Académique Documents

Professionnel Documents

Culture Documents

Development of Sheet Metal Component

Transféré par

TheVagabond HarshalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Development of Sheet Metal Component

Transféré par

TheVagabond HarshalDroits d'auteur :

Formats disponibles

www.ijmer.

com

International Journal of Modern Engineering Research (IJMER)

Vol. 3, Issue. 3, May.-June. 2013 pp-1787-1791

ISSN: 2249-6645

Opil;

Development of a Sheet-Metal Component with a Forming

Die Using CAE Software Tools (Hyper form) For Design

Validation and Improvement

Mr. Amit D. Madake1, Dr. Vinayak R. Naik2, Mr. Swapnil S. Kulkarni3

1(M.E. Mech-PDD appearing, Student of D.K.T.E.Ichalkaranji Department of Mechanical, Shivaji University, India)

2 (Head of Department of Mechanical, D.K.T.E.Ichalkaranji, Shivaji University, India)

3 (Director, Able Technologies India Pvt. Ltd., Pune, India)

ABSTRACT: Sheet-metal die is an inseparable constituent of the development process of any given automotive or

consumer appliance. In most of the cases, this accounts for a high proportion in the tooling needs of the large size and

structural member in any automotive like the chassis and the BIW. Many other brackets and gussets along with peripheral

clips etc are invariably made of Sheet-metal due to the strength characteristics complimented by this material and the

process of stamping.

Keywords: Blank holding Force, Die block, Forming Die Design, HYPERFORM, Punch.

I. INTRODUCTION

Sheet metal forming is one of the most commonly used processes in industry. Throughout the years, the sheet metal

forming industry experienced technological advances that allowed the production of complex parts. However, the advances

in die design progressed at a much slower rate, and they still depend heavily on trial-and-error and the experiences of skilled

workers. During the development of the Die, a reduction in the number of trials would directly influence the cycle time for

development. A shorter cycle time can be planned with due utilization of software tools that would predict the trial results

without actually conducting the same. The simulation offered by the software during the process of stamping lends important

insights into the modifications needed in the die and/or the component to effect a simplified and productive die. Normally, a

Forming die (including Draw die) calls for refined design parameters for ensuring a smooth passage through the trial phase

of the developed Die normally accompanied by crucial review inputs over the design of the component too. The study of the

papers offers enough inputs to take up the project work in identifying a `process-oriented solution that could be used as a

reference for academicians and the corporate entities while faced with the challenges associated with the elusive process of

`Forming

II. Sheet Metal Forming Process

Sheet metal forming processes are the complex interaction between specimen (geometry, tolerance, surface

topology, etc.), the forming process (tooling, forming machine, force, lubrication, etc.) and the material (ductility, material

parameters, microstructure, corrosion resistance, residual stress, etc.) which exist in forming processes. Most problems in

sheet metal forming come from a bad control of holding, restraining and spring back.

Figure 1.1: Schematic Diagram of Forming With Punch and Die

Figure 1.2: Schematic Diagram for the stages of `Forming process

Geometrical defects in sheet metal forming: The Forming or deep drawing process allows the production of large

quantities of sheet metal parts of various complexities. During the process a piece of sheet metal is clamped between the die

and the blankholder. A force is applied to the blankholder to prevent wrinkling of the sheet and to control the material flow

during the deformation. When the punch is pushed into the die cavity the sheet deforms plastically and thereby it takes the

www.ijmer.com

1787 | Page

www.ijmer.com

International Journal of Modern Engineering Research (IJMER)

Vol. 3, Issue. 3, May.-June. 2013 pp-1787-1791

ISSN: 2249-6645

specific shape of the tools The quality of the final product shape is determined by the tools design, process parameters, shape

and material of the blank. It is important to carefully consider all these factors prior to manufacturing; otherwise a defective

product could result. Typical defects which are observed in sheet metal forming practice are wrinkling, necking and

subsequent fracture, drawing grooves. In addition to these defects, there is also always geometrical distortion caused by

elastic springback. Right after forming, the shape of the deformed product closely conforms to the geometry of tools.

However, as soon as the tools are retracted, an elastically-driven change of the product shape takes place.

