Académique Documents

Professionnel Documents

Culture Documents

Resume Mechatronics

Transféré par

Dhiraj MahajanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Resume Mechatronics

Transféré par

Dhiraj MahajanDroits d'auteur :

Formats disponibles

Mechatronics Engineer

Dhiraj Shrikant Mahajan

Ft no-5, Dream land Society Near Raghavendra

Hotel, Behind Chinchwad RTO, Chikhali Pradhikaran,

Purnanagar, Chinchwad, Pune-411019(Maharashtra)

Mobile No: +919021583878 / 9403306488

Email: coep.engineer@gmail.com

mahajan.mechatronics@gmail.com

Objective:

To obtain a challenging position in a high quality engineering environment where my resourceful

experience or academic skills will add value to organizational operations.

Work Experience:

Working as Engineer in Badve Autocomp Pvt. Ltd, Chakan from 24 Jun 2013 to till

date

Design And Development of New Projects

Ability to analyze and Recommend improvements on Plant Equipment.

Management, Installation and Maintenance of Mechatronics & Electrical related Equipments. Install,

Calibrate, Operate or Maintain Robots. Provide technical Support for Robotic Systems.

Knowledge of Robot Programming, its operation and break down handling

(Panasonic/Fanuc/Universal/Motoman).

Integrate robotics with peripherals such as welders, Controllers or other equipments.

Design automated robotic systems to increase production volume or precision in high-throughput

operations.

Analyse existing development or manufacturing procedures and suggest improvements

Upgrade the design of existing devices by adding mechatronic elements

Design, Develop or implement control circuit or algorithms for Electromechanical, Pneumatic,

Electro-pneumatic and Hydraulic devices or systems.

Knowledge of PLC/HMI Programming, and Panel Design, SPM Design

Perform all the maintenance & Development of HMI, PLC and Communication Devices.

Maintenance & Development of Pneumatic & Hydraulic systems with valves of Festo,SMC,etc.

Design & Implementation of Electric Circuit And Implement or Test Design solutions.

Analysing the Power consumption data & Taking steps to conserve Energy

Research,Select or apply Sensors, Communication technologies or Control devices for Motion

control, Position Sensing, Pressure Sensing or Electronic Communication.

Investigate Mechanical failures or unexpected Maintenance problem

Carry out in dept investigation of equipment failure, submit reports of probable causes of failures

with suggested remedial action with particular emphasis on instrumentation & Control system

Welding Process Development like Penetration(Prepared Weld Templates of

Bajaj),

Knowledge of Weld Penetration and Weld Parameters

Handling Daily Break Down Activities (Eletrical/Electronics,Mechanical)

Why Why Analysis of Break-Down more than 30 min. (MTTR & MTBF Reports)

To do some Kaizen Ideas to save plant Cost, Energy and increase Productivity &

Improve Quality

Designed Some Special Purpose Machines(SPM)

Knowledge of Machines like Welding Machines, CNC M/C, Bending Machines, Spot Welding

Machines, Forming M/c, Scooping, Cutting, Utilities, etc

Maintaining the reports and Documents pertaining to the execution of Project.

Supervise technologists, technicians or other engineers.

Preparing daily, Weekly and Monthly technical reports.

Performed routine maintenance inspections of equipment to identify and respond to problems in a timely

manner, thus preventing breakdowns.

Plan Schedule of preventive maintenance (52 Week)

Completed training on Pneumatics and Electro-pneumatics in Bajaj Auto Ltd, Waluj

Skills & Qualifications :

Judgment and Decision Making: Considering the relative costs and benefits of potential actions to

choose the most appropriate one.

Active Listening: Giving full attention to what other people are saying, taking time to understand the

points being made, asking questions as appropriate, and not interrupting at inappropriate times.

Complex Problem Solving: Identifying complex problems and reviewing related information to

develop and evaluate options and implement solutions.

Critical Thinking: Using logic and reasoning to identify the strengths and weaknesses of alternative

solutions, conclusions or approaches to problems.

Reading Comprehension: Understanding written sentences and paragraphs in work related

documents.

Speaking: Talking to others to convey information effectively.

