Académique Documents

Professionnel Documents

Culture Documents

Hiller DECANTER

Transféré par

INDRAJIT SAODescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hiller DECANTER

Transféré par

INDRAJIT SAODroits d'auteur :

Formats disponibles

You can recognize a really

good idea by the fact that

its implementation seems

impossible in the first

place.

Albert Einstein

The new HILLER DecaPress

The ideal decanter!

Centrifuge technology

for municipal and industrial water

and wastewater treatment plants

"In order to get to the source,

you have to swim against the current."

Confucius

HILLER DecaPress

Diverse industrial applications demand for efficient

and cost-effective solutions for solid/liquid separating

tasks. Since its invention over 100 years ago the

solid bowl centrifuge, also called a decanter, has

established itself as conventional solution for this

task across many sectors. The majority of these

applications target the separation from the liquid

and solid phase whereby, generally, the least possible

residual moisture is required in the solid phase and

the lowest possible solid particle residues are

required in the separated liquid phase ("the

centrate").

A typical example of this type of two-phase

separation is the dewatering of sludge from

municipal or industrial sewage treatment. In this

case, the residual moisture in the dewatered solids

determines the disposal costs and the centrate

quality determines the pollution load fed back to

the treatment plant. Minimising both must be

achieved at the lowest possible cost, in plain text,

with the lowest possible polymer and energy

consumption, with low maintenance costs and with

the lowest possible number of staff deployed. In

practice, the operator quickly realises that there is

no clearly defined operating point but that daily

and seasonal fluctuations, changes in system intake

or configuration as well as malfunctions of every

sort always present new challenges that must be

met.

This is where the HILLER DecaPress has always

distinguished itself particularly well, as it is very

easy to set up and is extremely robust and stable

in everyday use, without this ease of handling

detracting from the quality of the operating results.

With the development of the new DecaPress,

HILLER has continued this tradition and all aspects

of this new machine generation have been designed

according to the motto "Quality not quantity"!

Innovative, sustainable technology

Design that optimises customer benefits

Sound, high-quality, German machine

technology

Reliable and stable operation in all

situations

Optimal operating results that stand up to

any comparison

This high level of machine technology was achieved

as a result of numerous innovations and improvements that HILLER provided for a group of experts

whose opinions are vital to us: Our Customers.

To do this HILLER made use of all the informations

from customers, regardless of whether they arose

through direct dialogue or were indirectly collected

in form of service reports by HILLER engineers. All

this data had been collected since the market launch

of the first DecaPress in 1999. They now flowed

into the design of the new machine.

That's why the new HILLER DecaPress is PURE

AND PRACTICAL! It offers decanter construction

and practicality at the highest level and is made

specifically for the customer that wants more:

More capacity - but never at the expense of

operating stability

Better separation results - constantly higher

dry substance and clearer centrate at any time

of day and in any season

Genuine peak performance - acceleration

values over 3000 x g and maximum scroll

torque available at any time, for peak loads

and for continuous operation

Lower operating costs - less polymer and

power consumption without affecting the

separation result

Investment without remorse - without any

unpleasant surprises in the maintenance costs

for the entire life of the machine

Optimal service - competent, fair, customeroriented

HILLER SEE-Drive

HILLER SEE-Control

Apart from countless improvements in detail, the

new HILLER DecaPress is distinguished by a

revolutionary drive concept: The HILLER SEE-Drive.

The new HILLER DecaPress is controlled by the

HILLER SEE-Control. This new controller was

developed in house at HILLER and is distinguished

by the following features:

The HILLER SEE-Drive is the first scroll drive that

is constructed stationary on the machine foundation

instead of being carried by the decanter rotor. This

has immediate positive effects with regard to

vibrations, bearing load, longevity, lubricant supply

and, not least, safety. The stationary construction

unlocked design options that lead to a minimisation

of the previously accepted energy loss of

conventional decanter and scroll drive systems. It

enabled splash and rolling losses in the scroll drive

to be eliminated as well as slip losses in the bowl

drive, which no longer has a belt. The HILLER SEEDrive: Stationary and Energy Efficient!

