Académique Documents

Professionnel Documents

Culture Documents

Refurbishment Is Vital To Efficiency (World Pumps June 2014) With Cover

Transféré par

German FavelaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Refurbishment Is Vital To Efficiency (World Pumps June 2014) With Cover

Transféré par

German FavelaDroits d'auteur :

Formats disponibles

THE INTERNATIONAL MAGAZINE FOR PUMP USERS

Number 570 June 2014

Oil & gas:

Improving the environmental

impact from oil tankers

Also:

Health & safety

Sealing solutions

Energy efficiency

in liaison with

Connect with us

www.worldpumps.com

36

Feature

WORLD PUMPS

June 2014

Energy efficiency

Refurbishment is

vital to efficiency

Efficiency testing is key towards lowering pump energy

consumption, improving operational performance, and further

significant benefits. In this article we report on a large-scale

water pump testing programme which supports the case for

routine testing and pump refurbishment.

he in situ operation of pumps is

aected by a variety of factors and to

varying degrees depending on the

unique circumstances of each pump and

its installation. It is both reasonable and

intuitive to expect that a pumps hydraulic

performance and energy eciency characteristics will degrade over time. Given the

importance of pumps in the service they

deliver, as well as the current and anticipated future cost of electricity, it is also

reasonable that these characteristics should

be observed so as to identify trends and

opportunities for improvement to restore

performance levels.

There are two generally accepted methods

for conducting pump tests: (i) the conventional method; and (ii) the thermodynamic

method. Both methods require direct

power and pressure measurements. The

conventional method relies upon ow

measurements in order to indirectly

calculate eciency. The thermodynamic

method relies on accurate temperature

measurements of the pumped uid

immediately upstream and downstream

of the pump in order to directly calculate

eciency (via thermal losses and the

properties of the uid). Both methods

have been successfully applied and,

depending on the specic eld installations of pumps and associated piping

works, the conditions may favour either,

both, or possibly neither, of the methods.

Field installations are typically unique and

often challenging to test, particularly in

relation to factory conditions. The availability of exposed piping, the piping conguration itself, dierences between actual

demand/system conditions and predicted

A sample pump floor during preparation for testing.

www.worldpumps.com

0262 1762/14 2014 Elsevier Ltd. All rights reserved

demands used for initial design purposes,

amongst other matters, contribute to

these challenges. Commissioning performance testing of pumps, while conducted, is

generally not a typical standard practice in

the North American water and wastewater

industry. The result is that utilities assume

that the installed pumps perform exactly

as their factory tests suggest, both initially

as well as over often long periods of time

once in operation. Accordingly, any deciencies in the piping and appurtenances

upstream and downstream of the pump

may not be discovered and may be erroneously ascribed to the pump well after

installation.

A typical case in point is where the piping

immediately upstream of the pump results

in low pressures causing cavitation which,

in turn, damages the pumps components

Data collection and analysis during pump testing using portable equipment.

WORLD PUMPS

Feature

June 2014

In fact, a case can be made for the continuous monitoring of those pumps which

fall in the indicated region of the testing

frequency guideline presented in the

Figure left. Fixed monitoring units can be

implemented for permanent or quasipermanent installations for continuous

monitoring, with or without real-time data

transmission. In addition to the large

pumps, an argument can be made for

using such xed units for any pumps

which are considered critical from an

operational perspective. The testing

frequency guideline considers electricity

pricing alone, but important additional

considerations include the value of

providing continuous, reliable service,

preventative maintenance practices, or

damages resulting from failures in service

delivery, as examples.

Pump testing frequency guideline for water pumps.

and negatively alters its performance. In

this example, the cause is the suction

piping characteristics, although it may

erroneously cast a negative light on the

pump itself. Commissioning testing can

be used to prove the pumps performance

and identify any problems in the system

in which the pump is connected that may

give rise to concerns.

