Académique Documents

Professionnel Documents

Culture Documents

Thermal Bridging

Transféré par

texas_peteCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermal Bridging

Transféré par

texas_peteDroits d'auteur :

Formats disponibles

LowCarb4Real; Design collection:

Thermal bridging

What is a thermal bridge?

Types of thermal bridge

A thermal bridge is created when materials that are poorer insulators Repeating: where bridges occur following a regular pattern, such as

than surrounding materials come in contact, allowing heat to flow

that made by wall ties penetrating a cavity wall or timber studs in a

through the path created.

timber frame external wall..

Insulation adjacent to a bridge is of limited help in preventing heat loss Non-repeating: where bridges occur that are detail specific, such as

(or gain) due to thermal bridging; the bridging has to be eliminated, rethe bridging of a cavity wall by a combined lintel or at a door threshbuilt with a reduced cross-section or with materials that have better inold.

sulating properties, or with an additional insulating component (a ther- Geometric: at the junction of two or more planes, such as at the

mal break).

corner of an external wall or at the eaves.

Geometric thermal bridges

Repeating thermal bridges

With a higher level of insulation, the relative importance of thermal bridges increases in the energy balance. With this in mind, repeating thermal bridges which

may have been acceptable in the past need to be designed out to achieve the energy performance standards required in todays lower carbon emission dwellings.

Timber studwork in standard timber frame construction, and in pre-manufactured

insulated panels (left), may create repeating thermal bridges that will need to be designed out; most commonly by the addition of a supplementary layer of insulation.

At Stamford Brook (right), traditional stainless

steel wall-ties would have significantly increased the heat loss through the masonrycavity external walls, effectively bypassing

much of the 142mm of retro-filled blownfibre insulation. The use of Kristiansen RefusI

250mm glass-filled thermoplastic polyester

wall-ties (with a thermal transmittance well

below that of steel) went some way to reducing the repeating thermal bridging.

Non-repeating thermal bridges

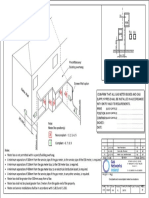

SAP Table K1 value for

combined lintel:

= 0.30 W/mK

Original separate lintel

design at Stamford Brook

= 0.016 W/mK

Steel toe added to inner leaf

lintel

Compromise 42mm gap:

= 0.068 W/mK

Worst case, 20mm gap:

= 0.18 W/mK

Non-repeating thermal bridges are intermittent and often caused by discontinuities in the designed thermal envelope. These may be constructive or material thermal bridges, frequently observed around openings and other instances where materials of different thermal conductivities form the external

envelope.

Thermal bridges can be quantified by calculating the linear thermal transmittance (-value), measured in W/mK. This is the additional heat loss (or gain)

through the building envelope per metre length of that detail, and can be calculate by using software such as the freely available THERM package from

LBNL (http://windows.lbl.gov/software/therm/therm.html) and the resultant values fed

back into SAP to establish the DER rather than use the default values for accredited construction details (see left).

Design changes, whether in the design or construction phases need to be reviewed and thermal bridging re-calculate to avoid potential problems (below).

In more extreme cases thermal bridging can significantly increase the risk of

surface or interstitial condensation and promote mould growth.

These can be either 2dimensional (where 2 planes

intersect) or 3-dimensional

(at the junction of 3 or more

planes).

Geometric thermal bridges

are due to the shape of the

building or, more specifically, due to the shape of the thermal

envelope. An increase in the complexity of the building

geometry is liable to increase the occurrence of junctions that

display a degree of geometric thermal bridging.

3-D junctions offer a level of complexity that is often difficult

to visualise from 2-D drawings alone and frequently require

changes in material as well as in direction.

Designs must ensure that such issues are not left to site

operatives to solve but are

addressed fully at the design

stage, considering such

concerns as continuity of

insulation, buildability, build

sequence and procedural

issues.

When calculating heat loss from a dwelling, variations

between as-designed and as-built details can have a

significant on the overall result.

The example illustrated here

shows the difference made by

omission of the intermediate

floor perimeter insulation in a

timber framed dwelling.

Thermal bridge at the Stamford Brook bay window head, the design included an insu- Designs need to ensure that

lated head liner which was omitted in the construction phase for aesthetic reasons.

the likelihood of such errors occurring are minimised.

Rules to assist in the avoidance of thermal bridging

Design Rule

Description

Prevention Rule

Where possible, do not interrupt the thermal envelope.

Penetration Rule

Where an interrupted insulating layer is unavoidable, thermal

resistance in the insulation plane should be as high as possible.

Junction Rule

At building element junctions, insulating layers should meet without any

gaps. Insulating layers should join without interruption or misalignment.

