Académique Documents

Professionnel Documents

Culture Documents

C3-200 Installation Guide V1.0.1

Transféré par

jessvelazquezCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

C3-200 Installation Guide V1.0.1

Transféré par

jessvelazquezDroits d'auteur :

Formats disponibles

4.

LED indicators, Wires, Auxiliary Input and Output

C3-200 Installation Instructions and Connection Guide

Vision:1. 0 .1

Date:O ct.2010

1.Cautions

Please note the following cautions.Mis-operation may lead to personal injury or equipment failure:

1 Do not energize the system before installation is complete; never carry out installation activities when

the system is energized.

2 All peripheral devices must be grounded.

Notes:

1)Meaning of LED indicators:

2)Recommended use of wires

LINK indicator(green): always(green) indicates TCP/IP

communication is proper;

A Use 2-conducotor power cord

ACT indicator(yellow):its flashing indicates data is in transmitting

through TCP/IP communication.

B Use 6-conductor wire between wiegand reader and control panal

(RVVP 6*0.5mm) (To choose the proper cord according to the

interface you connect, such as 6,8,10 cord.)

TX indicator(yellow):its flashing indicates it is sending data through

RS485 communication.

C Use 4-conducotor lock power cord (RVV 4*0.75mm)

D Use 2-conducotor switch power cordRVV 2*0.5mm)

RX indicator(green):its flashing indicates it is receiving data through

RS485 communication.

3)The auxiliary input may be connnected to infrared body detectors,

alam switches,etc.

Auxiliary output indicator(green):always(green) indicates it is in use.

Lock indicator(green):always(green) indicates lock is open.

4)The auxiliary output may be connected to door bells,alarms,etc.

3 It is preferred that all wires run through PVC or galvanized pipes.

POWER indicator(red): always(red) indicates control panel is power

on.

4 It is strongly recommended that the length of exposed part of any connection cable should not be longer

RUN indicator(green):its flashing indicates the system works normally.

than 4 mm. Professional clamping tools may be used to avoid unintentional contact of exposed wires to

CARD indicator(yellow):its flashing indicates card is punched on reader.

avoid short-circuit or communication failure.

5 It is recommended that card readers and buttons should be installed at height of 1.4m-1.5m above ground.

6 It is recommended to use the power supply in case for control panel, and external power supply for each

lock.

LINK

Key hole

TX

RX

Auxiliary output2

Thread hole

Door1

A

Power of Control panel

1

Get through the thread hole

2

Fixed case

LOCK POWER

Power of lock

V+

V+12V

GND

BEEP

GLED

WD1

WD0

GND

POWER

RUN CARD +12V

READER4

BEEP

GLED

WD1

WD0

GND

+12V

READER3

Thread hole

SEN

GND

NO

COM

NC

IN

GND

Door2

LOCK2

3Get through the thread hole

{

{

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

BUTTON2

Appearance of case

NO

COM

NC

LOCK1

Auxiliary output1

NO

COM

NC

AUXOUT2

{

{

AUXOUT1

Heat

dissipation

hole

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER2

PC

RS485 interface

TX

RX

485+

485GND

READER1

Backup battery Power supply Control panel

IN

BUTTON1

Advanced Access Control

GND

485485+

EXT

ON

5 6 7 8

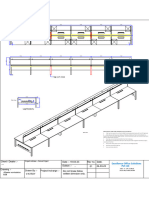

2Components

1 2 3 4

Dip switch

1# Door Button

1#Door

wiegand reader

1#Door

wiegand reader

+12V

ACT

Auxiliary input2

{

{

{

{

IN

GND

Auxiliary input1

GND

AUX2

Ethernet interface

AUX1

LAN

constantly and the RUN indicator(green) flashes.

IN

SD card

Connect the system to the power supply.If the system works properly,the POWER indicator(red) is lit

{

{

Description of normal working state:

2# Door Button

2#Door

wiegand reader

2#Door

wiegand reader

5.RS485 address setting, Restore factory setting, Terminal resistance setting

7.Equipment communication

Set RS485 address through DIP switch:

The background PC software is able to communicate with the system according to two protocols(RS485 and TCP/IP) for data

exchange and remote management. The communication cable should be away from high-voltage lines as far as possible. Do

1) Place 1-6 on DIP switch are for setting the number of control panel when communicating through

RS485, it is adopted for binary coding, and little endian, the address represented by place 1-6 are

shown as figurue(5-1).

not keep the communication cable in parallel with power cords or bind them together.