The attempt of this work would also be to minimize the defects evident during the development phase of the component.

III.

Die Design Calculations

The component chosen for this dissertation would is derived from the projects being undertaken by the sponsoring

company- Able Technologies (India) Pvt. Ltd., Pune. The case study shall incorporate the design and development of the

component named - `Cup that is used over the subassembly of a popular two wheeler mounting bracket.

III.1

The specs along with the drawing for this component are given below:

Component Name Cup

Material CRCA Steel EDD Grade as per IS513-1994

Thickness 1.00 +/- 0.03 mm

Figure 2: Extract from the part drawing for the component

III.2. Developed Blank Diameter = 112 mm. (radius at each step ignored for sake of simplicity since the component is

not required to mate in the assembly and the function does not call for precise control over the flange diameter)

III.3. Draw Ratio At this component, the Draw = H/d = 20.6/67.5 = 0.31 which indicates the draw is simple & may

require only one stage for completion.

III.4. Draw Force Draw Force can be calculated by empirical relation,

P = . d. t. s. ((D/d) C)

Where, P = Draw Force in Tons

D = Blank Diameter in mm = 112 mm

d = Punch Diameter in mm = 25 mm

t = Thickness of Metal in mm = 1.00 mm

S = Yield strength of Metal in Kg/mm2 = 40 Kg/mm2

C = Constant (Take 0.6 to 0.7)

We know that,

P = . d. t. s. ((D/d) C)

P = x 25 x 1 x 40 x ((112/25)-0.6)

P =12183.2 Kg

P =12 Ton

Factor of safety should be taken 1.25,

Therefore, Draw Force (P) = 12 x 1.25 = 16.25 17 Ton

III.5. Die Block Dimension

Diameter = 165 mm

Material for Die block should be use HCHCr & OHNS

Hardness Die Block should be harden upto 60 to 62 HRC

III.6. Top Plate Top Plate Dimension = 320 mm x 250 mm

Thickness for Top Plate should be 32 to 35 mm (Take 35 mm)

III.7. Bottom Plate Bottom Plate Dimension = 400 mm x 250 mm

Thickness for Bottom Plate should be 22 to 25 mm (Take 25 mm)

III.8. Punch Height Height for Punch should be 69.1 mm

www.ijmer.com

1788 | Page

www.ijmer.com

International Journal of Modern Engineering Research (IJMER)

Vol. 3, Issue. 3, May.-June. 2013 pp-1787-1791

ISSN: 2249-6645

III.9. Draw & Punch radius The Draw radius usually ranges from 4 to 10 times the Blank thickness,

Therefore, Radius of Draw Die = Rd =4.5 x 1 = 4.5 mm

The Punch radius usually ranges from 3 to 4 times the Blank thickness,

Therefore, Radius of Punch = Rp =3 x 1 = 3.0 mm

III.10. Shut Height The Shut Height of the unit shall be,

H = Die thickness + Lower shoe thickness + Punch Height + Punch Plate thickness + Upper shoe thickness Penetration of

Punch in Die = 45 + 25 + 69.1 + 29 + 35 3.1 = 200 mm.

III.11. Blank Holding Force Blank Holding Force (B.H.F.) is always 30 % of Draw Force, therefore B.H.F. can be

calculated as, Blank Holding Force (B.H.F.) = 30 % of Draw Force

= 30 % x 17 = 5.1 Ton 5.0 Ton

Material for Blank Holder should be use EN-353 or 20MnCr5

Hardness Blank Holder should be harden upto 30 to 35 HRC

III.12. Press Tonnage or Press capacity Press Tonnage can be calculated by using following formula,

Press Tonnage = Draw Force + Blank Holding Force (B.H.F.)

= 17 + 5 = 22 25 Ton

Therefore, Press Capacity of 25 Ton shall be suitable.

IV.

