Académique Documents

Professionnel Documents

Culture Documents

DFM Injection Molding Analysis 0614

Transféré par

anjal22Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DFM Injection Molding Analysis 0614

Transféré par

anjal22Droits d'auteur :

Formats disponibles

Design for Manufacturing

Analysis

How the DFM Analysis Will Save Your Project

Design For Manufacturing Analysis

Table of Contents

1

Introduction 3

Part Orientation and Parting Line 4

Draft Analysis

Features Requiring Side Actions 5

Ribs/Bosses to Wall Thickness Ratio 5

Thickness Analysis 6

Warp Analysis 6

Shut-off Conditions 7

Thin Tool Conditions 7

10

Areas Requiring EDM 8

11

Weld Lines 8

12

2D Print Review 9

Page 2

Design For Manufacturing Analysis

Introduction

When designing injection molded plastic parts, engineers

are often tasked with a common problem: making sure their

design is optimized to meet the guidelines of the process,

while simultaneously maintaining the designs intent. More

often than not, this becomes a two-way street, and a strong

relationship between engineer and toolmaker can be

invaluable.

Id estimate that about 80% of new tooling projects we

see require some form of modification to the 3D data, says

Andy Richardson, Senior Director of Inside Sales and Service.

Whether its a draft angle, a thickness concern, or a shut-off

condition that would result in decreased tool life, even the

most experienced engineers can overlook particular details.

In the modern era of manufacturing where time is

increasingly becoming more and more critical in the race

to get product to market, knowing how to optimize a

design for molding is a key component for any product

development group. The team at Quickparts strongly

believes that early detection of a questionable design

goes a long way. Quick feedback, technical banter, and

an in-depth Design for Manufacturing analysis (DFM) can

save a busy team of engineers time, money and, perhaps

most important, the headache of endless revisions to an

upcoming product.

Quickparts Design for Manufacturing analysis encompasses

injection molding requirements for specific part geometry.

Sections are dedicated to: Parting Line and Orientation,

Draft Analysis, Features Requiring Side Actions, Rib/Bosses

to Wall Thickness Ratio, Thickness Analysis, Warp Analysis,

Shut-off Conditions, Thin Tool Conditions, Areas Requiring

EDM, Weld Lines, as well as a comprehensive review of any

provided 2D prints. Each page is color-coded in order to

display a unique level of concern. Much like a traffic light,

green means go (good design), yellow means yield (review

of minor issue), and red means stop (unable to proceed

without modification). A more detailed look into each facet

of the DFM process is listed below.

Page 3

Design For Manufacturing Analysis

Part Orientation and Parting Line

Simply put, a parting line is the place where each part of the

mold halves meet. Parting lines occur as a result of small gaps

between the two mating faces of each mold half. Parting lines

generally show up as a tiny raised line on the surface of a

plastic part. When the part is ready for ejection and the mold

halves separate, excess plastic, known as gate vestige, is left

behind. Knowing ahead of time where the parting line will

be located can be essential to part function, as the remaining

gate vestige can interfere with sealing surfaces and critical

mating features.

Draft Analysis

Knowing how and where to correctly apply draft can be the

difference between a strikeout and a home run. The existence

of draft on vertical surfaces and for the removal of slides

enables a part to be easily removed from the mold. Generally

speaking, draft requirements differ from part to part, and some

designs allow for little to no draft; however, most designs

call for at least a half degree of draft on vertical walls. When

designing an assembly, it is important to account for draft

consistency from one design to its corresponding mate. More

aggressive textures require more draft, and vice versa. Its

perfectly acceptable to submit a preliminary design without

draft; the intent of the DFM review is to educate the engineer

as to where, and sometimes why, draft is required in specific

areas. The slightest of draft modifications can be the difference

between a red and green slide.

Page 4

Design For Manufacturing Analysis

Features Requiring Side Action

Parts with features that are not located within the line of draw

of the tool will require mechanisms to facilitate part production.

The term side action can take on a variety of synonyms (hand

loads, slides, cams, etc.), all of which can play a major role in

tooling and piece pricing. Modifying a design to eliminate a side

action can allow for quicker delivery and a less prohibitive cost.

