Académique Documents

Professionnel Documents

Culture Documents

A New Biomimicry Marine Current Turbine - Study of Hydrodynamic Performance

Transféré par

Nadji ChiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A New Biomimicry Marine Current Turbine - Study of Hydrodynamic Performance

Transféré par

Nadji ChiDroits d'auteur :

Formats disponibles

125

2016,28(1):125-141

DOI: 10.1016/S1001-6058(16)60614-5

A new biomimicry marine current turbine: Study of hydrodynamic performance and wake using software OpenFOAM*

Yung-Jeh CHU

Department of Civil Engineering, Faculty of Engineering, University of Malaya, Kuala Lumpur 50603, Malaysia,

E-mail: chujeh2022@gmail.com

(Received March 13, 2014, Revised August 20, 2015)

Abstract: Inspired by Dryobalanops aromatica seed, a new biomimicry marine current turbine is proposed. Hydrodynamic performance and wake properties are two key factors determining whether a new marine current turbine design is practical or not. Thus, a

study of hydrodynamic performance and wake of the proposed biomimicry turbine is conducted. The computational fluid dynamics

(CFD) software, OpenFOAM is used to generate the required results for the mentioned study. The hydrodynamic performance and

wake properties of the proposed biomimicry turbine is compared to two conventional turbines of Bahaj et al. and Pinon et al. respectively. The simulation results showed that the proposed biomimicry marine current turbine gives optimum power output with its

power coefficient, CP 0.376 at the tip speed ratio (TSR) of 1.5. Under the same boundary conditions, the maximum torque produced by the proposed biomimicry turbine at zero rotational speed is 38.71 Nm which is 1110% greater than the torque generated by

the turbine of Bahaj et al.. The recovery distance for the wake of the biomimicry turbine is predicted to be 10.6% shorter than that of

IFREMER-LOMC turbine. The above-mentioned results confirm the potential application of the proposed biomimicry marine current turbine in the renewable energy industry.

Key words: marine current turbine, wake, biomimicry, computational fluid dynamics (CFD), OpenFOAM

Introduction

The hydrodynamic performance and wake properties are two key factors to determine whether a new

marine current turbine design is applicable in industries or not. The torque and thrust generated by a rotating marine current turbine will determine its hydrodynamic performance during operation. On the other

hand, the wake property such as the wake recovery

distance is important in predicting the minimum spacing required between turbines in array. Thus, it is a

must to conduct hydrodynamic performance and wake

study through recognized methods in order to prove

that the new marine current turbine design is worth investing. There are a few recognized methods which

have been used to measure or predict the hydrodynamic performance and wake properties of marine current turbines, among them are experiments and numeri0F

* Biography: Yung-Jeh CHU (1987-), Male,

Graduate Civil Engineer

cal simulations.

There were few examples of successful experiments conducted in measuring marine current turbine

torque, thrust and wake properties such as those studied in Refs.[1-10]. A typical experiment consists of a

model scaled turbine which immersed in a flume tank

or a flow channel with supplies of inflow water in

close or open circuits. Sensors are used to measure the

torque and thrust on the turbine. The velocity at downstream flow at various positions is usually measured

with calibrated flow velocity measuring device such

as acoustic Doppler or laser Doppler velocimeter. The

experimental results of the turbine wake can be reliable if the scaled model of the turbine is sufficiently

large. In spite of the reliable results, many researchers

chose to predict the hydrodynamic performance and

turbine wake properties by using numerical simulations due to various restrictions on experiments such as

expensive set-up and long preparation time.

The CFD gains in popularity among researchers

as a tool for turbine research as shown in Refs.[11-15].

Several CFD software such as ANSYS-FLUENT and

OpenFOAM were available free or with affordable li-

126

cense price. Due to the fast growth of technology

nowadays most researchers are able to own at least a

high performance workstation for research study. This

enables accurate prediction of turbine wake properties

to be obtained with shorter period of time compared to

experimental methods. However, most of the predicted simulation results still need to be validated by experimental results due to the errors induced by the numerical method itself such as truncation errors.

The objective of this study is to predict the hydrodynamic performance and wake properties of a

proposed biomimicry horizontal axis marine current

turbine by using the open sourceCFD software,

OpenFOAM. The predicted hydrodynamic performance of the biomimicry marine current turbine is compared to Ref.[4] while the predicted wake properties are

compared to Ref.[11]. The results from the comparisons will give preliminary idea on the possible applications of the proposed biomimicry marine current turbine in renewable energy industry.

1. Background of the proposed biomimicry marine

current turbine

The idea of mimicking the Dryobalanops aromatica seeds in turbine design was proposed by Chu during his undergraduate, when Dryobalanops aromatica

seeds were found at the Geology Faculty in University

of Malaya. The inspiration came when one of the

Dryobalanops aromatica seed was seen rotating stably

in the air during a visit to the Geology Faculty. The

unique shape of the wings of Dyrobalanops aromatica

seeds might suggest a solution in optimum turbine

blade design. Thus, samples of Dryobalanops aromatica seeds were gathered, observed and photographed

for study use. Figure 1 shows the snapshots of a

Dryobalanops aromatica seeds found at Geology Faculty, University of Malaya.

Although the Dryobalanops aromatica seed uses

wind as the media of propagation, it is supposed that

its physical characteristics and flight mechanism can

be applied in the design of marine current turbine.

Thus, the biomimicry marine current turbine is proposed to have turbine blades similar to the shape of the

wings of Dryobalanops aromatica seed, three-bladed

and a downstream type turbine where the rotor is located behind the nacelle. Figure 2 further illustrates the

components of the proposed biomimicry turbine.

Fig.2 Sketch of the proposed 3-bladed biomimicry downstream

horizontal axis turbine

Fig.1 Snapshots of a Dryobalanops aromatica seeds found at

Geology Faculty, University of Malaya (Note: Due to the

near distance of photographing, the objects nearer to the

camera appear to be larger. The 0.01 m grid size is only

for rough estimation)

2. Numerical simulations

Two sets of numerical simulations were done in

terms of hydrodynamic performance and wake predictions. For prediction of hydrodynamic performance,

the geometrical properties of the proposed biomimicry

turbine such as the number of blades, rotor size, hub

size and boundary conditions were totally made the

same as those of the turbine reported[4]. For wake prediction, all the geometrical properties of the proposed

biomimicry turbine such as the number of blades,

rotor size, hub size and boundary conditions were also

made the same as those of the IFREMER-LOMC turbine from Ref.[11]. The power coefficient, CP was set

approximately the same in wake simulation for the

cases of IFREMER-LOMC and biomimicry turbine in

127

order to check the differences of their wake properties

when the power output of both turbines is roughly the

same. Grid independence test was conducted to determine the suitable mesh sizes for all simulation cases

on account of the limiting available computational

power. The numerical simulation was continued with

the preferable set of mesh sizes and number of iterations. The discussion includes the predicted results

such as the torque, thrust, velocity line plots, pressure

line plots, vorticity contour, velocity contour and particle streamlines.

ckness and pitch distribution presented in Table 1.

