Académique Documents

Professionnel Documents

Culture Documents

Environmental Benefits of Recycling

Transféré par

MBA103003Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Environmental Benefits of Recycling

Transféré par

MBA103003Droits d'auteur :

Formats disponibles

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

ENVIRONMENTAL BENEFITS OF RECYCLING

To investigate the ecological effects of the German DSD system, an analysis of the future

material flow was carried out for the DSD (2010 to 2020) by the ko-Institut e.V.

The major elements of the study were:

a system analysis which examined the question of how the Green Dot can contribute to

sustainable development

a comparative evaluation of the achievable ecological effects. To this end, the entire

consumption of energy and raw materials in the disposal of lightweight packaging and

the associated burdens on the environment were calculated and analysed

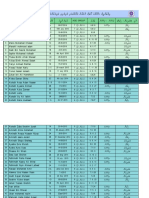

The study only dealt with lightweight packaging because it is uncontroversially accepted

that glass and paper recycling has a positive ecological effect. A total of five different waste

management scenarios with a number of sensitivity considerations were studied (see Table

3, below). The costs were analysed in a separate study. The following illustrations show the

life cycle values for complete mechanical recycling of the plastics.

15

WASTE PLASTICS RECYCLING A GOOD PRACTICES GUIDE

BY AND FOR LOCAL & REGIONAL AUTHORITIES

Environmental aspects

Recycling waste plastics can be helpful for L/RAs wishing to make local environmental improvements,

locally, regionally, nationally and globally through:

avoiding wastage of resources.

reducing the need for new waste disposal facilities

limiting greenhouse gases emissions

Avoiding wastage of resources.

Plastic manufacturing, which largely uses crude oil as the raw material, is estimated by industry to

account for four per cent of the global consumption of crude oil. For every kilogram of plastic that

is produced, roughly two kilograms of oil are needed. However, the resulting product (because of its

lightweight, insulating and protective properties) can often save more oil - through reduced

transport and energy use processes - than is required in its manufacture. By replacing crude oil in

plastics manufacture with recyclate, raw material consumption decreases, whilst the efficiency of

plastic at end-of-life increases.

However, the main benefit of plastics recycling rests in the savings associated with primary energy

consumption. Polymer production accounts for the largest proportion resource use in plastic product

manufacture, ranging from between 72 91 per cent of total energy consumption, depending on

the polymer9 . This compares with process energy usage of between 6 - 20 per cent, dependant on

the product being manufactured (i.e. bottles, pipes or films).

By contrast, the process energy necessary to produce recycled PET flakes can be reduced to 62-92

per cent of the energy required to produce virgin resin10 . Similarly, reported energy savings of ~38

per cent can be achieved by processing LDPE films into granulate and 77 per cent process energy

savings made by reprocessing rigid HDPE bottles, compared to the production of virgin material11 .

Oil and gas are converted into monomers (e.g. ethylene). The successive steps in production (of e.g.

polyethylene PE), are very energy-intensive, requiring both high temperatures and refrigeration.

Ethylene consumes around 20 megajoules (MJ) per kilogram of ethylene produced12 . If the entire

production process is taken into account from the extraction of raw material from the earth to the

end product, the energy use is between 60 and 120 GJ/t for the different plastic types (see table 4)13 :

9- considering HDPE, LDPE, PET, PVC and PP. " Eco-profiles of the European Plastics Industry Report 10 : Polymer Conversion. " I. Boustead (1997)

A technical paper from APME.

10- " Life Cycle Assessment - LCA and the PET Bottle " V. Matthews (1998). Referenced in :

11- " An Analysis of the recycling of LDPE at Alida Recycling Ltd " M. Henstock (1992). A Report by Nottingham Univeristy Consultants Ltd,

Nottingham, UK and " Assessment of the environmental imapct of plastic recycling in P&G packaging " T. Deurloo (1990). Procter and Gamble

European Technical Centre, internal Report. Referenced in : " Integrated Solid Waste Managment : A life Cycle Inventory " (2nd Edition, 2001)

by F. Mcdougall, P. White, M. Franke and P. Hindle. Blackwell Science, Oxford, UK.

12- Report of the Berkeley Plastics Task Force 1996, http://www.ecologycenter.org/plastics/report1996/report1996_toc.html

13- Eco-Profiles of Plastics and Related Intermediates Methodology, I. Boustead, Brussels 1999, and Association of Plastics Manufacturers in

Europe, LCA/Eco Profile fact sheets, www.apme.org , and Assessing the environmental potential of clean material technologies, EC/IPTS, Sevilla,

publication foreseen end 2002.