Writing: Communicating effectively in writing as appropriate for the needs of the audience.

Active Learning: Understanding the implications of new information for both current and future

problem-solving and decision-making.

Mathematics: Using mathematics to solve problems.

Systems Evaluation: Identifying measures or indicators of system performance and the actions

needed to improve or correct performance, relative to the goals of the system.

Monitoring: Monitoring/Assessing performance of yourself, other individuals, or organizations to

make improvements or take corrective action.

Systems Analysis: Determining how a system should work and how changes in conditions,

operations, and the environment will affect outcomes.

Operation Monitoring: Watching gauges, dials, or other indicators to make sure a machine is

working properly.

Quality Control Analysis: Conducting tests and inspections of products, services, or processes to

evaluate quality or performance.

Instructing: Teaching others how to do something.

Operations Analysis: Analyzing needs and product requirements to create a design.

Persuasion: Persuading others to change their minds or behavior.

Technology Design: Generating or adapting equipment and technology to serve user needs.

Learning Strategies: Selecting and using training/instructional methods and procedures appropriate

for the situation when learning or teaching new things.

Management of Personnel Resources: Motivating, developing, and directing people as they work,

identifying the best people for the job.

Science: Using scientific rules and methods to solve problems.

Operation and Control: Controlling operations of equipment or systems.

Service Orientation: Actively looking for ways to help people.

Management of Material Resources: Obtaining and seeing to the appropriate use of equipment,

facilities, and materials needed to do certain work.

Troubleshooting: Determining causes of operating errors and deciding what to do about it.

Equipment Selection: Determining the kind of tools and equipment needed to do a job.

Installation: Installing equipment, machines, wiring, or programs to meet specifications.

Equipment Maintenance: Performing routine maintenance on equipment and determining when

and what kind of maintenance is needed.

Repairing: Repairing machines or systems using the needed tools.

Professional Qualification

College/University

M.Tech

(Mechatronics Engineering)

B.E.(Electronics and

Telecommunication)

Educational Qualification

Higher Secondary Certificate

Examination (HSC)

Secondary Certificate

Examination (SSC)

Government College Of Engineering, Pune

(COEP)

Bharti Vidyapeeth College of Engineering,

Navi Mumbai (Mumbai University)

College/University

Maharashtra State Board, Pune

Maharashtra State Board, Pune

Areas of Interest:

Electronics Design and Telecommunication

Applications

Passing

Year

2012

Marks

Class

I(D)

2010

8.21

(CGPA)

62.12

Pass Year

2005

Marks

73.33

Class

I

2003

83.06

I(D)

Mechtronics System Design

Electronics+Mechanical+Instrumentation

System Modelling and Computer Simulation

Embedded System Design

Robotics and Automation

Autotronics and Vehicle Development

Computer Skills:

Operating Systems

:

Software

:

Design Tools

:

Programming Languages:

Windows XP/Vista/7/8

MS Office, RoboSoft

FluidSim, ExpressPCB, Pro-E, Proteus, Keil, MPlab, Matlab, Eagle.

C++, C#, VHDL,Embedded Programming

Strength:

M.Tech Mechatronics

Positive Attitude

Team Leader

Dedication for committed work

Project Work:

1. M.Tech Dissertation: Integrated Development Board of Motors Control

(Speed of DC motor and DC motor with encoder, position of RC Servo motor and Stepping

angle(steps) of Unipolar, Bipolar and Universal stepper motor was Controlled by using PC( Using

Visual Basic windows application and terminal software), Keypad and Remote. This work was done

using a single Microcontroller (PIC18F458).also interface microcontroller with LCD, and 7 Segment

Display to display data. Also windows application was developed in VB to send and display the data.

All the Motors were controlled by using a single development board. Therefore this integrated

development board is cost effective. Also design was simulated in Proteus software with

programming design software MPLab.)

2. BE Project Work: Development of highly secured information storage using SD Card.

In the project work, anyone who is wanted to carry any confidential data is supposed to carry

only a SD card along with him. The Data will be stored in the SD card by our system and can be

retrieved back by our system only. This system is basically a hardware and software combination.

And those who have our system can only retrieve the information present in the SD Card. This

project was Microcontroller (8051) Based Project.