FIGURES AND TABLES

Figure 3: Solid model of the component (Cup) using CAD software `Unigraphics NX-6

Analysis of component (Cup) using CAE/Simulation software `HYPERFORM

Figure 4.1: Result of Analysis for Blank holding force at 5 Ton

Observation: Maximum thinning recorded 25% of the thickness of the component (acceptable part quality)

Figure 4.2: Result of Analysis for `Blank holding force at 5 Ton

Observation: No splits or any major defects observed (acceptable part quality)

www.ijmer.com

1789 | Page

www.ijmer.com

International Journal of Modern Engineering Research (IJMER)

Vol. 3, Issue. 3, May.-June. 2013 pp-1787-1791

ISSN: 2249-6645

Figure 4.3: Result of Analysis for Blank holding force at 10 Ton

Observation: Maximum thinning recorded 30% of the thickness of the component (unacceptable part quality)

Figure 4.4: Result of Analysis for Blank holding force at 10 Ton

Observation: Large region exposed to the tendency for splits (unacceptable part quality)

Figure 5: Solid model of forming die for component (Cup) by using Unigraphics NX-6

`

Figure 6: Schematic sketch of forming die for component (Cup) by using Unigraphics NX-6

V. CONCLUSION

Sufficient research and deliberation using the proven QC tools backed up with CAE software support

(HYPERFORM) has offered a feasible solution to the problem at hand. Steel material like HCHCr (High carbon High

Chromium) & OHNS (Oil Hardening non Shrinkage) grade for both punch and die block to suit the components having

EDD (Extra Deep Draw) is recommended per the practices found in the industries. The operating condition involving the

magnitude of blank holding pressure is varied and the results analyzed. Thinning and Formability are ascertained in this

study. For finding the range of load at which the thinning or formability is unacceptable, the iteration for analysis with a

blank holding force of 10Ton was applied and the results recorded as per figure 4.3 & 4.4. Suitable blank holding pressure

(5Ton) is recommended for a defect-free component as per figure 4.1 & 4.2. The results obtained by mathematical treatment

and the results obtained through the use of software (analytical) agree reasonably well. These results also establish generic

guidelines for forming die design for Extra Deep Draw (EDD) materials. In order to expand the range of application of the

developed method, parts with more complex geometries can be considered as future scope of work.

www.ijmer.com

1790 | Page

www.ijmer.com

International Journal of Modern Engineering Research (IJMER)

Vol. 3, Issue. 3, May.-June. 2013 pp-1787-1791

ISSN: 2249-6645

ACKNOWLEDGEMENTS

The author gratefully acknowledges the support received from Mr.S.S.Kulkarni, Director- Able Technologies

(India) Pvt. Ltd.Pune, for his technical and administrative support from conceptual stage to the final stage for execution of

this work. The author also would like to thanks Dr.V.R.Naik, Head of Department of Mechanical Engineering,

Prof.A.R.Balwan, P.G.Coordinator, at D.K.T.E.Ichalkaranji, for guidance and crucial inputs over the project work.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

Arash Behrouzi, Bijan Molaee Dariani, Mahmood Shakeri Department Of Mechanical Engineering, Amirkabir University Of

Technology,Tehran, Iran,Majlesi Journal Of Mechanical Engineering, Die Shape Design In Channel Forming Process By

Compensation Of Springback Error Vol.3/No.2/Winter 2010 Page No.17-26.

Juraj HUDAK,Miroslav TOMAS, Department Of Technologies & Materials, Technical University Of Kosics, Annals Of Faculty

Engg.Hunedoara-International Journal Of Engineering, Analysis Of Forces In Deep Drawing Process, TOM IX (Year 2011)

Fascicule 1.( ISSN-1584-2665) Page No.219-221.

Hakim S. Sultan Aljibori Mechanical Engineering Department, Faculty Of Engineering University Malaya, 50603, Kuala Lumpur,

Malaysia, Abdel Magid Hamouda Mechanical And Industrial Engineering Department,Faculty Of Engineering, Qatar University,

Doha, Qatar,European Journal Of Scientific Reasearch, Finite Element Analysis Of Sheet Metal Forming Process,ISSN 1450-216X

Vol.33 No.1 (2009),PP.57-69.

Y. Park1 J. S. Colton Professor, Fellow ASME The George W. Woodruff School Of Mechanical Engineering, Georgia Institute Of

Technology, Atlanta, GA 30332-0405,Failure Analysis Of Rapid Prototyped Tooling In Sheet Metal Forming -Cylindrical Cup

Drawing, Vol.127,Feb 2005, Page No.126-137.