3. Computational hardware and software

A workstation with processor Intel Core i74770K CPU @ 3.50 GHz8, were used to run the simulations with Ubuntu 12.04 LTS as the operating

system. GetData and JavaFoil were used to generate

the coordinates required in turbine geometry modelling. GetData Graph Digitizer is a program for digitizing graphs and plots. JavaFoil is a relatively simple

program, which uses several traditional methods for

airfoil analysis. The geometry of the turbines was modelled by using SALOME. SALOME is an open-source software that provides a generic platform for Preand Post-Processing for numerical simulation. The

meshing and solving process was done in OpenFOAM.

OpenFOAM is a free, open source CFD software package developed by OpenCFD Ltd at ESI Group and

distributed by the OpenFOAM Foundation. ParaView

was used to view the simulation results. ParaView is

an open-source, multi-platform data analysis and

visualization application.

Fig.3 Conventional turbine geometry modelled according to the

details available from Ref.[4]

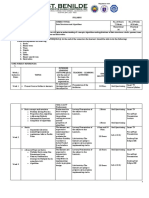

Table 1 Turbine blade section properties from Ref.[4]

r /m

c/R

Pitch/ o

t c 1 / %

0.08

0.125

15.0

24.0

0.12

0.116

9.5

20.7

0.16

0.106

6.1

18.7

0.20

0.097

3.9

17.6

0.24

0.088

2.4

16.6

0.28

0.078

1.5

15.6

0.32

0.069

0.9

14.6

0.36

0.059

0.4

13.6

0.40

0.050

0

12.6

Note: r is the radius of local blade element, c is the blade

chord, R is the blade tip radius and t is the section

thickness.

3.1 Bahaj et al.[4] turbine geometry modelling

The turbine from Ref.[4] consists of three turbine

blades. Its rotor diameter is 0.8 m, hub diameter is

0.1 m and the turbine blades were developed from the

profile shape of a NACA 63-8xx and with chord, thi-

Table 2 Blade section characteristics of the IFREMERLOMC turbine obtained from Ref.[11]

r/R

c/R

Pitch/ o

t c 1 / %

0.13

0.06

29.57

80

0.15

0.06

29.57

100

0.16

0.06

29.57

100

0.20

0.15

25.63

36

0.24

0.25

22.15

21

0.29

0.24

19.30

21

0.33

0.23

16.97

22

0.37

0.21

15.05

22

0.42

0.20

13.46

22

0.46

0.19

12.12

22

0.50

0.18

10.98

23

0.55

0.17

10.01

23

0.59

0.17

9.18

22

0.63

0.16

8.45

22

0.68

0.15

7.82

22

0.72

0.15

7.26

21

0.76

0.14

6.77

21

0.81

0.14

6.34

20

0.85

0.13

5.95

19

0.89

0.13

5.61

19

0.94

0.12

5.29

18

0.98

0.12

5.01

18

1.00

0.07

4.87

25

Note: r is the radial distance measured from the rotational

axis, R is the radius of turbine disk, c is the chord

length, t is the maximum thickness as a fraction of the

chord.

The blade set angle is the angle at the tip of the

blade, (i.e. the blade angles in Table 1 refer to a set

128

angle of 0o )[4]. The blade is designed such that maximum power would be produced at a 5o set angle[4].

Thus 5o set angle of the turbine from Ref.[4] is used

in this study as a benchmark to determine the hydrodynamic performance of the proposed biomimicry

marine current turbine. The coordinates of the turbine

blade surfaces in Ref.[4] were generated by using

JavaFoil according to the turbine blade section properties in Table 1. The generated coordinates of the turbine blade surfaces in Ref.[4] were then exported to

SALOME for turbine geometry modelling. The modelled turbine as that of Ref.[4] is shown in Fig.3.

Fig.7 Definition of rake, pitch and skew angles of the proposed

biomimicry turbine blade (viewed from the top of turbine)

in this study

Fig.4 The modelled IFREMER-LOMC turbine geometry using

SALOME

Fig.8 Power coefficient graph of the proposed biomimicry turbine with different combinations of turbine blades pitch

and skew angles e.g., 15p30s means 15o in pitch and

30o in skew

Fig.5 Photographs showing outlines (light grey) of a wing of

Dryobalanops aromatica seed used in biomimicry turbine

blade modelling. The left side of the photo shows concave surface while the right side shows the side view of a

wing of Dryobalanops aromatica seed

Fig.6 The modelled biomimicry turbine geometries inspired by

Dryobalanops aromatica seed

Fig.9 Power coefficient graph (zoomed in for the sake of clarification) of the proposed biomimicry turbine with different combinations of turbine blades pitch and skew angles

e.g. 15p30s means 15o in pitch and 30o in skew

129

Table 3 Grid independence test result for Ref.[4] turbine case with 5o set angle, TSR = 2 and U = 1.73 m / s

Number of cells

262 754

655 362

1 304 043

Average node interval size

on blades surfaces/m

0.0015

0.0010

0.0008

Number of iterations

CP

CT

500

0.0611

0.2721

5 000

0.0611

0.2722

10 000

0.0611

0.2722

500

0.0591

0.2680

5 000

0.0591

0.2683

10 000

0.0590

0.2684

500

0.0573

0.2649

5 000

0.0574

0.2658

10 000

0.0575

0.2660

Table 4 Grid independence test result for biomimicry turbine case with rake angle 40o , pitch angle 15o , skew angle 30o ,

TSR = 1 and U = 1.73 m / s

Number of cells

265 542

680 424

1 373 305

Average node interval size

on blades surfaces /m

Number of iterations

CP

CT

500

0.2715

0.8160

5 000

0.2729

0.8364

10 000

0.2728

0.8351

500

0.2735

0.8175

5 000

0.2730

0.8321

10 000

0.2747

0.8396

500

0.2744

0.8112

5 000

0.2752

0.8384

10 000

0.2747

0.8370

0.0015

0.0010

0.0008

3.2 IFREMER-LOMC turbine geometry modelling

The IFREMER-LOMC turbine geometry from

Ref.[11] consists of three turbine blades, 0.700 m

rotor diameter, 0.046 m hub radius and 0.720 m hub

length. The turbine blades were developed from the

profile shape details as shown in Table 2.

The background of the IFREMER-LOMC turbine is as shown in the following quotes extracted from

Ref.[11]:

The second set of blades used for validation

purposes was first designed by tidal generation limited

(TGL) and experimentally tested in the IFREMER

flume tank of Boulogne-sur-Mer (France). However,

this set of blades, presented in Maganga et al., is patented so a similar and open set of blades was developed for experimental validation at IFREMER and numerical trial at LOMC-Le Havre University (France).

In the present paper, this last open blades configuration will be named as the IFREMERLOMC configuration. The turbine blades are designed from a

NACA63418 profile.

JavaFoil and SALOME were used to produce the

geometry of the IFREMER-LOMC turbine. The modelled geometry was then exported to OpenFOAM for

simulation. Figure 4 shows the 3-D view of

IFREMER-LOMC turbine geometry modelled in this

study.