Personal Information:

Name

Dhiraj Shrikant Mahajan

Permanent Address

Date of Birth

Nationality

Languages

:

:

:

:

AT&PO-Chinawal, Tal-Raver, Dist-Jalgaon(425505) M.S, India

12/08/1987

Indian

English, Hindi, Marathi

Passport No

Declaration:

K4320805

All the information is true to the best of my knowledge.

DATE :

PLACE :

Dhiraj S Mahajan

Vous aimerez peut-être aussi

- Dhiraj 14112018Document3 pagesDhiraj 14112018Dhiraj MahajanPas encore d'évaluation

- Valves Instumentation and ControlDocument43 pagesValves Instumentation and ControlFayeez MukadamPas encore d'évaluation

- FFT.C File ReferenceDocument3 pagesFFT.C File ReferenceDhiraj MahajanPas encore d'évaluation

- Sensors and ActuatorsDocument31 pagesSensors and ActuatorsDhiraj MahajanPas encore d'évaluation

- Rocket CodeDocument11 pagesRocket CodeDhiraj MahajanPas encore d'évaluation

- Pro/ENGINEER Wildfire 3.0 Tips: Keyboard/mouse ShortcutsDocument6 pagesPro/ENGINEER Wildfire 3.0 Tips: Keyboard/mouse ShortcutsCADTDDPas encore d'évaluation

- Cadd SyllabusDocument6 pagesCadd SyllabussonyselvinPas encore d'évaluation

- Lecturer MechatronicsDocument3 pagesLecturer MechatronicsDhiraj MahajanPas encore d'évaluation

- Lec06a Sensor Actuator IntroDocument3 pagesLec06a Sensor Actuator IntroDhiraj MahajanPas encore d'évaluation

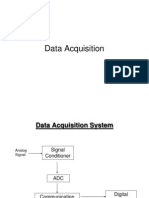

- Data AcquisitionDocument13 pagesData AcquisitionDhiraj MahajanPas encore d'évaluation

- Interview FAQDocument36 pagesInterview FAQSiva KrishnaPas encore d'évaluation

- Hyd Valves 07Document20 pagesHyd Valves 07Dhiraj MahajanPas encore d'évaluation

- ASP Net Question PaperDocument122 pagesASP Net Question Paperbhrantav0% (1)

- FFT.C File ReferenceDocument3 pagesFFT.C File ReferenceDhiraj MahajanPas encore d'évaluation

- AN Photodiode Parameters CharacteristicsDocument3 pagesAN Photodiode Parameters CharacteristicsnirgudeakshayPas encore d'évaluation

- Pro EDocument25 pagesPro EDhiraj MahajanPas encore d'évaluation

- Pro e GuideDocument111 pagesPro e GuideRajesh KumarPas encore d'évaluation

- Sample CV For FreshersDocument2 pagesSample CV For FreshersRavinder Singh BhadauriaPas encore d'évaluation

- Bal GeeteDocument2 pagesBal GeeteDhiraj MahajanPas encore d'évaluation

- Assignment 07Document15 pagesAssignment 07Dhiraj MahajanPas encore d'évaluation

- Java Interview QuestionsDocument21 pagesJava Interview QuestionsAnand BiradarPas encore d'évaluation

- Status Report 0315Document8 pagesStatus Report 0315Dhiraj MahajanPas encore d'évaluation

- Nasa Final ReportDocument31 pagesNasa Final ReportArul CharlesPas encore d'évaluation

- Biotribological Behavior of Ultra High Molecular WeightDocument7 pagesBiotribological Behavior of Ultra High Molecular WeightDhiraj MahajanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Advanced Algorithms Logic and Proving TechniquesDocument25 pagesAdvanced Algorithms Logic and Proving TechniquesTayyaba TanoliPas encore d'évaluation

- Day & Time Learning TasksDocument8 pagesDay & Time Learning TasksKarl Del CarmenPas encore d'évaluation

- NCP - AnxietyDocument4 pagesNCP - AnxietyRoyce Vincent TizonPas encore d'évaluation

