Académique Documents

Professionnel Documents

Culture Documents

Ford 3.2 Diesel

Transféré par

gordonjairoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ford 3.2 Diesel

Transféré par

gordonjairoDroits d'auteur :

Formats disponibles

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

AST5130 Diesel Engine Setting /

Locking & Injection Pump R+I Kit

AST5130

Kit Option:

AST5135 Updates AST4730 to include H.P. pump

removal on 2.4L engines in Transit and Defender,

(2006 onwards) with Denso common rail fuel

systems.

Applications:

FORD DURATORQ (PUMA)

2.0, 2.2, 2.4 & 3.2L Diesel engines in:

4

AST5135

7

8

5

6

Item Part Number Description

AST5130 - Timing Setting / Locking Tool Set - items 1-8

1

AST5131

Engine Cover Aligner

2

AST5132

Engine Cover / Crankshaft Seal

Removal / Installation Tool

AST5135 - AST4730 Update (2.4L 06-) items 3 & 4

3

AST5133

High Pressure Pump Sprocket

Retaining Tool

4

AST5134

H.P. Pump Removal Tool

5

6

7

8

-

AST4727

AST4728

AST4730F1

AST4593-1F

AST5130-84

Flywheel Locking Pin (Gold)

Flywheel Locking Pin (Silver)

Locking Pin Set (3 x Pins)

Tensioner Locking Pin

Case + Insert

Associated Tool:

AST4833 Auxiliary belt tensioner wrench

(Ford & Jaguar)

CITRON

Relay

Jumper III

FIAT

Ducato

FORD

Mondeo Transit

JAGUAR

X-Type

LAND ROVER

Defender

LDV

Convoy

PEUGEOT

Boxer III

2.0 Engines

ABFA, D3FA, D5BA, D6BA, F3FA, FIFA, FMBA, HJBA,

HJBB, HJBC, HJBE, N7BA, N7BB

2.2 Engines (Chain driven H.P. pump)

QJBA(BG), QJBB, QJBC, QJBD

2.2 Engines (Camshaft driven H.P. pump)

4HM, 4HU, 4HV, P8FA, P22DTE, QVFA, QWFA

2.4 Engines

244DT, D0FA, D2FA, D2FB, D4FA, F4FA, FXFA,

H9FA, H9FB, HEFA, HFFA, JXFA, PHFA, ZSD 424

3.2 Engines

SAFA (Engine timing only)

IMPORTANT: Always refer to the vehicle manufacturers

service instructions, or proprietary manual, to establish the current

procedures and data. Product Information Sets detail applications

and use of the tools with any general instructions provided as a

guide only. AST has a policy of continuous development & reserve

the right to change product specication or appearance without

prior notice.

Page 1/9

Auto Service Tools Limited, 2012

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

Introduction

The Ford Duratorq (PUMA) 2.0, 2.2, 2.4 and 3.2 engines are twin camshaft, chain drive, direct injection diesel units.

There have been several changes to the fuel system of these engines since their introduction in 2000.

Early variants feature a standard distribution type injection pump. This was replaced with a common rail fuel injection system in 2002.

Both systems use the camshaft/crankshaft timing chain to drive the diesel pump.

In 2006 a new Ford Transit was launched and the fuel system on the van based (2.4) engines was changed to a Denso common rail system.

At the same time the 2.0 engine was replaced with a new 2.2 engine this engine uses the inlet camshaft to directly drive the H.P. pump.

The H.P. pump conguration on the 2.4 engine remained unchanged.

Section 1 - Engine Timing (Setting & Locking engine)... page 2

Section 2 - Fuel Injection Pump Removal / Installation... page 5

AST4727 / AST4728 Flywheel Locking Pins

Section 1 - Engine Timing

(Setting & Locking engine)

When carrying out service work on the timing chains, cylinder

head, chain tensioner, etc, the crankshaft, camshaft and injection

pump timing positions are retained with locking pins. The 3 pins of

AST4730F1 set are required for the camshafts (x2) and injection

pump (x1).

