Académique Documents

Professionnel Documents

Culture Documents

Fire Fighting Services (Done) Modify

Transféré par

Anonymous UUw70xirblTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fire Fighting Services (Done) Modify

Transféré par

Anonymous UUw70xirblDroits d'auteur :

Formats disponibles

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECT. A

SCOPE OF WORK

1.0

FIRE FIGHTING SERVICES

1.1

GENERAL

The Contract shall include the complete supply, installation, testing and

putting into commission, handing-over in approved working order and

maintenance thereafter for the period of the Contract works as detailed

hereafter and as shown on the drawings.

The works to be carried out under this Contract shall include the whole of the

materials and all necessary labour for the complete installation strictly in

accordance with the current edition of the FOC rules, the British Standard

Specification, the British Standard Code of Practice, the requirements of the

local Fire Authority and all other relevant Authorities having jurisdiction over

the installation, together with all incidental works pertaining thereto even

though not specifically mentioned herein or shown on the drawings.

1.2

DESCRIPTION OF WORKS

The works to be carried out under this Contract shall include but not limited,

to the following items: -

1.3

Fire alarm system includes alarm panels

Portable fire extinguishers

Painting, finishing, testing and commissioning

CO2 Automatic Fire Extinguishing System

Provisional Work: Clean Agent or Inert Gas total flooding extinguishing in

replacement of CO2 System. Please indicate the total amount in Item 10 of

Schedule of Unit Rates.

WORK INSTALLED

All work installed, equipment and materials used shall be in full compliance to

the relevant British Standard, the Requirements of Chief Inspectorate of Fire

Services (CIFS) Malaysia and all other relevant authorities having jurisdiction

over the installation.

On completion of the installation, the Contractor shall certify in writing to the

Consultant and the Fire Authority that the installation is in full compliance with

the CIFS requirements and shall take all necessary steps, including the

payment of all the testing fees and getting the receipt in order to obtain the

approval of the installation from the Fire Authority.

The Contractor shall be fully responsible to obtain the approval of the

proposed fire prevention and detection system from the Jabatan Bomba Dan

Penyelamat Malaysia. Any other costs of works that are deemed necessary

and required by the Jabatan Bomba Dan Penyelamat Malaysia for approval

should be cost and appeared on the Summary of Prices as Other works not

listed above but deemed necessary for the approval of Jabatan Bomba Dan

Penyelamat Malaysia.

The Contractor shall have in their employment, a professional engineer

registered with the Board of Engineers, Malaysia to sign, endorse and submit

all the necessary drawings as instructed by the Consultant to the CIFS in order

Part 3

PLS-140032-C/M&E/DPE

FF 1

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

to obtain endorsement from the Fire Authority.

1.4

WORKMANSHIP

The following specific requirements shall apply to this service:

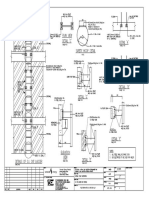

The Contractor shall provide all identifications for passage of pipes,

conduits, ducts through beams, walls, and floors sizes as limited by

Engineer and to check and obtain approval from Engineer for it.

To be responsible for accuracy of alignment plumb, fall and the like.

To provide 1 competent supervisor on site full time and 2 or 3 competent

workmen to carry out (1) and (2).

If the above are not done due to whatever reason, civil contractor shall

provide the same to the best of his ability and charge to the contractor,

the penetrations to be cored by specialist and costs to be borne by the

contractor.

All conduits and ducts embedded in concrete to be securely plugged to

prevent clogging. Any clogging is to be cleared at their own expenses.

All surface mounted items such as break glass, switch plates unless in

surface conduit shall be set flush with wall.

Mounting boxes in steel to be set level with finished surface of wall to

enable plastering or tiling to be finished flush with meat holes.

Contractor to deposit their debris at designated point on each floor for

main contractor to collect and dispose it.

To clear up area of work each day and deposit debris as above.

To complete the works in sequence, sections so that trades can follow up

such as room by room.

Part 3

PLS-140032-C/M&E/DPE

FF 2

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECT. B

FIRE ALARM SYSTEM

2.0

FIRE FIGHTING SERVICES

2.1

GENERAL

The Contractor shall supply, install, test and commission the complete fire

alarm system. The design and installation of all components and the system

shall comply with the requirement of the following bodies or standards:

Inspectorate of Fire Services, Malaysia

Fire and Accident Underwriters Association

Proposed Uniform Building By-laws, 1984

Current Edition of the Rules of the Fire Officers Committee for

Automatic Fire Alarm Installation

Latest Edition of CP 1019:1972. The installation and servicing of

Electrical Fire Alarm System

On completion of the installation, the Contractor shall be responsible for

certify in writing to the Inspectorate of Fire Services, Malaysia that the

installation is in full compliance with the above-mentioned regulations. The

Contractor shall also be responsible for obtaining written approval from the

CIFS stating that the completed installation is in proper working order.

The Contractor shall provide all labour, materials, tools and equipment

required to complete the Fire Alarm System installation. All materials shall be

new and unused, be of best quality of their respective kind, free from defects

and have been approved for use by the CIFS.

All location of manual call points, automatic detector and audible alarm are

approximate. The Contractor shall check on site location and shall adjust

accordingly to suit site conditions. No extra cost shall be allowed for the

minor adjustment. Engineers approval shall be obtained prior to installation.

The Contractor is required to submit the complete layout and wiring diagrams,

fire alarm panel circuitry diagram of the whole system to the Engineers for

approval at least two (2) weeks prior to the commencement of work.

The system shall consist of a master fire Alarm indicating panels, manual call

points, automatic detectors, alarm bells, batteries, battery charger and all

associated wiring and components. The system shall operate on the 24 volts

DC system.

2.2

MANUAL CALL POINTS

Manual call points shall be of the surface mounting type similar to Gent

Model 1102 suitable for 24 volts D.C. operation. They shall be fixed at a

height to be determined on site and it shall be normally of 1370mm (4 feet 6

inches) to 1525mm (5 feet) and in level with electrical switches nearby if any.

It shall be of the closed or open circuit floating contact break glass type

housed in a zinc corrosion proof pressure die casting case finished in red

enamel colour suitably glazed with bold white lettering inscribed Fire Smash

Glass.

Part 3

PLS-140032-C/M&E/DPE

FF 3

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

2.3

ALARM BELL

The alarm bell shall be of surface mounting type with 6 inches diameter gongs

made of pressed steel and stove enamelled red. The bells shall be suitable for

24 volts D.C. operation and the current consumption shall be limited to 50 mA.

They shall be similar to Gent Model 505 (D.C.). The sound level shall be

of minimum 85 decibel at 3 meters. The alarm bells shall comply with B.S.

5839: Part 1: 1988.

2.4

SMOKE DETECTORS

Smoke detectors shall be of the ionization chamber type radioactive source

and fitted with a built-in light emitting diode as per specification described in

MS1176 Part 7 and approved by the Fire Authority and suitable for flush

finishing to the ceiling. The detectors shall contain an LED, which is lighted up

when the detector is in alarm. Detectors mounted within ceiling voids

shall have remote indicator lights mounted on adjacent wall to indicate when

the detector has been operated.

Each detector shall have individual sensitivity adjustment so that unnecessary

alarm due to small amount of product in the air shall not occur.