Geometry Rule

Design edges to have as obtuse angles as possible.

Adapted from CEPHEUS (Cost Efficient Passive Houses as European Standards) - Projectinformation No. 36 (Feist, Peper & Gorg, 2001).

UrbanBuzz ProjectDeveloping Low Carbon Housing: Lessons from The FieldLowCarb4Real

Lead Organisations: Leeds Metropolitan University and University College London

Project Partners: Good Homes Alliance, National Trust, Taylor Wimpey, Redrow, University of Leeds.

Contacts: Prof. Malcolm Bell, Leeds Metropolitan University (m.bell@leedsmet.ac.uk), Prof. Bob Lowe, Bartlett School of Graduate Studies, UCL (robert.lowe@ucl.ac.uk)

Vous aimerez peut-être aussi

- RAPEX Alert - SPAX Concrete ScrewsDocument2 pagesRAPEX Alert - SPAX Concrete Screwstexas_petePas encore d'évaluation

- Home Security - DoorsDocument2 pagesHome Security - Doorstexas_petePas encore d'évaluation

- Irish National Survey of Housing Quality 2001 2002Document14 pagesIrish National Survey of Housing Quality 2001 2002texas_petePas encore d'évaluation

- A House in The Country - 2004 - Rhys-ThomasDocument3 pagesA House in The Country - 2004 - Rhys-Thomastexas_petePas encore d'évaluation

- Code of Practice For Wind Energy Development in Ireland - Guidelines For Community EngagementDocument10 pagesCode of Practice For Wind Energy Development in Ireland - Guidelines For Community Engagementtexas_petePas encore d'évaluation

- GM Guide Insulating SheathingDocument30 pagesGM Guide Insulating Sheathingtexas_petePas encore d'évaluation

- Slip ResistanceDocument4 pagesSlip Resistancetexas_petePas encore d'évaluation

- Interim Climate Actions 2021Document144 pagesInterim Climate Actions 2021texas_petePas encore d'évaluation

- Foreword: Fire Safety in Pre-SchoolsDocument47 pagesForeword: Fire Safety in Pre-Schoolstexas_petePas encore d'évaluation

- Brickwork and MMC Rev FDocument16 pagesBrickwork and MMC Rev Ftexas_petePas encore d'évaluation

- REC Factsheet April 2016Document4 pagesREC Factsheet April 2016texas_petePas encore d'évaluation

- Annex of Actions 2019Document90 pagesAnnex of Actions 2019texas_petePas encore d'évaluation

- Fire Doors Curtains & Shutters - General Overview & RequirementsDocument12 pagesFire Doors Curtains & Shutters - General Overview & Requirementstexas_petePas encore d'évaluation

- Climate Action Plan 2019: InfographicDocument4 pagesClimate Action Plan 2019: Infographictexas_petePas encore d'évaluation

- Cap 2019Document150 pagesCap 2019texas_petePas encore d'évaluation

- Safety Advice For Working in The Vicinity of Natural Gas Pipelines A5Document24 pagesSafety Advice For Working in The Vicinity of Natural Gas Pipelines A5texas_petePas encore d'évaluation

- Construction Product Regulation - Questions & Answers For ClientsDocument3 pagesConstruction Product Regulation - Questions & Answers For Clientstexas_petePas encore d'évaluation

- Ireland's Gas Network: Delivering A Reliable and Secure Gas SupplyDocument6 pagesIreland's Gas Network: Delivering A Reliable and Secure Gas Supplytexas_petePas encore d'évaluation

- Construction Product Regulation - Questions & Answers For ClientsDocument3 pagesConstruction Product Regulation - Questions & Answers For Clientstexas_petePas encore d'évaluation

- Loft Conversions DOEHLG 2004 PDFDocument2 pagesLoft Conversions DOEHLG 2004 PDFtexas_petePas encore d'évaluation

- Blue Guide - 2014 - en PDFDocument134 pagesBlue Guide - 2014 - en PDFjasonPas encore d'évaluation

- SK-701 Compliant and Noncompliant Meter Box LocationsDocument1 pageSK-701 Compliant and Noncompliant Meter Box Locationstexas_petePas encore d'évaluation

- Guide To Insulating Sheathing: Revised January 2007Document30 pagesGuide To Insulating Sheathing: Revised January 2007texas_petePas encore d'évaluation

- ESB Construction SafetyDocument12 pagesESB Construction Safetytexas_petePas encore d'évaluation

- Avoiding Danger From Overhead Electricity LinesDocument88 pagesAvoiding Danger From Overhead Electricity LinesRonnie Delos SantosPas encore d'évaluation