A larger locking pin is required for the ywheel (crankshaft). There

are two types of locking pin, Silver for common rail engines, and

Gold for non-common rail engines.

Gold, Non-Common Rail

Silver, Common Rail

1

The timing chain cover must be removed to gain access to the

camshaft sprockets, injection pump, timing chains etc.

Removal of the timing cover requires disassembly/removal of a

number of components including EVR valves, air intake ducting,

radiator, viscous fan and auxiliary drive belt.

NOTE: When removing the timing chain cover, great care must be

taken not to distort the cover. If the cover is damaged or distorted

during removal, then a new cover should be used.

Auto Service Tools Limited, 2012

3

Use the injection pump timing hole to help nd the ywheel position

for inserting the Locking Pin

To insert AST4727 or AST4728 Flywheel Locking Pin in the correct

datum hole, rst remove the crankshaft position sensor and then

position the ywheel by turning the crankshaft clockwise until the

timing hole in the injection pump sprocket is positioned at

a point just before it is fully aligned.

Page 2/9

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

4

Engine shown with gearbox removed

Insert the Flywheel Pin through the sensor holder so it rests on the

ywheel ring. Apply slight pressure to the end of the pin and turn the

crankshaft slowly and carefully until the Pin engages the slot in the

ywheel ring.

The crankshaft is now at 50 BTDC

AST4730F1 Pin Set comprises 3 locking pins, 1 for each of the

camshafts and 1 for injection pump timing.

Fit the 3 pins in position and release the camshaft sprocket bolts and

the 4 injection pump sprocket bolts.

WARNING: DO NOT use the Flywheel Locking Pin to

counter-hold the crankshaft when releasing or tightening the

crankshaft pulley bolts. The Flywheel Pin is located through

the sensor holder which will be damaged if used to restrain the

crankshaft. DO NOT turn the engine with the Flywheel Pin tted

A

C

6

AST4593-1F Chain Tensioner Locking Pin

To remove the timing chain, the chain tensioner must be locked

back and removed.

Release (A) and simultaneously push back (B) and insert

AST4593-1F Pin through the hole (C) to lock back tensioner.

Page 3/9

Auto Service Tools Limited, 2012

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

Remove the tensioner, rail and chain guides. Mark the camshaft

sprockets as inlet and exhaust before removing them, along with

the injection pump sprocket and timing chain.

IMPORTANT: AST4730F1 Locking Pins are designed to

allow removal of the sprockets without removing the timing pins.

DO NOT remove the pins from their timing holes when sprockets

have been removed.

When re-assembling the sprockets, chain and front end, ensure that

the 3 copper coloured links on the timing chain align with the timing

marks on all three sprockets, and the chain is taut on the nontensioned side. Loosely t the camshaft and injection pump sprocket

bolts (nger tight only). Re-t the chain guides and tensioner, then

withdraw AST4593-1F Pin from the tensioner to activate it.

Tighten all sprocket bolts to the specied torque and then remove

the locking pins.

Timing check

8

Locate AST5132 Engine Cover/Crankshaft Seal Tool onto the three

holes of the crankshaft front oil seal. Then locate AST5131 Engine

Cover Aligner onto AST5132 and remove the seal by rotating in an

anti-clockwise direction.

To ensure engine timing is correct, turn the engine over, by hand,

two revolutions, returning to 50 BTDC and insert the correct

ywheel locking pin.

Check that the 3 x AST4730F1 locking pins can be inserted into the

timing holes of the camshafts and injection pump timing holes.

If the 3 x AST4730F1 locking pins cannot be tted then remove the

chain and repeat the procedure, engine timing adjustment.

IMPORTANT: Do not slacken the sprocket bolts unless the

locking pins are tted. If only the injection pump locking pin will not

enter slacken the 4 sprocket bolts, turn pump shaft nut slightly

until the pin enters, then tighten sprocket bolts.