HILLER DecaPress

Maximum quality, manufactured in

Switzerland according to HILLER

specifications

Ultra-fast colour touchpanel, intense colour

and high contrast

Automatic, torque-dependent control of the

differential speed with freely adjustable

control behaviour

Evaluation and actuation of all peripheral

instruments and equipment on the decanter,

e.g. bearing temperature sensors or

lubricant pump

Communication via potential-free signals or

via Profibus DP

With the new DecaPress, SEE-Drive and SEEControl HILLER once again sets the benchmark

for reliability, ease of service, quality and efficiency

in decanter design.

HILLER looks forward to creating your customised

complete solution on this perfect basis, regardless

of whether it's a stationary or mobile installation

on a skid, trailer or in a container. Regardless of

how you want to set up your DecaPress: HILLER

is your partner of choice for reliable and highquality solutions that prove just how good a decanter

can be in practice every single day.

HILLER is providing competent solutions for these industries

and special applications:

Foods and beverages / DecaFood / OV

Mineral oil, gas, regenerative energies / DecaOil

Chemical and process industry, pharmaceutical industry / DecaChem / DecaPharm

Environmental technology / DecaPress / DecaThick / DecaDrain

Mining and tunnel construction, mineral raw materials, drilling fluids / DecaDrillingFluid

Subject to technical modification without prior notice.

Any commercial use of pictures and graphics

is only allowed after prior approval by the Hiller GmbH.

HILLER GmbH

Schwalbenholzstrae 2

84137 Vilsbiburg/Germany

Tel. +49 (0) 87 41/48-0

www.hillerzentri.de

Sales:

Tel. +49 (0) 87 41/48-164

Fax +49 (0) 87 41/48-710

e-mail: sales@hillerzentri.de

Vous aimerez peut-être aussi

- OSD Type Engl Separator WestfaliaDocument8 pagesOSD Type Engl Separator WestfaliaLTE002Pas encore d'évaluation

- Alfa Laval PHE For REFDocument4 pagesAlfa Laval PHE For REFNiraj ReginaldPas encore d'évaluation

- BTPX Series BTPX 305 SDocument4 pagesBTPX Series BTPX 305 SmcsabeeraliPas encore d'évaluation

- SJ 08 - BrochureDocument2 pagesSJ 08 - BrochureCentrifugal SeparatorPas encore d'évaluation

- TD - GSC 15-06-177 - Ecoplus - EN - KL - 4Document2 pagesTD - GSC 15-06-177 - Ecoplus - EN - KL - 4banerjeeamlanPas encore d'évaluation

- 0820 9001 000 - Moc515 Moc8015Document58 pages0820 9001 000 - Moc515 Moc8015gaby2003100% (1)

- PX 65 LeafletDocument2 pagesPX 65 LeafletrinthusPas encore d'évaluation

- Alpacon ALTREAT 400Document2 pagesAlpacon ALTREAT 400ECO Green and BluePas encore d'évaluation

- PB-05479 v00 PB300 Compact Flex OPDocument463 pagesPB-05479 v00 PB300 Compact Flex OPMichail AleksandrovPas encore d'évaluation

- Capacity WestfaliaDocument1 pageCapacity WestfaliaAlexanderPas encore d'évaluation

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićPas encore d'évaluation

- Centrifuge Manual FEUX 512Document86 pagesCentrifuge Manual FEUX 512Leonardo FerrantePas encore d'évaluation

- MIB 303 - Automatic Separation System Module - Operating Instructions - 2007Document13 pagesMIB 303 - Automatic Separation System Module - Operating Instructions - 2007Centrifugal SeparatorPas encore d'évaluation

- W-M-2421 - Otc 2Document2 pagesW-M-2421 - Otc 2Danny AriasPas encore d'évaluation

- Aldec Decanter CentrifugeDocument4 pagesAldec Decanter CentrifugejailtonpierrePas encore d'évaluation

- Seital Separation Technology - BREW CLARIFICATION PROCESS - BrochureDocument23 pagesSeital Separation Technology - BREW CLARIFICATION PROCESS - BrochureCentrifugal SeparatorPas encore d'évaluation

- Afpx 517Document2 pagesAfpx 517banerjeeamlanPas encore d'évaluation

- D5LC50 Summary Drawings ASSEMBLY: 36664: Edition Du 14/11/03Document21 pagesD5LC50 Summary Drawings ASSEMBLY: 36664: Edition Du 14/11/03Lionel TabeauPas encore d'évaluation

