Académique Documents

Professionnel Documents

Culture Documents

CT 02 - Salbidegoitia Et Al

Transféré par

Jon Bisu DebnathTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CT 02 - Salbidegoitia Et Al

Transféré par

Jon Bisu DebnathDroits d'auteur :

Formats disponibles

E F F E C T O F C O E X I S T I NG M A T E R I A L S O N

S T E A M G AS I F I C A T I O N O F E - W A S T E

J. A. Salbidegoitia1, M.P. Gonzlez-Marcos1, J.R. Gonzlez-Velasco1, T. Bhaskar2, T. Kamo*3

1Chemical

Engineering Department, Faculty of Science and Technology, University of Basque Country/E.H.U., 644, E-48080

Bilbao, Spain

2Thermo-Catalytic Processes Area (TPA), CSIR-Indian Institute of Petroleum (IIP), Dehradun 248005, Uttarakhand, India

3National Institute of Advanced Industrial Science and Technology (AIST), 16-1 Onogawa, Tsukuba, Ibaraki, 305-8569,

Japan

e-mail: tohru-kamo@aist.go.jp; Phone: +81298618427

Abstract

Steam gasification of tantalum electronic capacitors or phenolic boards in the presence of LNK ternary eutectic carbonates

(Li2CO3, Na2CO3, and K2CO3) was carried out at 550-675C under atmospheric pressure to produce clean hydrogen. Rates

of hydrogen formation were accelerated in the presence of the metal contained in tantalum (Ta) capacitors as well as nickel

metal powder (-50+100 mesh). The results showed that nonsupported nickel metal or the metal contained in the connecting

terminals of electronic devices is effective to increase the rate of hydrogen production by steam gasification.

Keywords: tantalum capacitor; steam gasification; ternary eutectic carbonates, WEEE

1. Introduction

Recovery of valuable metals from waste electrical and

electronic equipment (WEEE) is important to reduce

landfill. Also, conversion of plastics contained in the

electronic devices to clean hydrogen by steam

gasification has been demonstrated to be feasible [1].

Phenolic resin/polymer is a widely used material for the

manufacture of printed circuit boards. A tantalum (Ta)

capacitor is a component on the PCBs of electronic

devices and it is composed mainly of tantalum, which is

an essential material for manufacturing electronic

devices. Three different parts compose the capacitor:

terminal, sintered electrode and fireproof epoxy resin.

The terminal is made of iron, nickel, or copper. The inner

part of the capacitor is the sintered electrode and it is

mostly composed by compacted Ta fine powder (90 wt.

%). It is covered by a fireproof epoxy resin with SiO2

powder to enhance its thermal durability [2].

In this work, steam gasification experiments of phenolic

boards or Ta capacitors were carried out in the presence

of eutectic carbonates mixture (Li2CO3, Na2CO3, and

K2CO3) to produce clean hydrogen fuel. The presence of

nickel, inherent in WEEE, is studied in order to determine

its catalytic effect in steam gasification.

2. Materials and Methods

2.1 Samples

Ta capacitors and phenolic boards (PL-1102, Sumitomo

Bakelite Co., Ltd.) are grinded (0.15 mm of particle size)

and used as samples for the thermogravimetric studies

or steam gasification experiments. The eutectic LNK

carbonate was prepared by mixing equal weights of three

carbonates (Lithium carbonate, sodium carbonate, and

potassium carbonate, supplied by Wako Pure Chemical

Industries, Ltd.). Nickel powder (-50+100 mesh), with

99.7 % purity, was provided by ALFA AESAR.

2.2 Experimental procedure

2.2.1

Thermogravimetric studies

Thermogravimetric studies for phenolic boards were

performed in a Rigaku Thermoplus TG8120

thermobalance, in nitrogen and steam atmosphere.

Experiments for Ni (-50+100 mesh) and phenolic boards

plus 75% wt. Ni (-50+100 mesh) samples were also

carried out in order to study the behavior of the nickel

metal and its effect in the decomposition of phenolic

boards under steam conditions. The heating ramp was

10C/min to reach 900C and a 50 ml/min of nitrogen

flow was used for inert atmosphere. To obtain steam

conditions, the nitrogen flow is bubbled in water at 75C.