Front cover Installation

NOTE: If the front cover is damaged or distorted from removal,

then a new cover should be used.

Apply a 3mm bead of a suitable sealant around the contact face of

the front cover. Fit the front cover to the engine and retain in place

with a few bolts, loosely tted.

When installing the engine front cover it must be correctly positioned

relative to the crankshaft using AST5131 Engine Cover Aligner. This

ensures that the crankshaft seal located in the engine front cover is

correctly aligned and will not wear prematurely.

NOTE: To ensure correct alignment, the cover must be free to

move on the retaining bolts.

Ensure that the engine and front cover mating surfaces are clean and

that any old sealant has been removed.

7

Auto Service Tools Limited, 2012

bk

Page 4/9

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Fit AST5131 Engine Cover Aligner on to the crankshaft and into

the engine cover, ensuring that it is locating fully in the recess of the

engine cover.

Whilst maintaining the position of the cover, t and fully tighten all

nuts and bolts that attach the front cover to the engine.

Remove AST5131 Engine cover aligner.

Auto Service Tools Ltd

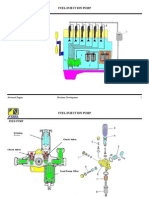

Section 2 - Fuel Injection Pump Removal &

Installation

WARNING: WAIT A MINIMUM OF 15 MINUTES AFTER

STOPPING THE ENGINE BEFORE BEGINNING WORK ON THE

HIGH PRESSURE FUEL SYSTEM.

NOTE: If a new injection pump is to be tted, it must be congured

to the PCM (Powertrain Control Module) using Dealer special

equipment.

IMPORTANT: Fuel line connections and their surrounding

areas must be thoroughly cleaned prior to dismantling. All fuel

circuit openings should be blanked off immediately to prevent

foreign matter from entering the fuel system. The components of

the high pressure fuel system may fail prematurely if this is not

observed. Once disconnected, the high pressure fuel lines that run

from the pump to the injectors/fuel rail should be discarded and

replaced.

bl

NOTE: A new oil seal comes with a sleeve to aid tment over the

crankshaft.

The engine design allows the injection pump to be removed and

installed without disturbing the engine timing.

An aperture allowing access to the injection pump sprocket is

provided in the front timing chain cover. Using AST5133 Sprocket

Retaining Tool the sprocket can be held securely in place whilst the

pump is removed.

The following instruction does not apply to the 2.2 engines with the

H.P. pump driven from the rear of the inlet camshaft. Removal of the

H.P. pump on these engines does not affect

the timing system (no special tools are required).

For 2.4 TDCi Engines from 2006 with Denso

common rail systems see instruction on page 8

TDDi & TDCi Fuel systems (NOT Denso)

bm

NOTE: Highlighted text applies to TDDi fuel systems only

Install the oil seal on to the crankshaft, ensuring that the seal

retaining tabs are positioned behind the timing cover.

Assemble AST5132 Crankshaft Seal Tool with AST5131 Engine

cover aligner and t into the three holes of the oil seal. Rotate the

seal clockwise until it is locked in position.

bn

Assemble AST5132 Engine Cover/Crankshaft Seal Tool with

AST5131 Engine Cover Aligner.

Page 5/9

Auto Service Tools Limited, 2012

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

Position the timing hole in the pump sprocket to:

TDDi engines - 12 oclock

TDCi engines - 1 oclock

WARNING: DO NOT use the Flywheel Locking Pin to

counter-hold the crankshaft when releasing or tightening the

crank pulley bolt. The Flywheel Pin is located through the sensor

holder which will be damaged if used to restrain the crankshaft.

DO NOT turn the engine with the Flywheel Pin tted.

bo

bp

With AST5132 located into the three holes of the access cover,

rotate the tools in an anti-clockwise direction to remove the pump

sprocket cover from the engine timing cover.

On engines with TDDi fuel systems it is necessary to lock the

ywheel in its timed position before removing the fuel pump.

