parallel or in series?

Explain your answer.

b)

What is the maximum C R that you can produce?

c)

If the reactors are V 10,000 L in size each, what flow rate Q of the feed can you

process in order to reach maximum C R and what is your maximum production rate of R,

FR Q C R , if the feed concentration is C Ao 1 mol L ?

Hint: Use CSTR design equations for A and R .

PROBLEM #3

A reversible, first-order exothermic reaction is carried out in a continuous flow stirred tank

reactor (CSTR). The stoichiometry is A R S and the reaction rate in mol L min is given

as:

R A 8.8 10 4 e 12 ,500 / RT C Ao 1 x A 4.2 1015 e 30 , 000 / RT C Ao x A

with activation energies in cal mol . Thus R 1.987 cal mol K .

We want to produce FR 1 mol min at the conversion of A of x A 0.9 .

a)

Find the optimal operating temperature for the reactor (i.e., the temperature that minimizes

the needed reactor volume).

b)

Find the necessary reactor size (volume).

c)

If the feed is available only at 300K, calculate the required rate of heating (or cooling) for

the reactor. Clearly specify whether the reactor is being heated or cooled.

H r

Cp

C Ao

Data :

17,500 cal mol

500 cal L K

10 mol L

Hint: Use the equation for the Tm line or derive it by taking R A T 0 .

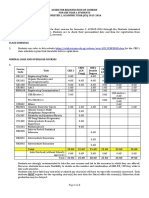

PROBLEM #4

A plug flow reactor with recycle shown below is used for an irreversible exothermic reaction

A P.

C Ao

To

Q

xA 0

To

x Ain

(R+1) Q

PFR

RQ

To

x Af

T

xAf

T

xAf

T

xAf

Q

The rate of reaction is second order and is given by:

2

R A 2.7 10 8 e 10, 000 / RT C A mol L min where the activation energy is given in

cal mol

R 1.987 cal mol K .

so that

The heat of reaction

is

H r 20,000 cal mol . The feed is at To 350 K and C Ao 1 mol L . The

physical properties of the mixture are such that C p 500 cal C K . We want to achieve

95% conversion x A f 0.95 .

The plug flow reactor section of the recycle reactor operates adiabatically but heat is removed

from the recycle loop via a heat exchanger so as to reduce the temperature of the reaction

mixture back to feed temperature as shown in the diagram. Your task is to operate the plug flow

reactor close to isothermally. You are told that you can consider the adiabatic plug flow reactor

section to be approximately isothermal if the value of the rate constant 2.7 108 e 10 , 000 / RT

at the exit adiabatic temperature T does not differ by more than 10% than the rate constant

evaluated at the inlet temperature To 350 K .

a)

Find the exit temperature T that satisfies this requirement (and round it off to the nearest

degree).

b)

Calculate the recycle ratio R that you must use in order to satisfy this requirement (i.e., not

exceed the desired exit temperature T).

Hint: Make a mass balance around mixing point M to relate x A to recycle ratio, R. Then make

the adiabatic energy balance around the plug flow section of the recycle reactor.

in

c)

Find the required reactor space time.

[Hint: use the rate constant evaluated at the mean temperature between To and T and the

isothermal formula for the recycle reactor].

d)

If we need to process Q 1000 L min find the required reactor size.

e) Find the cooling requirement for the heat exchanger (i.e., the required rate of heat

removal in the recycle loop).

Vous aimerez peut-être aussi

- ChE 471 EXAM 2 2004Document3 pagesChE 471 EXAM 2 2004Ian Patrick PerilePas encore d'évaluation

- HW 2 K 1606Document7 pagesHW 2 K 1606Primus OngPas encore d'évaluation

- Temperature, °C: SolutionDocument18 pagesTemperature, °C: Solutionمحمد حلمي هاريريPas encore d'évaluation

- 2010 ChE 471 HW 8 FinalDocument4 pages2010 ChE 471 HW 8 FinalSiti HannaPas encore d'évaluation

- Tut1 2016 QDocument5 pagesTut1 2016 QAbhishek SardaPas encore d'évaluation

- Revision QuestionsDocument12 pagesRevision QuestionsLiew Wen Xuan0% (2)

- Modul 3Document3 pagesModul 3Anonymous OecsqTAPas encore d'évaluation

- 2010 ChE 471 HW 8 FinalDocument4 pages2010 ChE 471 HW 8 FinalpinhoncetePas encore d'évaluation

- Department of Chemical Engineering, Iit Delhi Reactor Sizing and Selection Problems Assignment-4Document3 pagesDepartment of Chemical Engineering, Iit Delhi Reactor Sizing and Selection Problems Assignment-4ShubhamGuptaPas encore d'évaluation

