Académique Documents

Professionnel Documents

Culture Documents

Pic Micro Controller Based Remote Terminal Unit Fora Supervisory Cathodic Protection Monitoring System

Transféré par

rasim_m1146Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pic Micro Controller Based Remote Terminal Unit Fora Supervisory Cathodic Protection Monitoring System

Transféré par

rasim_m1146Droits d'auteur :

Formats disponibles

PIC micro c

1. IllstrWI1. Soc. India 38(4) 248-253

PIC MICRO CONTROLLER BASED REMOTE

TERMINAL UNIT FORA SUPERVISORY CATHODIC

PROTECTION MONITORING SYSTEM

s. Vincent and Nalini Thondiraj

Celltral Electrochemical Research Illstitllte, Karaiklldi - 630 006

ABSTRACT

The design, development and evalu8tion of a prototype Remote Tel111inal Unit (RTU) to

provide cathodic protection of buried pipe lines are presented. The impressed current

cathodic protection (CP) technique is applied in order that the pipe to soil potential is

1118intained in corrosion free region. The RTU is a closed loop control system designed

around a PIC l6F877 micro controller to provide CP to the buried pipe lines. With its on

chip peripheral 10 bit OAQ channels and I/O lines of the micro controller incorpor8ted,

the RTU is able to effectively meaSLlre the potential of the pipe line and assess the CP

stalus, RTU's serial communication link with a control room monitoring computer paves

way to a large supervisory CP monitoring system. The paper deals with the descriptions

of the hardware and software package of the RTU with suitable illustrations.

1. INTRODUCTION

Corrosion is an electrochemical phenomenon, whereby a corroding surface consists of

anodes and cathodes, with corrosion occurring at the former and protection at the latter. Hence

corrosion takes place due to the presence of micro galvanic cells on the same metal surface.

In other words, several regions of different electrode potentials on the same metal surface

cause corrosion of the mctal. Corrosion of metal ceases when the metal is polarized to a

potential corresponding to a local cell anode. By application of a suitable voltage, the whole

surface is rendered cathodic and hence fully protected [I]. 'The practice of using cathodic

protection (CP), is generally considered to be the most effective and technically appropriate

corrosion prevention methodology for buried pipelines [2,3]. CP is an electrochemical process

which prevents corrosion or the natural reaction of metals in a particular environment by

superimposing an electrochemical cell more powerful than the corrosion cell [4]. The criteria

for cathodic protection states that a negative potential swing by 300 mV from the corrosion

potential would be sufficient to achieve effective protection of the metal. In order to keep the

structure in corrosion free region, attainment of potential of O. 78 V Vs SCE (Saturated calomel

electrode) of the steel structure which needs to be protected ensures adequate corrosion

protection.

SCADA (Supervisory control and data acquisition) systems which are being installed to

protect large buried steel pipe lines or huge off-shore steel platform structures, comprise a

network of remote terminal units (RTU) installed to provide CP to various sections of the

steel structures [5]. The present work deals with design and development of a similar cr

control system which can be employed as an RTU of a SCADA system. The CP technique

incorporated is the impressed current technique. The RTU has been designed around a cost

effective and versatile micro-controller Microchip PIC (Peripheral Interface controller) IC

16f877. T

such as ma

RTU desig

smooth real

such as 10

protection t

DAQ chan

electrode 0

MOSFETi

(PWM) sue

2. HARD

As sho

includes a

communieat

supply (SM

anode (TSI

gal vanostati

terminal of

connected t

sampling res

its voltage

mY. If the

system is sa

protected 20

Control room PC

PC

PIC micro

COli troller

hasI'd remote talllillalullit for a slIfJavisory cathodic protectioll mOllitoril/g s)'stel1l 249

16f877. The PIC micro-controller, owing to its Harvard architecture and other advantages

such as maintainability, versatil ity and adaptabil ity has been chosen to be incorporated in the

RTU design, which can effectively execute complex control algorithm required to exercise

smooth real time control over the CP system. The micro-controller with its on-chip peripherals

such as 10 bit DAQ (Data acquisition) channels and digital 1/0 lines ably provides cathodic

protection to the steel structure by means of precision CP potential measurement through its

DAQ channels which corresponds to the soil to structure potential with respect to a reference

electrode of the CP system. A digital output of the micro-controller drives the high power

MOSFET incorporated in the analog interface unit suitably in pulse width modulation mode

(PWM) such that the potential ofCP system is always maintained in the corrosion frec region.