3.3 Biomimicry turbine blade geometry modelling

The photo of a wing of Dryobalanops aromatica

seed were used to generate the required blade surface

coordinates for the mentioned geometry modelling.

The coordinates of the outlines of the wing of

Dryobalanops aromatica seed is generated by using

GetData. The generated coordinates were then exported to SALOME for geometry modelling. In order to

have a fair comparison with the simulation cases of

Ref.[4] and IFREMER-LOMC turbine, the rotor diameter, hub and the number of turbine blades of the

two modelled biomimicry marine current turbines

130

were made the same as those in Refs.[4] and [11]. The

key difference between the biomimicry turbine and

the turbine from Refs.[4] and [11] is the shape of the

turbine blades. Figure 5 shows the photos of a wing of

Dryobalanops aromatica seed while Fig.6 shows the

two modelled biomimicry marine current turbines for

hydrodynamic performance and wake simulations.

3.4 Optimum biomimicry turbine geometry test

The definition of rake, pitch and skew angles of

the biomimicry turbine blade are as shown in Fig.7.

The rake angle was fixed to 40o while the skew and

pitch of the biomimicry turbine blades were altered in

order to see which combination will give optimum

power output. Lower mesh numbers (each case around

250 000) were applied in this test.

Simulation results from eight different combinations of pitch and skew angles of the biomimicry turbine blade in the optimum turbine geometry test are as

shown in Fig.8 and Fig.9. From the results shown, the

combinations of 15o pitch and 30o skew gives the

highest maximum power coefficient, CP which is

around 3.8 among other combinations. Thus, it was

decided that this combinations of 15o pitch and 30o

skew is to be implemented into the biomimicry turbine geometry for the hydrodynamic performance comparisons.

3.5 Boundary and initial conditions

For the simulation of hydrodynamic performance,

the free stream velocity, U = 1.73 m / s with initial

turbulence intensity = 5% were applied throughout the

mesh domain of all the turbine of Ref.[4] and biomimicry turbine. The rotational speed of the rotor was

altered according to the specific tip speed ratio (TSR)

for each simulation case. Standard k - wall function

was applied at the turbine blades surfaces.

On the other hand, the free stream velocity,

U = 0.8 m / s with initial turbulence intensity = 5%

were applied throughout the mesh domain of both the

IFREMER-LOMC turbine and biomimicry turbine

wake simulation cases. Standard k - wall function

was also applied at the turbine blades surfaces of both

simulation cases. Several trials with different rotational speed and tip speed ratio of rotor were done for

both simulation cases to obtain the same predicted

power coefficient, CP while it was not being concerned for the case of thrust coefficient, CT in this study.

Through trial and errors, it was found that the optimum predicted power coefficient, CP of both the

IFREMER-LOMC turbine and biomimicry turbine

cases were very near, 0.37 and 0.38, respectively.

Thus, the wake properties of the IFREMER-LOMC

turbine and biomimicry turbine simulation cases with

optimum TSR 3.67 and TSR 1.5 respectively were

compared.

The predicted power coefficient, CP and thrust

Coefficient CT in this study were calculated with

Eqs.(1)-(3).

CP =

2Q

U 3 R 2

(1)

CT =

2T

U 2 R 2

(2)

R

U

(3)

where CP is the power coefficient, CT is the thrust

coefficient, is the tip speed ratio, Q is the torque,

is the angular speed, is the density of fluid, U

is the free stream velocity, R is the radius of rotor

and T is the thrust.

Fig.10 Mesh domain slice sections

3.6 Solver, libraries and turbulence model

All the simulation cases in this study were solved

by using the OpenFOAM solver named

MRFSimpleFOAM. MRFSimpleFOAM is a steadystate solver for incompressible, turbulent flow of fluids with multiple reference frame (MRF) regions. The

131

Table 5 Mesh properties of simulation case for Biomimicry and IFREMER-LOMC turbine

IFREMER-LOMC

turbine case

Biomimicry

turbine case

Number of mesh cells

Blade surface mesh size/m

Rotor mesh size/m

Stator mesh size/m

525 982

0.0031

0.0250

0.050

1 610 174

0.0020

0.0165

0.033

3 667 938

0.0015

0.0125

0.025

592 672

0.0030

0.0250

0.050

1 765 874

0.0021

0.0165

0.033

3 937 105

0.0016

0.0125

0.025

SST k - turbulence model was adopted for the simulations in this study. The torque and thrust of the

turbine was calculated by the tool from a post-processing library named forces. The forces post-processing library provides tools for post-processing force/

lift/drag data with function objects.

3.7 Grid independence test for hydrodynamic performance simulation case

Grid independence test was conducted for the

Ref.[4] and biomimicry turbine case to ensure the

mesh quality is enough to achieve accurate results. Different number of cells and number of iterations were

applied in the test and the results are as shown in

Table 3 and Table 4.

From the result of the grid independence test, the

CP and CT values converged at 10 000 iterations and

1 304 042 mesh cells for the turbine of Ref.[4]. For

the biomimicry turbine, the CP and CT values converged at 10 000 iterations and 1 373 305 mesh cells.

Thus, all the hydrodynamic performance simulations

were run in 10 000 iterations and the mesh with

1 304 043 cells is chosen for simulations of turbine

from Ref.[4] while the mesh with 1 373 305 cells is

chosen for the biomimicry turbine simulations. Figure

10 shows the mesh domain slice sections for the simulation cases of Ref.[4] and biomimicry turbine.

The quantitative uncertainties for the grids were

estimated using the factor of safety method and they

are referred to [16-19]. The uncertainties of CP and

CT were 2.5%S and 15.7%S (where %S is percentage of fine grid solution) of the 1 304 042 mesh

cells solution for the turbine of Ref.[4] while it is

5.1%S and 10.2%S of the 1 373 305 mesh cells solution respectively for the biomimicry turbine.

3.8 Grid independence test for wake simulation case

Grid independence test was also conducted for

both IFREMER-LOMC turbine from Ref.[11] and

biomimicry turbine to ensure good mesh quality. Simulation of cases with different mesh cell numbers

were run in the test and their mesh properties are as

shown in Table 5.

The difference in mesh size and number of cells

between the IFREMER-LOMC turbine and Biomimicry turbine were adjusted to be as small as possible to

avoid different influence due to different grid size.

The velocity distribution located at a distance of 1.2D

(0.84 m) from the origin was adopted for the test. The

results from the test show that the influence of the grid

sizes was of minimum when the number of cells reaches 3 667 938 for IFREMER-LOMC turbine while it

was 3 937 105 for biomimicry turbine. The optimum

number of iterations for the best results is about

10 000. The velocity distribution plots were as shown

in Fig.11 while the slice sections of the mesh domains

are presented in Fig.12 and Fig.13.

Similar to grid independence test for hydrodynamic performance, the uncertainties for the grids were

estimated using the factor of safety method. The uncertainty of the axial velocity at lateral distance = 0

is 12.4%S of the 366 7938 mesh cells solution for

IFREMER-LOMC turbine while it is 14.2%S of the

3 937 105 mesh cells solution for biomimicry turbine.