In 2011 and 2012, over 150 water pumps

were tested across Ontario, Canadas most

populous province. The pumps motors

ranged in size from 30hp to 4,000hp, and

the pumps ranged in age from one year

to 61 years old. The dierent testing

methods were employed in the following

proportion: (i) thermodynamic method

only 90%; (ii) conventional method only

10%; both methods 38%. Some of the

results of the testing programme include:

Average pump eciency: 73.7%

Average wire-to-water eciency: 69.4%

Average eciency loss at Best Eciency

Point (BEP): 9.3%

These eciencies are considerably lower

than what pumps are typically able to

operate at when new. In addition to the

loss in eciency between the originally

manufactured BEP and that tested (9.3%, as

noted above), there is often further ineciency due to where the pump is operated

on its curve. Accounting for operational

ineciencies, the loss of 9.3% increases

signicantly to an overall eciency gap of

12.7% based on the pumps tested.

This information, in and of itself, can be

quite useful in developing business cases

in support of refurbishment or other

improvements to the pump and/or the

operating protocols controlling it. Still, an

estimate of the potential eciency

recovery from refurbishment or some

other intervention is needed to

strengthen the case. As part of the

testing programme, two pumps that had

been in operation for 34 years each were

tested before and after a refurbishment

exercise. The results showed that 65%

and 71% of the eciency lost from original manufacture was recovered through

the refurbishment. While these results are

insucient from a statistical perspective

to be extrapolated in a general sense,

they do provide an indication of the

potential that refurbishment can oer.

The testing results were used in

conjunction with an economic model to

provide utilities with guidance on testing

frequency (see Figure above). While this

guideline is specic to the Canadian

context in terms of electricity pricing and

typical water distribution system characteristics, it does provide some useful

insight of a generalized nature. For

instance, the value of pump testing and

refurbishment increases with the pumps

output for which the motor size (hp or

kW) can be used as a suitable proxy and

also with the pumps utilisation, both of

which are intuitive. Larger pumps that

are used more often will oer higher

potential savings as eciency degradation

occurs, on average. Accordingly, it is

more valuable to test such pumps more

frequently for purposes of early detection

of eciency concerns and to observe

performance trends.

Water systems are complex and pumping

is often central to the functioning of

these systems. The hydraulic performance

and energy eciency of pumps are therefore important to providing the service

demanded from them in a nancially and

environmentally responsible manner.

Routine testing, the frequency of which

can be prioritised based on pump energy

consumption and importance to system

operation, is a key component to making

intelligent decisions regarding interventions to improve pump behaviour, as well

as informing asset and operational

management practices. The nancial and

other benets of such testing and any

improvements often outweigh their costs

by quite some margin; the opportunities

for positive return on investment can be

guided by the testing frequency guideline

shown above and other ndings from the

testing programme conducted in Ontario,

Canada. Moreover, the testing results can

be extended well beyond the pumps

themselves and are useful for hydraulic

and energy optimisations that often yield

signicantly larger savings or improvement potential through consideration of

the larger system in which the individual

pumps operate.

Additional information is available at the

contat details below.

Contact

HydraTek & Associates Inc.

216 Chrislea Road, Suite 501

Woodbridge, Ontario

L4L 8S5 Canada

E-mail: info@hydratek.com

www.hydratek.com

www.worldpumps.com

37

Vous aimerez peut-être aussi

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceD'EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformancePas encore d'évaluation

- Canada Takes A Lead in Benchmarking Pump Energy EfficiencyDocument2 pagesCanada Takes A Lead in Benchmarking Pump Energy EfficiencyGERMAN1979Pas encore d'évaluation

- Analysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantDocument5 pagesAnalysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantResearch ParkPas encore d'évaluation

- Selecting A Centrifugal Pumps by System Analysis PDFDocument27 pagesSelecting A Centrifugal Pumps by System Analysis PDFmishraenggPas encore d'évaluation

- Guidelines Flare Vent MeasurementDocument36 pagesGuidelines Flare Vent MeasurementAngie Paola Sanabria MartinezPas encore d'évaluation

- Peerless Pump Tech BulletinsDocument176 pagesPeerless Pump Tech BulletinsWilhelm ThorleyPas encore d'évaluation

- Pump Life Cycle CostDocument19 pagesPump Life Cycle CostSAMEER100% (3)