2. HARDWARE

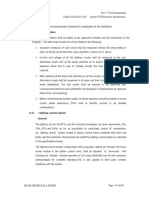

As shown in the schematic block diagram, Fig.l, the hardware package of the RTU

includes a PIC micro-controller, an analog interface unit, high power driver, serial

communication package that links RTU and the control room PC, a switched mode power

supply (SMPS) and the CP system comprising of an anode called Titanium substrate insoluble

anode (TSIA) along with reference electrodes and the buried steel structure (cathode). The

galvanostatic control unit enables the anode of the CP system to get connected to the positive

terminal of SM PS through the high power driver and the steel structure to be protected is

connected to the negative tenninal of the switched mode power supply through a current

sampling resistor, Rx. The reference electrode chosen for the present work is a zinc electrode,

its voltage range pertaining to the corrosion immune region lies between -300 mV and -100

mY. If the reference electrode voltage, VRE' is found more negative than -300, then the CP

system is said to be in corrosion prone region. Whereas the CP system is said to be in over

protected zone when its VRE is found less negative than -100 mY. For convenience of the

RllJ

PIC

Control room PC

PC

-;1- &TORllJ

.,

, f-'

RS485

16F 817

Oahanoslatic control

To PC

RS485

Driver

...!..

Slruclur. (cathode)

"

Fig. I : Schematic Block diagram of PIC microcontroller based RTU

25U

S. Vincellt alld Nalilli T1lOl1diruj

PIC micro co,

instrumentation control, the negative zinc electrode potential is converted as positivc

potential.

In view of its numerous merits such as high opcrational efficiency, low cost, less weight

and compact size, SMPS [6,7] has been chosen as thc dc power source for the CP system.

The analog intcrface unit renders signal conditioning to the elcctrode potentials of four reference

electrodes installed at the CP system. Signal conditionings such as buffering, amplification,

polarity rcversal and filtering of high frequency influences duc to surges have been provided

to these potential signals in such a manner that the reference electrode potential which rcpresents

the CP status of the structure, can be measurcd effcctively with 0.5 mY resolution, by

employing the lO bit DAQ channels of the micro-controller. In order to maintain constant

current across the CP system, analog interface unit also incorporates operational amplifier bascd

high power galvallostatic control system which using the micro-controller's on-chip digital

output, drives the high power driver, MOSFET IRF540, to impress the current as high as

27 amps in PWM mode, between the TSIA anode and the structure. The high powcr

galvanostat incorporatcs MOSFET as its power drivcr for its several advantages [8] such as

very fast switching, abscnce of second breakdown, wide safer operating area, voltage control,

negligible drive ClllTent and ease of paralleling etc. IC Max 1485, interfaced with the serial

ports of both the control room PC and the micro-controller [9, I 0] is the main component of

the RS-485 serial communication package which facilitates interactive communication between

the control room computer and the RTU installed at a distance around more than I km from

the control room. EIA Recommended Standard 485 is designed to provide bi-directional half

duplex multi-point data communications over a single two-wire bus. RS-485 serial

communication system has been chosen for its merits such as cnhanced communication

distance (1.2 Km) , high speed data (as high as 12 Mbps) . very low driver output level (as

low as 1.5 Y) and network of 32 drivers and receivers on the serial bus etc..

3. SOFTWARE DESCRIPTION

The software package or the firmware of the RTU is developed using a commercially

available C compiler. The firmware comprises of several sub software modules or software

driver programs such as DAQ module, CP control module, serial communication module

and control room front end virtual instrumentation module. DAQ module supports multi

channel precision reference electrode potential measurement with I mY accuracy. Each of

the four on-chip ADC channels interfaced with the analog interface unit, is selected and data

acquisition subroutine is executed. After each data acquisition routine, the digital output obtained

at the respective ADC channel is converted as the reference electrode potential by means of

a real value conversion subroutine incorporated in the software module.

The CP control module employing an output driver program enables a galvanostatic

current through an output line, across the CP system in pulse width modulation (PWM) mode.