4. Results and discussion

For the case of hydrodynamic performance, discussion is focused on the predicted hydrodynamic torque and thrust from the simulation results for the turbine of Ref.[4] and biomimicry marine current turbine.

Comparisons on power coefficient, CP and thrust coefficient, CT for each simulated turbines were also presented and discussed in this section. For the case of

wake predictions, several aspects of the turbine wake

properties of the IFREMER-LOMC turbine and the

proposed biomimicry turbine were discussed in detail.

The discussed aspects were the velocity distribution,

vorticity, pressure distribution, wake recovery distance and the particle streamlines from the predicted results. Through the comparisons of the results from

these aspects, the feasibility of the proposed biomimicry turbine to be adopted in turbine farm design can

132

of the IFREMER-LOMC turbine and biomimicry turbine.

Fig.11 Velocity line plots at distance of 1.2D from origin with

different mesh numbers. Velocity line plots at distance

of 1.2D from origin with different number of iterations

be predicted. Table 6 shows the summary of the conditions and predicted results for the wake simulation

4.1 Torque and thrust prediction

The hydrodynamic performance of the proposed

biomimicry marine current turbine outweighs the turbine of Ref.[4] in terms of torque. Referred to Table 7,

the hydrodynamic torque produced by the biomimicry

turbine is greater than that of Ref.[4] from TSR = 0

to TSR = 2.5 . The predicted maximum torque produced by the proposed biomimicry marine current turbine at zero rotational speed is 38.71 Nm which is

1 110% greater than the torque generated by the turbine of Ref.[4]. The high torque generated by the biomimicry turbine can overcome resisting torque (e.g. caused by friction) from the nacelle effectively and thus

avoids rotor jamming problems especially during initial stage when the turbine starts to rotate. Table 7

shows the hydrodynamic torque comparison between

turbine of Ref.[4] and biomimicry turbine.

The high thrust produced by the biomimicry turbine as shown in Table 7 is detrimental to the turbine

blade root due to the induced bending moment. The

required rigidity and elastic properties of the turbine

blade will be determined by the thrust produced by the

marine current turbine during its operation. Higher generated thrust will lead to more amount of or expensive materials needed to strengthen the turbine blade

root. However, the blade root bending moment might

be able to be alleviated by introducing flexible turbine

blade. Further study will be conducted in the future to

investigate the efficiency of flexible turbine blade in

relieving blade root bending moment. Despite the

blade rigidity issue, the thrust produced by the biomimicry turbine at optimum TSR, TSR = 1.5 is only

13.24% greater than the thrust produced by the turbine

of Ref.[4] at its optimum Tip Speed Ratio, TSR = 6.0 .

This extra 13.24% of thrust can be overcome by strengthening the blade root with stronger material and

proper reinforcement. The suitable blade thickness

and materials to strengthen the biomimicry blade will

also be investigated in future study.

The power coefficients, CP predicted in this

study show that the biomimicry marine current turbine

operates at lower, TSR. This means that with the same

rotor size and a given free stream velocity, the biomimicry turbine will rotates slower than conventional

turbine e.g. when compared to the turbine of Ref.[4].

This slow operating rotational speed makes the biomimicry marine current turbine environmental friendly

as the collision risk is expected to be low compared to

other conventional marine current turbines. Figure 14

and Fig.15 show the predicted power coefficient and

thrust coefficient with the results adopted from

Ref.[4].

133

Fig.12 Slice sections of mesh domains showing the turbine, rotor and stator

Fig.13 Enlarged view of the slice sections of mesh domain, showing the origin for downstream distance measurements

Similar to the hydrodynamic performance comparisons with Ref.[4], the power coefficient, CP and

thrust coefficient, CT of the biomimicry marine cu-

rrent turbine were also compared to IFREMERLOMC turbine from Ref.[11]. Referred to the

OpenFOAM results, the optimum TSR for the biomimicry marine current turbine is 1.5 and the maximum

power coefficient, CP is approximately 0.38 while the

optimum Tip Speed Ratio, TSR for the IFREMERLOMC marine current turbine is 3.67 and the maximum power coefficient, CP is approximately 0.37.

These approximately the same maximum power coefficients (0.37 and 0.38) of the IFREMER-LOMC and

biomimicry turbine will give valid wake properties

comparisons as shown in the next sections. Figure 16

and Fig.17 show the predicted power coefficient and

thrust coefficient graphs with the results adopted from

Ref.[4].

The predicted power coefficient, CP of the biomimicry marine current turbine decrease abruptly

once the TSR is larger than 2 which is much lower

than the two conventional marine current turbines according to Fig.14 and Fig.16. The range of operative

TSR (assuming preferable CP > 0.3 ) for the biomimicry marine current turbine is limited from 1 to 2.5

while it is wider for the case of the other two conventional marine current turbines. This limited range of

operative TSR will cause the necessity to control the

rotational speed of the turbine based on incoming flow

velocity in order to achieve optimum power extraction.

The mentioned control also applies to the limited operative TSR range for the biomimicry marine current

turbine in terms of the thrust coefficient, CT according to Fig.15 and Fig.17. Improvements on the design

134

Table 6 Summary of conditions and predicted results of wake simulation for IFREMER-LOMC and biomimicry turbine

Incoming

flow

velocity,

Rotor

diameter/

m

Number

of

blades

Hub

radius/

m

Hub

length/

m

Optimum

TSR

Rotational

speed/

rads1

Predicted

torque/

Nm

Predicted

thrust/N

CP

CT

IFREMERLOMC

0.8

0.7

0.046

0.720

3.670

8.390

4.360

82.980

0.370

0.670

Biomi-micry

0.8

0.7

0.046

0.720

1.500

3.430

10.920

125.450

0.380

1.018

U /ms1

Table 7 Hydrodynamic torque comparison between the turbine of Ref.[4] and biomimicry turbine

Bahaj et al.[4] turbine case

Biomimicry turbine case

TSR

Torque/

Nm

Thrust/

N

TSR

Torque/

Nm

Thrust/

N

3.20

95.41

38.71

373.72

0.5

3.28

105.20

0.5

43.03

418.18

1.0

4.23

128.87

1.0

82.67

629.61

2.0

8.66

200.15

1.5

75.39

767.99

4.0

25.59

448.31

2.0

52.14

840.54

6.0

25.99

678.18

2.5

33.13

972.73

8.0

19.55

798.37

3.0

1.48

1 004.85

10.0

11.93

870.14

3.5

34.41

1 039.75

4.0

74.71

1 079.62

Fig.14 Power coefficient graph of the turbines resulted from cavitation tunnel, towing tank, SERG-Tidal, GH-Tidal

Bladed and OpenFOAM simulations. The cavitation tunnel, towing tank, SERG-Tidal and GH-Tidal Bladed

results were adopted from Ref.[4]

Fig.15 Thrust coefficient graph of the turbines resulted from

cavitation tunnel, towing tank, SERG-Tidal, GH-Tidal

Bladed and OpenFOAM simulations. The cavitation tunnel, towing tank, SERG-Tidal and GH-Tidal Bladed

results were adopted from Ref.[4]

of this biomimicry marine current turbine with respect

to the stated limitation will be discussed in future

study.