2.2.2

Steam gasification

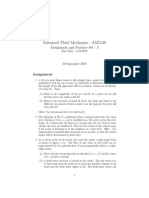

A diagram of the process is presented in Fig. 1 and it

shows that the equipment was composed of the sample

feeder, the reactor (ID: 32 mm, L: 125 mm), the heater,

the steam generator and a cooling system. Composition

of the gas products was analyzed every 5 min by gas

chromatography (Varian CP-4900) and the gas flow rate

was measured by an integrating flow meter. LNK

carbonates (30 g) and nickel (1.5 g) were preloaded in

FIC

GC

N2

Halogen

trap

Feeder

moisture

trap

Flow meter

Ice

cooler

exhaust

Gas-liquid

separator

H2O

pump

Pre-heater

Tar product

carbonates

mixture

PID thermo

controller

Fig. 1. Experimental diagram

7th International Symposium on Feedstock Recycling of Polymeric Materials (7th ISFR 2013)

New Delhi, India, 23-26 October 2013

Metals and

solid residue

the reactor vessel at the start of an experiment. N2 gas

(40 cm3/min) and ultra pure water (0.26 ml/min) were

introduced into the reactor after a preheating treatment at

500C. Phenolic boards or Ta capacitors (0.5 g) were fed

to the reactor after the reactor temperature reached the

set value (550, 600 and 675C). The mixture of N2 gas

and steam was injected into LNK molten carbonates to

improve the efficiency of physical contact between the

solid sample and the LNK molten carbonates.

obtained for steam gasification of phenolic boards are

similar than those obtained in previous studies [1].

Regarding steam gasification of Ta capacitors, the

activation energy in the presence of LNK carbonates was

88.5 kJ/mol. These experimental results indicate that

metals contained in WEEE have a catalytic role for steam

gasification of plastic components and can improve the

yield of hydrogen production on steam gasification of

WEEE.

3. Results and Discussion

Ni (-50+100)(H2O)

100

550 (30 g LNK)

550R (30 g LNK+1.5 g Ni)

ln(h) [mmol min-1]

The thermogravimetric profiles of phenol boards are

shown in Fig. 2, where a one-step degradation can be

seen to take place around 200C for phenolic boards in

inert or steam conditions, and char corresponding to 30%

of initial phenol board remained above 600C. However,

in the presence of nickel metal, phenolic board reacted

completely by steam gasification. Nickel metal (-50+100

mesh) and terminal metal samples had no significant

weight loss in the same conditions. Thus, these results

suggest that the presence of nickel metal particles can

improve steam gasification of phenolic boards above 600

C.

600 (30 g LNK)

600 (30 g LNK+1.5 g Ni)

675 (30 g LNK)

675 (30 g LNK+1.5 g Ni)

-2

-3

-4

-5

45

95

145

time [min]

Fig 3. Hydrogen production from steam gasification of

phenolic board

-1

80

550 (30 g LNK)

Phenolic board

+75%Ni(H2O)

60

600 (30 g LNK)

-2

675 (30 g LNK)

40

Phenolic board(N2)

Phenolic board(H2O)

20

200

400

600

800

Temperature (C)

1000

1200

Fig. 2. TG profiles of the samples

Steam gasification of Ta capacitors and phenolic boards

is described by: C + 2H2O CO2 + 2H2

(1)

H2 and CO2 were the main products, but traces of CH4

and CO were also detected. The results obtained in

previous studies showed that steam gasification of

phenolic board in the presence of LNK carbonates

mixtures was complete. In this work, the results for steam

gasification of phenolic boards and Ta capacitors at 550,

600 and 675C are presented in Fig. 3 and Fig. 4,

respectively. Hydrogen production by steam gasification

of phenolic boards and Ta capacitors increased with

temperature. In the presence of 1.5 g of nickel in LNK

carbonates mixture, higher rate of hydrogen production

was observed. The experimental results indicate that

nickel powder accelerated hydrogen production in the

steam gasification of phenolic boards.