The flow chart of the impressed current cathodic protection (lCCP) control algorithm, as

depicted in Fig.2, shows that the ga]vanostatic pulse current is modulated in direct proportiorl

to the potential of the reference electrode critically chosen to monitor the CP status of the

buried steel structure. The off-time of the impressed current has been set as 5 s while the

on-time, ToC" is calculated from the difference between the reference electrode voltage Y\\\.

and the set potential, Y SET' where YSET is set as 200 mY which is the center of thc corrosion

Fig. 2:

Immune re

be 10 sand

as 5 s. The

when V RE is

current wh

when VRE is

Immune re

smooth con

The se

and the su

on line mo

of the CP s

chip serial

and treats a

PIC lIIicro controller based relllo/e terlllinal lin it for a supervisory cathodic protec/ioll monitoring system 251

Switch olr

Impressed current

Set impressed current

in pulse width modulated

mode with Ton ex:: V diff

where Vd,~ = Vs V RIl

V Sd = 200mV

Fig. :: : Flow chart of ICCP COll/ro! Sojiware package

0/ PIC Microcoll/roller

based RTU

immune region. As the reference electrode potential approaches near 300 mY, TON tends to

be 10 s and it tends towards zero when Y!'Eis found nearer 100 mY. At 200 mY, TON is set

as 5 s. The CP current control module ceases to employ PWM mode of impressed cunent

when Y RL is found greater than 300 or less than 100 m V. It either switches off the impressed

current when it detects overprotected zone or switches on the impressed current continuously

when Y RE is found in corrosion region. By exercising PWM control only in the corrosion

immune region which lies between 300 and 100 mY, the control algorithm enables a very

smooth control over the CP system.

The serial communication module provides effective operational link between the RTU

and the supervisory control room computer. It enables the supervisory computer to execute

on line monitoring and control of the CP parameters such as Y RE and the impressed current

of the CP system being controlled by the RTU. By employing the interrupt feature of the on

chip serial port's receive line, this module incorporates suitable interrupt service routines (lSR)

and treats any instruction received in the form of data from the host computer as an interrupt

252

S. Vincent and NaIini Thondiraj

and executes its relevant ISR and returns to its main functional operation of rendering cathodic

protection to the structure which comprises reference electrode potentials measurement and

execution of galvanostatically impressed current in PWM mode.

The virtual instrumentation module which is installed at the control room PC has been

developed using Microsoft Visual Basic language. The software is developed as modular virtual

instruments (V I) that one can easily examine, experiment with, and enhance or integrate into

the tests of different groups [J 1,12]. Virtual instrumentation is the programming technique to

use a general purpose computer to mimic real instruments with their dedicated controls and

displays. The software package renders versatility to the VI technique. One major development

resulting from the ubiquity of the PC is the concept of virtual instrumentation, which offers

several benefits to engineers and scientists who require increased productivity, accuracy, and

performance. Virtual instruments in the front panel, created by Visual Basic software package,

provide online display of V RE' anode voltage (it can be connected to another on-chip ADC

channel), the CP current and the CP status depending upon the value of V RE A window to

exhibit an X-Y plot included in the virtual instrumentation package of the supervisory computer

facilitates on line data logging and plot of V RE Vs time together with the display of the CP

status. The display message such as 'Over protected' appears when V RE is found to be

less than 100 mV and when it exceeds the value of 300 mY, thcn 'Under protected' appears

on the CP status slot. The CP status slot in the front panel virtual instrumentation window

shows 'Protectcd zone' when V RE lies between 300 and 100 mV . The on line data logging

feature of the front end software package of the supervisory PC, supports creation of data

file for logging the CP data periodically at an interval of every two hours. In order to monitor

entire stretch of the steel structure, all the four reference electrode potentials along with their

respective CP status are logged and displayed in the front end virtual instrumentation window.

4. THE CP CONTROL SYSTEM [1,13-16]

For an experimental study, a 20 m long steel pipe line segment with 20 cm diameter,

buried in soil was chosen as the structure to be protected. As per the CP design whieh satisfies

the impressed current density requirement of 0.1 mA/m 2 for bare steel structures, location

and placement of the anode and thc reference electrodes were determined. A few tens of meters

away from the structure, the TSIA anode along with four reference electrodes were so suitably

installed that the potentials of the reference electrodes which were placed farther from the

anode indicate corrosion immune region at the application of 20 V, 2 A de supply. The RTU

was installed near the structure and its communication with the control room PC 100 m away

from the RTU, was established through a leased telephonc link cable supported by the serial

RS-485 drivers installed at the serial ports of the both the PC and the PIC micro-controller of

the RTU.ln bi-directional, half-duplex mode, at 9600 baud rate, the serial RS-485 communication

facilitates effective interactions such as transferring of multi-channel data pertaining to reference

electrode potentials and the impressed current value etc., from the RTU to the control room

PC and receiving control commands corresponding to the termination or execution of thc

impressed current either in dc mode or in PWM mode from the control room computer to

the RTU. A few weeks after thc installation of the RTU, from both the data and the graphical

plots obtained at the control room PC, the buried pipe line's CP status has been found shifted

from corrosion region to immune (corrosion free) region. The average value of V RE was

found to be around 240 mV and the impressed current was seen to be around 1.5 A in PWM

mode.

s.