Validation of the OpenFOAM predicted CP and

(where %E is percentage of experimental data) while

it is 15.38%E and 17.59%E respectively for the

case of IFREMER-LOMC turbine. These large average comparison error may be due to the limitations of

the implemented turbulence model or solver in predicting accurate hydrodynamic forces especially in high

pressure gradient region e.g. blade surfaces and near

wake region. The cause of this large average comparison error will be studied in future by comparing the

CT were done by referring to the experimental results

from Ref.[4] and also Ref.[11]. The average comparison error of the OpenFOAM predicted CP and CT

with Ref.[4] turbine is 20.63%E and 10.65%E

135

results from implementing different turbulence models

and solvers to simulation of the turbine of Ref.[4] and

IFREMER-LOMC marine current turbine e.g. other

Low-Reynolds turbulence model with transient solver.

Fig.16 Power coefficient graph of the turbines resulted from

experiment, particle method and OpenFOAM simulations. The IFREMER-LOMC experiment and particle method results were adopted from Ref.[11]. represents

smoothing parameter in particle method prediction by

Ref.[11].

Fig.17 Thrust coefficient graph of the turbines resulted from

experiment, particle method and OpenFOAM simulations. The IFREMER-LOMC experiment and particle method results were adopted from Ref.[11]

4.2 Velocity, vorticity and pressure distribution

The axial velocity contour plots and velocity line

plots of the wake of IFREMER-LOMC turbine and

biomimicry turbine were discussed in this study. The

axial velocity contour plots show no significant difference of the turbine wake pattern at the far wake region while the degree of fluctuations of axial velocity

is very much different at the near wake region. The

near wake region is defined as the wake region within

distances of 4D from origin while the far wake region

is farther than 4D away in the downstream direction

according to Ref.[11]. Figure 18 shows the simulated

velocity contour plots along the downstream direction

for the IFREMER-LOMC turbine and biomimicry turbine.

To go in depth on the turbine wake properties,

the velocity line plots are discussed. This discussion

will focus on the difference of OpenFOAM results on

turbine wake between the IFREMER-LOMC turbine

and biomimicry turbine. The purpose of including the

experimental and particle method results from Ref.[11]

is to validate the results for IFREMER-LOMC turbine

predicted by OpenFOAM. Since the velocity line plots

of the IFREMER-LOMC turbine predicted by

OpenFOAM lies within the ranges of the experimental

and particle method results from Ref.[11] as shown in

Figure 19 and Figure 20, the validation is considered

done for this study. Figure 19 shows the near wake

while Figure 20 shows the far wake of the axial velocity distribution line plots for IFREMER-LOMC turbine and Biomimicry turbine.

For the case of near wake, the velocity distribution of the biomimicry turbine wake predicted by

OpenFOAM shows lower axial velocity values at the

axis of rotation, z / D = 0 compared to IFREMERLOMC turbine. This low axial velocity suggests that

the larger blade area of the biomimicry turbine captures more incoming flow near the hub region compared

to IFREMER-LOMC turbine. This is different at far

wake region where the axial velocity on the axis of

rotation of the biomimicry turbine wake is higher

compared to IFREMER-LOMC turbine. This might

means that the wake recovery of the biomimicry turbine wake is shorter than the IFREMER-LOMC turbine

wake. The axial velocity distribution for the biomimicry turbine and IFREMER-LOMC turbine were of no

much difference at the wake region outside the rotor

area, for z / D > 0.5 and z / D < 0.5 . This suggests

that the wake expansion for the biomimicry turbine

wake is the same as the IFREMER-LOMC turbine

wake throughout the downstream direction. This result

also implies that the spacing of a biomimicry turbine

farm in lateral can be the same as a turbine farm from

IFREMER-LOMC turbines.

There are significant differences observed in the

vorticity contour plots of the predicted wake of

IFREMER-LOMC turbine and biomimicry turbine.

More vortices formed in a turbine wake means more

translational flow being converted to local rotational

flow. If more translational flow is being converted to

local rotational flow, then there will be less energy left

for extraction in the downstream wake. For the case of

IFREMER-LOMC turbine wake, the flow with high

vorticity magnitude (Vorticity magnitude 1 ) is distributed further downstream compared to the biomimicry turbine wake. The high vorticity regions are distributed at the tip of the IFREMER-LOMC turbine and

also behind its hub. The biomimicry turbine wake vorticity is observed to be concentrated nearer to the turbine. These differences further support that the biomimicry turbine wake recovery distance is shorter compared to IFREMER-LOMC turbine wake. Figure 21

136

Fig.18 Velocity contour plots

Fig.19 Velocity line plots showing axial velocity distribution at different locations in near wake at downstream direction for

IFREMER-LOMC and Biomimicry turbine cases from this study and Ref.[11]. Note: The letter D denotes measurement of

distance in diameters of rotor, in this case 1.0D is 0.7 m. e.g. 1.2D means 1.2 times diameter of rotor measured from

origin. The lateral bars for the experimental data represent the standard deviation around the mean velocity value

137

Fig.20 Velocity line plots showing axial velocity distribution at different locations in far wake for IFREMER-LOMC turbine and

Biomimicry turbine from this study and Ref.[11]

Fig.21 Vorticity contour plots of simulation

138

Fig.22 Pressure distribution line plots at different locations in

near wake in downstream direction for IFREMERLOMC turbine and Biomimicry turbine simulated by

OpenFOAM

Fig.23 Pressure distribution line plots at different locations in

far wake in downstream direction for IFREMERLOMC turbine and Biomimicry turbine simulated by

OpenFOAM

further illustrates the vorticity of the IFREMERLOMC and biomimicry turbine.

The wakes of IFREMER-LOMC turbine and biomimicry turbine show significant reduction of pressu-

139

re at the axial region ( z = 0) . This reduction of pressure indicates that the flow is disturbed and slowed

down by the rotating turbine. It is observed that the

dip of the pressure distribution of the biomimicry turbine at the near wake is lower than the IFREMERLOMC turbine (at y = 1.2 D , 2.0D , 3.0D and 4.0D ).

The dip of the pressure distribution of the biomimicry

turbine wake becomes higher than the dip of the pressure distribution of the IFREMER-LOMC turbine

wake further downstream from the location at y =

6.0D . This observation also strengthens the idea that

the wake recovery distance for the biomimicry turbine

is shorter than the wake recovery distance of

IFREMER-LOMC turbine wake. Figure 22 shows the

pressure distribution plot of the IFREMER-LOMC

and biomimicry turbine at near wake while Fig.23

shows the pressure distribution plot of the IFREMERLOMC and biomimicry turbine at far wake.