The activation energy for steam gasification of phenolic

boards in the presence of LNK carbonates was

calculated as 146 kJ/mol. However, when steam

gasification of the same sample took place in the

presence of both LNK carbonates and nickel metal, the

activation energy decreased to 131 kJ/mol. The values

ln(h) [mmol min -1]

Weight (%)

-1

-3

-4

-5

-5

15

time [min]

35

55

Fig 4. Hydrogen production from steam gasification of

Ta capacitor

4. Conclusions

The results showed that nickel metal particles improve

hydrogen production rate for steam gasification of WEEE

in the presence of LNK carbonates mixture. It can be

concluded that metal scrap can act as a cheap and

valuable catalyst for WEEE degradation which can be

easily recovered after the process.

Acknowledgements

The authors want to thank the Basque Government (BFI2010-150) and the Spanish Ministry for Science and

Innovation (CTQ2010-17277) for their economical

support.

References

[1] S. Zhang, K. Yoshikawa, H. Nakagome and T. Kamo.

Applied Energy 101 (2013) 815-821.

7th International Symposium on Feedstock Recycling of Polymeric Materials (7th ISFR 2013)

New Delhi, India, 23-26 October 2013

[2] K. Mineta & T. H. Okabe. Journal of Physics and

Chemistry of Solids 66 (2005) 318-321.

7th International Symposium on Feedstock Recycling of Polymeric Materials (7th ISFR 2013)

New Delhi, India, 23-26 October 2013

Vous aimerez peut-être aussi

- The Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFDocument10 pagesThe Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFYohana MelianthaPas encore d'évaluation

- IR Ni LanthanaDocument6 pagesIR Ni LanthanaNelly RojasPas encore d'évaluation

- Temperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneDocument9 pagesTemperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneImran KhanPas encore d'évaluation

- AC Catalst PTDocument5 pagesAC Catalst PTJarretPas encore d'évaluation

- Chan 2020Document8 pagesChan 2020marianoastePas encore d'évaluation

- Pyrolysis Behavior of Electric Cable PVC Insulation MaterialDocument8 pagesPyrolysis Behavior of Electric Cable PVC Insulation Materialmontie3Pas encore d'évaluation

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôPas encore d'évaluation

- Azargohar 2005Document7 pagesAzargohar 2005gueabdelkaderPas encore d'évaluation

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaDocument6 pagesCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôPas encore d'évaluation

- Electrolytic Activity of Carbon-supportedPt-Au Nano Particles ForDocument7 pagesElectrolytic Activity of Carbon-supportedPt-Au Nano Particles ForAmitvikram DubeyPas encore d'évaluation

- 24IJAERS 06202012 Cheapzeolite PDFDocument5 pages24IJAERS 06202012 Cheapzeolite PDFIJAERS JOURNALPas encore d'évaluation

- Cheap Zeolite Catalyst (Na3PO4/NaX) For Toluene/methanol Side Chain AlkylationDocument5 pagesCheap Zeolite Catalyst (Na3PO4/NaX) For Toluene/methanol Side Chain AlkylationIJAERS JOURNALPas encore d'évaluation

- For English Editing (Done)Document23 pagesFor English Editing (Done)api-3728640Pas encore d'évaluation

- Production of Pure Hydrogen by Ethanol DehydrogenationDocument9 pagesProduction of Pure Hydrogen by Ethanol DehydrogenationAbdulwahid SultanPas encore d'évaluation

- Bright Blue Pigment Coal O Nanocrystals Prepared by Modified Sol-Gel MethodDocument7 pagesBright Blue Pigment Coal O Nanocrystals Prepared by Modified Sol-Gel Methodjeremy parkerPas encore d'évaluation

- JPC 2014Document8 pagesJPC 2014Danesh AzPas encore d'évaluation

- Arc Plasma Processing of PT and PD Catalysts SupportedDocument4 pagesArc Plasma Processing of PT and PD Catalysts SupportedFei ZhouPas encore d'évaluation

- Autothermal Reforming of Simulated Gasoline and Diesel FuelsDocument8 pagesAutothermal Reforming of Simulated Gasoline and Diesel FuelsMOHAMMAD HASHIM KHANPas encore d'évaluation