1.TCP/IP Communication

2) Before setting the address, please keep the system is power off, Jump place 1-6 to desired status,

and the address number shall not be the same as another one in the network. For example: to set the

device number as 39 (39=1+2+4+32), the corresponding RS485 code is 111001, then Jump place 1,

2,3 and 6 at ON status.

PC

ON

Switch

1

3) Place 7 is for restoring factory default settings, Jump it for three times within 10 seconds and restart

the system, then all information in RAM of control panel will be cleared and the system restores factory

default settings.

1# control panel

LINK

GND

485485+

EXT

IN

BUTTON1

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

BEEP

GLED

WD1

WD0

GND

+12V

READER2

IN

GND

READER3

BEEP

GLED

WD1

WD0

GND

+12V

BUTTON2

LOCK POWER

LOCK POWER

GND

AUX2

LOCK2

SEN

GND

NO

COM

NC

SEN

GND

NO

COM

NC

NO

COM

NC

LOCK1

READER3

AUXOUT2

BUTTON2

AUXOUT1

READER2

NO

COM

NC

BEEP

GLED

WD1

WD0

V+

V+12V

GND

POWER

RUN CARD +12V

GND

GND

POWER

RUN CARD +12V

GND

2.RS485 Communication

BEEP

GLED

WD1

WD0

GND

POWER

RUN CARD +12V

V+

V+12V

AUX1

LAN

TX

RX

485+

485GND

TX

RX

BEEP

GLED

WD1

WD0

V+

V+12V

Advanced Access Control

PC

READER1

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

ACT

5 6 7 8

BUTTON1

GND

BEEP

GLED

WD1

WD0

GND

+12V

ON

EXT

IN

GND

IN

GND

+12V

1 2 3 4

AUX2

GND

485485+

READER3

SEN

GND

NO

COM

NC

LOCK2

Restore

factory setting.

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

SEN

GND

NO

COM

NC

LOCK POWER

LOCK1

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

BUTTON2

NO

COM

NC

NO

COM

NC

AUXOUT2

RS485

terminal

resistance.

AUXOUT1

32

16

8

4

2

1

SEN

GND

NO

COM

NC

LOCK2

TX

RX

NO

COM

NC

LOCK1

NO

COM

NC

AUXOUT2

TX

RX

485+

485GND

AUXOUT1

GND

Advanced Access Control

PC

READER2

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

PC

TX

RX

BUTTON1

5 6 7 8

Advanced Access Control

485+

485GND

GND

485485+

EXT

ON

1 2 3 4

ACT

BEEP

GLED

WD1

WD0

GND

POWER

RUN CARD +12V

V+

V+12V

5 6 7 8

LOCK POWER

+12V

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

ON

GND

IN

GND

AUX2

LAN

ON

AUX1

IN

1 2 3 4

LOCK2

SEN

GND

NO

COM

NC

LINK

GND

+12V

ACT

TX

RX

READER3

LOCK1

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

BUTTON2

AUXOUT2

NO

COM

NC

NO

COM

NC

AUXOUT1

Diagram of places of DIP switch.

IN

GND

READER2

PC

TX

RX

GND

485485+

BEEP

GLED

WD1

WD0

GND

+12V

READER1

TX

RX

IN

SD card

LAN

5 6 7 8

Advanced Access Control

BUTTON1

ACT

485+

485GND

EXT

ON

1 2 3 4

4) Place 8 is for setting terminal resistance when communicating through RS485. Jump it at ON status,

then it is equivalent to have a terminal resistance of 120 ohm between 485+ and 485-.

IN

SD card

LINK

+12V

AUX1

IN

GND

AUX2

LAN

GND

AUX1

IN

SD card

SD card

n# control panel

2# control panel

LINK

485+

485GND

figure( 5 -1)

485

Converter

serial line

6.Connection of lock

485+

485+

485+

485-

485-

485-

GND

GND

GND

1) Control panel provides lock control output interfaces. For NO lock ,it is open when power is on, and

PC

closed when power is off, so COM and NO interfaces should be used; For NC lock, it is open when

LINK

LINK

LINK

the polarities.