2.5

MASTER FIRE ALARM INDICATOR AND ALARM PANEL

The master indicator and alarm panel to be installed shall comprise the

required numbers of way indicator plus spares as specified in specification

suitable for a 24V D.C. supply operation. The exact position of the master

indicator and alarm panel shall be determined at site.

2.6

STANDBY POWER UNITS

The D.C. supply shall consist of batteries together with battery charger,

transformer, rectifiers, all the necessary charging indicating meters, circuit

fuses, charging failure alarm devices and to have sufficient capacity to cater

for the supply of the complete fire alarm system including future additions.

The battery shall be of the flat plate nickel-cadmium type and the ampere

hour capacity of the batteries shall be in accordance with the latest CIFS

requirements.

The battery charger shall incorporate dual charging rate, one for quick

boosting and the other for trickle charging. The unit shall be completed with

output voltmeter charging ampere rates, D.C. fuses, switches, relays and

resistance transformer shall be semi-conductor (metallic) full wave.

2.7

CODE OF PRACTICE

The fire alarm system to be installed shall comply with the B.S. Code of

Practice C.P. 1019:1972 Fire Office committee latest edition and of the fire

authorities having jurisdiction over the installation.

2.8

WIRING SYSTEM

All above ground inside the building wiring shall be in G.I. conduit to B.S.31

Part 3

PLS-140032-C/M&E/DPE

FF 4

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

and concealed cables shall not be smaller than 1.5mm PVC insulated and

rated at 250 volts to B.S. 2004.

Fittings and accessories shall be galvanised and manufactured from steel or

malleable cast iron to B.S. 31.

Conduits shall be concealed throughout. Screwed conduits buried in concrete

shall have the thread coated with approved jointing compound during

assembly and joints treated with a rust inhibiting paint after jointing. All

conduit and accessories shall also be painted with a rust inhibiting paint

wherever the exposed galvanised surface has been cut or otherwise damaged.

Conduits shall be fixed securely to prevent movement and all ends, boxes

shall be effectively plugged to prevent the ingress of water and dirt before

concrete is poured. All bends must be made with the proper conduit bending

machine so that the inner radius of any bend is not less than 2 times the

outside diameter of the conduit. Where condensation is likely to take place,

provision shall be made for the water to drain off without entry into

terminations. The detailed layout of conduit will be the responsibility of the

Contractor. Conduit shall be run neatly in straight lines parallel to walls, floors

and ceilings wherever possible.

Where multiple conduit runs occur, metal brackets multi-way saddles fixed by

means of metal threads shall be used. The ends of conduits shall be cut

square, filed and reamed out after screwing and care shall be taken to ensure

removal or cutting oil and swaf.

Conduit terminations at switches,

switchboards, distribution boards, etc. are to be properly secured with coupler

and male brass bushes.

Conduit terminations to apparatus subject to

vibration or movement shall be made of flexible metallic conduit with brass

adaptors for connection to the rigid conduit system at each end. Where

conduits cross expansion joints they shall be installed so as not to resist

relative movement of the sections.

A suitable crossing shall comprise conduits telescoped one inside the other

with the free end or ends projecting immediately to one side of the crossing.

Where long runs of conduit are unavoidable, adaptable boxes shall be

provided for ease of drawing-in of cables. Draw-in wires shall be provided

inside each conduit to facilitate the drawing-in of cables. Where exposed,

conduits shall be painted orange.

Conduit sizes shall be selected so as to allow removal or replacement of any

one cable without disturbing the others and shall not be less than diameter

without the permission of the Engineer. In no circumstances, the number of

cables drawn into any one conduit shall exceed that stated in tables B5 and

B6 of the 14th Edition of the I.E.E. Regulations. All conduits shall be swabbed

out and free from moisture to the Engineers satisfaction before wiring is

commenced.

2.9

PVC ARMOURED MULTI-CORE CABLE INSTALLATION

All external and buried underground fire alarm wiring shall be PVC armoured

4-core cable. No joint shall be allowed for the installation of multi-core, PVC

insulated steel wire armoured cables except at junction boxes as approved by

Engineers.

At terminal sealing boxes, cable cores shall be carried through unbroken to the

terminals and cores shall be seated solid where they pass through case resin.

The design of compressor glands is to be such that the cable is not twisted

when the gland is tightened. It is impossible to erect and dismantle any cable

compression gland without the use of special tools.

Part 3

PLS-140032-C/M&E/DPE

FF 5

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

Each core of cable shall be identified by a number or colour code.

2.10

EXCAVATION OF TRENCHES

The Engineer will settle the exact location of each cable trench on the site

when work is ready to commence.

Trenches shall be kept as straight as possible and shall be excavated to

approval formation and dimensions, and shall generally by 30 inches deep.

Trenches shall have vertical sides and are to be timbered and sheeted where

necessary to prevent subsidence.

The excavation of trenches shall include, by way of amplification but not of

limitation, all timbering, pumping and baling required and the provision of all

necessary labour, plant, tools additional soil, fuel and motive power for such

purposes and the cost of this service and of the expendable materials shall be

included.

Before the cables are laid, the bottom of the trench is to be lined with sand or

sifted soil, which is to be punned down to a thickness of 3 inches to form a

bed. After the cables are laid, the first 3 depth of cover backfill shall consist

of sand or sifted soil over which shall be placed protective covers.

Backfilling and reinstatement of open trenches after placing of the cable

protective covers shall also be carried out.

Particular attention shall be taken to ensure that trenches are evenly graded

prior to placing the bedding materials.

Cables passing under roadways shall be installed in duct buried to a minimum

depth of 30 inches.

Cables shall be snaked at every joints or junction box and cables shall not

cross in straight runs of trench or in any other position except where a cross

may be permitted if it is impossible to avoid by advance planning of the day of

cables in a trench.

Routing and excavation of all trenches shall be carried out correctly and

satisfactorily and at such times and places to suit the program of cable

installation work.

Only enough ground shall be opened at a time such that cable laying and

backfilling may proceed without delaying order to avoid having trenches

opened for long periods.

2.11

PROTECTIVE COVERS

Cable covers shall consist of good quality house bricks and shall be laid over

all cables in ground so that there shall be no gap between the covers.

The Supply and lying of cable protective covers are to be included in the rate

for cable laying.

2.12

BACKFILLING AND REINSTATEMENT

After all cables and protective covers have been laid, the trenches shall be

refilled in 6 layers, each layer being well rammed and consolidated. The

surface of refilled trenches shall be temporarily reinstated and maintained in a

thoroughly safe condition until complete consolidation of the soil is achieved.

Part 3

PLS-140032-C/M&E/DPE

FF 6

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

2.13

CABLE MARKERS

Cable markers shall be provided and installed with the top surface flush with

ground level to identify cable routes and joints positions, other than tee joints

at street lighting columns, or cables laid direct in the ground. Markers shall be

inscribed with indented lettering reading Fire Alarm Cable and shall be

installed at every 100 feet along the route and at any changes in direction.

Part 3

PLS-140032-C/M&E/DPE

FF 7

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECT. C

PORTABLE FIRE EXTINGUISHERS

3.0

FIRE FIGHTING SERVICES

3.1

GENERAL

The Contractor shall supply, install, test and commission the necessary

equipment as generally shown on the drawings and to the Specification of

Local Fire Authorities. Samples of equipment before installation shall be

submitted for the Engineers approval.

3.2

PORTABLE FIRE EXTINGUISHERS

Each Fire Extinguisher shall be supplied complete with its own automatic

safety valve, outer lid, hose nozzle and mounting bracket. The design of the

extinguishers shall be such that it is ready for instant use, simple to operate,

internal pressure always shown on the pressure gauge and easy to service.