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystDocument6 pagesProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121Pas encore d'évaluation

- Highly Dispersed SevillaDocument19 pagesHighly Dispersed SevillaRuben FelipePas encore d'évaluation

- CVD Graphene Supported Cobalt (II) Phthalocyanine As Cathode Electrocatalyst For PEM Fuel CellsDocument8 pagesCVD Graphene Supported Cobalt (II) Phthalocyanine As Cathode Electrocatalyst For PEM Fuel CellsAndres Carmona OsorioPas encore d'évaluation

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoPas encore d'évaluation

- Production of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneDocument8 pagesProduction of Hydrogen Over Bimetallic Pt-Ni/d-Al O I. Indirect Partial Oxidation of PropaneleylaPas encore d'évaluation

- Nanopowders of Na0.5K0.5NbO3 Prepared by The Pechini Method.Document4 pagesNanopowders of Na0.5K0.5NbO3 Prepared by The Pechini Method.musonlyPas encore d'évaluation

- Materials Science in Semiconductor Processing: Rahul Kumar, Parag BhargavaDocument6 pagesMaterials Science in Semiconductor Processing: Rahul Kumar, Parag BhargavaMohammad IrwanPas encore d'évaluation

- Lactose Fueled SmokeDocument8 pagesLactose Fueled SmokeMehran NosratiPas encore d'évaluation

- Methane Steam ReformingDocument8 pagesMethane Steam ReformingPanda BoyPas encore d'évaluation

- Ghita Danuta 1 16Document5 pagesGhita Danuta 1 16Anonymous p52JDZOdPas encore d'évaluation

- Polymers: The Effect of Introducing B and N On Pyrolysis Process of High Ortho Novolac ResinDocument17 pagesPolymers: The Effect of Introducing B and N On Pyrolysis Process of High Ortho Novolac ResinHiến Đinh VănPas encore d'évaluation

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezPas encore d'évaluation

- Thermal Degradation of Poly (Acrylic Acid) Containing Metal Nitrates and The Formation of Yba Cu ODocument9 pagesThermal Degradation of Poly (Acrylic Acid) Containing Metal Nitrates and The Formation of Yba Cu OPham Thi Thu HongPas encore d'évaluation

- Specific Heat Capacity of Lithium Polymer Battery Components: Thermochimica Acta June 2003Document7 pagesSpecific Heat Capacity of Lithium Polymer Battery Components: Thermochimica Acta June 2003Arghya MukherjeePas encore d'évaluation

- Irnano Ti O2Document8 pagesIrnano Ti O2Sutha SenthilPas encore d'évaluation

- Synthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsDocument9 pagesSynthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsSangHao NgPas encore d'évaluation

- The Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholDocument23 pagesThe Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholFiqkyAkbarPas encore d'évaluation

- 2013-Hydrogen Rich Gas Production From Etanol Steam Reaction - Energy ResearchDocument12 pages2013-Hydrogen Rich Gas Production From Etanol Steam Reaction - Energy ResearchDanCosminPas encore d'évaluation

- A Novel One-Step Chemical Method For Preparation of Copper NanofluidsDocument4 pagesA Novel One-Step Chemical Method For Preparation of Copper NanofluidsbacPas encore d'évaluation

- J Jcat 2004 10 020Document9 pagesJ Jcat 2004 10 020valePas encore d'évaluation

- Methanol OxidationDocument7 pagesMethanol OxidationJohndannPas encore d'évaluation

- RevisionDocument22 pagesRevisionapi-3728640Pas encore d'évaluation

- A Transient Response Study of The Selective Catalytic Oxidation of Ammonia To Nitrogen On Pt-CuO-Al2O3 Olofsson Et Al Chem. Eng. Sci. 2004Document11 pagesA Transient Response Study of The Selective Catalytic Oxidation of Ammonia To Nitrogen On Pt-CuO-Al2O3 Olofsson Et Al Chem. Eng. Sci. 2004juan davidPas encore d'évaluation