- Four Basic Language SkillsDocument6 pagesFour Basic Language SkillsAnisa TrifoniPas encore d'évaluation

- SEL in The Music ClassroomDocument57 pagesSEL in The Music ClassroomBabydoll MariePas encore d'évaluation

- Jane Burry and Mark Burry The New Mathematics of ArchitectureDocument3 pagesJane Burry and Mark Burry The New Mathematics of Architectureccamiloo moraPas encore d'évaluation

- Students' Attitudes Towards Learning English, Filipino and Ilocano LanguagesDocument11 pagesStudents' Attitudes Towards Learning English, Filipino and Ilocano LanguagesAnthony Miguel RafananPas encore d'évaluation

- Familiar Colloquial StyleDocument1 pageFamiliar Colloquial Styleliza lyubetskayaPas encore d'évaluation

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityMihir PatelPas encore d'évaluation

- LessonPlan Year 1 Unit 18Document5 pagesLessonPlan Year 1 Unit 18Aemo LoveaPas encore d'évaluation

- 1.1-Berge-2008-Why It Is So Hard To Evaluate Training in The WorkplaceDocument8 pages1.1-Berge-2008-Why It Is So Hard To Evaluate Training in The WorkplaceNguyễn Thị Huyền TrangPas encore d'évaluation

- Big Data MSC ThesisDocument4 pagesBig Data MSC Thesislynnwebersaintpaul100% (2)

- Ejercicios Del Presente, Pasado Simple y Presente ContinuoDocument3 pagesEjercicios Del Presente, Pasado Simple y Presente Continuoclmc3Pas encore d'évaluation

- Beginnings of The Semiotics of Culture 2013 - LIBRODocument131 pagesBeginnings of The Semiotics of Culture 2013 - LIBROEduardo SalPas encore d'évaluation

- English As A Lingua Franca EltDocument3 pagesEnglish As A Lingua Franca EltNataly LeónPas encore d'évaluation

- Format and Question - ESEM5553 ASSIG 2 UNITARDocument3 pagesFormat and Question - ESEM5553 ASSIG 2 UNITARMiz TatyPas encore d'évaluation

- Tos Template 2020 NewDocument4 pagesTos Template 2020 NewElsa LinsanganPas encore d'évaluation

- What Is Instructional Design?Document33 pagesWhat Is Instructional Design?ronentechPas encore d'évaluation

- Soal UAS Structure 1 2021 Evening PDFDocument3 pagesSoal UAS Structure 1 2021 Evening PDFAswar HamidPas encore d'évaluation

- PETA1 TopicPoolDocument6 pagesPETA1 TopicPoolRich BlancaflorPas encore d'évaluation

- Lesson 7 ENGLISHDocument10 pagesLesson 7 ENGLISHJackaii Waniwan IIPas encore d'évaluation

- PROGRESS REPORT-Academic and Research Report WritingDocument2 pagesPROGRESS REPORT-Academic and Research Report WritingArpita ChoudharyPas encore d'évaluation

- Neuroplasticity - The Moldable BrainDocument24 pagesNeuroplasticity - The Moldable BrainWinnie Claire100% (1)

- PhilosophyDocument7 pagesPhilosophyCarlos Mario MorenoPas encore d'évaluation

- LSPU Module Explores Math as a LanguageDocument37 pagesLSPU Module Explores Math as a Languagepluto bautistaPas encore d'évaluation

- Consumer BehaviourDocument125 pagesConsumer BehaviourZico RodriguesPas encore d'évaluation

- LCP Interpretation Manual VIRTUAL v2022.1Document48 pagesLCP Interpretation Manual VIRTUAL v2022.1Khurram ShahzadPas encore d'évaluation

- Direct To Indirect RulesDocument11 pagesDirect To Indirect Rulesrajeeeva100% (1)

- Week 3: Writing A Position Paper: at The End of The Lesson, You Should Be Able ToDocument8 pagesWeek 3: Writing A Position Paper: at The End of The Lesson, You Should Be Able ToDharyn KhaiPas encore d'évaluation

- Part 1 Introduction Qualitative MethodsDocument16 pagesPart 1 Introduction Qualitative MethodsJane MuliPas encore d'évaluation