The extinguishers shall be easily carried to the best position for fighting a fire

and the operator can vary the discharge, including complete interruption if

desired, to meet the changing needs of the fire situation and so get the

optimal results. All types of extinguishers shall be filted with a locking pin

arrangement to prevent accidental discharges; the safety pins being secured

to the unit by a chain or wire cable to prevent loss.

The container shall be constructed according to relevant ASME or BS Codes

and approved by Jabatan Bomba, Malaysia. The cylinders shall have bursting

pressure 2 times above the working pressure and each cylinder shall be fully

tested with compressed air during manufacture. The cylinder shall be coated

with epoxy resin to give optimal protection against corrosion.

The braided flexible hose shall be of sufficient and length, terminating in a

suitable nozzle. The hose and nozzle shall be heat resistant and designed for

the pressure and chemical of the Fire Extinguisher used.

All Fire Extinguishers shall be mounted with the base of the cylinder at the

height of above 1050 mm above floor in a conspicuous and readily accessible

position.

The contractor shall mount the supporting brackets with an

approved method.

The exact position of the Extinguishers shall be determined on site to avoid

direct exposure to heat and sunlight.

Standard design of the extinguishers shall include a pressure gauge.

Pressure gauges to be provided to all extinguishers to indicate the status and

when re-filling is required.

3.3

ABC DRY POWDER FIRE EXTINGUISHERS

The Contractor shall supply and install ABC Dry Powder Fire Extinguisher of

capacity as indicated. Dry chemical fire extinguishers shall be pre-pressured

ABC Tri-Class type and shall contain a number of special features designed to

give most efficient operation and maximum fire killing effectiveness against A,

B and C class fires.

The powder shall be effective on extinguishing fire on flammable liquid. The

powder shall be of non-toxic, non-corrosion and non-freezing type. On

actuation, the dry powder shall be expelled from the container by pressurised

carbon dioxide or nitrogen gas. The nozzle shall be completed with a control

valve of grid type or equivalent, to enable the operator to have complete

Part 3

PLS-140032-C/M&E/DPE

FF 8

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

control

of

the

stream

of

chemical

powder.

The dry chemical portable fire extinguishers shall conform to MS 1539.

The finishing colour shall be light blue.

3.4

CO2 FIRE EXTINGUISHERS

The Contractor shall supply and install CO2 extinguishers as indicated. Carbon

Dioxide Fire extinguishers shall be designed for extinguisher B Class fires

(flammable liquids, such as petrol, oils, paint, etc.) and C Class fires (live

electrical equipment).

The extinguisher shall consist of a strong steel cylinder containing compressed

carbon dioxide and shall be fitted with suitable closure and discharge

mechanism. The extinguishers shall be equipped with control cable gas

discharge through a swivel horn assembly. A robust carrying handle shall be

incorporated. The extinguishers shall conform to MS 1539 and to the approval

of Jabatan Bomba dan Penyelamat, Malaysia.

Part 3

PLS-140032-C/M&E/DPE

FF 9

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECT. D

CO2 AUTOMATIC FIRE EXTINGUISHING

4.0

FIRE FIGHTING SERVICES

4.1

GENERAL

The contractor shall supply, install, commission and maintain for one year of

an automatic CO2 fire extinguishing agent system at locations as specified in

the drawings.

Generally, the Automatic Carbon Dioxide Extinguishing System shall consist of

but not limited to the following:

Cylinders of carbon dioxide complete with discharge valves and discharge

cables.

Manual discharge break glass device.

Piping complete with fittings, brackets and painting.

Gas discharge nozzles.

Smoke and heat detectors for detection and actuation of carbon dioxide

system.

Wiring in metal conduit.

Control panel complete with battery charger, booster charger, 24 D.C NiCd battery, alarm bell, gas discharging system, ammeter, voltmeter,

function indicators and alarm test switches, etc. The control panel must be

approved by the Jabatan Bomba dan Penyelamat Malaysia.

Any necessary warning signs and instruction.

Red and green flashing indicating lights.

The extinguishing agent shall be carbon dioxide gas. The system shall be

designed for TOTAL FLOODING. The capacity of the system shall be as

specified and shown on the drawing.

4.2

OPERATION

The system shall be arranged to detect smoke and heat and actuate the

system automatically. Manual actuation through a "PULL BOX" Station and

Manual Break Glass complete with key switch shall be provided.

The heat/smoke detector shall be of the dual circuit system whereby two

numbers of neighbouring detectors have to be activated before the release of

the gas. The activation of only one detector shall raise the alarm.

The system shall conform generally to the recommendation of the National

Fire Protection Association (NFPA) - 12.

Part 3

PLS-140032-C/M&E/DPE

FF 10

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

4.3

LOCATION

Heat/Smoke detectors, gas cylinders shall be installed within locations

specified. The CO2 cylinders shall be completely enclosed by the provision of a

metal wire guard.

4.4

CO2 CYLINDERS

Each cylinder shall be supported in an upright position by a mild steel cylinder

support frame suitable for wall and floor mounting. The frame shall include

facilities for convenient individual servicing.

Each bank of cylinders shall be connected to a common header. Automatic

means shall be provided to prevent the loss of gas from manifold if the system

is operated when any cylinder is removed for maintenance.

Each cylinder shall be fitted with a lever valve. The valve shall incorporate in a

safety outlet being designed to burst and release the gas should the pressure

in the cylinder rise to a dangerous level.

The cylinder shall be of the rechargeable type, as constructed and tested to

conform with ASME code and to hold pressurized carbon dioxide in liquid form

at atmospheric temperature, corresponding to a nominal pressure of 850 psi

at 70oF.

The cylinder shall be fabricated to satisfy the relevant Factory and Machinery

Act, Malaysia. Certificate of fitness for such cylinder shall be presented to the

Engineer when required.

4.4.1 NOTICE

An approved notice in English DO NOT ENTER THE ROOM, WHEN CO 2

SYSTEM IS ACTIVATED shall be provided on the door of the room protected

by CO2 system. Red and green lights shall be provided at every door to

indicate the status of the equipment.

Each cylinder shall be provided with a notice containing the following

information:

4.5

Set weight of gas

Set pressure of gas at temperature

Serial number

Manufacturer

Date of testing

Certificate number

Owner

Purpose

DISTRIBUTION SYSTEM

4.5.1 Piping

All pipes below 20mm diameter shall be Schedule 40 and 20 mm diameter

and above shall be Schedule 80 or other materials when approved by the

manufacturer's manual and the authority having. All pipes shall be reamed

before treading. All lubricant and chips shall be removed from the inside of

pipe before assembly. All fittings shall be standard weight galvanised

Part 3

PLS-140032-C/M&E/DPE

FF 11

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

malleable steel. All unions shall be the ground joint type with both seating

areas matched.

The extinguishing system cylinders and valves shall not be relied upon the

support of piping. All piping shall be rigidly secured by means of 10 mm rod to

the building structure. Pipe supports shall be spaced at intervals not

exceeding 1800 mm for 6mm to 31 mm diameter pipe, 2400 mm for 40 to

75mm diameter pipe.

There shall be a support on the horizontal run with 150 mm or less of any

vertical drop. Lateral bracing shall be provided at nozzles where required to

absorb forces developed during discharge. There shall be a least 15 mm

clearance around pipe or fittings where they pierce floors or ceilings. A

one-piece escutcheon shall be provided to dress the opening.