CONC

The de

maintain the

systcm toge

impressed c

of the struc

maintenance

RTU is also

CP current

size of the pi'

current i.e.,

modules of

current requ

in the SeA

the control

RTU can be'

REFERE

I. K.Myl

Publis

2.

3.

4.

5.

6.

7.

8.

9.

10.

II. Ron

12.

13.

14.

15. L.S. H

system

16. S. Aok

Bound

PIC lI1icro

COil troller

hased rell10te termillallll1itfor a supervisal]' cathodic protectioll II/onitoring systclI/ 253

5. CONCLUSIONS

The designed RTU was successfully installed and it is being observed to protect and

maintain the buried pipeline in corrosion free region. Remote monitoring and control of CP

systcm together with front end virtual instrumentation window to provide display of V RE , the

impressed current of the CP system, logging of CP parameters and graphical plot of CP status

or the structure etc., is the unique feature of the SCADA design. Because of its low

maintenance and design cost due to improved and versatility of PIC micro-controllcr, this

RTU is also attractive for usc in many other industries. With its high power driver of handling

CP currcnt as high as 27 amps, the RTU can provide CP to a pipe line as long as 15 times the

size of the pipe line employed for this CP experiment. For handling much higher values ofCP

current i.e., for protecting a pipeline of several hundred metres length, suitable number of

modules of high powcr MOSFET IRF 150 (1 OOV,40A) can be employed to combat high CP

current requircment. With RS-485 serial communication protocol, 32 RTUs can be networked

in the SCADA system with the communication distance around 1.2 kl11 between RTUs and

the control room PC. In addition to its primary role of monitoring, reporting and control, the

RTU can be programmed to implement complex algorithms to suit numerous applications.

REFERENCES

I. K.Mylcs and Associatcs, 'Corrosion Control: Principlcs and applications' First Edilion.Jaico

Publishing House, Mumbai (2003 ) p.93

2.

R.A.Cummow and P.Eng, 'G IC effects on pipeline corrosion and corrosion control systcms "

J.Atmos.solr tcrrl.phys. 64, 1755-1764 (2002)

3. R.H. llcidcrsbach, 'Cathodic protcction: Co/'rosio/l " Vol. 13, 9th Edition, ASM Intcrnalion;Jl,

I\talcl'lals Park (1998) p. 466

4. www.mgdut'fco.uk

5. GT.Hcng, 'Microcomputer - based rcmotc tcrminal unit for a SCADA systcm " Microproccssors

and M icrosystcms, 20, 39-45 (1996).

6. Winn L.Rosch, "Hardware Bible", Techmcdia,New Delhi, (2002) p.ll 09

7. P.E.Stuart Asser, P.E.Vincent Stigliano, Richard Bahrenburg, "Microcomputer Servicing

Practical systems and trouble shooting", Merrill Publishing Company, Columbus (1996) p.217

8.

Brian R.Pelly and Stcve M.Cle111cntc, "HEXFET data book", Intcrnational Rectilier, CA,USA

(1985) p. A-II

9. www.microchip.com

10.

www.maxim-ic.com

It.

Ron Wolfe, Instrumentation Newslettcr, 8, 6,(1996)

12. National Instrumcnts LabVicw Real-Time User Manual,2001 Edn., p. 3.3

13.

Luiz C. Wrobel and Panayiotis Miltiadou, 'Genetic Algorithms for invcrsc cathodic protcction

problems', EngngAnaIBoundElem., 28, 266-277 (2004).

14. N.G Zamani and J.M. Chuang, Optimal control of current in a cathodic protection systcm: a

numerical invcstigation.Optimal Control Appl Meth., 8, 339-350 (1987)

15. L.S. Hou and W. Sun,' Numcrical mcthods for optimal control

systcl11s'.lnt J Num MethEngng., 37, 2779-2796 (1994).

0['

imprcssed cathodic protcction

l6. S. Aoki and K. Amaya, 'Optimisation of cathodic protection system by BEM', Engng Anal

BOllnd Elem 19,147-156 (1997).