On engines with TDCi fuel systems (NOT Denso) it is only necessary

to visually position the timing hole in the pump sprocket before

removing the fuel pump.

Removal

br

Remove the crankshaft position sensor. Insert AST4727 Flywheel

Locking Pin through the sensor holder so it rests on the ywheel ring.

Apply slight pressure to the end of the pin and turn the crankshaft slowly

and carefully until the Pin engages the slot in the ywheel ring.

The crankshaft is now at 50 BTDC.

Rotate the engine in the normal direction of rotation whilst observing

the fuel pump sprocket.

bs

bq

Auto Service Tools Limited, 2012

Assemble AST5133 Sprocket Retaining Tool, AST5132 Engine Cover/

Crankshaft Seal Tool with AST5131 Engine Cover Aligner.

Page 6/9

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

bt

Auto Service Tools Ltd

cl

Position the assembled tools through the access cover aperture

and the recess of the pump sprocket, ensuring that the 3 tabs of

AST5133 Sprocket Retaining Tool are positioned behind the engine

front cover.

Rotate the assembled tools clockwise until they reach the stop

position and then remove AST5131 Engine Cover Aligner and

AST5132 Engine Cover/Crankshaft Seal Tool. The fuel pump

sprocket is now secured in position.

WARNING: AST5133 Sprocket Retaining Tool MUST NOT

be removed once the fuel pump bolts are released. If the pump

sprocket is not secured correctly and moves, the timing cover

will need to be removed to enable the engine timing and chain

tensioner to be re-set.

Remove the 4 injection pump sprocket retaining bolts, releasing the

pump from the sprocket.

At the rear of the pump slacken the bolts xing the pump to its

mounting bracket and remove the bolts xing the bracket to the

cylinder block.

Remove the pump, taking care to ensure that the spacer remains on

the front ange.

Installation

Fit the H.P. pipes to the pump using new washers and t the spacer

and new gasket.

Remove electrical connections to the fuel pump.

Remove all fuel line connections to the pump, tting suitable

blanking caps that will prevent foreign matter from entering the fuel

system.

cm

TDDi fuel systems only

Fit one of the AST4730F1 Locking Pins through the slot in the pump

ange prior to re-locating the pump.

ck

Using a Tx45 Drive Bit, locate and release the 3 bolts that secure the

injection pump body. These bolts are accessed through the 3 holes

in AST5133 Sprocket Retaining Tool.

NOTE: These securing bolts cannot be fully removed and remain in

the sprocket throughout this procedure.

Clean and apply Loctite (270) to the three pump securing bolts and

re-locate the pump on to the engine, screw the three bolts nger

tight at this stage.

Loosely secure the mounting bracket at the rear of the pump to the

cylinder block.

Fully screw in the four pump sprocket retaining bolts, then release

them back turn.

Page 7/9

Auto Service Tools Limited, 2012

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

Auto Service Tools Ltd

Tighten the three injection pump securing bolts using a suitable Tx45

Drive Bit to 22Nm and then fully tighten the sprocket retaining bolts

to 32Nm.

Remove AST5133 Sprocket Retaining Tool securing the pump

sprocket.

Tighten the four pump mounting bracket bolts to secure the bracket

to pump and cylinder block.

TDDi fuel systems only

Remove AST4730F1 Injection Pump Locking Pin.

TDDi fuel systems only - Checking pump timing

Paint mark the crankshaft position on crank pulley and timing cover.

Remove the Flywheel Locking Pin and turn the engine over twice, by

hand, returning to the paint timing marks.

Fit AST4727 Flywheel Locking Pin into the ywheel sensor ring.

Check that pump timing is correct by ensuring that AST4730F1

Pump Locking Pin can be fully inserted.

co

WARNING: DO NOT remove the fuel pump bolts. If the

pump sprocket is not secured correctly and moves, the timing

cover will need to be removed to enable the engine timing and

chain tensioner to be re-set.

