Académique Documents

Professionnel Documents

Culture Documents

Basics of Injection Molding

Transféré par

George MarkasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Basics of Injection Molding

Transféré par

George MarkasDroits d'auteur :

Formats disponibles

Basics of Injection Molding

Nov 08 2010 01:30 PM | Chris Haslego

in Bulk Solids

Share this topic:

|More

Making polymers is a fantastic science. Then there is the matter of shaping the plastic into useful

objects....another fantastic science. One of the most common methods of shaping plastic resins is a

process called injection molding. Injection molding is accomplished by large machines called injection

molding machines.

Resin is fed to the machine through the hopper. Colorants are usually fed to the machine directly

after the hopper. The resins enter the injection barrel by gravity though the feed throat. Upon

entrance into the barrel, the resin is heated to the appropriate melting temperature.

The resin is injected into the mold by a reciprocating screw or a ram

injector. The reciprocating screw apparatus is shown above. The

reciprocating screw offers the advantage of being able to inject a smaller

percentage of the total shot (amount of melted resin in the barrel). The ram

injector must typically inject at least 20% of the total shot while a screw

injector can inject as little as 5% of the total shot. Essentially, the screw

injector is better suited for producing smaller parts.

Figure 1: Diagram of

Injection Molding Machine

Figure 2: Photo of Injection

Molding Machine

Figure 3: Diagram of

Heated Screw Conveyor

The mold is the part of the machine that receives the plastic and shapes it

appropriately. The mold is cooled constantly to a temperature that allows

the resin to solidify and be cool to the touch. The mold plates are held

together by hydraulic or mechanical force. The clamping force is defined as

the injection pressure multiplied by the total cavity projected area. Typically

molds are overdesigned depending on the resin to be used. Each resin has

a calculated shrinkage value associated with in.

Some Typical Complications

Burned or Scorched Parts: Melt temperature may be too high. Polymer may be becoming trapped

and degrading in the injection nozzle. Cycle time may be too long allowing the resin to overheat.

Warpage of Parts: Uneven surface temperature of the molds. Non-uniform wall thickness of mold

design.

Surface Imperfections: Melt temperature may be too high causing resin decomposition and gas

evolution (bubbles). Excessive moisture in the resin. Low pressure causing incomplete filling of

mold.

Incomplete Cavity Filling: Injection stroke may be too small for mold (ie. not enough resin is being

injected). Injection speed may be too slow causing freezing before mold is filled.

Diagrams courtesy of Plastics: Materials and Processing, Prentice Hall by A. Brent Strong

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Rotomoulding Machine FINAL0000000000Document42 pagesRotomoulding Machine FINAL0000000000Nikhil PanchalPas encore d'évaluation

- 05 Processing Data For The Injection Molder - MS005757Document58 pages05 Processing Data For The Injection Molder - MS005757George MarkasPas encore d'évaluation

- Supply Chain OptimizationDocument103 pagesSupply Chain OptimizationGeorge MarkasPas encore d'évaluation

- Color Measurement of PET Pellets - CTHTPlasticDocument2 pagesColor Measurement of PET Pellets - CTHTPlasticGeorge MarkasPas encore d'évaluation

- 2 Spaseska 379-384Document6 pages2 Spaseska 379-384Tien TranPas encore d'évaluation

- Contactors ManagementDocument5 pagesContactors ManagementGeorge MarkasPas encore d'évaluation

- Supply Chain Optimization PDFDocument12 pagesSupply Chain Optimization PDFGeorge MarkasPas encore d'évaluation

- Aldehyde Scavenging Agents & Packaging MaterialsDocument19 pagesAldehyde Scavenging Agents & Packaging MaterialsGeorge MarkasPas encore d'évaluation

- Production KPIDocument7 pagesProduction KPICucak RowoPas encore d'évaluation

- GS33J01A10-01EN Main Centum VP Part Selection R6Document40 pagesGS33J01A10-01EN Main Centum VP Part Selection R6timsar1357Pas encore d'évaluation

- A43010109 PDFDocument9 pagesA43010109 PDFGeorge MarkasPas encore d'évaluation

- Loop Checking Technicians Guide PDFDocument151 pagesLoop Checking Technicians Guide PDFinfoasim2100% (1)

- Loop Checking GuideDocument4 pagesLoop Checking GuideGeorge MarkasPas encore d'évaluation

- Dust Control HandbookDocument314 pagesDust Control HandbookJoseph RileyPas encore d'évaluation

- Yokogawa Centum VP DCSDocument24 pagesYokogawa Centum VP DCSGeorge MarkasPas encore d'évaluation

- Fme Leadership TheoriesDocument48 pagesFme Leadership TheoriesBraulio MartinezPas encore d'évaluation

- THanna StudentversionDocument10 pagesTHanna StudentversionMahesh KhamitkarPas encore d'évaluation

- Team Leadership Style PDFDocument38 pagesTeam Leadership Style PDFDavid Sulca CoronadoPas encore d'évaluation

- Effective Bin DesignDocument8 pagesEffective Bin DesignGeorge Markas100% (1)

- Fme Understanding Emotional Intelligence PDFDocument50 pagesFme Understanding Emotional Intelligence PDFrgscribd61Pas encore d'évaluation

- Fme Understanding Emotional Intelligence PDFDocument50 pagesFme Understanding Emotional Intelligence PDFrgscribd61Pas encore d'évaluation

- Distributed Control System - OverviewDocument7 pagesDistributed Control System - OverviewGeorge MarkasPas encore d'évaluation