- Performance To Boost Power Generation - GEA Westfalia Separator EagleclassDocument20 pagesPerformance To Boost Power Generation - GEA Westfalia Separator EagleclassbanerjeeamlanPas encore d'évaluation

- 040 - 2052 9001 041Document170 pages040 - 2052 9001 041babubhaiyya4211Pas encore d'évaluation

- Gunclean Toftejorg T-73 Fixed IM-TE91A450-En3Document39 pagesGunclean Toftejorg T-73 Fixed IM-TE91A450-En3cengiz kutukcuPas encore d'évaluation

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaPas encore d'évaluation

- Separator Spares InternationalDocument8 pagesSeparator Spares InternationalAlexanderPas encore d'évaluation

- Tornado Lobe Pump BrochureDocument20 pagesTornado Lobe Pump BrochureAnonymous T7zEN6iLHPas encore d'évaluation

- SPX Seital Separation Technology - ApplicationDocument44 pagesSPX Seital Separation Technology - ApplicationmikafazPas encore d'évaluation

- Gea 1Document43 pagesGea 1Jhony Darcy Choquehuanca ReyesPas encore d'évaluation

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdPas encore d'évaluation

- AlfaLaval PX 313 Parts ManualDocument31 pagesAlfaLaval PX 313 Parts Manual81q1iyPas encore d'évaluation

- Filtrex (Eng)Document49 pagesFiltrex (Eng)hamidouhouPas encore d'évaluation

- HH 845 Render Pure Parts ManualDocument20 pagesHH 845 Render Pure Parts ManualhelbertortizPas encore d'évaluation

- Fesx 412B-30Document74 pagesFesx 412B-30Anonymous mGZOP8Pas encore d'évaluation

- GEA Separator enDocument4 pagesGEA Separator enApurba Sen SinghaPas encore d'évaluation

- MBR Decanter 9997 1227 020Document8 pagesMBR Decanter 9997 1227 020banerjeeamlanPas encore d'évaluation

- Product Range Alfa LavalDocument13 pagesProduct Range Alfa LavalSoficu DanielPas encore d'évaluation

- WSPX 209TGT-20-70 - 210TGT-20-70 - PartsDocument31 pagesWSPX 209TGT-20-70 - 210TGT-20-70 - PartsCentrifugal SeparatorPas encore d'évaluation

- Introduction To Direct Drive - BrochureDocument10 pagesIntroduction To Direct Drive - BrochureCentrifugal SeparatorPas encore d'évaluation

- Centrifuga Westfalia MOC 515 PDFDocument58 pagesCentrifuga Westfalia MOC 515 PDFgaju08Pas encore d'évaluation

- 2 Gear Drive Decanters 010807Document4 pages2 Gear Drive Decanters 010807banerjeeamlanPas encore d'évaluation

- February 2018Document64 pagesFebruary 2018Treatment Plant Operator MagazinePas encore d'évaluation

- PX 70 - 80 - (Non EX & EX) - Foundation DrawingDocument1 pagePX 70 - 80 - (Non EX & EX) - Foundation DrawingCentrifugal SeparatorPas encore d'évaluation

- Electrical Load - Full Operation ModeDocument14 pagesElectrical Load - Full Operation ModeAris KancilPas encore d'évaluation

- Product Catalogue Hägglunds CBM: Radial Piston Hydraulic MotorDocument36 pagesProduct Catalogue Hägglunds CBM: Radial Piston Hydraulic MotorsoniaPas encore d'évaluation

- Separators From GEA Westfalia Separator For The Dairy IndustryDocument40 pagesSeparators From GEA Westfalia Separator For The Dairy IndustryYacinePas encore d'évaluation

- Disc Separator SpecificationDocument4 pagesDisc Separator SpecificationyovanPas encore d'évaluation

- Compatible Spare Parts FOR Centrifugal Separators: Alfa LavalDocument4 pagesCompatible Spare Parts FOR Centrifugal Separators: Alfa LavalJerom RonquilloPas encore d'évaluation

- Parts Catalogue: Model: Serial-No.: Bowl S/N: Order-No.Document58 pagesParts Catalogue: Model: Serial-No.: Bowl S/N: Order-No.Jhonathan RodriguezPas encore d'évaluation

- Centrifugal Filter UpgradeDocument10 pagesCentrifugal Filter UpgradeAndrew Park100% (1)