Vous aimerez peut-être aussi

- MCD80 574Document12 pagesMCD80 574Rinda_RaynaPas encore d'évaluation

- Three-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDocument13 pagesThree-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDenise JenningsPas encore d'évaluation

- CIGRE-118 Practical Experience With IEEE 1588 High Precision Time Synchronization in Electrical Substation Based On IEC 61850 Process BusDocument10 pagesCIGRE-118 Practical Experience With IEEE 1588 High Precision Time Synchronization in Electrical Substation Based On IEC 61850 Process BusEleazar Sierra EspinozaPas encore d'évaluation

- ABB LMU 574 - mcd80Document12 pagesABB LMU 574 - mcd80gadware2011bplPas encore d'évaluation

- Specification - FOTE MPPTCLDocument14 pagesSpecification - FOTE MPPTCLscada.wupptclPas encore d'évaluation

- Design and Simulation of RF Energy Extracting CircuitsDocument28 pagesDesign and Simulation of RF Energy Extracting CircuitsHaresh SinghPas encore d'évaluation

- SCADA System Architecture & RTUDocument49 pagesSCADA System Architecture & RTUsreelakshmi.p100% (1)

- Transmission Through PowerlineDocument10 pagesTransmission Through Powerlineyameogoangela2015Pas encore d'évaluation

- Specification - PLCC & FOTE For 400kVDocument8 pagesSpecification - PLCC & FOTE For 400kVscada.wupptclPas encore d'évaluation

- Coiled For ProtectionDocument6 pagesCoiled For ProtectionAbdelsalam ElhaffarPas encore d'évaluation

- Development of DC Power Line Carrier Communication Interface For Digital Networking For Control of COILDocument5 pagesDevelopment of DC Power Line Carrier Communication Interface For Digital Networking For Control of COILMehboob AlamPas encore d'évaluation

- A Complete Narrow-Band Power Line Communication Node For AMRDocument6 pagesA Complete Narrow-Band Power Line Communication Node For AMRSudheer KakaniPas encore d'évaluation

- Advanced Railway Security System (Arss) Based On Zigbee Communication For Track Fault DetectionDocument23 pagesAdvanced Railway Security System (Arss) Based On Zigbee Communication For Track Fault DetectionRashmi100% (2)

- A 1.8Ghz Cmos: Low-Power Truly-Modular Programmable Divider in Standard TechnologyDocument4 pagesA 1.8Ghz Cmos: Low-Power Truly-Modular Programmable Divider in Standard TechnologyMuhammad_Swilam_2010Pas encore d'évaluation

- Part2 WorkrequirementDocument5 pagesPart2 WorkrequirementManglesh SinghPas encore d'évaluation

- Digital Substation TestsDocument10 pagesDigital Substation Testsraghavendran raghuPas encore d'évaluation

- Sat TM 1703 Acp PDF 745kbDocument6 pagesSat TM 1703 Acp PDF 745kbIbrar H MalikPas encore d'évaluation

- Implementation Using Power Line Communications in Telephone SystemDocument5 pagesImplementation Using Power Line Communications in Telephone SystemGopinath KudaravalliPas encore d'évaluation

- Railway Signalling Axle-Counter SystemDocument2 pagesRailway Signalling Axle-Counter SystemJitendraKalerPas encore d'évaluation

- Cpre 2017 8090038Document19 pagesCpre 2017 8090038Rahaf WaheepPas encore d'évaluation

- Micom P740Document18 pagesMicom P740vsrikala68Pas encore d'évaluation

- Ijert Ijert: Lighting Control System Using Power Line Communication NetworkingDocument7 pagesIjert Ijert: Lighting Control System Using Power Line Communication NetworkingSỹ RonPas encore d'évaluation

- Analysis of An IEC 61850 Based Electric Substation Communication ArchitectureDocument6 pagesAnalysis of An IEC 61850 Based Electric Substation Communication ArchitectureHari NairPas encore d'évaluation

- GSM Based Water Pump ControllerDocument30 pagesGSM Based Water Pump ControllerSatyanarayan MahantaPas encore d'évaluation

- Specification - PLCC & FOTE JewarDocument20 pagesSpecification - PLCC & FOTE Jewarscada.wupptclPas encore d'évaluation

- Speed Control of Single Phase Induction Motor Using Infrared Receiver ModuleDocument6 pagesSpeed Control of Single Phase Induction Motor Using Infrared Receiver ModuleSanjay ShelarPas encore d'évaluation

- 1MW Grid-Connected PV System Design PlanDocument10 pages1MW Grid-Connected PV System Design PlanengmswilamPas encore d'évaluation

- Scada TrainingDocument53 pagesScada TrainingLalit Soni100% (1)

- Remote Operation of Substation - A GlimpseDocument2 pagesRemote Operation of Substation - A GlimpseSomiran DasPas encore d'évaluation

- Digital Substation AlstomDocument36 pagesDigital Substation Alstomdipteshypatel100% (1)

- B3 109 2014 PDFDocument7 pagesB3 109 2014 PDFRazvan DonciuPas encore d'évaluation