4.5.2 Discharge Nozzles

The discharge nozzles shall consist of an orifice and any associated horn,

shield or baffle. They shall be rated for use with the expected working

pressure, be able to resist normal mechanical damage, and withstand

expected temperatures without deformation. Corrosion resistant metal shall

be used. All nozzles shall be protected with capes so as to prevent the

entrance of foreign object, such as insert. These devices shall provide an

unobstructed opening upon system operation. The discharge nozzles shall

have the discharge characteristics as listed in the N.F.P.A. No. 12.

4.5.3 Cylinder Valve

The cylinder valves shall be operated either manually by the trip mechanism

in the mount or electrically by the smoke/heat detectors. Valves may be also

arranged to fire by agent pressure from another cylinder.

The cylinder discharge valve shall be of brass with a mittered seat and steam

held closed against pressure by a mechanical quick-release can and level

system. All valves shall be suitable for the intended use, particular in regard to

flow capacity and operation shall be located so as to be safe from mechanical,

chemical or other damages and shall have a minimum bursting pressure of

6000 psi.

4.6

OPERATING DEVICES

All devices shall be designed for the service they will encounter and shall not

be readily rendered inoperative or susceptible to accidental operation.

All devices shall be located, installed or suitably protected so that they are not

subjected to mechanical, chemical or other damage, which would render them

inoperative. All manual operating devices shall be identified as to the hazard

they protect.

4.7

AUDIBLE ALARM

Continuously rated 6 inch bell audible alarms shall be installed as shown to

warn personnel within the protected area.

4.8

CONTROL PANEL

The panel shall have the following:-

Part 3

PLS-140032-C/M&E/DPE

FF 12

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

Main isolator with MCB

Mains on indicator in duplicate (green)

Charger on indicator (green)

A/C fail indicator (red)

Battery on indicator (green)

Battery fail indicator (red)

Alarm visual and audio indicator (red)

Gas operated indicator (red flashing)

Gas isolated indicator (red)

Circuit isolated indicator (red)

Fault indicator (red)

A/C fuse screw on type

D/C fuse screw on type

Reset button

Normal/Test Fault/Test Alarm/Test Isolation button

Gas isolation button

Ammeter

Voltmeter

Manual operation with key

On actuation of the system, audio and visual indication shall be provided at

the fire alarm control panel.

4.9

GAS DISCHARGE INDICATING LIGHT

A Red and Green incandescent indicating light is required at every entrance

to the room to warn people not to enter the room when the system is

activated.

4.10

POWER SUPPLY

The control and indication equipment shall be adaptable or operation either on

the mains electrical supply, or storage battery exclusive for this system. The

power supply equipment shall also include battery charger, rectifier,

transformer, protective circuit fuses, ammeter, voltmeter and fault warning

devices.

The contractor shall supply, install and connect a D.C. battery supply system,

complete with all accessories for the satisfactory operation of the fire

detection system, fire alarm and detection system.

The system should preferably operate on 24V supply. The battery shall be of

the nickel cadmium type of sufficient capacity to maintain the standing loss or

losses of the system for a continuous period of at least 4 days. The battery

provided shall be able to supply the maximum alarm load at an adequate

voltage for at least one hour. The need for battery charging shall be indicated

automatically by a short flashing signal.

The battery shall be mounted in the lower compartment of the cubicle. The

charging equipment shall be mounted above the battery and readily

accessible. The charged shall incorporate dual charging, rate, one for quick

boosting and the other for trickle charge. The unit shall be completed with

output voltmeter, charging ampere meter(s), D.C. fuses, switches and relays.

Transformer shall be full wave and of the semi conductor type. Fault warning

devices shall be included to indicate any charging failure or mains failure.

Part 3

PLS-140032-C/M&E/DPE

FF 13

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

The Contractor shall submit calculations on the battery loadings to the

Engineer to ensure its capacity to satisfy the conditions stated above.

4.11

SMOKE AND HEAT DETECTORS

Combustion detectors shall be installed at locations shown in the drawings.

The smoke detector unit shall operate on the photo-electric principles and

shall be calibrated for detection of 1-2% smoke density per U.L. and F.M.

Standards.

The detector shall be fully transistorised with solid state switching and shall

fully conform to the requirement of BS 5445: Part 5:1977 and BS 5839:Part

4:1988.

The heat detectors shall have both RATE OF RISE and FIXED temperature

operating characteristics. The detectors shall be rated for normal operating

temperature of 150oF, capable of operating from 24V DC supply, twin circuit

type.

4.12

WIRING CABLES

All wiring to each point shall be of PVC/PVC in GI. The wiring shall be exclusive

to the fire alarm, installation and shall be completely separated from the

wiring of any other circuit.

4.13

REUSING

All parts of the extinguishing system shall be capable of being tested and

reused. The entire extinguishing system shall be capable of being refilled and

rearmed on site without disassembly or replacement of parts.

4.14

GRAVITY SHUTTERS (GLASS FIBRE CURTAINS)

The glass fibre curtains shall be installed wherever required at all opening of

the ventilation louvers, windows etc. which shall be covered to prevent escape

or the discharge CO2 gas. The curtains shall be rolled up, tighten and held by

hangers complete with at least 2 nos. solenoids on each piece of curtain. On

actuation and immediately before the discharge of gas, each blanket shall be

released and dropped with the gravity.

4.15

CONSTRUCTION OF CUBICLES

After fabrication the cabinet shall be treated with two coats of rust inhibiting

primer and finished with at least two coats of spray enamel of selected colour,

to be approved by the Engineer, applied and dried in accordance with the

paint manufacturer's recommendations. For outdoor installation, the cabinet

shall be splash proof type.

4.16

DESIGN OF PANEL

All equipment not required for warning or indicator shall be concealed in the

cabinet but shall be readily accessible for maintenance.

Indicators shall be of neon lamp and shall be installed in such a way that they

cannot be tempered with by unauthorised persons while at the same time,

Part 3

PLS-140032-C/M&E/DPE

FF 14

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

leaving them exposed to view. Indication lamps are to include two lamps in

parallel, each mounted behind a separate bezel for each indicator. The lamps

are to be mounted in such a way that they may be changed from the front of

the board.

4.17

MAINTENANCE

The complete installation is to be maintained in accordance with the following

schedule:

4.17.1Daily Tests / Monthly Test

Check all circuits for continuity of wiring. Check telephone line to Fire Brigade.

Operate two indicator circuits and check operation of code transmitter. Check

battery and charger.

Tenders shall allow for carrying out the daily tests for a period of one month

after the system is commissioned. They shall also allow for carrying out the

monthly checks throughout the maintenance period.

4.17.2Every Six Months

Repeat monthly maintenance work.

Remove control head from cylinder and check manual operation.

Disconnect cylinder from discharge piping and weigh cylinders. Cylinder

shall be recharged if weight is 0.2 kg less than stamped weight or if

pressure gauge pointer is put side of "operable range".

Replace cylinder in bracket and re-attach discharge piping.

Reset manual control head & reseal with wire and head sealing device.

Re-attach control to cylinder.

Check nozzles to see that seal plug are intact.

4.18

INFORMATION TO BE SUPPLIED WITH TENDER

The following information is to be submitted with Tender. Tenders that do not

include this information may be considered informal.