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Document6 pagesChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaPas encore d'évaluation

- Tutorial QuestionsDocument8 pagesTutorial QuestionsMaame Efua Neizer100% (1)

- Introduction To Chemical Reactor Engineering - Problems PDFDocument75 pagesIntroduction To Chemical Reactor Engineering - Problems PDFJojie-Ann Alabarca100% (1)

- Microsoft Word - 6 - Prob RTD-Non Id React 11-12 61-78 - EnglishDocument9 pagesMicrosoft Word - 6 - Prob RTD-Non Id React 11-12 61-78 - EnglishPavithra Sivaraja100% (1)

- r05310805 Chemical Reaction Engineering IDocument8 pagesr05310805 Chemical Reaction Engineering ISrinivasa Rao GPas encore d'évaluation

- CRE IdocxDocument8 pagesCRE IdocxParth DesaiPas encore d'évaluation

- Assignment 6Document3 pagesAssignment 6Yi Hong LowPas encore d'évaluation

- Assignment 4Document5 pagesAssignment 4Yi Hong LowPas encore d'évaluation

- HW2 2009 SolnsDocument13 pagesHW2 2009 SolnsMatthew RichardsonPas encore d'évaluation

- Week 2Document37 pagesWeek 2HAJEYYPas encore d'évaluation

- R09 Set No. 2Document8 pagesR09 Set No. 2Shakoor MalikPas encore d'évaluation

- 3 - Prob PFR 11-12 23-35 English-1Document4 pages3 - Prob PFR 11-12 23-35 English-1Biniyam hailePas encore d'évaluation

- Chapter 8 - Steadystate Non-Isothermal ReactorDocument49 pagesChapter 8 - Steadystate Non-Isothermal ReactorAbdul Majid IaPas encore d'évaluation

- Reactor EnggDocument75 pagesReactor EnggarunperthPas encore d'évaluation

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 6Document4 pagesCHE3044F, 2013: Reactor Design 1: TUTORIAL 6nmhatityePas encore d'évaluation

- Rr320802chemicalreactionengineeringiDocument8 pagesRr320802chemicalreactionengineeringiSanthosh KumarPas encore d'évaluation

- Tutorial-3 CRE1 CLL122 PDFDocument4 pagesTutorial-3 CRE1 CLL122 PDFSunandita BorahPas encore d'évaluation

- S 19cre1Document2 pagesS 19cre1nalkandeaditya7Pas encore d'évaluation

- nr320802 Chemical Reaction Engineering IDocument2 pagesnr320802 Chemical Reaction Engineering ISRINIVASA RAO GANTAPas encore d'évaluation

- Chemical Recator Design: 6 Semester B.Sc. Chemical EngineeringDocument19 pagesChemical Recator Design: 6 Semester B.Sc. Chemical EngineeringzeeshanPas encore d'évaluation

- Ch4-E - Fogler-4th Ed PDFDocument16 pagesCh4-E - Fogler-4th Ed PDFsandra thalia parmithaPas encore d'évaluation

- Assignment-3 (ChE 401 CRD - Deadline 26th Oct 2018)Document1 pageAssignment-3 (ChE 401 CRD - Deadline 26th Oct 2018)Hassaan NaeemPas encore d'évaluation

- Conversion and Reactor SizingDocument40 pagesConversion and Reactor SizingsiskieoPas encore d'évaluation

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 5Document2 pagesCHE3044F, 2013: Reactor Design 1: TUTORIAL 5nmhatityePas encore d'évaluation

- Chemical Reaction DesignDocument3 pagesChemical Reaction DesignZohaib AliPas encore d'évaluation

- Essy Questions On Non-Ideal ReactorsDocument9 pagesEssy Questions On Non-Ideal ReactorsRobinson APas encore d'évaluation

- JNTU Old Question Papers 2007Document8 pagesJNTU Old Question Papers 2007Srinivasa Rao GPas encore d'évaluation

- Reactors Sizing: Transesterification ReactorsDocument20 pagesReactors Sizing: Transesterification ReactorsJobb Six-steps MatheusPas encore d'évaluation

- CHP 482 - TutorialsDocument4 pagesCHP 482 - Tutorialsgeofrey oburuPas encore d'évaluation

- CHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignDocument16 pagesCHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignPranav NakhatePas encore d'évaluation

- Department of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2Document2 pagesDepartment of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2ShubhamGuptaPas encore d'évaluation