- Signal List 1024Document27 pagesSignal List 1024Harsh PandeyPas encore d'évaluation

- SCD5200 CPU OptoNet Power Supply Ethernet (COPE) ModuleDocument8 pagesSCD5200 CPU OptoNet Power Supply Ethernet (COPE) ModuleWisnu HartonoPas encore d'évaluation

- REMOTE TERMINAL UNIT (RTU) - Rev-3Document25 pagesREMOTE TERMINAL UNIT (RTU) - Rev-3Ammar JassimPas encore d'évaluation

- A New Differential Protection Scheme For Busbar Considering CT Saturation EffectDocument4 pagesA New Differential Protection Scheme For Busbar Considering CT Saturation EffectMuruganPas encore d'évaluation

- A Mixed Signal AsicDocument6 pagesA Mixed Signal AsicbmmostefaPas encore d'évaluation

- Microcontroller Based Numerical Relay For Induction Motor ProtectionDocument4 pagesMicrocontroller Based Numerical Relay For Induction Motor ProtectionRama Krishna SamireddyPas encore d'évaluation

- 128122-Accelerometer & VelomitorTransducerOperationDocument22 pages128122-Accelerometer & VelomitorTransducerOperationNorman MoralesPas encore d'évaluation

- OPTCL Substation Automation SpecificationDocument45 pagesOPTCL Substation Automation SpecificationManas Kumar SahooPas encore d'évaluation

- Multi-Motor Control System Design Based On Can BusDocument4 pagesMulti-Motor Control System Design Based On Can BusPrakash ArulPas encore d'évaluation

- Rex521 Broch 755156 Lrenc PDFDocument2 pagesRex521 Broch 755156 Lrenc PDFMinh HoangPas encore d'évaluation

- Design and Testing of An TCSC For Distribution Network Applications PDFDocument5 pagesDesign and Testing of An TCSC For Distribution Network Applications PDFRuchitaPas encore d'évaluation

- REMOTE TERMINAL UNIT (RTU) TECHNICAL SPECIFICATIONDocument24 pagesREMOTE TERMINAL UNIT (RTU) TECHNICAL SPECIFICATIONrupadhyaayPas encore d'évaluation

- Electronic Instrument TransformerDocument6 pagesElectronic Instrument Transformerraghavendran raghuPas encore d'évaluation

- Grid Stds AlkaDocument54 pagesGrid Stds AlkaTshering PeljorPas encore d'évaluation

- Multi-Terminal DC System Line Protection Requirement and High Speed Protection SolutionsDocument9 pagesMulti-Terminal DC System Line Protection Requirement and High Speed Protection SolutionsMuhammad AftabuzzamanPas encore d'évaluation

- RTU Amlesher Spec.Document7 pagesRTU Amlesher Spec.Piyush OjhaPas encore d'évaluation

- The Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunDocument9 pagesThe Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunMarco LisiPas encore d'évaluation

- 3-Phase PFC KolarDocument7 pages3-Phase PFC KolarJayant SalianPas encore d'évaluation

- Automatic Speed and Torque Monitoring in Induction Motors Using Zigbee and SmsDocument6 pagesAutomatic Speed and Torque Monitoring in Induction Motors Using Zigbee and SmsRaghul RamasamyPas encore d'évaluation

- LINE DIFF PROTDocument6 pagesLINE DIFF PROTNirmal RajaPas encore d'évaluation

- Design and Research On Air Conditioning Control Network of Electric Vehicle Based On CAN-busDocument4 pagesDesign and Research On Air Conditioning Control Network of Electric Vehicle Based On CAN-busSabriPas encore d'évaluation

- DDC Solid State Power Controllers 2Document4 pagesDDC Solid State Power Controllers 2David BaillyPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsD'EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsPas encore d'évaluation

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- 2016 Horvach-Rarlew PDFDocument12 pages2016 Horvach-Rarlew PDFmedioperroPas encore d'évaluation

- ABB Photo Voltaic PlantsDocument116 pagesABB Photo Voltaic PlantsfiestastefPas encore d'évaluation

- Influence of Temperature On Power FactorDocument10 pagesInfluence of Temperature On Power Factorrasim_m1146Pas encore d'évaluation

- Service Manual - Model Pp1808-28Document56 pagesService Manual - Model Pp1808-28rasim_m1146Pas encore d'évaluation

- MEGA AC Electric VehiclesDocument52 pagesMEGA AC Electric Vehiclesrasim_m1146Pas encore d'évaluation

