Académique Documents

Professionnel Documents

Culture Documents

DB460CBV

Transféré par

Razvan BarbuCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DB460CBV

Transféré par

Razvan BarbuDroits d'auteur :

Formats disponibles

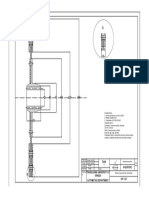

DB 460CBV

ELECTRIC SYSTEM

CONCRETE BATCH CONTROLLER

It consists of two interlocked units with

printer and USB port for data transfer

and report printing. It can store up to 20

recipes including 32 different components

each. Drum rotation sensor for RPM and

end-of-cycle calculation. SLUMP integrated

and printable in the cycle report. Acoustic

alarm triggered by a wrong loading procedure. Additive system complete with two

tanks, for a total of 30 litres.

Alternator: 12V - 55 A

Battery:12 V - 132 A/h (600 A)

Road light and signalling system.

4X4 FOUR-WHEEL DRIVE

Hydrostatic automotive transmission with

variable displacement pump and variable

displacement hydraulic motor with electro-hydraulic control, and reverse gear control on the

steering wheel and via joystick, inching pedal.

Electro-hydraulically controlled mechanical

gearbox for working speed and road transfer speed.

SPEED

4 forward gears 2 reverse gears

Ist 0 - 3.7 Km/h 0 - 3.7 Km/h

IInd 0 - 9.5 Km/h 0 - 3.7 Km/h

IIIrd 0 - 11.8 Km/h 0 - 11.8 Km/h

IVth 0 - 30.0 Km/h 0 - 11.8 Km/h

Traction / weight ratio 48%

AXLES AND WHEELS

Front load-bearing, oscillating ( 6) and

steering with planetary reduction gears on the

wheel hubs.

Rear load-bearing and steering with planetary

reduction gears on the wheel hubs and directly

anged gearbox.

Tyres ...................................... 18 -19.5 14PR

BRAKES

Internal oil-bath disc service and emergency

brakes acting on the 4 wheels, activation with

miniservo pump on independent dual circuit.

Negative type parking brake, with internal oil-

bath discs on the rear axle and electro-hydraulically controlled release.

STEERING

Assisted by means of load-sensing power

steering with double displacement on 4 steering wheels; steering selection device for: 2

steering wheels, 4 steering wheels - crab

steering.

EQUIPMENT HYDRAULIC SYSTEM

Gear pump

Max. ow rate: ........................... 45 litres/min.

Maximum pressure: ........................... 180 bar

5 - element distributor servo-controlled with

joystick.

Electrohydraulic chute distributor with control

on the ground.

Aluminium heat exchanger for hydraulic oil

cooling.

Pressurised closed-circuit intake with oil lter

replaceable from the outside.

MIXING AND POURING

Double-cone drum with double-spiral mixing

screws

Geometrical drum volume: ............5050 litres

Drum rotation speed: ......................... 24 rpm.

Class S1 concrete produced as : ......4.0 cu m

Counterframe mounted on heavy-duty

slewing ring, with 245 hydraulic rotation and

automatic locking with negative brake.

Drum rotation by means of a piston pump with

variable ow rate and an orbital hydraulic motor in closed circuit with innitesimal electrical

control positioned in the cabin and at the rear

of the machine.

Drum raising up to the horizontal position by

means of 2 double-acting jacks.

Chute with hydraulic tilting by means of a double-acting jack and 180 rotation, independent

from the mixing drum inclination. Removable

chute, for direct puring from hopper.

3 chute extensions provided as standard

equipment.

LOADING SHOVEL

Loading arms with self-compensated kinematic mechanism, double-acting loader lifting and

return cylinders, electro-hydraulically controlled hatch.

Volumetric capacity: ........................560 litres

Number of shovelfuls per load .............. 9 - 10

Production capacity: up to 4 cycles/hour

CAB

WATER SYSTEM

Self-priming volumetric water pump with

quick-suction.

Max. capacity:.......................... 260 litres/min.

Maximum head: ..................................... 4 bar

Two connected tanks positioned opposite

each other made of superlinear polyethylene

with a total capacity of ....................870 litres.

Mix Control system for programmable and

controlled management of water feeding to

the drum and of mixing and unloading from

the ground panel. Water feeding to the drum

controlled by means of electromagnetic ow

meter and fed litre reading on both the cabin

display and at the rear of the vehicle

Water pump activation from the drivers seat

and from the ground panel. Suction selection

from the ground with quick-coupling pipes.

High-pressure power jet cleaner (150 bar) for

easier cleaning, with lter and suction from the

water tanks.

Closed cab with heating system, designed in

accordance with ROPS FOPS standards.

180 pivoting driving post. Anatomic seat with

exible suspension and height adjustment,

seat belts.

Driving and equipment controls with ergonomic arrangement.

SERVICE REFILL CAPACITIES

Fuel tank in cross-linked polyethylene, 90 litres

Total hydraulic system capacity: ......100 litres

Engine oil: ............................................9 litres

WEIGHTS

Operating weight .............................. 7300 kg

Max gross weight: ........................... 16500 kg

load-carring capacity: ....................... 9200 kg

Valid as of 07/2011. All the data are purely indicative and may change without prior notice.