16

Vous aimerez peut-être aussi

- Recycling of Plastics - A Materials Balance Optimisation Model PDFDocument14 pagesRecycling of Plastics - A Materials Balance Optimisation Model PDFLeoChokPas encore d'évaluation

- Final Denkstatt Report (Vers 1 3) September 2010Document45 pagesFinal Denkstatt Report (Vers 1 3) September 2010Yesid Nieto MuñozPas encore d'évaluation

- Plastic Waste Management: Is Circular Economy Really The Best Solution?Document3 pagesPlastic Waste Management: Is Circular Economy Really The Best Solution?MEnrique ForocaPas encore d'évaluation

- Monomer Type Energy Tonnes CO (GJ/T Product) (Fossil/t Product)Document2 pagesMonomer Type Energy Tonnes CO (GJ/T Product) (Fossil/t Product)MBA103003Pas encore d'évaluation

- PlasticDocument18 pagesPlasticCesar Guevara GamarraPas encore d'évaluation

- Energies: Physical and Chemical Properties of Waste From PET Bottles Washing As A Component of Solid FuelsDocument17 pagesEnergies: Physical and Chemical Properties of Waste From PET Bottles Washing As A Component of Solid FuelsCQ SHOPas encore d'évaluation

- Pagbasa at Pagsusuri WEEK 7-8Document3 pagesPagbasa at Pagsusuri WEEK 7-8Wends HahaPas encore d'évaluation

- Energies 16 02199 PDFDocument15 pagesEnergies 16 02199 PDFMahmoud Hussein EbeidPas encore d'évaluation

- Recycling Plastics in GermanyDocument24 pagesRecycling Plastics in GermanyEvanCamilleriPas encore d'évaluation

- 1 s2.0 S0141391012002492 MainDocument8 pages1 s2.0 S0141391012002492 MainAICHA ABIDOUPas encore d'évaluation

- Waste Plastic Pyrolysis: An Efficient Way of Plastic RecyclingDocument7 pagesWaste Plastic Pyrolysis: An Efficient Way of Plastic RecyclingShaunotPas encore d'évaluation

- 0 - Grace's ProjectDocument43 pages0 - Grace's ProjectGrace KujePas encore d'évaluation

- Schwarz 2021 (Plastic Recycling)Document12 pagesSchwarz 2021 (Plastic Recycling)maria helenaPas encore d'évaluation

- Applied Machine LearningDocument10 pagesApplied Machine LearningDelagona Lyka MaePas encore d'évaluation

- Pyrolysis PlasticDocument16 pagesPyrolysis Plasticdiego NPas encore d'évaluation

- Qualitative and Energy Recovery Potential AnalysisDocument12 pagesQualitative and Energy Recovery Potential AnalysismarialejandrapuertoPas encore d'évaluation

- Cutting plastics pollution: Financial measures for a more circular value chainD'EverandCutting plastics pollution: Financial measures for a more circular value chainPas encore d'évaluation

- Plastic Waste ManagementDocument12 pagesPlastic Waste Managementikhamate emmanuelPas encore d'évaluation

- Waste Energy Plastic 2Document8 pagesWaste Energy Plastic 2Jorge Alejandro DelaVega Lozano100% (2)

- Plastic Waste Management A Matter For The CommuniDocument3 pagesPlastic Waste Management A Matter For The CommuniKindricks Devon Labador LibreaPas encore d'évaluation

- Environmental Assessment of Bio-Based Polymers and Natural FibresDocument59 pagesEnvironmental Assessment of Bio-Based Polymers and Natural FibresCorina PopaPas encore d'évaluation

- Clean Energy From Plastic Production ofDocument8 pagesClean Energy From Plastic Production ofsumeet ranaPas encore d'évaluation

- Processes 10 01503 v3Document18 pagesProcesses 10 01503 v3Tristan SantiagoPas encore d'évaluation

- Treenate Et Al AcademicDocument10 pagesTreenate Et Al AcademicAbdurrahim KhalifaPas encore d'évaluation

- Catalytic Pyrolysis of Plastic Waste A ReviewDocument45 pagesCatalytic Pyrolysis of Plastic Waste A ReviewAndre Basantes100% (1)