The type of detector proposed, the factory testing procedure and the

area of coverage as approved by the Fire Underwriters' Association.

The number of detectors offered indicating to what extent (if any) this

differs from the plans.

A complete sample detector unit together with a second cut-away

sample, or alternatively, a detailed drawing, if this is necessary to show

the detailed operation of the detector.

Details of the Main Indicator Board showing relays, testing facilities and

terminal arrangements together with details of the normal and minimum

operating voltages for the system and the method of obtaining this

voltage.

Details of the testing procedure recommended for the complete

installation together with details of how the equipment offered complies

with the testing and maintenance provisions of this specifications.

Typical wiring diagrams for the system offered.

Details of maintenance agreement. Such details are to include a

description of the service afforded, the fee charged, the currency of the

Part 3

PLS-140032-C/M&E/DPE

FF 15

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

agreement at this fee, the extent of service covered by the fee and

provision for renewal.

4.19

PARTICULAR REQUIREMENT OF EXHAUST/VENTILATION FAN

The control of the exhaust/ventilating fan installed in the same room shall be

interlocked with that of the CO 2 Control Panel. When theCO2 Extinguishing

System is activated either automatically or manually, power supply to the fan

will be cut-out to prevent operation of the exhaust fan.

The Contractor shall supply and install a pair of alarm signal wiring, in conduit

from the CO2 Control Panel to the exhaust/ventilating fan control panel where

required. All necessary cut-out relays shall be included.

4.20

PRESSURE GAUGE

A pressure gauge shall be fitted at each CO 2 cylinder provided. The gauge

shall have marking to indicate low pressure or loss of gas.

SECT. E

5.0

CLEAN AGENT or INERT GAS FIRE FIGHTING SYSTEM

FIRE FIGHTING SERVICES

Part 1 General

5.1.1 SUMMARY

This section includes Total-Flooding extinguishing systems and the following:

Extinguishing-agent containers.

Extinguishing agent.

Detection and alarm/actuation devices.

Control and alarm panels.

Accessories.

Connection devices for and wiring between system components.

Connection devices for power and integration into buildings fire alarm

system.

5.1.2 PERFORMANCE REQUIREMENT

Design total-flooding extinguishing system and obtain approval from

relevant authorities having jurisdiction. Design system for class A, B, or C

fires as appropriate for areas being protected and include safety factor.

Total-flooding indicated and in concentration suitable for normally

occupied areas.

Part 3

PLS-140032-C/M&E/DPE

FF 16

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

Performance Requirements: Discharge within 2 minutes and maintain

100g/m3 concentration by weight at 21 C (70 F) for 10-minutes holding

time in hazard areas.

i.

Concentration in hazard areas less than 100g/m3 throughout holding time

will not be accepted without written authorization from Engineer and local

authorities having jurisdiction.

ii.

System Capabilities: Ceiling or wall mounted, zero pressure, zero pressure

canisters capable of complete discharge within 2 minutes as stipulated in

NFPA 2010. System shall require no piping network or floor space.

Cross-Zoned Detection: Devices located in two separate zones. Sound

alarm on activating single-detection device (smoke detectors), and

discharge extinguishing agent on actuating Thermal Activation Device

(TAD) single-detection device in other zone.

Verified Detection: Devices located in single zone. Sound alarm on

activating single-detection device, and initiate discharge on activation of

second-detection device (TAD).

System operating. Sequence as follows:

i.

Actuating First Detector: Visual indication on annunciator panel, Energize

audible alarm and visual alarms (slow pulse), shut down air-conditioning

and ventilating systems serving protected area, close doors in protected

area, and send signal to the building fire alarm system.

ii.

Actuating Thermal Activation Device (TAD): Visual indication on

annunciator panel, energize audible and visual alarms (fast pulse), shut

down power to protected equipment.

iii.

Extinguishing-agent discharge will operate audible alarms and strobe

lights inside and outside the protected area.

Manual pull stations, locally or remotely when provided, shall immediately

discharge extinguishing agent when activated.

5.1.3 SUBMITTALS

Product Data: For the following:

i.

Extinguishing-agent containers.

ii.

Extinguishing agent.

iii.

Control panels.

iv.

Detection Devices.

v.

Thermal Activation Device (TAD)

vi.

Manual Pull Stations.

Shop Drawings: Include design calculations and demonstrate compliance

with NFPA 2010. Include the following for hazard-area enclosure, drawn to

scale:

Part 3

PLS-140032-C/M&E/DPE

FF 17

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

i.

Plans, elevations, sections, details, and attachments to otherwork.

Indicate dimensions, weights, loads, required clearances, method of field

assembly, installed components and location and size of each field

connection.

ii.

Wiring Diagrams: Power, signal, and control wiring.

iii.

Design Calculations:

For weight, volume, and

extinguishing agent required for each hazard area.

iv.

Reflected Ceiling Plans: Show ceiling penetrations, ceiling-mounted items,

and the following:

concentration

of

a. Extinguishing-agent containers, connectors and accessories.

b. Method of attaching brackets to building structure.

Permit Approved Drawings: Working plans, prepared according to NFPA

2010, that have been approved by authorities having jurisdiction. Include

design calculations and demonstrate code compliance.

Field quality-control test procedures and reports.

Maintenance Data: For any and all components, include in maintenance

manuals.

5.1.4 QUALITY ASSURANCE

Fire Protection Engineer Qualifications: A professional fire protection

Engineer who is legally qualified to practice in Malaysia and who is

experienced in providing engineering services of the kind indicated.

Engineering services are defined as those performed for installations of

the total-flooding extinguishing systems that are similar to those indicated

for this Project in material, design, and extent and magnitude of the

specified systems.

Product Options: Drawings indicate size, profiles, and dimensional

requirements of the total-flooding extinguishing systems and are based on

the specific system indicated.

Electrical Components, Devices, and Accessories: Listed and labelled as

defined in NFPA 70, Article 100, by testing agency acceptance to

authorities having jurisdiction, and marked for intended use.

Part 2

Products

5.2.1 MANUFACTURERS

In other Part 2 articles were titles below introduce lists, the following

requirements apply to product selection:

a. Available Manufacturers: Subject to compliance with requirements,

manufacturers offering products that may be incorporated into the work

Part 3

PLS-140032-C/M&E/DPE

FF 18

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

include, but are not limited to, Manufacturers specified in the following

paragraphs, or Approved Equal.

b. Manufacturers: Subject to compliance with requirements, provide products

by one of the manufacturers specified in the following paragraphs, or

Approved Equal.

5.2.2 EXTINGUISHING-AGENT CONTAINERS

Description:

i.

Finish: Red color, enamel or epoxy paint.

ii.

Storage-Tank Brackets: Factory or field-fabricated retaining brackets

consisting of steel ears; suitable for container support, maintenance, or

replacement.

Non-pressurised steel containers.

5.2.3 FIRE-EXTINGUISHING AGENT

Hartindo for Total-flooding.

Argonite

5.2.4 CONTROL PANELS

Description:

FM approved and/or NRTL listed, including equipment

and features required for testing, status supervision and operation of fire extinguishing system.

Power Requirements:

240V single-phase AC supply; with electrical

contacts for connection to system components and fire alarm system, and

transformer or rectifier as needed to produce power at voltage required

for accessories and alarm devices.

Enclosure: NEMA ICS 6, Type 1, enameled-steel cabinet.

i.

Mounting: Surface.

Supervised Circuits:

area.

i.