- Pump EE by ThermodynamicsDocument21 pagesPump EE by Thermodynamicsrazali131266Pas encore d'évaluation

- Selecting A Centrifugal Pump by SystemDocument27 pagesSelecting A Centrifugal Pump by SystemBogdan ChivulescuPas encore d'évaluation

- BDocument11 pagesBDany MedinaPas encore d'évaluation

- Select Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsDocument4 pagesSelect Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsHongwei GuanPas encore d'évaluation

- 10 Steps To Pump ReliabilityDocument13 pages10 Steps To Pump ReliabilityfalconesasPas encore d'évaluation

- Flow Meter Proving by E. L. Upp 1970'sDocument6 pagesFlow Meter Proving by E. L. Upp 1970'sSofyan HadiPas encore d'évaluation

- LCC Guide For Pumps PDFDocument19 pagesLCC Guide For Pumps PDFAshish ThapliyalPas encore d'évaluation

- Technical Assessments For Refinery and Petrochemical OperationsDocument8 pagesTechnical Assessments For Refinery and Petrochemical OperationsSamsi B HanifPas encore d'évaluation

- 53 - Improving Energy Efficiency of Pumps PDFDocument69 pages53 - Improving Energy Efficiency of Pumps PDFberkiPas encore d'évaluation

- LCC Executive SummaryDocument23 pagesLCC Executive SummarySuhartomtPas encore d'évaluation

- Development of A Smart Pumping SystemDocument22 pagesDevelopment of A Smart Pumping Systemcjp6124Pas encore d'évaluation

- Guidelines Flare Vent Measurement PDFDocument36 pagesGuidelines Flare Vent Measurement PDFVivek JoshiPas encore d'évaluation

- Dinamica de Fluido Sucker Rod PumpDocument26 pagesDinamica de Fluido Sucker Rod PumpyeralhPas encore d'évaluation

- The Ways How To Save Energy Efficiency On Pump SystemDocument3 pagesThe Ways How To Save Energy Efficiency On Pump SystemAfiqPas encore d'évaluation

- Pump Systems Energy Efficiency Reference ManualDocument0 pagePump Systems Energy Efficiency Reference ManualAlda England100% (1)

- Test Standard Benefits ArticleDocument8 pagesTest Standard Benefits Articleverat81Pas encore d'évaluation

- Gas SamplingDocument8 pagesGas Samplingmagobo220772100% (1)

- General Reactor Model - GTC TechnologyDocument7 pagesGeneral Reactor Model - GTC TechnologyWiroon Tanthapanichakoon CharlesPas encore d'évaluation

- 1 s2.0 S1359431115000368 MainDocument12 pages1 s2.0 S1359431115000368 MainJulio CésarPas encore d'évaluation

- Improving Energy Efficiency of Centrifugal Pumps EU Commision-1Document70 pagesImproving Energy Efficiency of Centrifugal Pumps EU Commision-1Abdulrahman AlkhowaiterPas encore d'évaluation

- Best Practice Guide PumpDocument39 pagesBest Practice Guide PumpjavgeekPas encore d'évaluation

- Power Consumption Optimization For Multiple Parallel Centrifugal PumpsDocument6 pagesPower Consumption Optimization For Multiple Parallel Centrifugal PumpshachanPas encore d'évaluation

- Literature Review Centrifugal PumpDocument5 pagesLiterature Review Centrifugal Pumpea44a6t7100% (1)

- ERA Technology Reformer Life AssessmentDocument4 pagesERA Technology Reformer Life Assessmentmahesh070Pas encore d'évaluation

- An Integrated Study of Poor Intake Conditions and Its Effect On A Pumping Station PerformanceDocument11 pagesAn Integrated Study of Poor Intake Conditions and Its Effect On A Pumping Station Performancedalia elgazzarPas encore d'évaluation

- Pump EffDocument15 pagesPump Effawhk2006Pas encore d'évaluation

- Verifying Flowmeter Accuracy PDFDocument8 pagesVerifying Flowmeter Accuracy PDFAyman TermaniniPas encore d'évaluation