- Bosch20182019 Catalog - Taps and DiesDocument8 pagesBosch20182019 Catalog - Taps and Diesrasim_m1146Pas encore d'évaluation

- A Harmonic Impedance Estimation MethodDocument7 pagesA Harmonic Impedance Estimation Methodrasim_m1146Pas encore d'évaluation

- Bosch20182019 Catalog - Routerssandersplaners-SpecialtyDocument48 pagesBosch20182019 Catalog - Routerssandersplaners-Specialtyrasim_m1146Pas encore d'évaluation

- Click and CleanDocument40 pagesClick and Cleanrasim_m1146Pas encore d'évaluation

- KM1500 SM UK Rev1Document179 pagesKM1500 SM UK Rev1EKTshnikPas encore d'évaluation

- Bosch20182019 Catalog - Woodmetalcutting-2Document60 pagesBosch20182019 Catalog - Woodmetalcutting-2rasim_m1146Pas encore d'évaluation

- 1758 In001 - en PDocument28 pages1758 In001 - en Prasim_m1146Pas encore d'évaluation

- 2 - Transient Stability ImprovementDocument10 pages2 - Transient Stability Improvementrasim_m1146Pas encore d'évaluation

- Self-Healing Control With Multifunctional Gate Drive Circuits ForDocument8 pagesSelf-Healing Control With Multifunctional Gate Drive Circuits Forrasim_m1146Pas encore d'évaluation

- Roadmap for Advanced Distribution Management System (ADMSDocument3 pagesRoadmap for Advanced Distribution Management System (ADMSrasim_m1146Pas encore d'évaluation

- Rems Katalog 2015 GbropDocument244 pagesRems Katalog 2015 Gbroprasim_m1146Pas encore d'évaluation

- Roadmap for Advanced Distribution Management System (ADMSDocument3 pagesRoadmap for Advanced Distribution Management System (ADMSrasim_m1146Pas encore d'évaluation

- Permanent Magnet Motor Drives With Switched Stator WindingsDocument315 pagesPermanent Magnet Motor Drives With Switched Stator Windingsrasim_m1146Pas encore d'évaluation

- Robin Shortform Catalogue 2014 v7Document28 pagesRobin Shortform Catalogue 2014 v7rasim_m1146Pas encore d'évaluation

- EngDocument4 pagesEngrasim_m1146Pas encore d'évaluation

- Transformer Terminal, RET 541/543/545 Release NoteDocument16 pagesTransformer Terminal, RET 541/543/545 Release NotebajricaPas encore d'évaluation

- Electrical Machines and DrivesDocument123 pagesElectrical Machines and Drivesanon-427532100% (14)

- Permanent Magnet Motor Drives With Switched Stator WindingsDocument315 pagesPermanent Magnet Motor Drives With Switched Stator Windingsrasim_m1146Pas encore d'évaluation

- 001 018Document18 pages001 018rasim_m1146Pas encore d'évaluation

- Electric Vehicles Modelling and SimulationsDocument479 pagesElectric Vehicles Modelling and Simulationsrasim_m114650% (2)

- 2007 - 34 Wind TurbineDocument9 pages2007 - 34 Wind TurbineLin ChongPas encore d'évaluation

- Power Electronics and Power SystemsDocument49 pagesPower Electronics and Power Systemsrasim_m1146Pas encore d'évaluation

- Stator Winding Fault Diagnosis of Three-Phase Induction Motor by Park'S Vector ApproachDocument6 pagesStator Winding Fault Diagnosis of Three-Phase Induction Motor by Park'S Vector Approachrasim_m1146Pas encore d'évaluation

- Torque Profiles of Asymmetrically Wound Six-Phase Induction Motor (AWSP-IM) Under Phase-Loss ConditionsDocument13 pagesTorque Profiles of Asymmetrically Wound Six-Phase Induction Motor (AWSP-IM) Under Phase-Loss Conditionsrasim_m1146Pas encore d'évaluation

- CV 1Document4 pagesCV 1Fa DiPas encore d'évaluation

- Pink Fall Service Catalog'14Document9 pagesPink Fall Service Catalog'14Đoàn Đức ĐềPas encore d'évaluation

- How Postilion Calculates Uptime of Installed ApplicationDocument1 pageHow Postilion Calculates Uptime of Installed ApplicationPrashant BansalPas encore d'évaluation

- Tangix TesterPRO Error 2019-04-29 225216Document64 pagesTangix TesterPRO Error 2019-04-29 225216AhmedPas encore d'évaluation