Validation of the OpenFOAM predicted turbine

wake axial velocity was done by referring to the experimental results from Ref.[11]. The average comparison error of the OpenFOAM predicted axial velocities

with Ref.[11] turbine ranges from 8.83%E to

3.30%E with a decreasing magnitude of %E towards downstream direction.

( y ) = 100[1 u ( y )]

(5)

R* = R + r

(6)

where u ( y ) is the mean axial velocity, R is the radius of the disc representing the turbines area of influence, z is the lateral distance, u ( y, z ) is the axial

velocity, ( y ) is the mean axial velocity deficit, R

is the radius of the turbine disc and r is the assumed

radial increment due to turbines area of influence.

Pinon et al.[11] took r 0.05 m = 0.14 R . This

enlarged the integration interval to the two nearest experimental measurement nodes outside the rotor. The

whole velocity deficit was taken into account in this

way including the velocity deficit of the biomimicry

turbine wake. Figure 24 shows the mean axial velocity

deficit graphs between wakes IFREMER-LOMC turbine and biomimicry turbine.

Fig.25 Predicted wake recovery distance of IFREMER-LOMC

turbine and biomimicry turbine simulated by

OpenFOAM on the mean axial velocity deficit against

downstream distance graph. It is about 16.0D

(11.21 m) for biomimicry turbine while it is about

17.9D (12.54 m) for IFREMER-LOMC turbine

Fig.24 Mean axial velocity deficit against downstream distance

graph for experimental and numerical results on the

wake of IFREMER-LOMC turbine and biomimicry

tidal turbine

4.3 Wake recovery distances

The mean axial velocity deficits along the downstream direction of the turbine wake were calculated

by using the integrated axial velocity deficit equations

from Ref.[11]. Equations (4)-(6) as shown below were

the related equation used in obtaining the mean velocity deficits.

u ( y) =

1

R*2

R*

R*

z u ( y, z )d y

(4)

Fig.26 Particle streamlines at zero rotational speed (Note: Left

side image shows back view while right side image

shows side view of the mentioned particles streamlines)

140

Fig.27 Particle streamlines

The curves of the mean axial velocity deficit

graph for the IFREMER-LOMC turbine and biomimicry turbine simulated by OpenFOAM were extended

forward and their intercepts on the horizontal axis,

y / D show the predicted wake recovery distances. It

was assumed that the mean axial velocity deficit curves at further downstream to be represented by natural

log equations. Thus, a logarithmic trend line is applied

to the mean axial velocity deficit curves in MS Excel.

The intercepts show the wake recovery distances for

biomimicry turbine case is about 16D (11.21 m)

while it is about 17.9D (12.54 m) for IFREMERLOMC case. This made the wake recovery distance of

the proposed biomimicry turbine 10.6% shorter than

the case of IFREMER-LOMC turbine. This implies

that the spacing of a biomimicry turbine farm in downstream direction can be shorter than the spacing of

a turbine farm from IFREMER-LOMC turbines. This

reduction in turbine spacing by implementing the proposed biomimicry turbine will increase the performance of a turbine farm as more turbines can be included

in a specific area. Figure 25 shows the predicted wake

recovery distance of IFREMER-LOMC turbine and

biomimicry turbine simulated by OpenFOAM on an

enlarged scale of the mean axial velocity deficit graph.

Validation of the OpenFOAM predicted turbine

wake mean axial velocity deficit was done by referring to the experimental results from Ref.[11]. The

average comparison error of the OpenFOAM predicted mean axial velocity deficit with Ref.[11] turbine

is 19.46%E (where %E is percentage of experimental data).

4.4 Particle streamlines

The particle streamlines obtained from the simulation results further explain why the biomimicry turbine exhibits higher torque at zero or lower rotational

speed. Swirling is clearly seen in the particle streamlines behind the biomimicry turbine while it is less obvious for the turbine of Ref.[4]. The ability to deflect

more incoming water particles into the direction tangentially to the rotational axis enables the biomimicry

turbine to generate higher torque. The spoon like

shape of the biomimicry turbine blade causes the rea-

ction forces from the deflected water particles to be

more concentrated near the blade tip. Thus, this blade

property provides longer moment arm for higher torque generation. Figure 26 shows the particle streamlines around the turbine of Ref.[4] and biomimicry

turbine at zero rotational speed.

On the other hand, the predicted particle streamlines of the wakes of IFREMER-LOMC turbine and

biomimicry turbine show similar characteristics which

is helical. However, the pitch of the helical streamlines in the near wake region was different for both

cases. From the observations, the pitch of the predicted helical streamlines for the biomimicry turbine

wake is shorter compared to IFREMER-LOMC turbine wake. The water particles at the biomimicry turbine

wake rotate more than the water particles at the

IFREMER-LOMC turbine wake. This suggests that

the biomimicry turbine is able to convert the translational energy into rotational energy effectively despite

the low operating rotational speed applied. Figure 27

shows the particle streamlines of the IFREMERLOMC turbine and biomimicry turbine.

5. Conclusions

The preliminary results from the predictions by

OpenFOAM showed the proposed biomimicry marine

current turbine inspired by Dryobalanops aromatica

seed have high potential to be implemented in the renewable energy industry as an environmental friendly

and effective energy extractor. The following are the

research findings in this study:

(1) The hydrodynamic torque produced by the

biomimicry turbine is greater than the turbine of

Ref.[4] from at lower TSR which is from TSR = 0

to TSR = 2.5 . This high torque generated by the biomimicry turbine overcome the resisting torque from

the nacelle and thus avoids rotor jamming problems.

(2) The thrust produced by the biomimicry turbine at optimum TSR, TSR = 1.5 is 13.24% greater

than the thrust produced by the turbine of Ref.[4] at

optimum TSR, TSR = 6.0 . This extra 13.24% of thrust can be overcome by strengthening the blade root

with stronger material and proper reinforcement.

141

(3) The power coefficients predicted in this study

show that the biomimicry marine current turbine operates at lower TSR. This low operating rotational

speed makes the biomimicry marine current turbine

environmental friendly as the collision risk is expected

to be relatively low compared to other conventional

marine current turbines.

(4) The near wake region of the biomimicry marine current turbine showed significant reduction in

axial velocity. This result may indicate the effectiveness in capturing incoming flow due to larger blade

area of the proposed biomimicry turbine. The far wake

region of the biomimicry marine current turbine showed that the expansion of the wake is not much different from the IFREMER-LOMC turbine wake. This

result suggests that the spacing of the biomimicry turbine farm in lateral can be the same compared to a turbine farm from IFREMER-LOMC turbines.

(5) The predicted wake recovery distances is

about 16.0D (11.21 m) for biomimicry turbine case

while it is about 17.9D (12.54 m) for IFREMERLOMC turbine. This made the wake recovery distance

of the proposed biomimicry turbine 10.6% shorter

than that of IFREMER-LOMC turbine. This short

wake recovery distance suggests that the performance

of a turbine farm will be improved by implementing

the proposed biomimicry turbine as more turbines can

be included in a specific area.