1# control panel

2# control panel

ON

GND

POWER

RUN CARD +12V

8# control panel

7 8

GND

READER3

LOCK POWER

BEEP

GLED

WD1

WD0

V+

V+12V

BUTTON2

LOCK2

GND

BEEP

GLED

WD1

WD0

GND

+12V

LOCK1

IN

AUXOUT2

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

READER2

AUXOUT1

NO

COM

NC

SEN

GND

NO

COM

NC

IN

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

PC

NO

COM

NC

GND

485485+

BUTTON1

TX

RX

EXT

5 6 7 8

Advanced Access Control

1 2 3 4 5 6

AUX2

ON

GND

POWER

RUN CARD +12V

1 2 3 4

GND

ACT

485+

485GND

READER3

LOCK POWER

BEEP

GLED

WD1

WD0

V+

V+12V

BUTTON2

LOCK2

GND

BEEP

GLED

WD1

WD0

GND

+12V

LOCK1

IN

AUXOUT2

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

GND

IN

GND

+12V

TX

RX

READER2

AUXOUT1

NO

COM

NC

SEN

GND

NO

COM

NC

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

PC

NO

COM

NC

IN

BUTTON1

TX

RX

EXT

5 6 7 8

Advanced Access Control

485+

485GND

GND

485485+

AUX1

IN

SD card

LAN

AUX2

ON

1 2 3 4

diode (equipped in the package) to prevent the self-inductance EMF affecting the system, do not reverse

LAN

GND

BEEP

GLED

WD1

WD0

GND

POWER

RUN CARD +12V

READER3

+12V

BEEP

GLED

WD1

WD0

GND

+12V

ACT

TX

RX

BUTTON2

LOCK POWER

V+

V-

IN

GND

LOCK2

3) When the Electrical Lock is connected to the Access Control System, you need to parallel one FR107

SEN

GND

NO

COM

NC

BEEP

GLED

WD1

WD0

GND

+12V

READER2

LOCK1

SEN

GND

NO

COM

NC

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

NO

COM

NC

NO

COM

NC

AUXOUT2

200/400 access control panel installation instructions>>.

TX

RX

AUXOUT1

factory default setting is dry mode. For setting dry mode and wet mode, please refer to <<C3-100/

TX

RX

485+

485GND

PC

connecting V+ V- Input interfaces to supply power for locks, please shorten 2-3 and 4-5. Equipment

IN

GND

IN

GND

+12V

BUTTON1

5 6 7 8

Advanced Access Control

EXT

ON

1 2 3 4

2) Control panel supports dry mode and wet mode by setting the jumper, it is wet mode when

GND

485485+

ACT

IN

SD card

+12V

AUX1

IN

GND

AUX2

LAN

GND

AUX1

IN

SD card

power is off, and closed when power is on, so COM and NC interfaces should be used.

DIP switch

FR107

LINK

READER3

GND

IN

BEEP

GLED

WD1

WD0

GND

+12V

BUTTON2

+

-

V+

V+12V

READER2

LOCK POWER

Lock power

input

BEEP

GLED

WD1

WD0

GND

+12V

GND

LOCK2

FR107

SEN

GND

NO

COM

NC

GND

BEEP

GLED

WD1

WD0

GND

+12V

READER1

LOCK1

SEN

GND

NO

COM

NC

NC

IN

BUTTON1

NO

COM

NC

NO

COM

NC

AUXOUT2

TX

RX

AUXOUT1

TX

RX

485+

485GND

GND

485485+

EXT

PC

COM

LOCK

Advanced Access Control

GND

NO

AUX2

SEN

Diode

ACT

5 6 7 8

ON

GND

IN

GND

Notes

+12V

1 2 3 4

Diode

LAN

LOCK

IN

SD card

Enlarged diagram

of lock ports

AUX1

NO Lock

LED

1

2

3

4

5

Jumper

terminal

BEEP

GLED

WD1

WD0

GND

POWER

RUN CARD +12V

NC Lock

Wet mode wiring diagram of lock connecting with external power supply.

1)Internationally accepted RVSP(shielded twisted-pair) wires should be used for communication to effectively avoid interference.

RS485 communication wires should be connected by means of bus cascade connection.

2)Considering stability of communication, it is recommended the length of RS485 bus is less than 600m

3One RS485 BUS may hold 63 units of control panel, but it is not recommended to connect with more than 32 units.

access control panels.

4)When the bus is longer than 300m, to enhance the stability of communication, it is necessary to keep place 8 of DIP

switches of the first and the last control panel at ON status.