- Loda LeleDocument3 pagesLoda Lele;(Pas encore d'évaluation

- Fixed-Bed Catalytic ReactorDocument19 pagesFixed-Bed Catalytic ReactorHesham MashaalPas encore d'évaluation

- Tutorial Four-TutorialDocument4 pagesTutorial Four-Tutorialhagt813Pas encore d'évaluation

- ChE 125 LE - 04 PDFDocument1 pageChE 125 LE - 04 PDFJojie-Ann AlabarcaPas encore d'évaluation

- Exercise TRK 1Document14 pagesExercise TRK 1Ananda CahyaPas encore d'évaluation

- Assignment 5Document3 pagesAssignment 5Moosa NaseerPas encore d'évaluation

- TRK1 2013 Chapt 2Document14 pagesTRK1 2013 Chapt 2Putri JulietaPas encore d'évaluation

- Isothermal Reactor DesignDocument31 pagesIsothermal Reactor Designdeepshikhasingh100% (1)

- Exercise 1: Reactors: 1.1 Reactor SelectionDocument4 pagesExercise 1: Reactors: 1.1 Reactor SelectionAnh Đỗ HoàngPas encore d'évaluation

- EstDocument2 pagesEstAdityaPas encore d'évaluation

- Thermo OldStylePastPaper 2007-19Document54 pagesThermo OldStylePastPaper 2007-19manjeet gajbhiyePas encore d'évaluation

- A Modern Course in Statistical PhysicsD'EverandA Modern Course in Statistical PhysicsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- CHFEN 3553 Chemical Reaction Engineering: April 7, 2004 12:55 PM - 1:45 PM Answer All QuestionsDocument3 pagesCHFEN 3553 Chemical Reaction Engineering: April 7, 2004 12:55 PM - 1:45 PM Answer All QuestionsHungDoPas encore d'évaluation

- Rev Exam2Document1 pageRev Exam2HungDoPas encore d'évaluation

- Midterm2 KeyDocument6 pagesMidterm2 KeyHungDoPas encore d'évaluation

- Exam 3 SolDocument3 pagesExam 3 SolHungDoPas encore d'évaluation

- Final 04 SolDocument6 pagesFinal 04 SolHungDo0% (1)

- Final 99 SolDocument17 pagesFinal 99 SolHungDoPas encore d'évaluation

- Che 471 Quiz No 8 Fall 2008 Closed Book and Closed Notes, No Crib SheetDocument1 pageChe 471 Quiz No 8 Fall 2008 Closed Book and Closed Notes, No Crib SheetHungDoPas encore d'évaluation

- Che 471fall HW 7 2008Document5 pagesChe 471fall HW 7 2008HungDoPas encore d'évaluation

- Che 471 Quiz No 7 Fall 2008 Find The Adiabatic Temperature Rise For The Following Reaction: 2A R DataDocument1 pageChe 471 Quiz No 7 Fall 2008 Find The Adiabatic Temperature Rise For The Following Reaction: 2A R DataHungDoPas encore d'évaluation

- Che 471 Exam 1 (Closed Book & Notes, 1 Crib Sheet Allowed) : C O O C O C O O O CDocument2 pagesChe 471 Exam 1 (Closed Book & Notes, 1 Crib Sheet Allowed) : C O O C O C O O O CHungDoPas encore d'évaluation

- ChE 471 EXAM 2 2000Document3 pagesChE 471 EXAM 2 2000HungDoPas encore d'évaluation

- ChE471 Quiz - 5 2008Document1 pageChE471 Quiz - 5 2008HungDoPas encore d'évaluation

- ChE 471 EXAM 1 2005Document2 pagesChE 471 EXAM 1 2005HungDoPas encore d'évaluation

- 471 Homework 1 2008Document3 pages471 Homework 1 2008HungDoPas encore d'évaluation

- Guide For CBE 1 Sem 2 AY1516Document2 pagesGuide For CBE 1 Sem 2 AY1516HungDoPas encore d'évaluation

- Che 471: Chemical Reaction Engineering Homework AssignmentsDocument1 pageChe 471: Chemical Reaction Engineering Homework AssignmentsHungDoPas encore d'évaluation

- Geopolymers and Polymers in The Conservation of Tile FacadesDocument10 pagesGeopolymers and Polymers in The Conservation of Tile FacadesJuan Jose Perez MolinaPas encore d'évaluation

- Safety Data Sheet: Oxysan Acid SanitizerDocument11 pagesSafety Data Sheet: Oxysan Acid SanitizerVictor RamirezPas encore d'évaluation

- Earthquakes Intro WorksheetDocument1 pageEarthquakes Intro WorksheetDean BevanPas encore d'évaluation