- Gasification of Plastic Waste As Waste-To-Energy or Waste-To-Syngas Recovery RouteDocument10 pagesGasification of Plastic Waste As Waste-To-Energy or Waste-To-Syngas Recovery RouteJalcamPas encore d'évaluation

- Effects of Heating Rate and Temperature On The Thermal Pyrolysis of Expended PolystyreneDocument17 pagesEffects of Heating Rate and Temperature On The Thermal Pyrolysis of Expended PolystyrenePrathwiraj MeenaPas encore d'évaluation

- Chapter-01: Sartourius L. 2012Document68 pagesChapter-01: Sartourius L. 2012ravi kumarPas encore d'évaluation

- Sustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in SwedenDocument21 pagesSustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in SwedenBetül SurPas encore d'évaluation

- Plastic Waste Management A Matter For The CommuniDocument3 pagesPlastic Waste Management A Matter For The Communihsri72639Pas encore d'évaluation

- Seminar Report 416Document18 pagesSeminar Report 416akshay kumar100% (1)

- Analysis of Energy Foorprints With Recycling of Glass and Plastic Case Studies For Inbdustrial EcologyDocument15 pagesAnalysis of Energy Foorprints With Recycling of Glass and Plastic Case Studies For Inbdustrial EcologyrelampagomxPas encore d'évaluation

- Department of First Year EngineeringDocument20 pagesDepartment of First Year Engineeringaishwarya pareekPas encore d'évaluation

- Energy Conversion and Management: Federica Cucchiella, Idiano D'Adamo, Massimo GastaldiDocument14 pagesEnergy Conversion and Management: Federica Cucchiella, Idiano D'Adamo, Massimo GastaldiMikaya LunaPas encore d'évaluation

- Plastic Waste To Syngas - 1Document30 pagesPlastic Waste To Syngas - 1waseemkhan49Pas encore d'évaluation

- Final Denkstatt Report (Vers 1 3) September 2010 PDFDocument45 pagesFinal Denkstatt Report (Vers 1 3) September 2010 PDFzamballePas encore d'évaluation

- Waste To Liquid FuelDocument11 pagesWaste To Liquid FuelEbenezer EffisahPas encore d'évaluation

- 3-Production Oil From Waste PlasticsDocument125 pages3-Production Oil From Waste Plasticshamza A.laftaPas encore d'évaluation

- Plastic Waste Management: Submitted By: Javeriya Siddiqui M.Tech (Env. Engg.) 2 Year Roll No.6104206008Document20 pagesPlastic Waste Management: Submitted By: Javeriya Siddiqui M.Tech (Env. Engg.) 2 Year Roll No.6104206008Harishwar ReddyPas encore d'évaluation

- Waste Plastic Pyrolysis: Title of The ProjectDocument11 pagesWaste Plastic Pyrolysis: Title of The ProjectAmrit PathakPas encore d'évaluation

- Waste ManagementDocument9 pagesWaste ManagementvenkiteshksPas encore d'évaluation

- Plastic Waste ManagementDocument21 pagesPlastic Waste ManagementGopika GhPas encore d'évaluation

- 10 11648 J Ajche 20180605 13Document5 pages10 11648 J Ajche 20180605 13SparrowGospleGilbertPas encore d'évaluation

- Bioplastic Wastes: The Best Final Disposition For Energy SavingDocument8 pagesBioplastic Wastes: The Best Final Disposition For Energy SavingShanaiah Charice GanasPas encore d'évaluation

- Thermal Degradation of Waste Plastics Under Non-Sweeping AtmosphereDocument12 pagesThermal Degradation of Waste Plastics Under Non-Sweeping AtmosphereNiti KlinkaewPas encore d'évaluation

- FinalDocument4 pagesFinalmisterpokePas encore d'évaluation

- Sub - and Supercritical Water For Chemical Recycling of Plastic WasteDocument22 pagesSub - and Supercritical Water For Chemical Recycling of Plastic WasteChristhy Vanessa Ruiz MadroñeroPas encore d'évaluation

- Plastic Recycling - WikipediaDocument18 pagesPlastic Recycling - Wikipediadavid manuelPas encore d'évaluation

- Studentpaper 4 - Voorbeeld ABMDocument30 pagesStudentpaper 4 - Voorbeeld ABMWisal BoujeddainePas encore d'évaluation

- Plastic Waste ManagementDocument19 pagesPlastic Waste ManagementGopika GhPas encore d'évaluation