- WSST Oi Ose 5 10 20 40 80 enDocument2 pagesWSST Oi Ose 5 10 20 40 80 enjing qiangPas encore d'évaluation

- Epc 50Document1 pageEpc 50mihalikj2190Pas encore d'évaluation

- Separator Manual High Speed Separator: MMB 305S-11Document164 pagesSeparator Manual High Speed Separator: MMB 305S-11Bima Surya UtamaPas encore d'évaluation

- Sondex S7A-S14A-S20A-IDocument2 pagesSondex S7A-S14A-S20A-IEdwin GallegosPas encore d'évaluation

- Instruction Manual: Mineral Oil Centrif Uge With Self-Cleaning Bow L OSE 5-91-037Document210 pagesInstruction Manual: Mineral Oil Centrif Uge With Self-Cleaning Bow L OSE 5-91-037Thineshraaj Naidu JayaramanPas encore d'évaluation

- Purifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsDocument4 pagesPurifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsJohn Lemuel Arquisola0% (1)

- MAPX 207S-20 - Instructions Book - RUDocument117 pagesMAPX 207S-20 - Instructions Book - RUCentrifugal SeparatorPas encore d'évaluation

- Aldec G2 PDFDocument2 pagesAldec G2 PDFJulio TovarPas encore d'évaluation

- SA - Separation System - Operating Instructions - 2002Document30 pagesSA - Separation System - Operating Instructions - 2002Centrifugal SeparatorPas encore d'évaluation

- Tranter PHE GCD-09 X 43Document4 pagesTranter PHE GCD-09 X 43alokPas encore d'évaluation

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairPas encore d'évaluation

- DH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsDocument16 pagesDH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsVijay KumarPas encore d'évaluation

- Understanding Infrared Thermography Reading 6 (PDFDrive) PDFDocument510 pagesUnderstanding Infrared Thermography Reading 6 (PDFDrive) PDFINDRAJIT SAOPas encore d'évaluation

- Action Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!Document1 pageAction Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!INDRAJIT SAOPas encore d'évaluation

- V-Imp - USA-Diagonostics Important PaperDocument81 pagesV-Imp - USA-Diagonostics Important PaperINDRAJIT SAOPas encore d'évaluation

- Estad-Jsi 2014Document3 pagesEstad-Jsi 2014INDRAJIT SAOPas encore d'évaluation

- Three Common Mistakes in LubricationDocument11 pagesThree Common Mistakes in LubricationINDRAJIT SAOPas encore d'évaluation

- A Practical Approach For Evaluating Oil Analysis Results With Limit ValuesDocument12 pagesA Practical Approach For Evaluating Oil Analysis Results With Limit ValuesINDRAJIT SAOPas encore d'évaluation

- Tags and Labels Billet MarkingDocument2 pagesTags and Labels Billet MarkingINDRAJIT SAOPas encore d'évaluation

- Kaizen TrainingDocument5 pagesKaizen TrainingINDRAJIT SAOPas encore d'évaluation

- Coke Making in Byproduct Coke Oven Batteries - e Plant MaintenanceDocument13 pagesCoke Making in Byproduct Coke Oven Batteries - e Plant MaintenanceINDRAJIT SAO0% (1)

- Billet MarkerDocument4 pagesBillet MarkerINDRAJIT SAOPas encore d'évaluation

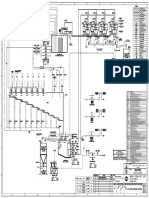

- Ash Handling P&IDDocument1 pageAsh Handling P&IDINDRAJIT SAOPas encore d'évaluation

- NASA - Safety For Oxygen Systems GuidelinesDocument288 pagesNASA - Safety For Oxygen Systems GuidelinesINDRAJIT SAO100% (1)

- Ox Ygen System Safety: ScopeDocument4 pagesOx Ygen System Safety: ScopeINDRAJIT SAOPas encore d'évaluation

- Summer Training: Submitted ByDocument29 pagesSummer Training: Submitted ByBadd ManPas encore d'évaluation

- HT32F1655-1656 Datasheet v100Document48 pagesHT32F1655-1656 Datasheet v100Viktor SpeicherPas encore d'évaluation

- Poster Vourch Et Al IEEE Sensors 2013dDocument1 pagePoster Vourch Et Al IEEE Sensors 2013dMarcelo BaptistaPas encore d'évaluation