- 2005 Electrochemcomm ZhaoDocument6 pages2005 Electrochemcomm ZhaoGuerrero OmarPas encore d'évaluation

- The Selective Oxidation of Toluene To Benzaldehyde Applying A Fuel Cell System in The Gas PhaseDocument7 pagesThe Selective Oxidation of Toluene To Benzaldehyde Applying A Fuel Cell System in The Gas PhaseOana VasilePas encore d'évaluation

- Korean Journal of Chemical Engineering, 28 (2), 383-387 (2011)Document5 pagesKorean Journal of Chemical Engineering, 28 (2), 383-387 (2011)KhangKGBPas encore d'évaluation

- Modification of TiO2 With Graphic Carbon - Photocatalyst - 2016Document9 pagesModification of TiO2 With Graphic Carbon - Photocatalyst - 2016srowbothamPas encore d'évaluation

- High resistance silica-coated Ni catalysts for propane steam reformingDocument6 pagesHigh resistance silica-coated Ni catalysts for propane steam reformingumidwijayantiPas encore d'évaluation

- 5-PtCo Alloy Nanoparticles Supported On Graphene Nanosheets WithDocument9 pages5-PtCo Alloy Nanoparticles Supported On Graphene Nanosheets WithAlhassan NasserPas encore d'évaluation

- Combined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessDocument8 pagesCombined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessKeysler PoncePas encore d'évaluation

- ManuscriptDocument20 pagesManuscriptapi-3728640Pas encore d'évaluation

- Metallic NanoparticlesDocument5 pagesMetallic NanoparticlesPatrick Koch Savi MondoPas encore d'évaluation

- Kaneda Cu-Free Wacker Oxidation of Internal Olefins ACIEE 2010Document3 pagesKaneda Cu-Free Wacker Oxidation of Internal Olefins ACIEE 2010Victor CiocalteaPas encore d'évaluation

- Co3O4 Nanocrystals Catalyze Cyclohexane OxidationDocument6 pagesCo3O4 Nanocrystals Catalyze Cyclohexane OxidationSuhaila MohammadPas encore d'évaluation

- Oxidation of Cyclohexane and Ethylbenzene by Hydrogen Peroxide Over Co-Substituted Heteropolytungstate CatalystDocument6 pagesOxidation of Cyclohexane and Ethylbenzene by Hydrogen Peroxide Over Co-Substituted Heteropolytungstate Catalystrungrawin ngamkhumPas encore d'évaluation

- Estudio de Soportes (1), Xu-Lei Sui and Col., Journal of Power Sources 255 (2014) 43 - 51Document9 pagesEstudio de Soportes (1), Xu-Lei Sui and Col., Journal of Power Sources 255 (2014) 43 - 51Martín Nicolás GattiPas encore d'évaluation

- Apl XGDocument3 pagesApl XGPravin ShindePas encore d'évaluation

- 12po MC 3 5 PDFDocument2 pages12po MC 3 5 PDFMarcelo Varejão CasarinPas encore d'évaluation

- Effects of Adsorption and Temperature On A Nonthermal Plasma Process For Removing VocsDocument13 pagesEffects of Adsorption and Temperature On A Nonthermal Plasma Process For Removing VocsJaya KaruppiahPas encore d'évaluation

- Electrocatalysis-of-CO-Tolerance-in-Hydrogen-Oxidation-Reaction-in-PEM-Fuel-CellsDocument11 pagesElectrocatalysis-of-CO-Tolerance-in-Hydrogen-Oxidation-Reaction-in-PEM-Fuel-CellsFaseeh KKPas encore d'évaluation

- Characterization and Stability of Doped SnO2 AnodeDocument7 pagesCharacterization and Stability of Doped SnO2 AnodeSergio Parra MartiPas encore d'évaluation

- Energy Day Report Highlights Priority ActionsDocument3 pagesEnergy Day Report Highlights Priority ActionsJon Bisu DebnathPas encore d'évaluation

- Larry BaxterDocument28 pagesLarry BaxterJon Bisu DebnathPas encore d'évaluation