- Chapter 2 EnergyDocument6 pagesChapter 2 EnergyJaishree RamPas encore d'évaluation

- Linear Algebra LessonsDocument20 pagesLinear Algebra Lessonsgolden kittenPas encore d'évaluation

- Domingo, Joevani T. (Laboratory Manuals)Document141 pagesDomingo, Joevani T. (Laboratory Manuals)Joevani DomingoPas encore d'évaluation

- Carbon Fibre Physics CourseworkDocument8 pagesCarbon Fibre Physics Courseworksyn0tiwemym3100% (2)

- CHE-504 Lecture 6 Mass Spectrometery-II by Dr. Charu C. PantDocument24 pagesCHE-504 Lecture 6 Mass Spectrometery-II by Dr. Charu C. PantAbhishek Singh ChandelPas encore d'évaluation

- Formulas of Hydrocarbons and IsomersDocument13 pagesFormulas of Hydrocarbons and IsomersJohn Steven Batronel CalaraPas encore d'évaluation

- Organic ReagentsDocument3 pagesOrganic ReagentsKushagra Rai100% (1)

- Cobalt Free CompositeDocument10 pagesCobalt Free CompositeFadil KhayrPas encore d'évaluation

- Form 1 Chapter 1-7 Science NotesDocument11 pagesForm 1 Chapter 1-7 Science Noteswentao0420100% (1)

- Experiment 1Document16 pagesExperiment 1Izhharuddin100% (2)

- 18 Quantitative Aspects of Chemical ChangeDocument30 pages18 Quantitative Aspects of Chemical Changeapi-235269401Pas encore d'évaluation

- Scirce All ChaptersDocument20 pagesScirce All ChaptersshirinPas encore d'évaluation

- Micro Nutrients & Macro NutrientsDocument18 pagesMicro Nutrients & Macro Nutrientssde100% (1)

- Shanmugam 1997 ESR The Bouma Sequence and The Turbidite MindDocument29 pagesShanmugam 1997 ESR The Bouma Sequence and The Turbidite MindEric EspirituPas encore d'évaluation

- Laboratory Investigation of Enhanced Light-Oil Recovery by CO /flue Gas Huff-n-Puff ProcessDocument9 pagesLaboratory Investigation of Enhanced Light-Oil Recovery by CO /flue Gas Huff-n-Puff Processjrluva096Pas encore d'évaluation

- HydranauticsDocument17 pagesHydranauticsNafian AwaludinPas encore d'évaluation

- Group 17 ElementsDocument28 pagesGroup 17 Elementstapas kunduPas encore d'évaluation

- CH 2 Coulombs Law APEMDocument3 pagesCH 2 Coulombs Law APEMJames FlaughPas encore d'évaluation

- Uop938 PDFDocument22 pagesUop938 PDFNur Indah KartikasariPas encore d'évaluation

- Temperature and Heat: Powerpoint Lectures ForDocument32 pagesTemperature and Heat: Powerpoint Lectures ForAbdullah ZafarPas encore d'évaluation

- Sulfuric Acid As A Dehydrating AgentDocument7 pagesSulfuric Acid As A Dehydrating AgentSidhant GakharPas encore d'évaluation

- Center For Advancing Research in Transportation Emissions, Energy, and HealthDocument25 pagesCenter For Advancing Research in Transportation Emissions, Energy, and HealthRoberttPas encore d'évaluation

- FinFET Evolution Toward Stacked-Nanowire FET For CMOS Technology ScalingDocument6 pagesFinFET Evolution Toward Stacked-Nanowire FET For CMOS Technology ScalingThiago Henrique SantosPas encore d'évaluation

- R. Ingram Performance Task & Rubric: Break Down and Digest FoodsDocument2 pagesR. Ingram Performance Task & Rubric: Break Down and Digest Foodsapi-361030663Pas encore d'évaluation

- Z 200 Libs Analyser Laser Induced Breakdown Spectroscopy21 - 59 - 37Document2 pagesZ 200 Libs Analyser Laser Induced Breakdown Spectroscopy21 - 59 - 37BUTUCARU PETRICAPas encore d'évaluation

- Dark Matter PDFDocument120 pagesDark Matter PDFAswin VengatPas encore d'évaluation

- Australian National Measurement Institune - Monograph 7 - Pressure Measurement - Randall Anderson Et Al. - 2nd Edition - 2003Document246 pagesAustralian National Measurement Institune - Monograph 7 - Pressure Measurement - Randall Anderson Et Al. - 2nd Edition - 2003teewohdPas encore d'évaluation