A.Wifi, A.Mosallam Department Of Mechanical Design & Production, Faculty Of Engg, Cariro University, Giza12316, Egypt,

Some Aspects Of Blank-Holder Force Schemes In Deep Drawing Process, Vol.24 Issue 1 Sept.2007, Page No.315-321.

Se-Ho Kim, Seung-Ho Kim, Hoon Huh,Department Of Mechanical Engineering, Korea Advanced Institute Of Science And

Technology, Science Town, Taejon, 305-701 South Korea,Tool Design In A Multi-Stage Drawing And Ironing Process Of A

Rectangular Cup With A Large Aspect Ratio Using Finite Element Analysis, Received 16 October 2001; Accepted 3 January

2002, Page No.863-875.

Peter Kostka,Peter Cekan,Slovak University Of Technology In Bratislava, Faculty Of Mechanical Engineering, Department Of

Materials & Technologies, Computer Simulated And Experimental Verification Of Tooling For Progressive Deep Drawing,8th

International LS- DYNA Users Conference Metal Forming (1),Page No.9-59 To 9-65.

Fuh-Kuo Chen, And Yeu-Ching Liao,Department Of Mechanical Engineering National Taiwan University, Finite Element

Analysis Of Draw-Wall Wrinkling In A Stamping Die Design, VIII International Conference On Computational Plasticity

COMPLAS VIII.E.Onate And D.R.J.Owen,2005.Page No.1-4.

Z. Marciniak The Technical University Of Warsaw,Poland J.L. Duncan The University Of Auckland, New Zealand, S.J. Hu The

University Of Michigan, USA. Mechanics Of Sheet Metal Forming, ISBN 0 7506 5300 0, Page No.1-163.

Simtech Simulation Technologies Simtech 37 Rue Des Acacias, Introduction To Sheet Metal Forming Processs, 75017 Paris

France.Smith & Associates,530 Hollywood Drive, Monroe, Michigan 48162- 2943 1993, 2001,Forming Flanges And Process

Limitations,C041 REV June 23, 2005.

I.A. Burchitz Project Number: MC1.02121 I.A. Burchitz, Rotterdam, Netherlands, Improvement Of Springback Prediction In Sheet

Metal Forming,Page No.5-134.

Author - Mr. Amit Dattatray Madake

Author Biography

(M.E. Mech-PDD appearing, Student of D.K.T.E.Ichalkaranji Department of Mechanical, Shivaji University,

India)

M. E. (Mech.) Product design and development student department of mechanical engineering Textile and Engg.

Institute, Ichalkaranji, Kolhapur. Has four years of academic experience and six years of industrial experience.

To his credit there is one paper at international journal.

Prof. (Dr.) V. R. Naik

Working presently as professor and HOD (Mech.) has 17 years of academic experience and six years of

industrial experience. He has around in various reputed organisations in the areas of Design and Development.

To his credit there are twenty two papers at national and international conferences and five papers in the various

journals of national and international repute. He is also principal investigation to various funded project.

Mr. Swapnil Shashikant Kulkarni

Director at AbleTech/ Mentor at IdeaMaps has been associated with the function of R&D over his career of 18

years in the industry. While addressing his role, he has dealt with the techno-commercial aspects in `Product and

`Tool Design assignments for OEMs. Besides, he has had been applying the learning in the Mechanical

Engineering domain with the Electronics and IT segment for evolving innovative products in the `Renewable

Energy sector as also the `Consumer products.

www.ijmer.com

1791 | Page

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Fundamental Analysis For InvestorsDocument213 pagesFundamental Analysis For InvestorsTheVagabond Harshal100% (19)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Implement <Project Name> SystemDocument19 pagesImplement <Project Name> SystemHazel JiaoPas encore d'évaluation

- 15 - Piezo Pyro & FerroelectricityDocument23 pages15 - Piezo Pyro & FerroelectricityMd. Rafiqul Islam50% (2)

- Materials Selection Lecture NotesDocument104 pagesMaterials Selection Lecture NotesKarthick N100% (2)

- Cast IronDocument22 pagesCast IronDuong Do NgocPas encore d'évaluation

- Strength of Materials PDFDocument13 pagesStrength of Materials PDFWalter RuedaPas encore d'évaluation