- SPE 137184 Statistical Approach For PCP StandardizingDocument10 pagesSPE 137184 Statistical Approach For PCP StandardizingJosé TimanáPas encore d'évaluation

- Variables PpedDocument24 pagesVariables PpedLuis LopezPas encore d'évaluation

- Aga 11Document7 pagesAga 11elijbbPas encore d'évaluation

- Pump MaintenanceDocument5 pagesPump MaintenanceCheyanSathish100% (1)

- 10 Steps To Pump ReliabilityDocument5 pages10 Steps To Pump ReliabilityallmcbeallPas encore d'évaluation

- Conclusion & SuggestionsDocument2 pagesConclusion & SuggestionsAfiqah MossPas encore d'évaluation

- Best Practice For Lift StationsDocument5 pagesBest Practice For Lift StationsLuisSilvaPas encore d'évaluation

- Steam Turbine Risk Assessment - Project: Inspection and Overhaul Optimization of Steam TurbinesDocument8 pagesSteam Turbine Risk Assessment - Project: Inspection and Overhaul Optimization of Steam TurbinesAnonymous PkeI8e84Rs100% (1)

- Applied Sciences: Identification of Water Hammering For Centrifugal Pump Drive SystemsDocument27 pagesApplied Sciences: Identification of Water Hammering For Centrifugal Pump Drive SystemsAs VilankPas encore d'évaluation

- Improving Pump Performance DOEDocument122 pagesImproving Pump Performance DOELaurentiu GheorghitaPas encore d'évaluation

- Calibration Frequency enDocument4 pagesCalibration Frequency enGrandy Anantha SaktiPas encore d'évaluation

- Benefits of HI 14-6 FINAL FULL VERSION PDFDocument8 pagesBenefits of HI 14-6 FINAL FULL VERSION PDF1sympatyagaPas encore d'évaluation

- Energy & EnvironmentDocument227 pagesEnergy & EnvironmentBalasundaramSrinivasaRajkumar0% (1)

- Application of Genetic Algorithms Pump Scheduling For Water SupplyDocument6 pagesApplication of Genetic Algorithms Pump Scheduling For Water SupplySam ArPas encore d'évaluation

- Variable Speed PumpingDocument22 pagesVariable Speed Pumpingbmat100% (1)

- ReprocatingPump Pages 1Document2 pagesReprocatingPump Pages 1Deepak ChaurasiaPas encore d'évaluation

- Variable Speed Pumping, A Guide To Successful ApplicationDocument6 pagesVariable Speed Pumping, A Guide To Successful Applicationongjoel0% (1)

- What Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyDocument10 pagesWhat Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyANILPas encore d'évaluation

- Pump SelectionDocument2 pagesPump Selectionankesh_ghoghariPas encore d'évaluation

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineD'EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineÉvaluation : 5 sur 5 étoiles5/5 (1)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsD'EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsPas encore d'évaluation

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsD'EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowD'EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowÉvaluation : 2 sur 5 étoiles2/5 (1)

- Blue Energy Extraction Using Salinity Gradients: A Critical Evaluation of Case StudiesD'EverandBlue Energy Extraction Using Salinity Gradients: A Critical Evaluation of Case StudiesPas encore d'évaluation

- A 105 - A 105M - 03 Qtewns9bmta1tqDocument5 pagesA 105 - A 105M - 03 Qtewns9bmta1tqLuis Armando Palacios VargasPas encore d'évaluation

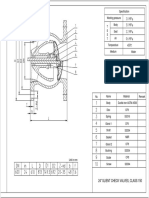

- Drawing For Silent Check ValvesDocument1 pageDrawing For Silent Check ValvesGerman FavelaPas encore d'évaluation

- Ax P1Document40 pagesAx P1German FavelaPas encore d'évaluation

- SSPC SP 17Document8 pagesSSPC SP 17German Favela100% (3)

- Flyer E10 HP PDFDocument4 pagesFlyer E10 HP PDFGERMAN1979Pas encore d'évaluation

- A 105 - A 105M - 01 Qtewns0wmq - PDFDocument4 pagesA 105 - A 105M - 01 Qtewns0wmq - PDFGyna SHPas encore d'évaluation