- Statistical Process ControlDocument18 pagesStatistical Process ControlGeorge MarkasPas encore d'évaluation

- Measurement and Control of Polymerization ReactorsDocument17 pagesMeasurement and Control of Polymerization ReactorsahsanbasherPas encore d'évaluation

- Reaction Calorimetry Guide A4 PDFDocument10 pagesReaction Calorimetry Guide A4 PDFGeorge Markas100% (1)

- Basics of Injection MoldingDocument2 pagesBasics of Injection MoldingGeorge MarkasPas encore d'évaluation

- Finding Root Cause of Process UpsetsDocument11 pagesFinding Root Cause of Process UpsetsGeorge MarkasPas encore d'évaluation

- Reliance Industries Limited: Trouble Shooting Guide # Problem Cause Reason Action Side EffectsDocument6 pagesReliance Industries Limited: Trouble Shooting Guide # Problem Cause Reason Action Side EffectsGeorge MarkasPas encore d'évaluation

- A Short Guide To Pneumatic Conveying of Powders and Bulk SolidsDocument3 pagesA Short Guide To Pneumatic Conveying of Powders and Bulk SolidsGeorge MarkasPas encore d'évaluation

- Team Leadership Style PDFDocument38 pagesTeam Leadership Style PDFDavid Sulca CoronadoPas encore d'évaluation

- Fme Leadership TheoriesDocument48 pagesFme Leadership TheoriesBraulio MartinezPas encore d'évaluation

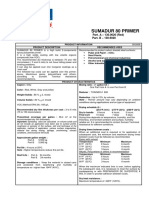

- 130.0020 - Sumadur 80 PrimerDocument2 pages130.0020 - Sumadur 80 Primerhelioxavier2Pas encore d'évaluation

- Api 1104Document38 pagesApi 1104Tang Na Ker100% (3)

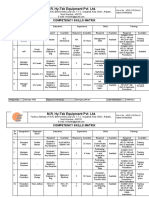

- MRH Competence Skill Matrix - To CheckDocument7 pagesMRH Competence Skill Matrix - To CheckParag WadekarPas encore d'évaluation

- HBFLEX Catalogue ENDocument8 pagesHBFLEX Catalogue ENDuy Phạm VănPas encore d'évaluation

- Export Price List Liquid GroupDocument1 pageExport Price List Liquid GroupAbbas SaqibPas encore d'évaluation

- Catalog 2023 - Aerogas Industrial Supply SDN BHDDocument20 pagesCatalog 2023 - Aerogas Industrial Supply SDN BHDapi-677550906Pas encore d'évaluation

- Polyken 1619 Liquid Adhesive: Product Data SheetDocument2 pagesPolyken 1619 Liquid Adhesive: Product Data SheetCarlos Albán SalazarPas encore d'évaluation

- Fronius Cold Metal TransferDocument16 pagesFronius Cold Metal Transferbonmarche28Pas encore d'évaluation

- Insta Hardware Upvc Catalog 2023Document32 pagesInsta Hardware Upvc Catalog 2023HeeRokBarickPas encore d'évaluation

- En GJS 400 15CDocument1 pageEn GJS 400 15CCAT MINING SHOVELPas encore d'évaluation

- PublicationDocument167 pagesPublicationavicohvacrPas encore d'évaluation

- Drill Collar BehnamDocument2 pagesDrill Collar BehnamBehnamPas encore d'évaluation

- 94B17, 94B17HDocument3 pages94B17, 94B17HGil CabreraPas encore d'évaluation

- Experimental and Simulation Study On The Microstructure of TA15 Laser WeldingDocument11 pagesExperimental and Simulation Study On The Microstructure of TA15 Laser Weldingadnan domlogePas encore d'évaluation

- Jis B 2291-1994Document9 pagesJis B 2291-1994Ilka RaffaelliPas encore d'évaluation

- TDS Permax 3300Document1 pageTDS Permax 3300Syamsul MaripPas encore d'évaluation

- BOLTS Heavyhexbolts Astm A193 b7 Astm A307 GradeABDocument3 pagesBOLTS Heavyhexbolts Astm A193 b7 Astm A307 GradeABLukman Nul HakimPas encore d'évaluation

- Material Unit Unit Price Concrete: FormworksDocument3 pagesMaterial Unit Unit Price Concrete: FormworksLester MuscaPas encore d'évaluation

- Standard Test Method For Macroetching MeDocument11 pagesStandard Test Method For Macroetching MeMostri Mostri100% (1)

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsJolettitoPas encore d'évaluation

- Rough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Document178 pagesRough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Edwin ThieroffPas encore d'évaluation

- Previous Years GATE Questions Sub: Production Technology (Welding)Document12 pagesPrevious Years GATE Questions Sub: Production Technology (Welding)KAUSTUB CHAUHANPas encore d'évaluation

- 06 Flash and Fire PointDocument9 pages06 Flash and Fire PointanmarPas encore d'évaluation

- Options For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Document14 pagesOptions For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Rodrigo GarcíaPas encore d'évaluation

- X-Roc Multibond LX: Multi-Purpose Primer and Mortar AdditiveDocument2 pagesX-Roc Multibond LX: Multi-Purpose Primer and Mortar AdditiveAmr RagabPas encore d'évaluation

- SSAB Weld DefectsDocument16 pagesSSAB Weld Defectspozolab0% (1)

- Havi Rae Form Hf001Document2 pagesHavi Rae Form Hf001mevansmetreelPas encore d'évaluation

- BMP - RollingDocument46 pagesBMP - Rollingmantra2010Pas encore d'évaluation