Detection circuits equal to the required number of zones, or addressable

devices assigned to the required number of zones.

Provide the following control-panel features:

i.

Separate circuits for each independent hazard

Electrical contacts for shutting down fans, activating dampers,

and

operating system electrical devices.

Automatic switch over to standby power at loss of primary power.

Service disconnect to interrupt system operation for maintenance with

visual status indication on the Annunciator Panel.

ii.

iii.

i.

Annunciator Panel:

Graphic type showing protected, hazard-area plans and locations of

detectors, abort, EPO, and manual stations. Include lamps to indicate

Part 3

PLS-140032-C/M&E/DPE

FF 19

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

device-initiating alarm, electrical contacts for connection to control panel,

and stainless-steel or aluminium enclosure. Captions on graph displays

shall be English.

Standby Power:

ii.

Sealed lead-acid or nickel-cadmium batteries with capacity to

operate system for 72 hours and alarm for minimum of 15 minutes.

Include automatic battery charger, with varying charging rate

between trickle and high depending on battery voltage that is

capable of maintaining batteries fully charged. Include manual

voltage control, dc voltmeter, dc ammeter, electrical contacts for

connection to control panel, and suitable enclosure.

2.5

DETECTION DEVICES

A.

Description: Comply with NFPA 2010, NFPA 72 or AFP 1781, of the same

manufacture as those in the building and include the following

type:

2.6

1.

Ionization Detectors: Comply with UL 268, dual-chamber type,

having sampling and referencing chambers, with smoke-sensing

element.

2.

Photoelectric Detectors: Comply with UL 268, consisting of LED

light source and silicon photodiode receiving element.

3.

Thermal Activation Device (TAD): Self-activation device with

temperature ratings of 45 C, 72 C or 110 C, depending on

hazard type.

MANUAL PULL STATIONS

A.

General Description: Incorporating a dual-action manual pull handle,

when operated will activate an inbuilt TAD

device.

B.

Manual Release:

and

MANUAL RELEASE caption, and similar caption,

red finish. Unit can manually

extinguishing

agent with operating device

engaged until

unlocked.

2.7

high.

discharge

that

remains

ALARM DEVICES

A.

Description:

FM approved and/or NRTL listed, low voltage and

surface mounting, unless otherwise indicated.

Provide identical devices to those in the building.

B.

Bells:

Minimum 150-mm diameter.

C.

Horns:

90 to 94dBA, or higher when background noise level is

D.

Strobe lights: Translucent lens, with FIRE and similar caption in

BM API.

Part 3

PLS-140032-C/M&E/DPE

FF 20

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

2.8

ELECTRICAL POWER AND WIRING

A.

Electrical power, wiring, and devices as specified.

Part 3 Execution

3.1

EXAMINATION

A.

3.2

3.3

3.4

Examine areas and conditions, with installer present, for compliance

with hazard-area leakage requirements, installation tolerances, and

other conditions affecting work performance. Proceed with installation

only after unsatisfactory conditions have been corrected.

MOUNTING AND INSTALLATION

A.

The canisters or containers shall be installed either horizontally or

vertically. Some units for raised floors may have bi-directional

discharge capability.

B.

Mounting height shall be according to individual models height

limitation as specified by the manufacturer.

C.

Canisters or containers shall be mounted onto wall/ceiling with 6mm

diameter wall plugs. The units are fixed directly onto wall via in-built

brackets, and onto ceiling either directly or drop down using threaded

rod extensions. Detailed installation shall follow manufacturers written

instruction.

D.

The units are linked together for activation via parallel wiring in loops.

Each unit shall be wired through junction box.

E.

A minimum clearance for discharge outlet shall be observed. The

distance shall follow manufacturers recommended distance for each

model.

CONNECTIONS

A.

Drawings indicate general arrangement and connection only.

B.

Install junction boxes adjacent to extinguishing-agent containers to

allow service and maintenance.

C.

Connect electrical devices to control panel and to building fire alarm

system. Electrical power, wiring and devices are specified. All wiring

shall be enclosed in G.I. conduit paint in red colour.

LABELLING

A.

Install labelling on extinguishing-agent containers, other equipment

and panels according to NFPA 2010.

B.

Install signs at entry doors for protected areas to warn occupants that

they are entering a room protected with fire extinguishing system.

C.

Install signs at entry doors to advise persons outside the room the

meaning of the horn(s) , bell(s), and strobe light(s) outside the

protected space.

Part 3

PLS-140032-C/M&E/DPE

FF 21

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

3.5

FIELD QUALITY CONTROL

A.

Comply with operating instructions and procedures of NFPA 2010,

Section Approval of Installations. Include the following tests and

inspections to demonstrate compliance with requirements:

1.

2.

3.

4.

5.

6.

7.

8.

B.

Check mechanical items.

Inspect extinguishing-agent containers and extinguishing-agent

and check mountings for adequate anchoring to substrate.

Check electrical systems.

Check enclosure integrity. Comply with NFPA 2010, Section

Enclosure Inspection, and Appendix C, Enclosure Integrity

Procedure.

Perform functional pre-discharge test.

Perform system functional operational test including, EPO, abort

and manual release.

Check remote monitoring operations.

Check control-panel primary power source.

Perform field-acceptance tests of each canisters extinguishing system

when installation is complete. Perform system testing only after

hazard-area enclosure construction has been completed and openings

sealed. Comply with operating instructions and procedures of NFPA

2010, Section Approval of Installations. Include the following to

demonstrate compliance with requirements.

1.

2.

3.

4.

Perform functional pre-discharge test.

Perform system functional operational test.

Check remote monitoring operations.

Check control-panel primary power source.

C.

The inspection and testing of the system shall be witnessed by the

Bomba and relevant authorities.

D.

Correct mal-functioning equipment, then re-test to demonstrate

compliance. Replace equipment that cannot be corrected or does not

perform as specified and indicated, then re-test to demonstrate

compliance. Repeat procedure until satisfactory results are obtained.

Report test results promptly and in writing to Engineer and authorities

having jurisdiction.

Part 3

PLS-140032-C/M&E/DPE

FF 22

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECTION F FIRE ALARM

1.

GENERAL

The Fire Indicating Panel shall be type approved by Jabatan Bomba Dan

Penyelamat, Malaysia and certified by approving authority (e.g. SIRIM) to BS

5839 Part 4: 1988 and to be located at the position as indicated on the

drawings. The panel shall have the most up to date design and can

accommodate a wide variety of detectors, sounding devices with line

supervised outputs provided for zone and bell circuits. The design shall be

modular. The panel shall be mounted at eye level and of console type to the

approval of the Engineer and shall include the following equipment.1.1)

A signal unit fitted with three lamps:Green to indicate "supply on"

White to indicate "partial disablement"

Blue to indicate "power failure"

1.2)

Zone indicating units with the following lamp indicators:Red to signal a fire in the zone

Amber to indicate a fault

Green to indicate normal

Each zone indicating unit shall be self-contained incorporating a

tamper-proof, key-operated rotary selector switch with provisions for

testing circuit fault and alarm condition and also for circuit isolation.

1.3)

Alarm muting switch and indication for AC supply ON/OFF, and

1.4)

Isolation/normal selector switch and indication for alarm bell, fault

buzzer, auxiliary trip and manual evacuate-

1.5)

Test switch for lamp, battery, alarm, fault and

1.6)

Reset switch for alarm.

1.7)

Light indication of status for bell, battery and charger.