Slacken the four sprocket retaining bolts.

WARNING: DO NOT use the fuel pump nut or bolts to

adjust the timing chain tension.

Tension the timing chain by applying a force in an anti-clockwise

direction to the pump sprocket using a screwdriver.

Tighten the sprocket retaining bolts to 32Nm and remove the

AST4730F1 Injection Pump Locking Pin.

Remove AST4727 Flywheel Locking Pin.

cp

With AST5132 Engine Cover/Crankshaft Seal Tool located into the

three holes of the pump sprocket access cover, rotate the tools anticlockwise to remove the access cover from the timing chain cover.

Using AST5132 Engine Cover/Crankshaft Seal Tool with AST5131

Engine Cover Aligner, re-t the pump sprocket access cover.

2.4 Engines from 2006 - Denso common rail

system

Removal

cq

Assemble AST5133 Sprocket Retaining Tool, AST5132 Engine

Cover/Crankshaft Seal Tool with AST5131 Engine Cover Aligner.

cn

Assemble AST5132 Engine Cover/Crankshaft Seal Tool with

AST5131 Engine Cover Aligner.

Page 8/9

Auto Service Tools Limited, 2012

www.asttools.co.uk

AST5130.01

AST5130

Diesel Engine Setting / Locking & Injection Pump Removal / Installation Kit

cr

ct

Fit the assembled tools into the access cover aperture and the pump

sprocket, and then rotate the tools clockwise until they reach the

stop position. The fuel pump sprocket is now secured in position.

WARNING: AST5133 MUST NOT be removed once the fuel

pump bolts are released. If the pump sprocket is not secured

correctly and moves, the timing cover will need to be removed

to enable the engine timing and chain tensioner to be re-set.

Fit AST5134 H.P. Pump Removal Tool and rotate the force screw

in a clockwise direction, pushing the pump out of the sprocket.

Support the fuel pump during this procedure to prevent it from

falling. Remove the fuel pump.

Remove AST5134 H.P. Pump Removal Tool from the pump

sprocket.

Installation

Clean the mating surfaces of the fuel pump and the engine.

Replace the o-ring oil seal on the fuel pump.

Fit the fuel pump and two securing bolts at rear of the pump,

tightening to 23Nm.

cs

Shown without AST5133 tted for clarity.

IMPORTANT: If the incorrect bolts are removed it will not

be possible to install AST5134 H.P. Pump Removal Tool correctly.

Ensure that AST5133 Pump Sprocket Retaining Tool is tted before

releasing sprocket bolts.

Remove the two sprocket bolts as shown and the central nut from

the pump spindle.

Remove the electrical connections to the fuel pump.

Remove all fuel line connections to the pump, tting suitable

blanking caps that will prevent foreign matter from entering the fuel

system.

Remove the two securing bolts from the rear of the pump.

dk

Ret the central nut to the pump spindle, tightening to 64Nm.

Ret the two sprocket bolts and tighten to 33Nm.

Remove AST5133 Pump Sprocket Retaining Tool and ret the

access cover to the timing chain.

Reconnect the low pressure fuel lines and electrical connections to

the fuel pump.

Fit a new H.P. fuel line from the pump to the fuel rail.

Fit both end nuts nger tight, then tighten to a nal torque to 35Nm.

Using main dealer level special equipment, carry out the fuel

injection pump learning procedure.

Auto Service Tools Ltd, Padgets Lane, Moons Moat South, Redditch, Worcestershire, B98 0RD, England.