- EWASTEDocument11 pagesEWASTEJon Bisu DebnathPas encore d'évaluation

- E Waste BanglaDocument1 pageE Waste BanglaJon Bisu DebnathPas encore d'évaluation

- Biofuel PolicyDocument18 pagesBiofuel Policyiitian2005Pas encore d'évaluation

- 1 s2.0 S1366554514001744 MainDocument14 pages1 s2.0 S1366554514001744 MainJon Bisu DebnathPas encore d'évaluation

- Yang2012 PDFDocument10 pagesYang2012 PDFJon Bisu DebnathPas encore d'évaluation

- Adobe Illustrator 10 Software Read Me: Serial NumberDocument3 pagesAdobe Illustrator 10 Software Read Me: Serial Numberakmal_07Pas encore d'évaluation

- Copper Recovery From PCBDocument11 pagesCopper Recovery From PCBJon Bisu DebnathPas encore d'évaluation

- Bio EnergyDocument54 pagesBio EnergyJon Bisu DebnathPas encore d'évaluation

- Lecture 2Document10 pagesLecture 2William WatersPas encore d'évaluation

- 1 s2.0 S0360835206000763 MainDocument20 pages1 s2.0 S0360835206000763 MainJon Bisu DebnathPas encore d'évaluation

- Cost of Quality: What Is Coq? Coq MapDocument4 pagesCost of Quality: What Is Coq? Coq MapJon Bisu DebnathPas encore d'évaluation

- Certificate: Project Supervisor Chemical Engineering Department Jadavpur University, Kolkata-32Document1 pageCertificate: Project Supervisor Chemical Engineering Department Jadavpur University, Kolkata-32Jon Bisu DebnathPas encore d'évaluation

- 1 s2.0 S0924013602006143 MainDocument4 pages1 s2.0 S0924013602006143 MainJon Bisu DebnathPas encore d'évaluation

- Performance Evaluation Based On EFQM Excellence Model in Sport OrganizationsDocument10 pagesPerformance Evaluation Based On EFQM Excellence Model in Sport OrganizationsJon Bisu DebnathPas encore d'évaluation

- Chi 2011 WasteMgmtDocument12 pagesChi 2011 WasteMgmtJon Bisu DebnathPas encore d'évaluation

- Self Assessment Report 2013Document233 pagesSelf Assessment Report 2013Jon Bisu Debnath100% (2)

- 1 s2.0 S0360544210005293 MainDocument9 pages1 s2.0 S0360544210005293 MainJon Bisu DebnathPas encore d'évaluation

- A Review of The Recycling of Non-Metallic Fractions of Printed Circuit BoardsDocument11 pagesA Review of The Recycling of Non-Metallic Fractions of Printed Circuit BoardsJon Bisu DebnathPas encore d'évaluation

- BioRefinery ReportDocument6 pagesBioRefinery ReportJon Bisu DebnathPas encore d'évaluation

- 2011Document1 page2011Jon Bisu DebnathPas encore d'évaluation

- Mother Dairy Case Study SchemeDocument4 pagesMother Dairy Case Study SchemeJon Bisu DebnathPas encore d'évaluation

- 6 ML SharmaDocument14 pages6 ML SharmaSumit NagpalPas encore d'évaluation

- 3Document2 pages3Jon Bisu DebnathPas encore d'évaluation

- Disaster Management Plan For Thermal Power PlantsDocument11 pagesDisaster Management Plan For Thermal Power PlantsJon Bisu Debnath100% (1)

- E WasteDocument1 pageE WasteJon Bisu DebnathPas encore d'évaluation

- Falling Slowly ChordsDocument2 pagesFalling Slowly ChordsJon Bisu DebnathPas encore d'évaluation

- PF ChordsDocument2 pagesPF ChordsJon Bisu DebnathPas encore d'évaluation

- Concentration of SolutionDocument3 pagesConcentration of SolutionJoon Bok NamleePas encore d'évaluation

- 4.4 Electric & Magnetic FieldsDocument12 pages4.4 Electric & Magnetic FieldsMozammel AnowarPas encore d'évaluation