1.8)

Key operated switches for isolation of 24 volts D.C. fire alarm signal

risers. Keys shall be withdrawable only at "ON" position.

1.9)

1.10)

A relay system to wiring the alarm bells of the entire building.

Signal lamps etc relating to D.C. power supply unit as specified in other

section.

1.11)

All necessary labels (clear perspex, reverse engraved and machine

screwed), fuses, terminal blocks, relays and wiring.

1.12)

10 Nos. spare ways in the panel for future uses.

1.13) All other necessary items specified elsewhere in these Specifications

and the Drawings and/or required by the Local Authority and Chief

Inspector of Fire Service, Malaysia.

Part 3

PLS-140032-C/M&E/DPE

FF 23

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

All lamp indicators shall be neon lamps and duplicated for zone indication,

arranged for easy replacement from the front.

The casing for the indicating panel shall be dustproof console type fabricated

from 16 swg sheet steel with hinged lockable door upon which are mounted

the indicator lamps and all other external control.

All metal work shall be treated against corrosion, painted with primer,

undercoat and furnished outside with light grey synthetic enamels all as

specified elsewhere in these Specifications.

Wiring shall be neatly bundled and secured by means of self-locking nylon

cable ties. Cable terminations involving different voltages shall be properly

segregated and labelled to the approval of the Engineer.

A suitable perspex with colour reversed engraved diagram showing in reduced

scale the areas covered by the fire alarm system, escape corridors, staircase,

heat/smoke detectors, manual call points, zone delineations etc., shall be

provided and mounted on this panel.

2.

Power Supply Unit

The control and indication equipment shall be adaptable for operation either

on the mains electrical supply, standby emergency supply or storage battery

exclusive for this system. The power supply equipment shall also include

battery charger, rectifier, transformer, protective circuit fuses, ammeter,

voltmeter and fault warning device.

Three centralised D.C. power supply units shall be provided. Each D.C. power

supply unit shall comprise 24 volts nickel cadmium batteries of sufficient

capacity such that it is capable of maintaining the standing loss or losses of

the portion of the system for at least 72 hours plus the maximum alarm load

for at least one hour. For each D.C. power supply unit, a proprietary make fully

automatic two rate battery trickler charger (constant voltage type) comprising

double-wound vacuum impregnated transformer, full wave bridge connected

rectifier and relays, etc shall be provided to keep the batteries fully charges

under all condition of service for all the panels. The battery and charger shall

be supplied complete with MCB distribution board, first grade MISC ammeters

to read D.C. charging current and D.C. load current, D.C. voltmeter marked to

indicate both float and boost charge voltage, mains on indicating lamp,

non-locking load test switch and suitable rate test load with the voltmeter

scale clearly marked in red showing the terminal voltage considered desirable

when feeding the test load, float/manual selector switch, battery charger

failure alarm, battery cut-off alarms, battery earth leakage detector, engraved

instruction labels for manner duration of test labels, all necessary cable

connections etc., and these items shall be mounted in the top compartment of

the unit concerned or in the associated fire indicator board.

The compartment housing the batteries shall be fitted with vermin proof

louvers at the front plate. The internal shall be fully lined with Formica, or

other materials against corrosive elements from the batteries.

3.

Wiring System

All wiring shall be enclosed in conduit run in the following manner:3.1)

Wiring within false ceiling spaces, riser ducts, electrical switchrooms,

and mechanical plant rooms shall be in surface mounted conduits.

3.2)

Wiring for all other areas shall be in concealed conduits to be

buried/cast in wall plastering/column/concrete slabs etc.

Part 3

PLS-140032-C/M&E/DPE

FF 24

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

Fire alarm circuits shall be separated from other circuit runs and

conduit/trunking for fire alarm system shall not in any circumstances contain

wiring other than that associated with the fire alarm system. Wiring shall be

multi-strand of sizes to suit the system but shall not be less than 1.5 Sq. min

section, of tinned high conductivity copper wire insulated with 250/440 volt

grade fire resistance.

4.

Operation Of Fire Alarm System

The fire alarm system shall be capable of performing all the functions

described herein and/or required by the local fire authorities. Among these

function shall include Priority 1 Fire Alarm.

Priority 1 fire alarm is initiated when any one of the automatic detection

devices in the fire alarm system is activated. These detection devices shall

include smoke and heat detectors.

Under priority 1 alarm condition, the fire alarm system shall automatically

initiate.

5.

4.1)

Audible alarm signal at firemen control console. Continuous ringing of

fire bells in fire zone area and the intermittent ringing of fire bells in

designated areas adjacent to fire zone.

4.2)

Visual indication of the activated fire zone on the central fire display

and control panel.

Priority 2 Fire Alarm

Priority 2 fire alarms initiated when any of the break glass call point or CO 2

gaseous system detector is activated.

Under priority 2 alarm condition, the fire alarm system shall automatically

initiate events (a) to (b) inclusive listed for priority 1 alarm condition.

Part 3

PLS-140032-C/M&E/DPE

FF 25

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECTION G PAINTING & LABELLING

1.

Painting and Protection

Only the best primers and paints shall be used on all equipment, piping,

fittings, valves, hangers, conduits, switchboard, etc. and all work exposed to

view.

Painting shall only be done in suitable weather and all final coatings shall be

to the approval of the Engineer.

Tarpaulins, sheets and coverings to protect floor, walls, etc. shall be provided

by this Sub-Contractor.

All metallic items to be painted shall be clean, free of grease and rust.

Each coat of paint shall be applied by brush and when thoroughly dry,

smoothed with suitably abrasive paper or cloth before the next coat is applied.

Should any corrosion or signs of faulty painting technique become apparent

during the maintenance period, the Sub-Contractor shall required to remove

the defective paint work or component part at his own and retreat and/or

repaint it as directed and to the satisfaction of the Consulting Engineer.

The painting shall be carried out as follow:(a)

All pipes where exposed in the building shall be painted as follow:1

approved rust inhibitive primer

undercoat

coats of high gloss finish

(b)

All underground concealed pipework shall be painted 2 coats of

bituminous paint. Care shall be taken in the choice of this paint in

regard to its melting point and adhesive properties.

(c)

All screw heads, wing nuts and other means of fixing shall be painted

at the time of installation and refinished after the final testing and

commissioning is completed.

(d)

All cut ends of galvanised steel or sheet metal works shall be prepared

as mentioned above and painted 2 coats of zinc chromate paint.

(e)

All manufactured items that are delivered in a painted condition,

whether under or finish, coated shall be prepared as mentioned above

and then repainted as before.

(f)

All items that are considered liable to oil or grease splashes shall be

finished painted using 2 coats of appropriate oil proof paint.

All items subjected to corrosive or hazardous condition shall be specially

treated and painted with suitable anti-corrosive paint as recommended by the

manufacturers.

A schedule of paint colours to be used will be issued to the Sub-Contractor as

the work progress on site.

Part 3

PLS-140032-C/M&E/DPE

FF 26

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

2.

Labelling

Lettering on piping shall be painted in contrasting colours and shall be in

centre of bands. The lettering shall be in block letters with minimum

dimension of in. high for pipes 2 ins. and under and 1 ins. High for pipes

over 2 ins.

Directional arrows shall be in black on two visible sides of all pipings at each

valve, firings and long runs at 6 ft. centres. The size of arrow shall be 3 ins.

long on pipes up to and including 2 ins. diameter and 6 ins. long on pipes over

2 ins. diameter.