Tel: +44 (0)1527 528848 Email: sales@asttools.co.uk

www.asttools.co.uk

Auto Service Tools Limited, 2012

Page 9/9

AST5130.01

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- P 1867Document1 pageP 1867gordonjairoPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- DTC C1141, C1142, C1143,... 234, C1235, C1236 (Abs)Document3 pagesDTC C1141, C1142, C1143,... 234, C1235, C1236 (Abs)gordonjairoPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocument4 pagesAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Early Tacoma ECUs v1Document142 pagesEarly Tacoma ECUs v1gordonjairo0% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Sensor CatalogueDocument72 pagesSensor Cataloguefurious man67% (3)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- DowsingDocument76 pagesDowsingBacean Aurel IoanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hazardous Areas Stanwell Power StationDocument19 pagesHazardous Areas Stanwell Power Stationghostamir100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Republic v. Pilipinas Shell, GR 173918Document10 pagesRepublic v. Pilipinas Shell, GR 173918Glenn FortesPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- MSZ-FH09-15NA Operation JG79A806H02 03-14Document44 pagesMSZ-FH09-15NA Operation JG79A806H02 03-14JordanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Fixture Units Sizing ChartDocument4 pagesFixture Units Sizing ChartAfrooz Momeni100% (1)

- Security - Assessment 1 Questioner - With ANSWER KEYDocument4 pagesSecurity - Assessment 1 Questioner - With ANSWER KEYTfig Fo EcaepPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Abb Make Hybrid Switchgear PassDocument23 pagesAbb Make Hybrid Switchgear PassAjith AjiPas encore d'évaluation

- Molarity and Polarity Report ChemistryDocument23 pagesMolarity and Polarity Report ChemistryLydia Mae S. Ela100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Control Sheet RwadDocument9 pagesControl Sheet RwadrawadPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Low Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDocument8 pagesLow Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDeyuan GuoPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- KCA Bladder Tanks en 2010Document11 pagesKCA Bladder Tanks en 2010NovancyPas encore d'évaluation

- 1.0 Engine Data Sheet S4L2 61SD SPC S4L 093 Rev 9 For Reference OnlyDocument27 pages1.0 Engine Data Sheet S4L2 61SD SPC S4L 093 Rev 9 For Reference OnlyJoãoCarlosDaSilvaBranco100% (2)

- LIEBHERR R934-StageV-EN-PI-2021-01Document24 pagesLIEBHERR R934-StageV-EN-PI-2021-01ganendra santantikaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Peb Fabrication Project WorkDocument16 pagesPeb Fabrication Project Workmadhu krishnaPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- klx250 h6fh7f Parts List PDFDocument91 pagesklx250 h6fh7f Parts List PDFOliverPas encore d'évaluation

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgePas encore d'évaluation

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- Downhole Gas SeparatorDocument7 pagesDownhole Gas SeparatorleoarzuzaPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Turbocor ChillerDocument14 pagesTurbocor ChillerRahulPas encore d'évaluation

- Business Portfolio ExampleDocument30 pagesBusiness Portfolio ExampleFajar Seno AdiPas encore d'évaluation

- Deputy Engineer ElectricalDocument3 pagesDeputy Engineer ElectricalSargi BeepumohanPas encore d'évaluation

- CV6312 S1 OverviewDocument6 pagesCV6312 S1 Overviewlim kang haiPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Workbook Answers: CCEA GCSE PhysicsDocument40 pagesWorkbook Answers: CCEA GCSE PhysicsCanioPas encore d'évaluation

- Forms of EnergyDocument15 pagesForms of EnergyTrajce StojanovPas encore d'évaluation

- EV Landscape - Opportunities For India's Auto Component IndustryDocument112 pagesEV Landscape - Opportunities For India's Auto Component IndustryPreran PrasadPas encore d'évaluation

- Soldadura de Hierro ColadoDocument10 pagesSoldadura de Hierro ColadoclnPas encore d'évaluation

- Peugeot Tweet Servicemanual PDFDocument64 pagesPeugeot Tweet Servicemanual PDFEric FlayaPas encore d'évaluation

- Energy Engg.-Lab ManualDocument51 pagesEnergy Engg.-Lab ManualManish JhadhavPas encore d'évaluation

- Mercury 02l STDDocument2 pagesMercury 02l STDNoursine NoursinePas encore d'évaluation

- LM741Document7 pagesLM741vila mathanki100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)