(6) The predicted water flow at the wakes of biomimicry turbine and IFREMER-LOMC turbine is helical. The shorter pitch of the helix water particle pathway at biomimicry turbine wake suggest that the biomimicry turbine is able to convert the translational

energy into rotational energy effectively despite the

low operating rotational speed applied.

Experiments will be conducted in future study to

further validate the predicted results. Through these

studies, it is hope that the proposal of this biomimicry

marine current turbine will be able to bring advancement in marine current turbine industries.

Acknowledgements

The author wish to extend his gratitude to University of Malaya for the facilities and services provided in supporting this study and also the effort in preserving the Dryobalanops aromatica trees in the campus.

References

[1] MCADAM R. A., HOULSBY G. T. and OLDFIELD M. L.

G. Experimental measurements of the hydrodynamic performance and structural loading of the transverse horizontal axis water turbine: Part 2[J]. Renewable Energy,

2013, 59(6): 141-149.

[2] MCADAM R. A., HOULSBY G. T. and OLDFIELD M. L.

G. Experimental measurements of the hydrodynamic per-

formance and structural loading of the transverse horizontal axis water turbine: Part 3[J]. Renewable Energy,

2013, 59(6): 82-91.

[3] BAHAJ A. S., MOLLAND A. F. and CHAPLIN J. R. et al.

Power and thrust measurements of marine current turbines

under various hydrodynamic flow conditions in a cavitation tunnel and a towing tank, Renew[J]. Renewable Energy, 2007, 32(3): 407-426.

[4] BAHAJ A. S., BATTEN W. M. J. and MCCANN G. Experimental verifications of numerical predictions for the

hydrodynamic performance of horizontal axis marine current turbines[J]. Renewable Energy, 2007, 32(15): 24792490.

[5] MYERS L., BAHAJ A. S. Wake studies of a 1/30th scale

horizontal axis marine current turbine[J]. Ocean Engineering, 2007, 34(5-6): 758-762.

[6] MYCEK P., GAURIER B. and GERMAIN G. et al. Experimental study of the turbulence intensity effects on marine current turbines behaviour. Part I: One single turbine[J]. Renewable Energy, 2014, 68(7): 729-746.

[7] MYCEK P., GAURIER B. and GERMAIN G. et al. Experimental study of the turbulence intensity effects on marine current turbines behaviour. Part II: Two interacting

turbines[J]. Renewable Energy, 2014, 68(7): 876-892.

[8] MYCEK P., GAURIER B. and GERMAIN G. et al. Numerical and experimental study of the interaction between

two marine current turbines[J]. International Journal of

Marine Energy, 2013, 1: 70-83.

[9] TEDDS S. C., OWEN I. and POOLE R. J. Near-wake

characteristics of a model horizontal axis tidal stream turbine[J]. Renewable Energy, 2014, 63(1): 222-235.

[10] MAGANGA F., GERMAIN G. and KING J. et al. Experimental characterisation of flow effects on marine current

turbine behaviour and on its wake properties[J]. Iet Renewable Power Generation, 2010, 4(6): 498-509.

[11] PINON G., MYCEK P. and GERMAIN G. et al. Numerical simulation of the wake of marine current turbines with

a particle method[J]. Renewable Energy, 2012, 46(5):

111-126.

[12] ZHAO Guang, YANG Ran-sheng and LIU Yan et al. Hydrodynamic performance of a vertical-axis tidal-current

turbine with different preset angles of attack[J]. Journal

of Hydrodynamics, 2013, 25(2): 280-287.

[13] WANG Ji-feng, PIECHMA Janusz and MLLER Norbert

A novel design of composite water turbine using CFD[J].

Journal of Hydrodynamics, 2012, 24(1): 11-16.

[14] MAGANGA F., PINON G. and GERMAIN G. et al. Numerical simulation of the wake of marine current turbines

with a particle method (congress)[J]. World Renewable

Energy Congress X 2008. Glasgow, UK, 2008.

[15] KANG S., BORAZJANI I. and COLBY J. A. et al. Numerical simulation of 3D flow past a real-life marine hydrokinetic turbine[J]. Advances in Water Resources, 2012,

39: 33-43.

[16] OBERKAMPF W. L., ROY C. J. Verification and validation in scientific computing[M]. New York, USA:

Cambridge University Press, 2010.

[17] ROACHE P. J. Verification of codes and calculations[J].

AIAA Journal, 1998, 36(5): 696-702.

[18] XING T., STERN F. Closure to Discussion of Factors of

safety for Richardson extrapolation[J]. Journal of

Fluids Engineering, 2011, 133(11): 115501.

[19] XING T., STERN F. Factors of safety for Richardson extrapolation[J]. Journal of Fluids Engineering, 2010,

132(6): 061403.

Vous aimerez peut-être aussi

- Wave Forces On Floating BodiesDocument4 pagesWave Forces On Floating BodiesNadji ChiPas encore d'évaluation

- Evaluation of Added Mass and Damping PDFDocument10 pagesEvaluation of Added Mass and Damping PDFNadji ChiPas encore d'évaluation

- On The Radiation and Diffraction Ofwater WavesDocument18 pagesOn The Radiation and Diffraction Ofwater WavesNadji ChiPas encore d'évaluation

- Evans 1989 - Active Devices For The Reduction of Wave IntensityDocument7 pagesEvans 1989 - Active Devices For The Reduction of Wave IntensityNadji ChiPas encore d'évaluation

- Evaluation of Added Mass and Damping PDFDocument10 pagesEvaluation of Added Mass and Damping PDFNadji ChiPas encore d'évaluation

- SPH BasicsDocument27 pagesSPH BasicsSubash Gerrard DhakalPas encore d'évaluation

- Linton 1991 - RADIATION AND DIFFRACTION OF WATER WAVES BY A SUBMERGED SPHERE IN FINITE DEPTHDocument14 pagesLinton 1991 - RADIATION AND DIFFRACTION OF WATER WAVES BY A SUBMERGED SPHERE IN FINITE DEPTHNadji ChiPas encore d'évaluation

- LOOK For FORCE - 00 Prime Scattering and Radiation of Water Waves by Permeable BreakwatersDocument13 pagesLOOK For FORCE - 00 Prime Scattering and Radiation of Water Waves by Permeable BreakwatersNadji ChiPas encore d'évaluation

- Abbreviated Hardy CrossDocument6 pagesAbbreviated Hardy CrossChun SeongPas encore d'évaluation

- Analysis of Water Distribution Networks Using MATLAB PDFDocument13 pagesAnalysis of Water Distribution Networks Using MATLAB PDFNadji ChiPas encore d'évaluation

- Multigrid IntroDocument23 pagesMultigrid IntroNadji ChiPas encore d'évaluation

- An Introduction of Multigrid Methods For Large-Scale ComputationDocument61 pagesAn Introduction of Multigrid Methods For Large-Scale ComputationNadji ChiPas encore d'évaluation

- XIX Paper 14 PDFDocument20 pagesXIX Paper 14 PDFMathiTwadCPas encore d'évaluation

- FinalThesisWork TransientDocument111 pagesFinalThesisWork Transientger80100% (2)