- Phrama Companies in IndiaDocument53 pagesPhrama Companies in IndiaambreeshbajpaiPas encore d'évaluation

- List of Award Winners for 2019-2020 Textile IndustryDocument4 pagesList of Award Winners for 2019-2020 Textile Industrymukund khandelwalPas encore d'évaluation

- Internship Seashell Logistics PDFDocument1 pageInternship Seashell Logistics PDFTheVagabond HarshalPas encore d'évaluation

- User ManualDocument5 pagesUser ManualVishal BhansaliPas encore d'évaluation

- Trek-A-Way Registration Form (24.06 Mahuli)Document1 pageTrek-A-Way Registration Form (24.06 Mahuli)TheVagabond HarshalPas encore d'évaluation

- Carton Adams Ammon 08Document20 pagesCarton Adams Ammon 08TheVagabond HarshalPas encore d'évaluation

- Vicious and Virtuous Cycles in ERP ImplementationDocument12 pagesVicious and Virtuous Cycles in ERP ImplementationomisoreyPas encore d'évaluation

- B.E. Prod Viii Cbsgs May 2017Document16 pagesB.E. Prod Viii Cbsgs May 2017TheVagabond HarshalPas encore d'évaluation

- E Cig S NayanDocument32 pagesE Cig S NayanTheVagabond HarshalPas encore d'évaluation

- Trek-A-Way Registration Form (24.06 Mahuli)Document1 pageTrek-A-Way Registration Form (24.06 Mahuli)TheVagabond HarshalPas encore d'évaluation

- ERP Implementation Project ReportDocument27 pagesERP Implementation Project ReportAmit KumarPas encore d'évaluation

- Questia PasswordsDocument1 pageQuestia PasswordsTheVagabond HarshalPas encore d'évaluation

- Company SecDocument2 pagesCompany SecTheVagabond HarshalPas encore d'évaluation

- Circular No. 17 18 - 200Document2 pagesCircular No. 17 18 - 200TheVagabond HarshalPas encore d'évaluation

- Circuler 10.07.2017Document3 pagesCirculer 10.07.2017TheVagabond HarshalPas encore d'évaluation

- A & C QB 2 AnsDocument7 pagesA & C QB 2 AnsTheVagabond HarshalPas encore d'évaluation

- Alalshuhai 2015Document5 pagesAlalshuhai 2015TheVagabond HarshalPas encore d'évaluation

- Mumbai University ME ManualDocument15 pagesMumbai University ME ManualAditya DarekarPas encore d'évaluation

- Six Sigma: A Retrospective and Prospective Study: Corresponding AuthorDocument40 pagesSix Sigma: A Retrospective and Prospective Study: Corresponding AuthorTheVagabond HarshalPas encore d'évaluation

- A and C Theory QuestionDocument53 pagesA and C Theory QuestionTheVagabond HarshalPas encore d'évaluation

- Determining Sample Size for Proportion and Mean EstimationDocument16 pagesDetermining Sample Size for Proportion and Mean EstimationKhaled AbuzayanPas encore d'évaluation

- Wa0010Document7 pagesWa0010TheVagabond HarshalPas encore d'évaluation

- Wa0004Document1 pageWa0004TheVagabond HarshalPas encore d'évaluation

- Adu Bode PlotDocument6 pagesAdu Bode PlotTheVagabond HarshalPas encore d'évaluation

- Wa0003Document1 pageWa0003TheVagabond HarshalPas encore d'évaluation

- HRM HSDocument7 pagesHRM HSTheVagabond HarshalPas encore d'évaluation

- A&C KKDocument27 pagesA&C KKKaustubh KokanePas encore d'évaluation

- 18 10 SA V1 S1 Solved Problems SC PDFDocument14 pages18 10 SA V1 S1 Solved Problems SC PDFTheVagabond HarshalPas encore d'évaluation

- WTC 9-11 Design IssuesDocument8 pagesWTC 9-11 Design IssuesMANDARAWPas encore d'évaluation

- 3.2 DeformationDocument8 pages3.2 DeformationSalmanPas encore d'évaluation

- Machine Design Examination 6Document5 pagesMachine Design Examination 6SYBRELLE CRUZPas encore d'évaluation