As shown in the figure above, place 8 of the DIP switches of units 1# and 8# is placed at "ON

ON

1 2 3 4 5 6 7 8

" status.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- VW Piezometer Input Calculation Sheet V1.1Document5 pagesVW Piezometer Input Calculation Sheet V1.1Gauri 'tika' Kartika100% (1)

- Clan Survey Pa 297Document16 pagesClan Survey Pa 297Sahara Yusoph SanggacalaPas encore d'évaluation

- 5 GL&V Conflo FillingsDocument1 page5 GL&V Conflo FillingsjessvelazquezPas encore d'évaluation

- GL&V Refiner Plates: Low Consistency-Cast Fillings For Disk RefinersDocument2 pagesGL&V Refiner Plates: Low Consistency-Cast Fillings For Disk RefinersjessvelazquezPas encore d'évaluation

- Specs: Instructions:: 4 Glass Signage Logo MockupsDocument1 pageSpecs: Instructions:: 4 Glass Signage Logo MockupsjessvelazquezPas encore d'évaluation

- VTH1500AHDocument2 pagesVTH1500AHjessvelazquezPas encore d'évaluation

- ZKAccess User Manual V1.1Document80 pagesZKAccess User Manual V1.1jessvelazquezPas encore d'évaluation

- C3-400 Installation GuideDocument2 pagesC3-400 Installation GuidejessvelazquezPas encore d'évaluation

- ZKAccess5.0 Quick Installation Guide V1.0Document12 pagesZKAccess5.0 Quick Installation Guide V1.0jessvelazquezPas encore d'évaluation

- C3-100 Installation GuideDocument2 pagesC3-100 Installation GuidejessvelazquezPas encore d'évaluation

- ZKAccess User Manual V1.1Document80 pagesZKAccess User Manual V1.1jessvelazquezPas encore d'évaluation

- Security Officer/GuardDocument2 pagesSecurity Officer/Guardapi-121358674Pas encore d'évaluation

- NDP-25 Data SheetDocument4 pagesNDP-25 Data SheetsetyaPas encore d'évaluation

- LECTURE 6-Forming and Shaping of Plastics and CompositesDocument52 pagesLECTURE 6-Forming and Shaping of Plastics and CompositesM.k. VarmaPas encore d'évaluation

- LogDocument2 pagesLogFerdian SumbaPas encore d'évaluation

- Swifty Loudspeaker KitDocument5 pagesSwifty Loudspeaker KitTNPas encore d'évaluation

- 4ghz Low Noise Amplifier For Satellite D ImpDocument5 pages4ghz Low Noise Amplifier For Satellite D ImpAbhishek JajuPas encore d'évaluation

- Circuit Regulating Valve STRÖMAX 4218 GFDocument14 pagesCircuit Regulating Valve STRÖMAX 4218 GFMario Mô Ri APas encore d'évaluation

- Regulatory Compliance and Generator ControlDocument59 pagesRegulatory Compliance and Generator ControlsulemankhalidPas encore d'évaluation

- OpenSAP Byd4 Week 5 Unit 5 Additional ExerciseDocument2 pagesOpenSAP Byd4 Week 5 Unit 5 Additional ExerciseHong YangPas encore d'évaluation

- Spherical Pillow Block Manual (MN3085, 2018)Document13 pagesSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyePas encore d'évaluation

- 2.0 Intro To Small Basic GraphicsDocument18 pages2.0 Intro To Small Basic GraphicspatoturboPas encore d'évaluation

- Surveyor C.VDocument2 pagesSurveyor C.VMasood Shabbir Khan Niazi100% (1)

- ACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1Document33 pagesACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1mlkrembsPas encore d'évaluation

- Ecen 607 CMFB-2011Document44 pagesEcen 607 CMFB-2011Girish K NathPas encore d'évaluation

- Syllabus New PDFDocument107 pagesSyllabus New PDFmassPas encore d'évaluation

- Brake Actuator Instruction - ManualDocument32 pagesBrake Actuator Instruction - ManualJoePas encore d'évaluation

- Database Testing: Prepared by Sujaritha MDocument21 pagesDatabase Testing: Prepared by Sujaritha Mavumaa22Pas encore d'évaluation

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaPas encore d'évaluation

- Experiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsDocument24 pagesExperiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsVarun GargPas encore d'évaluation

- Journal Approval WorkflowDocument46 pagesJournal Approval Workflowvarachartered283Pas encore d'évaluation

- Compacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Document4 pagesCompacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Agustin GerardoPas encore d'évaluation

- Arni AdvertisementDocument2 pagesArni AdvertisementHemanthPas encore d'évaluation

- Revised Syllabus Filipino 2 PAGSASALINDocument8 pagesRevised Syllabus Filipino 2 PAGSASALINErza Scarler100% (4)

- Ahsmrw30dam SD101Document48 pagesAhsmrw30dam SD101ibrahimPas encore d'évaluation

- PDF CatalogEngDocument24 pagesPDF CatalogEngReal Gee MPas encore d'évaluation

- MBR Presentation LatestDocument12 pagesMBR Presentation LatestRuchi GuptaPas encore d'évaluation

- 6seater Workstation B2BDocument1 page6seater Workstation B2BDid ProjectsPas encore d'évaluation