- EirGrid Group Transmission System Geographic Map Sept 2016Document1 pageEirGrid Group Transmission System Geographic Map Sept 2016texas_petePas encore d'évaluation

- Tool Box Talks ConstructionDocument12 pagesTool Box Talks Constructiontexas_petePas encore d'évaluation

- BS7543Document7 pagesBS7543texas_petePas encore d'évaluation

- Energy Efficiency in Historic BuildingsDocument17 pagesEnergy Efficiency in Historic Buildingstexas_petePas encore d'évaluation

- Irc First Aid A2 Poster 09.2013 PDFDocument1 pageIrc First Aid A2 Poster 09.2013 PDFtexas_petePas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CADS Revit Scia Engineer Link Best PracticesDocument32 pagesCADS Revit Scia Engineer Link Best PracticestrevorPas encore d'évaluation

- 1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016Document3 pages1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016api-292307509Pas encore d'évaluation

- Homophones WorksheetDocument3 pagesHomophones WorksheetAmes100% (1)

- Fatigue Consideration in DesignDocument3 pagesFatigue Consideration in DesigngouthamPas encore d'évaluation

- AdPoe The Hunting of The HareDocument2 pagesAdPoe The Hunting of The HarePI CubingPas encore d'évaluation

- Cateora2ce IM Ch012Document9 pagesCateora2ce IM Ch012Priya ShiniPas encore d'évaluation

- Sotero 05activity EnvironmetnDocument3 pagesSotero 05activity Environmetnbernadette soteroPas encore d'évaluation

- Epilepsy Lecture NoteDocument15 pagesEpilepsy Lecture Notetamuno7100% (2)

- Notice: Environmental Statements Notice of Intent: Eldorado National Forest, CADocument2 pagesNotice: Environmental Statements Notice of Intent: Eldorado National Forest, CAJustia.comPas encore d'évaluation

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDocument6 pagesModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕPas encore d'évaluation

- Scientific American Psychology 2nd Edition Licht Test BankDocument44 pagesScientific American Psychology 2nd Edition Licht Test Bankpurelychittra3ae3100% (24)

- Lab Centre of Pressure Ecw341Document4 pagesLab Centre of Pressure Ecw341danialPas encore d'évaluation

- CFD - Basement Car ParkDocument43 pagesCFD - Basement Car ParkTanveer HasanPas encore d'évaluation

- AC350 Specs UsDocument18 pagesAC350 Specs Uskloic1980100% (1)

- Output Process Input: Conceptual FrameworkDocument4 pagesOutput Process Input: Conceptual FrameworkCHRISTINE DIZON SALVADORPas encore d'évaluation

- Nammiaca 000032Document5 323 pagesNammiaca 000032gangadhark196Pas encore d'évaluation

- En LF Drivers 10nw76 8Document3 pagesEn LF Drivers 10nw76 8ChrisPas encore d'évaluation

- Faujifood Pakistan PortfolioDocument21 pagesFaujifood Pakistan PortfolioPradeep AbeynayakePas encore d'évaluation

- EB-300 310 Service ManualDocument32 pagesEB-300 310 Service ManualVictor ArizagaPas encore d'évaluation

- XC24M MG DatasheetDocument3 pagesXC24M MG DatasheetAbdulJawad Ibrahim ElmezoghiPas encore d'évaluation

- InTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesDocument20 pagesInTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesM VetriselviPas encore d'évaluation

- Afectiuni Si SimptomeDocument22 pagesAfectiuni Si SimptomeIOANA_ROX_DRPas encore d'évaluation

- High Performance Dialysis GuideDocument28 pagesHigh Performance Dialysis GuideRoxana ElenaPas encore d'évaluation

- Panasonic Refrigeraor NR-B472TZ - B412TZ v1.1Document24 pagesPanasonic Refrigeraor NR-B472TZ - B412TZ v1.1Anonymous 2iQ1B59Pas encore d'évaluation

- Avionic ArchitectureDocument127 pagesAvionic ArchitectureRohithsai PasupuletiPas encore d'évaluation

- 19 Work Energy TNDocument2 pages19 Work Energy TNAna DorueloPas encore d'évaluation

- RA9275Document49 pagesRA9275znarf_ryanPas encore d'évaluation

- Under Pass Wing Wall (4.1m)Document12 pagesUnder Pass Wing Wall (4.1m)Naveed NazPas encore d'évaluation

- ScheduleDocument1 pageScheduleparag7676Pas encore d'évaluation

- Gcat Threathorizons Full Jan2023Document26 pagesGcat Threathorizons Full Jan2023josbjsPas encore d'évaluation