- Strain Gauge Training System: Page 1/3 02/2011Document3 pagesStrain Gauge Training System: Page 1/3 02/2011fifafifaPas encore d'évaluation

- Note CHP 1-Material Science 281 Uitm Em110Document59 pagesNote CHP 1-Material Science 281 Uitm Em110bino_rye100% (3)

- Strength, Deformation Capacity and Failure Modes of RC Walls Under Cyclic LoadingDocument24 pagesStrength, Deformation Capacity and Failure Modes of RC Walls Under Cyclic Loadingjiliang liuPas encore d'évaluation

- DSR Cables de AceroDocument36 pagesDSR Cables de Acerojhon rodriguezPas encore d'évaluation

- Forms of Variable Resistance Training.10Document15 pagesForms of Variable Resistance Training.10Juan LamaPas encore d'évaluation

- Materials Engineering Online Phase Test OverviewDocument21 pagesMaterials Engineering Online Phase Test OverviewSam StidePas encore d'évaluation

- Span-To-Height Ratio Limits For Prestressed Concrete MembersDocument9 pagesSpan-To-Height Ratio Limits For Prestressed Concrete MembersMILL3482Pas encore d'évaluation

- Chapter 8 - NotesDocument20 pagesChapter 8 - NotesPraneethPas encore d'évaluation

- Mechanics of Materials 71E44Document3 pagesMechanics of Materials 71E44OblackPas encore d'évaluation

- 06 ES13 Axially Loaded MembersDocument22 pages06 ES13 Axially Loaded MembersMich Angeles100% (1)

- Tension Test Analysis and Material ComparisonDocument8 pagesTension Test Analysis and Material ComparisonUsman ishaqPas encore d'évaluation

- A Review On The Mechanical Methods For Evaluating Coating Adhesion-Acta MechDocument23 pagesA Review On The Mechanical Methods For Evaluating Coating Adhesion-Acta MechReflexion AndoPas encore d'évaluation

- Iglidur Bearings For High Resistance To Liquid MediaDocument46 pagesIglidur Bearings For High Resistance To Liquid MediaigusukPas encore d'évaluation

- Shooting Rubber Bands: Two Self-Similar Retractions For A Stretched Elastic WedgeDocument5 pagesShooting Rubber Bands: Two Self-Similar Retractions For A Stretched Elastic WedgeMohamad NasroPas encore d'évaluation

- Crip LingDocument24 pagesCrip LingMohamed NkPas encore d'évaluation

- 2023 - New Control Method of Casing Deformation in Shale Gas Slip Fault Based On Solid Expandable TubularDocument13 pages2023 - New Control Method of Casing Deformation in Shale Gas Slip Fault Based On Solid Expandable TubularOmar S Al-AbriPas encore d'évaluation

- Dynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Sonic ResonanceDocument9 pagesDynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Sonic ResonanceEric GozzerPas encore d'évaluation

- Mechanical Properties of Materials - MechaniCalcDocument11 pagesMechanical Properties of Materials - MechaniCalcharieduidPas encore d'évaluation

- C. K. Pithawala College of Engineering & Technology: New-Mark's Influence Chart Westergaard's Formula, Contact PressureDocument14 pagesC. K. Pithawala College of Engineering & Technology: New-Mark's Influence Chart Westergaard's Formula, Contact PressureParth AnajwalaPas encore d'évaluation

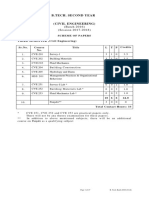

- B.Tech. Second Year Civil Engineering Scheme of PapersDocument27 pagesB.Tech. Second Year Civil Engineering Scheme of PapersHoe BhajiPas encore d'évaluation

- 4.122 MSC Chem Phy Sem III and IVDocument32 pages4.122 MSC Chem Phy Sem III and IVAsma MerchantPas encore d'évaluation

- 3 Design and Analysis of Gearless TransmissionDocument68 pages3 Design and Analysis of Gearless TransmissionRåjêßh M Ińtü100% (2)

- Concrete Masonry ArchesDocument10 pagesConcrete Masonry ArchesArda YıldırımPas encore d'évaluation