DIESEL ENGINE

PERKINS series turbo engine 1104

Mechanical control with direct injection

Max. power 83 kW (113 HP)

Adj. power 83 kW (113 HP) at 2200 rpm

Max. torque 418 Nm at 1400 rpm

Bore/stroke: 105/127 mm

4 cylinders - total displacement 4400 cc

Water cooling, dry air lter

Self-propelled mixing sistem

FIORI S.p.A. | Via per Ferrara, 7 | 41034 FINALE EMILIA (Modena) - Italia | Tel. +39.0535.92357 | www.origroup.com

Scheda Tecnica BETONIERE - UK.indd 8

31/10/2011 14.03.11

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Ventilation of The Industrial Environment PDFDocument7 pagesVentilation of The Industrial Environment PDFnelson escuderoPas encore d'évaluation

- The Breaker Failure Protection BFP Schemes in UtilitiesDocument9 pagesThe Breaker Failure Protection BFP Schemes in UtilitiesTrigras Bangun PerkasaPas encore d'évaluation

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- KJHFLDocument1 pageKJHFLRazvan BarbuPas encore d'évaluation

- Irregular VerbsDocument2 pagesIrregular VerbsRazvan BarbuPas encore d'évaluation

- Curs EnglezaDocument1 pageCurs EnglezaRazvan BarbuPas encore d'évaluation

- Tanase ModelDocument1 pageTanase ModelRazvan BarbuPas encore d'évaluation

- Method Statement of Foundation Concrete CoatingDocument17 pagesMethod Statement of Foundation Concrete CoatingGerry Dwi PutraPas encore d'évaluation

- Air Entrainment in Manhole Drops-Paper - Final - ReviewedDocument8 pagesAir Entrainment in Manhole Drops-Paper - Final - ReviewedManuel SueroPas encore d'évaluation

- Performance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.Document8 pagesPerformance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.atul100% (8)

- Closer #1Document32 pagesCloser #1Mike SmallPas encore d'évaluation

- VCO Based ADCDocument3 pagesVCO Based ADCBlake PayricePas encore d'évaluation

- The Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysDocument10 pagesThe Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysJose Fernandez AdellPas encore d'évaluation

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarPas encore d'évaluation

- Sugar Industry in Pakistan (17-UGLC-650)Document16 pagesSugar Industry in Pakistan (17-UGLC-650)Waqar IbrahimPas encore d'évaluation

- Effect of Clearance On Volumetric Efficiency in 2D Piston PumpsDocument12 pagesEffect of Clearance On Volumetric Efficiency in 2D Piston PumpsSiddharth SinghPas encore d'évaluation

- Project Report - TarunDocument5 pagesProject Report - TarunrajuPas encore d'évaluation

- AZ E-Lite LED Lighting CatalogDocument2 pagesAZ E-Lite LED Lighting CatalogsujiPas encore d'évaluation

- PH1031 Wednesday Batch July-Dec 2016Document2 pagesPH1031 Wednesday Batch July-Dec 2016devajithPas encore d'évaluation

- Sennheiser Digital 9000 System Manual 2017 ENDocument126 pagesSennheiser Digital 9000 System Manual 2017 ENAnder APas encore d'évaluation

- Hybrid Safety and Service Procedures: Automotive Technology, Fifth EditionDocument40 pagesHybrid Safety and Service Procedures: Automotive Technology, Fifth EditionSkyAnimal ChannelPas encore d'évaluation

- Power and Wiring Cables GuideDocument82 pagesPower and Wiring Cables GuideZzzdddPas encore d'évaluation

- Cyclotron Booklet Black Final PrintDocument10 pagesCyclotron Booklet Black Final PrintNawaf BamasoudPas encore d'évaluation

- Strength Improvement of Loose Sandy Soils Through Cement GroutingDocument56 pagesStrength Improvement of Loose Sandy Soils Through Cement Groutinganilsmg09Pas encore d'évaluation

- Vat Rates enDocument27 pagesVat Rates enpacocastroPas encore d'évaluation

- 3 Goshu 3Document18 pages3 Goshu 3nega cheruPas encore d'évaluation

- Generate Electricity From Park Revolving DoorDocument39 pagesGenerate Electricity From Park Revolving Doortariq7660% (5)

- Alternating Current TechnologyDocument118 pagesAlternating Current TechnologyMadhav DeshpandePas encore d'évaluation

- CHEMIST LICENSURE EXAM TABLEDocument8 pagesCHEMIST LICENSURE EXAM TABLEJasmin NewPas encore d'évaluation

- Miroljub Todorović - ApeironDocument25 pagesMiroljub Todorović - Apeiron"Mycelium" samizdat publishersPas encore d'évaluation

- Unit GC2 Element 6 - InternationalDocument14 pagesUnit GC2 Element 6 - InternationalSatya NaiduPas encore d'évaluation

- 04-Sistema de Refrigeracao PDFDocument26 pages04-Sistema de Refrigeracao PDFFabio MacielPas encore d'évaluation

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhPas encore d'évaluation