- Visual Basic Programming: Multiple Forms, Standard Modules, and MenusDocument30 pagesVisual Basic Programming: Multiple Forms, Standard Modules, and MenusZennolWanHärisPas encore d'évaluation

- Installation Guide TeradataDocument10 pagesInstallation Guide TeradataMe MePas encore d'évaluation

- T24 Close of Business (COB) : 1 Free Org Charß MakerDocument17 pagesT24 Close of Business (COB) : 1 Free Org Charß Makervikki chowdaryPas encore d'évaluation

- MultiplexingDocument38 pagesMultiplexingBindhya Basini Mishra0% (1)

- Keysight i3070 Inline 4 Module In-Circuit Test SystemDocument11 pagesKeysight i3070 Inline 4 Module In-Circuit Test SystemDanielPas encore d'évaluation

- What Does Alibaba's "New Retail" Concept Mean For Amazon?Document2 pagesWhat Does Alibaba's "New Retail" Concept Mean For Amazon?Marsha ReginaPas encore d'évaluation

- MAT060 - 2 - Limit (Formal Definition)Document16 pagesMAT060 - 2 - Limit (Formal Definition)Love RosieePas encore d'évaluation

- 2.2.2.5 LabDocument3 pages2.2.2.5 LabHarman HayerPas encore d'évaluation

- Machine LanguageDocument3 pagesMachine LanguageAniket ShetyePas encore d'évaluation

- Evaluation of The Distance Mediation Project: Report On Phase II of The Technology-Assisted Family Mediation Project Volume II: AppendicesDocument34 pagesEvaluation of The Distance Mediation Project: Report On Phase II of The Technology-Assisted Family Mediation Project Volume II: AppendicesMediate BCPas encore d'évaluation

- Cs 372Document2 pagesCs 372Balakumar RamadossPas encore d'évaluation

- Sartorius Basic Sartorius Gem: Operating InstructionsDocument30 pagesSartorius Basic Sartorius Gem: Operating InstructionsJosé FariaPas encore d'évaluation

- PW Series Intelligent Digital Controller Introduction and SpecificationDocument5 pagesPW Series Intelligent Digital Controller Introduction and SpecificationВячеславPas encore d'évaluation

- Plastic Memory Stores 1,000 Photos in 1 Cubic CentimeterDocument9 pagesPlastic Memory Stores 1,000 Photos in 1 Cubic CentimeterNavami Aykara JPas encore d'évaluation

- Get Security, Convenience and Smart Control with ENTR Smart Lock SolutionDocument20 pagesGet Security, Convenience and Smart Control with ENTR Smart Lock Solutionpacopepe77Pas encore d'évaluation

- Brocade Bottel Neck CMDDocument32 pagesBrocade Bottel Neck CMDragservPas encore d'évaluation

- (IEEE Expert Vol. 1 Iss. 2) Hubert, - Dreyfus, Stuart - Why Expert Systems Do Not Exhibit Expertise (1986) (10.1109 - MEX.1986.4306957) - Libgen - LiDocument5 pages(IEEE Expert Vol. 1 Iss. 2) Hubert, - Dreyfus, Stuart - Why Expert Systems Do Not Exhibit Expertise (1986) (10.1109 - MEX.1986.4306957) - Libgen - LiTomas AliceaPas encore d'évaluation

- Sinai Auction 2018Document52 pagesSinai Auction 2018SinaiAcademyPas encore d'évaluation

- HW Components of A ComputerDocument8 pagesHW Components of A ComputerRashi MrBRDPas encore d'évaluation

- Extract Essbase Data and Load into SQLDocument14 pagesExtract Essbase Data and Load into SQLWichaiWongchariyakulPas encore d'évaluation

- Job Bingo Cards PDFDocument6 pagesJob Bingo Cards PDFDaniela CerrudoPas encore d'évaluation

- AMD Education AppDocument8 pagesAMD Education Appmanuel saludoPas encore d'évaluation

- Manual n1050 v10x F EnglishDocument10 pagesManual n1050 v10x F EnglishmilosPas encore d'évaluation

- Sungrow SG250HX-V112-User ManualDocument100 pagesSungrow SG250HX-V112-User ManualGopi Laal BahadurPas encore d'évaluation

- BCM5340X/BCM5341X: 160 Gb/s Multilayer SwitchDocument2 pagesBCM5340X/BCM5341X: 160 Gb/s Multilayer SwitchJoeyPas encore d'évaluation

- The Sims 4 + ALL DLC & Latest Crack May 2017Document4 pagesThe Sims 4 + ALL DLC & Latest Crack May 2017Akhmad Badaruddin SaktiPas encore d'évaluation