- Biotechnology: Unit 2: Microbiological TechniquesDocument45 pagesBiotechnology: Unit 2: Microbiological TechniquesMary CroxonPas encore d'évaluation

- Binoculars Mechanics c1Document34 pagesBinoculars Mechanics c1jose cabelloPas encore d'évaluation

- Lab Guide - Kaplan TurbineDocument55 pagesLab Guide - Kaplan TurbineBonifacioPas encore d'évaluation

- Microsoft Powerpoint - Tooth Colored Inlays and Onlays - IDocument53 pagesMicrosoft Powerpoint - Tooth Colored Inlays and Onlays - Ianastoma100% (1)

- Quantum MechanicsDocument3 pagesQuantum MechanicsSteven ScottPas encore d'évaluation

- FinalDocument17 pagesFinalMatt Pribadi100% (1)

- Khan Research Centre Chemical BondingDocument4 pagesKhan Research Centre Chemical BondingAnup KumarPas encore d'évaluation

- Chapter 8 Multiple-Choice QuestionsDocument11 pagesChapter 8 Multiple-Choice Questionsteresa tsoiPas encore d'évaluation

- Scrap Tire Recycling, Elt Proposal Project Desing, Wo PricesDocument19 pagesScrap Tire Recycling, Elt Proposal Project Desing, Wo PricesCemalKaldırımcıPas encore d'évaluation

- Assignment 3Document4 pagesAssignment 3shafin sharafPas encore d'évaluation

- b7f1 PDFDocument9 pagesb7f1 PDFmohamed hamedPas encore d'évaluation

- Libros Solo PetróleosDocument6 pagesLibros Solo PetróleosSebastián AltamiranoPas encore d'évaluation

- Fullbond 960 Technical Data SheetDocument1 pageFullbond 960 Technical Data SheetHadrat MoulanaPas encore d'évaluation

- CRSO Meeting Shielding Calculations PresentationDocument34 pagesCRSO Meeting Shielding Calculations PresentationJared Medina BlanquicettPas encore d'évaluation

- API 571 Damage MechanismsDocument42 pagesAPI 571 Damage MechanismsIsmail Jamaluddin100% (1)

- ACIO GA - GK General Awareness Strategy & Previous PaperDocument54 pagesACIO GA - GK General Awareness Strategy & Previous PaperMukherjeeLinaPas encore d'évaluation

- AmberTools ManuelDocument405 pagesAmberTools ManuelmayankgiaPas encore d'évaluation

- Tech Spec - SLPB120255255 - 75ahDocument12 pagesTech Spec - SLPB120255255 - 75ahMuhammadWaqarButtPas encore d'évaluation

- Utilization of Plastic Waste For Making Plastic BricksDocument3 pagesUtilization of Plastic Waste For Making Plastic BricksEditor IJTSRD100% (1)

- Bhel Traning ReportDocument31 pagesBhel Traning Reportdivyank kumarPas encore d'évaluation

- Fundamentals ThoughtsDocument21 pagesFundamentals ThoughtsNicole Casanova0% (1)

- Fluorometric Assay of QuinineDocument5 pagesFluorometric Assay of QuinineCecilia CindyPas encore d'évaluation

- (Tawas) Sodium Aluminate High Performance CoagulantDocument3 pages(Tawas) Sodium Aluminate High Performance CoagulantANNaPas encore d'évaluation

- Human Humascope - User ManualDocument15 pagesHuman Humascope - User ManualgatotachaPas encore d'évaluation

- Gujarat Technological University: Diploma in Mechanical Engineering Semester: 3Document4 pagesGujarat Technological University: Diploma in Mechanical Engineering Semester: 3vp02091988Pas encore d'évaluation

- Aero Lab 1Document6 pagesAero Lab 1hdslmnPas encore d'évaluation

- Bilz ThermoGrip Liquid Cooled ISG2200Document31 pagesBilz ThermoGrip Liquid Cooled ISG2200Mauricio Baron100% (1)

- Welded and Seamless Steel Pipe Piles: Standard Specification ForDocument7 pagesWelded and Seamless Steel Pipe Piles: Standard Specification ForDang Thanh TuanPas encore d'évaluation