- Group Chat Project ReportDocument18 pagesGroup Chat Project ReportSoham JainPas encore d'évaluation

- Specifications of 3c20ks-lcd En-Sp011222-3c20ks-LcdDocument4 pagesSpecifications of 3c20ks-lcd En-Sp011222-3c20ks-LcdBbb AaaPas encore d'évaluation

- Analyzing Art Culture and Design in TheDocument23 pagesAnalyzing Art Culture and Design in TheLívia NonatoPas encore d'évaluation

- Software Dev Processes Project 1Document2 pagesSoftware Dev Processes Project 1ereter50% (8)

- Google Chrome Keyboard ShortcutsDocument2 pagesGoogle Chrome Keyboard ShortcutsMaRkY A1r0E1s6Pas encore d'évaluation

- Mandriva Linux One 2009: Starter GuideDocument10 pagesMandriva Linux One 2009: Starter GuideDarren JayPas encore d'évaluation

- Dnp3 Master Ethernet ManualDocument143 pagesDnp3 Master Ethernet ManualunnikuttanPas encore d'évaluation

- XK3100 Series IbnDocument9 pagesXK3100 Series IbnLuis HuertaPas encore d'évaluation

- Lab FilmsDocument7 pagesLab FilmsSantiago AliPas encore d'évaluation

- DEEP SEA - DSE8620-MKII - Installation InstructionsDocument2 pagesDEEP SEA - DSE8620-MKII - Installation InstructionsGustavo DuartePas encore d'évaluation

- TA30 - G7 Service ManualDocument436 pagesTA30 - G7 Service ManualAndrés Aroca93% (14)

- Presentation On Core JavaDocument16 pagesPresentation On Core Javaprince himanshu0% (1)

- ABX00063 SchematicsDocument8 pagesABX00063 SchematicsIoan TudosaPas encore d'évaluation

- Extio 2 Remote Peripheral Solutions Installation Kit Instruction EP-DPCX24Document98 pagesExtio 2 Remote Peripheral Solutions Installation Kit Instruction EP-DPCX24akramhomriPas encore d'évaluation

- Q3. Quiz1Document2 pagesQ3. Quiz1Jinkee F. Sta MariaPas encore d'évaluation

- CS544 - Cloud Application DevelopmentDocument3 pagesCS544 - Cloud Application DevelopmentMayur PatilPas encore d'évaluation

- Schrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysDocument3 pagesSchrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysJadi PurwonoPas encore d'évaluation

- Volvo Transport SolutionsDocument16 pagesVolvo Transport SolutionsForomaquinas100% (1)

- Sample Assignment of Robotics PDFDocument2 pagesSample Assignment of Robotics PDFKamal PatelPas encore d'évaluation

- Modula WMSDocument8 pagesModula WMSIbai Zabala BengoaPas encore d'évaluation

- Spec Sheet - 60cm 5 Function Built-In Oven Stainless Steel + Black Glass - HNTB65XLDocument2 pagesSpec Sheet - 60cm 5 Function Built-In Oven Stainless Steel + Black Glass - HNTB65XLJohn MurdochPas encore d'évaluation

- Pengenalan Dan Pemanfaatan Marketplace E-Commerce Untuk Pelaku Ukm Wilayah CilegonDocument8 pagesPengenalan Dan Pemanfaatan Marketplace E-Commerce Untuk Pelaku Ukm Wilayah CilegonPemetaanPendidikanPas encore d'évaluation

- DFC-90 Cirrus Config and Testing AVDFC-096Document15 pagesDFC-90 Cirrus Config and Testing AVDFC-096Anderson RamalhoPas encore d'évaluation

- Preparing For Successful Data Integrity AuditsDocument23 pagesPreparing For Successful Data Integrity AuditsDante Iulli100% (1)

- OSPF Part of The CCIE EI Workbook Orhan ErgunDocument123 pagesOSPF Part of The CCIE EI Workbook Orhan ErgunYoussef Fatihi100% (1)

- Advanced Lidar Data Processing With LastoolsDocument6 pagesAdvanced Lidar Data Processing With Lastoolsaa_purwantaraPas encore d'évaluation

- Integrated Language Environment: AS/400 E-Series I-SeriesDocument15 pagesIntegrated Language Environment: AS/400 E-Series I-SeriesrajuPas encore d'évaluation