- ReportDocument7 pagesReportRaja HarjaiPas encore d'évaluation

- Effects of Heating Rate and Temperature On The Yield of Thermal Pyrolysis of A Random Plastic MixtureDocument12 pagesEffects of Heating Rate and Temperature On The Yield of Thermal Pyrolysis of A Random Plastic MixturePrathwiraj MeenaPas encore d'évaluation

- Plastic PyrolysisDocument32 pagesPlastic Pyrolysisgoogle userPas encore d'évaluation

- A Report: B.Tech Student MNIT, Jaipur Under The Guidance ofDocument19 pagesA Report: B.Tech Student MNIT, Jaipur Under The Guidance ofSushant GoswamiPas encore d'évaluation

- A Mini-Review On Expanded Polystyrene Waste RecyclDocument15 pagesA Mini-Review On Expanded Polystyrene Waste RecyclSy Nguyen VietPas encore d'évaluation

- Waste Management: Saeed Kazemi NajafiDocument8 pagesWaste Management: Saeed Kazemi Najafiiuliana_negrisoiuPas encore d'évaluation

- Chemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)Document7 pagesChemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)Imanol FuenPas encore d'évaluation

- Bioplastic Wastes: The Best Final Disposition For Energy SavingDocument7 pagesBioplastic Wastes: The Best Final Disposition For Energy SavingTegar BudiPas encore d'évaluation

- Final PublishedDocument25 pagesFinal PublishedAshadi PwPas encore d'évaluation

- Utilization of Polymer Wastes As Transport Fuel Resources-A Recent DevelopmentDocument5 pagesUtilization of Polymer Wastes As Transport Fuel Resources-A Recent DevelopmentGlan DevadhasPas encore d'évaluation

- Revised Plumbing Code of The Philippines - Part15Document2 pagesRevised Plumbing Code of The Philippines - Part15MBA103003Pas encore d'évaluation

- Revised Plumbing Code of The Philippines - Part27Document2 pagesRevised Plumbing Code of The Philippines - Part27MBA103003Pas encore d'évaluation

- Revised Plumbing Code of The Philippines - Part16Document2 pagesRevised Plumbing Code of The Philippines - Part16MBA103003Pas encore d'évaluation

- Revised Plumbing Code of The Philippines - Part24Document2 pagesRevised Plumbing Code of The Philippines - Part24MBA103003Pas encore d'évaluation

- Revised Plumbing Code of The Philippines - Part1Document2 pagesRevised Plumbing Code of The Philippines - Part1MBA103003Pas encore d'évaluation

- Type of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)Document2 pagesType of Waste Plastic Kg/inh/y Per Cent: Table 37: Waste Plastics Management in France (1993)MBA103003Pas encore d'évaluation

- 2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pages2002 Recycling Levels: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesWaste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Economic Instruments: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesEconomic Instruments: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Ban of Landfilling And/or Incineration: FranceDocument2 pagesBan of Landfilling And/or Incineration: FranceMBA103003Pas encore d'évaluation

- Collection Sorting Processing Transport Total: PVC PipesDocument2 pagesCollection Sorting Processing Transport Total: PVC PipesMBA103003Pas encore d'évaluation

- Selective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesSelective Collection Costs: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- How To Find Recycled Products?: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesHow To Find Recycled Products?: Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Development of Green Procurement PoliciesDocument2 pagesDevelopment of Green Procurement PoliciesMBA103003Pas encore d'évaluation

- How To Promote and Support The Development of Supply of and Demand For Recycled Plastics?Document2 pagesHow To Promote and Support The Development of Supply of and Demand For Recycled Plastics?MBA103003Pas encore d'évaluation

- Hydro-Pulping: A Pulper - A Large, Agitated Water Tank - Is Used To Separate PaperDocument2 pagesHydro-Pulping: A Pulper - A Large, Agitated Water Tank - Is Used To Separate PaperMBA103003Pas encore d'évaluation

- Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesWaste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Aveyron (France) : Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesDocument2 pagesAveyron (France) : Waste Plastics Recycling A Good Practices Guide by and For Local & Regional AuthoritiesMBA103003Pas encore d'évaluation

- Union Bank of The Philippines V CADocument2 pagesUnion Bank of The Philippines V CAMark TanoPas encore d'évaluation

- Gujarat Technological UniversityDocument5 pagesGujarat Technological Universityvenkat naiduPas encore d'évaluation

- Times Leader 03-16-2013Document61 pagesTimes Leader 03-16-2013The Times LeaderPas encore d'évaluation