- Dimensioning CabinetDocument3 pagesDimensioning CabinetGerman FavelaPas encore d'évaluation

- Welding Machine Calibration ProcedureDocument10 pagesWelding Machine Calibration ProcedureGerman Favela0% (1)

- Stairways & Ladders - A Guide To OSHA RulesDocument15 pagesStairways & Ladders - A Guide To OSHA Ruleseafarmihar2554100% (3)

- Ductile-Iron Compact Fittings For Water Service: AWWA StandardDocument48 pagesDuctile-Iron Compact Fittings For Water Service: AWWA StandardGerman FavelaPas encore d'évaluation

- Suspension Trauma Orthostatic Intolerance OSHADocument4 pagesSuspension Trauma Orthostatic Intolerance OSHAThanos TsirkosPas encore d'évaluation

- Electrocution SafetyTips PDFDocument2 pagesElectrocution SafetyTips PDFGerman FavelaPas encore d'évaluation

- Scaffold SafetyDocument2 pagesScaffold SafetyGerman FavelaPas encore d'évaluation

- Cranes and RiggingDocument1 pageCranes and RiggingGerman FavelaPas encore d'évaluation

- Ce 90indicetablas PDFDocument4 pagesCe 90indicetablas PDFGerman FavelaPas encore d'évaluation

- Aws Preheat Calculations From HardnessDocument6 pagesAws Preheat Calculations From HardnessElias KapaPas encore d'évaluation

- 01 PDFDocument40 pages01 PDFLeandro Benini de AlmeidaPas encore d'évaluation

- Iq 260Document4 pagesIq 260German FavelaPas encore d'évaluation

- Ce 90indicetablasDocument4 pagesCe 90indicetablasGerman FavelaPas encore d'évaluation

- Brochure Fc101Document16 pagesBrochure Fc101German Favela100% (1)

- 469man A9Document338 pages469man A9Cecy QuijadaPas encore d'évaluation

- 61 A Systems Approach To EarthingDocument12 pages61 A Systems Approach To EarthingRamakrishnan PmpPas encore d'évaluation

- Ce 90indicetablas PDFDocument4 pagesCe 90indicetablas PDFGerman FavelaPas encore d'évaluation

- Iti (Cbema) Curve Application NoteDocument3 pagesIti (Cbema) Curve Application NoteGerman FavelaPas encore d'évaluation

- S416sea EsDocument76 pagesS416sea EsGerman FavelaPas encore d'évaluation

- Desing Guide MG16C202 2016Document228 pagesDesing Guide MG16C202 2016German FavelaPas encore d'évaluation

- Flyer E10 HPDocument4 pagesFlyer E10 HPGerman FavelaPas encore d'évaluation

- Link Belt RTC8040Document20 pagesLink Belt RTC8040German FavelaPas encore d'évaluation

- S416sea EsDocument76 pagesS416sea EsGerman FavelaPas encore d'évaluation

- 01 PDFDocument40 pages01 PDFLeandro Benini de AlmeidaPas encore d'évaluation

- Solar Cell PresentationDocument26 pagesSolar Cell Presentationraj1090Pas encore d'évaluation

- Arc Model PscadDocument6 pagesArc Model Pscadkra_amPas encore d'évaluation

- Resume (Syed Waqar Ul Haq)Document1 pageResume (Syed Waqar Ul Haq)Syed Waqar Ul HaqPas encore d'évaluation

- 4.1 DC Motor SpecificationDocument6 pages4.1 DC Motor SpecificationAsgher KhattakPas encore d'évaluation

- ComPact NSX - LV431870 - 250ADocument4 pagesComPact NSX - LV431870 - 250ASenthil SankarasubramanianPas encore d'évaluation

- MDVN EnglishDocument2 pagesMDVN EnglishKhaled KamelPas encore d'évaluation

- PowerCube 500 V200R001C00 User Manual (ICC50)Document128 pagesPowerCube 500 V200R001C00 User Manual (ICC50)SUPAT PUMJANPas encore d'évaluation