Part 3

PLS-140032-C/M&E/DPE

FF 27

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECTION H TESTING AND COMMISSIONING

1.

General

All necessary balancing, testing, calibrating and setting of the equipment and

controls associated with this installation shall be done and all instruments and

labour necessary for this shall be supplied by this Contractor.

The Sub-Contractor shall provide all notices and pay all fees in connection

with all necessary tests to be carried out to the approval of the Jabatan Bomba

Dan Penyelamat, Malaysia and any Authority having jurisdiction over the

installation.

If tests are not specified in any clause of the Specification such tests shall be

carried out when the Consulting Engineer may deem necessary without any

extra charge.

All tests shall be done in the presence of and certified by the Engineer.

Completion Certificates including a brief description of the test method and

instrumentation used shall be submitted to the Consulting Engineer.

Only competent and experienced personnel shall be employed to carry out all

the tests.

The cost for these tests including electricity and necessary instruments and

labour shall be included and at all times the testing instruments and

accessories shall remain the property of the Owner. These apparatus shall be

handed over to the Owner in good condition at the expiry of the Defects

Liability Period.

2.

CO2 Fire Extinguishing System (Discharge Test)

The contractor shall provide sufficient nitrogen gas to replace the CO 2 gas

during testing and commissioning of the installed system. The test shall be

carried out in such a manner that the detectors, alarm control panel, valve

assembly, piping system etc. are tested during the nitrogen gas discharge. All

cost and indirect cost for this test shall be deemed to be included in the

tender price.

Part 3

PLS-140032-C/M&E/DPE

FF 28

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECTION I MAINTENANCE

1.

Contract Maintenance

The Contractor shall guarantee against fault, or defects, all materials and work

as set out in this Specification from the date of issue of the Certificate of

Practical Completion. The Contractor shall at his own expense pay for spare

parts and other items necessary for the operation of the pumps.

Contract maintenance shall consist of servicing of equipment installed

including attention to emergency call for the warranty period before release of

final retention sum.

The Engineer may issue the Certificate of Practical Completion at his

discretion provided that:(a) All required testing has been completed and approved by the Consulting

Engineer and Jabatan Bomba Dan Penyelamat, Malaysia.

(b) All adjustment to equipment, which may be necessary to ensure

satisfactory operation, has been made.

(c) All operation instruction, wiring diagrams and layouts have been

received.

(d) A Maintenance Schedule setting out the proposed program of

maintenance inspection and servicing, together with advice of

arrangements of prompt attention to emergency call has been submitted

to and approved by the Engineer.

At the beginning of the Maintenance Period the Contractor shall provide a

logbook, which shall be lodged with a person nominated by the Engineer. The

log book shall remain at the site and shall be used to accurately record all

service calls, whether emergency or routine, setting out the work performed,

the date, the duration of each visit, the repairs or adjustments made. All

entries to the logbook shall be handed over to the Inspecting Engineer on

completion of the Maintenance Period.

At the conclusion of the Maintenance Period a complete check over and if

necessary a re-adjustment of the installed equipment shall be made in the

presence of the Engineer.

During the Maintenance Period, the Contractor shall train maintenance

personnel nominated by the Owner in all aspects of operation and

maintenance of the whole installation.

2.

Service Contract

The Owner shall have the option to enter into an annual service Contract,

after the Contractor has fulfilled the Contract Maintenance and guarantee

obligations. The service Contract shall include emergency service and regular

maintenance. The cost of spare parts shall be charged to the Owner.

Part 3

PLS-140032-C/M&E/DPE

FF 29

FIRE FIGHTING SERVICES

SARAWAK ENERGY BERHAD

SEJINGKAT 132KV/33KV SUBSTATION REINFORCENT

PART 3 SUPPLY, INSTALLATION, TESTING AND COMMISSIONING OF MECHANICAL AND ELECTRICAL

SERVICES

SECTION J MAINTENANCE EQUIPMENT

1.

General

The following items of equipment shall be provided at the completion of the

installation. The equipment and spares shall include:(a)

1 no. spare smoke detector for each different type of detector used.

(b)

1 no. spare heat detector for each different type of detector used.

(c)

2 nos. key for each different padlock used. Each key shall be provided

with a tag with identification clearly written.

(d)

1 no. break glass for each type of break glass point.

(e)

1 no. alarm bell for each type of alarm bell using.

(f)

5 nos. of indicating bulb for each type of indicating bulb used.

(g)

1 no. spare MCCB/MCB/fuse for each type of MCCB/MCB/fuse.

Part 3

PLS-140032-C/M&E/DPE

FF 30

FIRE FIGHTING SERVICES

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- SMK Samarahan Detention Pond ReportDocument16 pagesSMK Samarahan Detention Pond ReportAnonymous UUw70xirbl100% (2)

- Summary of Project Progress December 2019Document17 pagesSummary of Project Progress December 2019Anonymous UUw70xirblPas encore d'évaluation

- GroundDocument25 pagesGroundAnonymous UUw70xirblPas encore d'évaluation

- Bem Scale of FeesDocument22 pagesBem Scale of FeesAnonymous UUw70xirblPas encore d'évaluation

- DTM Excel ReportDocument3 pagesDTM Excel ReportAnonymous UUw70xirblPas encore d'évaluation

- 1Document1 page1Anonymous UUw70xirblPas encore d'évaluation

- SG - Merah - Bill 3 Civil Works BOQ2Document82 pagesSG - Merah - Bill 3 Civil Works BOQ2Anonymous UUw70xirblPas encore d'évaluation

- Drainage Layout Plan NG - Merit 17-12-2018-ModelDocument1 pageDrainage Layout Plan NG - Merit 17-12-2018-ModelAnonymous UUw70xirblPas encore d'évaluation

- Drainage Layout Plan - (Nanga Merit)Document1 pageDrainage Layout Plan - (Nanga Merit)Anonymous UUw70xirblPas encore d'évaluation

- 1.0 General Report InformationDocument27 pages1.0 General Report InformationAnonymous UUw70xirblPas encore d'évaluation

- NomographDocument1 pageNomographAnonymous UUw70xirblPas encore d'évaluation

- Iview QuestionsDocument1 pageIview QuestionsAnonymous UUw70xirblPas encore d'évaluation

- Checking For Sewerpipe at PH 2Document3 pagesChecking For Sewerpipe at PH 2Anonymous UUw70xirblPas encore d'évaluation

- Inlet ControlDocument13 pagesInlet ControlAnonymous UUw70xirblPas encore d'évaluation

- Costing 271217Document214 pagesCosting 271217Anonymous UUw70xirblPas encore d'évaluation

- Costing 271217Document214 pagesCosting 271217Anonymous UUw70xirblPas encore d'évaluation

- DMT-Ls Computation and Comparison Tables Rev02 040517Document9 pagesDMT-Ls Computation and Comparison Tables Rev02 040517Anonymous UUw70xirblPas encore d'évaluation

- M&E Cost Estimate 6dec17Document3 pagesM&E Cost Estimate 6dec17Anonymous UUw70xirblPas encore d'évaluation

- Progress Up To 231117Document103 pagesProgress Up To 231117Anonymous UUw70xirblPas encore d'évaluation

- DMT-Ls Computation and Comparison Tables Rev02 040517Document10 pagesDMT-Ls Computation and Comparison Tables Rev02 040517Anonymous UUw70xirblPas encore d'évaluation