- Open Quruan 2023 ListDocument6 pagesOpen Quruan 2023 ListMohamed LaamirPas encore d'évaluation

- Organizational Behavior: Chapter 6: Understanding Work TeamDocument6 pagesOrganizational Behavior: Chapter 6: Understanding Work TeamCatherinePas encore d'évaluation

- Medieval Societies The Central Islamic LDocument2 pagesMedieval Societies The Central Islamic LSk sahidulPas encore d'évaluation

- Daniel Salazar - PERSUASIVE ESSAYDocument2 pagesDaniel Salazar - PERSUASIVE ESSAYDaniel SalazarPas encore d'évaluation

- Gandhi An Exemplary LeaderDocument3 pagesGandhi An Exemplary LeaderpatcynPas encore d'évaluation

- Chapter 11: Re-Situating ConstructionismDocument2 pagesChapter 11: Re-Situating ConstructionismEmilio GuerreroPas encore d'évaluation

- Au L 53229 Introduction To Persuasive Text Powerpoint - Ver - 1Document13 pagesAu L 53229 Introduction To Persuasive Text Powerpoint - Ver - 1Gacha Path:3Pas encore d'évaluation

- Labor Law BarVenture 2024Document4 pagesLabor Law BarVenture 2024Johnny Castillo SerapionPas encore d'évaluation

- QuickRecharge - Ae Is Launched by Paynet - OneDocument2 pagesQuickRecharge - Ae Is Launched by Paynet - OnePR.comPas encore d'évaluation

- Philippine Literature During Spanish ColonizationDocument4 pagesPhilippine Literature During Spanish ColonizationCharisel Jeanne CasalaPas encore d'évaluation

- WT WIAB Reworked CH 3 FullDocument5 pagesWT WIAB Reworked CH 3 Fulljack3314sonyPas encore d'évaluation

- Double Tax Avoidance Agreement ModelsDocument39 pagesDouble Tax Avoidance Agreement ModelsReubenPhilipPas encore d'évaluation

- TDS Rate Chart For Financial Year 2022 23 Assessment Year 2023 24Document9 pagesTDS Rate Chart For Financial Year 2022 23 Assessment Year 2023 24Sumukh TemkarPas encore d'évaluation

- Power of Attorney UpdatedDocument1 pagePower of Attorney UpdatedHitalo MariottoPas encore d'évaluation

- CT 1 - QP - Icse - X - GSTDocument2 pagesCT 1 - QP - Icse - X - GSTAnanya IyerPas encore d'évaluation

- How To Claim Your VAT RefundDocument5 pagesHow To Claim Your VAT Refundariffstudio100% (1)

- Elaine Makes Delicious Cupcakes That She Mails To Customers AcrossDocument1 pageElaine Makes Delicious Cupcakes That She Mails To Customers Acrosstrilocksp SinghPas encore d'évaluation

- WFP AF Project Proposal The Gambia REV 04sept20 CleanDocument184 pagesWFP AF Project Proposal The Gambia REV 04sept20 CleanMahima DixitPas encore d'évaluation

- Financial Report: The Coca Cola Company: Ews/2021-10-27 - Coca - Cola - Reports - Continued - Momentum - and - Strong - 1040 PDFDocument3 pagesFinancial Report: The Coca Cola Company: Ews/2021-10-27 - Coca - Cola - Reports - Continued - Momentum - and - Strong - 1040 PDFDominic MuliPas encore d'évaluation

- Garrido Vs TuasonDocument1 pageGarrido Vs Tuasoncmv mendozaPas encore d'évaluation

- Ch.6 TariffsDocument59 pagesCh.6 TariffsDina SamirPas encore d'évaluation

- Jurnal AJISDocument16 pagesJurnal AJISElsa AugusttenPas encore d'évaluation

- NZAA ChartsDocument69 pagesNZAA ChartsA340_600100% (5)

- Objectives of Financial AnalysisDocument3 pagesObjectives of Financial AnalysisMahaveer SinghPas encore d'évaluation

- Sharmeen Obaid ChinoyDocument5 pagesSharmeen Obaid ChinoyFarhan AliPas encore d'évaluation

- 01-Cost Engineering BasicsDocument41 pages01-Cost Engineering BasicsAmparo Grados100% (3)

- Holiday/Vacation Policy: Annual HolidaysDocument18 pagesHoliday/Vacation Policy: Annual HolidaysmalaysianheartPas encore d'évaluation