- Materi Sosialisasi Juknis PTB - 0021 - 18102022 - ShareDocument50 pagesMateri Sosialisasi Juknis PTB - 0021 - 18102022 - ShareUtomo FebbyPas encore d'évaluation

- 2023 - EU - Energy Performance of Buildings - UpdatedDocument128 pages2023 - EU - Energy Performance of Buildings - Updatedheerali singhPas encore d'évaluation

- Simoprime SwithgearDocument16 pagesSimoprime Swithgearmohamed IbrahPas encore d'évaluation

- High Rise Multi-Storied Office Building in Unit-VDocument1 pageHigh Rise Multi-Storied Office Building in Unit-VNaveen kishorePas encore d'évaluation

- Love. Through The Lens of Pitirim SorokinDocument11 pagesLove. Through The Lens of Pitirim SorokinMihai RusuPas encore d'évaluation

- EXLIM-P To 550kV - 2GNM110009 - 12-11Document14 pagesEXLIM-P To 550kV - 2GNM110009 - 12-11Mochamad RidwanPas encore d'évaluation

- Leroy Somer r120 Avr DatasheetDocument16 pagesLeroy Somer r120 Avr DatasheetalexdanniPas encore d'évaluation

- Research Based Project ON Electric VehicleDocument21 pagesResearch Based Project ON Electric VehicleSaurabh BhardwajPas encore d'évaluation

- Investigation of The Plastification Behavior of Polymers in High-Speed Twin Screw ExtrudersDocument4 pagesInvestigation of The Plastification Behavior of Polymers in High-Speed Twin Screw ExtrudersReza MansouriehPas encore d'évaluation

- Optimal Control of Two Level Quantum Systems: Application To Ammonia MaserDocument6 pagesOptimal Control of Two Level Quantum Systems: Application To Ammonia MaserShashank Gothankar100% (1)

- Fuse MCB ELCBDocument29 pagesFuse MCB ELCBIshitaBhatt30Pas encore d'évaluation

- Third Eye EemgDocument24 pagesThird Eye Eemgshamna AbdullaPas encore d'évaluation

- Ibc Polysol 270 GX enDocument2 pagesIbc Polysol 270 GX enZouhir ZerouallPas encore d'évaluation

- SHORT CIRCUITS CALCULATIONS OF WIND FARM "PODVELEŽJE" - Senior Design Project FINAL VERSION 06.07 PDFDocument84 pagesSHORT CIRCUITS CALCULATIONS OF WIND FARM "PODVELEŽJE" - Senior Design Project FINAL VERSION 06.07 PDFHaris Serdarević100% (1)

- WSCE Mini LNG Plant Case StudiesDocument4 pagesWSCE Mini LNG Plant Case StudiesKopi BrisbanePas encore d'évaluation

- 5th Sem. B. Tech. - Power Station Practice - BEEE505T - 30 JuneDocument3 pages5th Sem. B. Tech. - Power Station Practice - BEEE505T - 30 Juneptarwatkar123Pas encore d'évaluation

- Ansi c84.1 Voltage Level and RangeDocument6 pagesAnsi c84.1 Voltage Level and RangeJesús Valdez RPas encore d'évaluation

- Chitungwiza Hospital 5kvaDocument51 pagesChitungwiza Hospital 5kvawebsterchikambaPas encore d'évaluation

- Customer Course CatalogDocument119 pagesCustomer Course CatalogLeticia1705Pas encore d'évaluation

- Chemistry For Engineers - Week 1 - v5Document65 pagesChemistry For Engineers - Week 1 - v5Desny LêPas encore d'évaluation

- Midea Product SplitDocument4 pagesMidea Product SplitYUVI RAJPas encore d'évaluation

- Half Wave and Full Wave RectifiersDocument8 pagesHalf Wave and Full Wave RectifiersRavindra SinghPas encore d'évaluation

- For JEE MAINS 2022: Work, Energy and Power, SHMDocument34 pagesFor JEE MAINS 2022: Work, Energy and Power, SHMSubham priyanshu sutarPas encore d'évaluation