- PRESENTATION - Modal AnalysisDocument25 pagesPRESENTATION - Modal AnalysisNadji ChiPas encore d'évaluation

- Water Resource Engineering Illustrations Using Excel: David H. Huddleston, PH.D, P.EDocument12 pagesWater Resource Engineering Illustrations Using Excel: David H. Huddleston, PH.D, P.ENadji ChiPas encore d'évaluation

- A Review of Water Hammer Theory and PracticeDocument28 pagesA Review of Water Hammer Theory and Practicejulio49Pas encore d'évaluation

- Water Resource Engineering Illustrations Using Excel: David H. Huddleston, PH.D, P.EDocument12 pagesWater Resource Engineering Illustrations Using Excel: David H. Huddleston, PH.D, P.ENadji ChiPas encore d'évaluation

- Minor Loss of HydraulicsDocument37 pagesMinor Loss of Hydraulicsjdj2007Pas encore d'évaluation

- Experimenta and Numerical Identification of Flutter Derivatives For Nine Bridge Deck Sections (Starossek, Aslan, Thiesemann) PDFDocument35 pagesExperimenta and Numerical Identification of Flutter Derivatives For Nine Bridge Deck Sections (Starossek, Aslan, Thiesemann) PDFNadji ChiPas encore d'évaluation

- PRESENTATION - Modal AnalysisDocument25 pagesPRESENTATION - Modal AnalysisNadji ChiPas encore d'évaluation

- Materials 10 00135 ImpppDocument15 pagesMaterials 10 00135 ImpppRavi ThejaPas encore d'évaluation

- Bridge Aeroelastic Analysis - NotsubmitDocument11 pagesBridge Aeroelastic Analysis - NotsubmitingciviloctaviouamPas encore d'évaluation

- Modeling Europe With CAMx For The Air Quality Model Evaluation InternationalDocument10 pagesModeling Europe With CAMx For The Air Quality Model Evaluation InternationalNadji ChiPas encore d'évaluation

- Flutter Suppression in Long-Span Suspension Bridges by Arrays of Hysteretic Tuned Mass DampersDocument10 pagesFlutter Suppression in Long-Span Suspension Bridges by Arrays of Hysteretic Tuned Mass DampersNadji ChiPas encore d'évaluation

- Modeling Europe With CAMx For The Air Quality Model Evaluation InternationalDocument10 pagesModeling Europe With CAMx For The Air Quality Model Evaluation InternationalNadji ChiPas encore d'évaluation

- Sub-Continental Transport Mechanisms and Pathways During Two Ozone Episodes in Northern SpainDocument16 pagesSub-Continental Transport Mechanisms and Pathways During Two Ozone Episodes in Northern SpainNadji ChiPas encore d'évaluation

- Meteorology and Photochemical Air Pollution in WestDocument8 pagesMeteorology and Photochemical Air Pollution in WestNadji ChiPas encore d'évaluation

- Meteorology and Photochemical Air Pollution in WestDocument8 pagesMeteorology and Photochemical Air Pollution in WestNadji ChiPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter 12Document15 pagesChapter 12kk5522Pas encore d'évaluation

- BBO2020Document41 pagesBBO2020qiuPas encore d'évaluation

- Eco EssayDocument3 pagesEco EssaymanthanPas encore d'évaluation

- STRUNK V THE STATE OF CALIFORNIA Etal. NYND 16-cv-1496 (BKS / DJS) OSC WITH TRO Filed 12-15-2016 For 3 Judge Court Electoral College ChallengeDocument1 683 pagesSTRUNK V THE STATE OF CALIFORNIA Etal. NYND 16-cv-1496 (BKS / DJS) OSC WITH TRO Filed 12-15-2016 For 3 Judge Court Electoral College ChallengeChristopher Earl Strunk100% (1)

- APRStt Implementation Notes PDFDocument36 pagesAPRStt Implementation Notes PDFCT2IWWPas encore d'évaluation

- Material Safety Data Sheet: - AdsealDocument12 pagesMaterial Safety Data Sheet: - Adsealwuhan lalalaPas encore d'évaluation

- Your Bentley Bentayga V8: PresentingDocument9 pagesYour Bentley Bentayga V8: PresentingThomas SeiferthPas encore d'évaluation

- Maintenance Performance ToolboxDocument6 pagesMaintenance Performance ToolboxMagda ScrobotaPas encore d'évaluation

- Vignyapan 18-04-2024Document16 pagesVignyapan 18-04-2024adil1787Pas encore d'évaluation

- SCC5-4000F Single ShaftDocument15 pagesSCC5-4000F Single ShaftudelmarkPas encore d'évaluation

- Activity Sheet Housekeeping Week - 8 - Grades 9-10Document5 pagesActivity Sheet Housekeeping Week - 8 - Grades 9-10Anne AlejandrinoPas encore d'évaluation

- Caddy Arc 251i Service ManualDocument52 pagesCaddy Arc 251i Service Manualrikycien100% (8)

- Commercial BanksDocument11 pagesCommercial BanksSeba MohantyPas encore d'évaluation

- Lab Report 2Document5 pagesLab Report 2Md jubayer SiddiquePas encore d'évaluation

- MFD16I003 FinalDocument16 pagesMFD16I003 FinalAditya KumarPas encore d'évaluation

- 1000 KilosDocument20 pages1000 KilosAbdullah hayreddinPas encore d'évaluation

- Business OrganizationDocument32 pagesBusiness OrganizationSaugandh GambhirPas encore d'évaluation

- Kamapehmilya: Fitness Through Traditional DancesDocument21 pagesKamapehmilya: Fitness Through Traditional DancesValeriePas encore d'évaluation

- Overview of Incorporation in CambodiaDocument3 pagesOverview of Incorporation in CambodiaDavid MPas encore d'évaluation

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocument27 pagesChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenPas encore d'évaluation

- ФО Англ.яз 3клDocument135 pagesФО Англ.яз 3клБакытгуль МендалиеваPas encore d'évaluation

- Differential Calculus ExamDocument6 pagesDifferential Calculus ExamCaro Kan LopezPas encore d'évaluation

- Sample Valuation ReportDocument15 pagesSample Valuation Reportayush singlaPas encore d'évaluation

- Eu Clinical TrialDocument4 pagesEu Clinical TrialAquaPas encore d'évaluation

- QuerySurge Models Mappings DocumentDocument28 pagesQuerySurge Models Mappings Documentchiranjeev mishra100% (1)

- Malampaya Case StudyDocument15 pagesMalampaya Case StudyMark Kenneth ValerioPas encore d'évaluation

- Data Structures and Algorithms SyllabusDocument9 pagesData Structures and Algorithms SyllabusBongbong GalloPas encore d'évaluation

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Document44 pagesAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaPas encore d'évaluation

- PDF Synopsis PDFDocument9 pagesPDF Synopsis PDFAllan D GrtPas encore d'évaluation

- Industry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineDocument14 pagesIndustry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineCalebPas encore d'évaluation