Identifying these features in the early stages of design can go a

long way. There are many ways to design around a side action,

but the first step is identifying where the features exist, and

then understanding why the side action is required. Once the

initial education is in place, design alternatives can be explored,

paving the way for a cost saving opportunity.

Ribs/Bosses to Wall Thickness Ration

The backbone of any plastic part lies in the integration of

ribs and bosses. Not only do these features provide structural

integrity, but they also assist in reducing the amount of

potential warp a part can have. However, a poor rib and boss

design can lead to drastic results in the form of undesirable

cosmetic sink. A good rib/boss design will generally show

a thickness of 50%-60% of the corresponding nominal wall,

with the height of these features not exceeding three times

the thickness of the nominal wall. At times, exceeding this

ratio can be unavoidable, but with early feedback via DFM,

there should be no surprises when molded samples are

delivered. Educating a part designer up front via graphical

representations and screen shots showing where and why sink

can occur can lead to alternative options surrounding each

area in question. The resulting T1 samples will surely cut down

on costly mold modifications that could have occurred had

preliminary feedback not been provided.

Good Rib & Boss

Design

Page 5

Design For Manufacturing Analysis

Thickness Analysis

Generally speaking, each grade of plastic resin has a unique

recommended minimum and maximum wall thickness.

Understanding the constraints of prospective resins can give

any engineer an edge when designing a part. Certain resins

are able to accommodate thinner-walled designs, while others

cater to thicker, bulkier designs. When selecting a resin, the

best course of action is to contact a material representative.

Based on the desired grade, a DFM review can provide muchneeded insight into the wall thickness limitations of a design,

thus clearing the path for uninhibited part design.

Warp Analysis

As mentioned earlier, ribs and bosses play a crucial role in

supporting a plastic part. Parts with open faces and long, thin

unsupported walls can lead to warp, which can be a disaster

when trying to assemble a group of designs. Knowing when

and where to add a rib to an unsupported wall can lead to

a much better design. A DFM analysis will certainly identify

potential areas of improvement by taking these concerns

into account. The last thing an engineer wants to stomach is a

circuit board housing shaped like a crispy potato chip!

Page 6

Design For Manufacturing Analysis

Shut-Off Conditions

A shut-off refers to an area on a part that is created by mold

halves coming together (metal sliding on metal). A minimum

of three degrees of draft is required on all shut-off conditions.

Anything less could potentially result in shortened tool life,

excessive flash, and part ejection failure. In the latter example,

the mold would lock up and be unable to open. An upfront

understanding of how shut-off features play a key role in

the injection molding process is crucial; otherwise, a rude

awakening is certainly in store. Parts delivered with excessive

flash, along with a mold life barely able to exceed 1000 parts,

are never a good sign.

Thin Tool Conditions

Making sure a part design does not include any thin tool

conditions will ensure a longer tool life, consistent geometry

from part to part, and can avoid hefty maintenance fees down

the road. As a rule of thumb, any area on a part that requires

tool metal of less than 0.050 has a higher probability of tool

failure during a future run of parts than features exceeding this

benchmark. As a general rule, the depth vs. width ratio of a

feature should not exceed 3:1. These marks are by no means a

showstopper and can be overcome with good tool design, but

they may increase the cost of producing your mold. Keep in

mind that the thinner the tool metal, the lesser the likelihood

of a longstanding, reliable mold.

Page 7

Design For Manufacturing Analysis

10

Areas Requiring EDM

EDM stands for Electrical Discharge Machining, sometimes

referred to as burning or sparking. The process is used when a

desired shape, often very sharp corners or deep ribs, cannot be

constructed within the mold via the traditional CNC machining

operation. Material is removed from the mold by a series of

rapidly recurring current discharges between two electrodes,

separated by a dielectric liquid and subjected to an electric

11

voltage. Features with sharp corners or a height-to-thickness

ratio of 8:1 require EDM. Why is this important? EDM, although a

generally common means of tool manufacture, does add to the

upfront cost of the mold. Knowing ahead of time which features

will require EDM can allow an engineer to round off sharps,

avoid the extra work, and save time and money.

Weld Lines

Whenever plastic must flow around an obstruction, such as

a hole, it will inevitably meet up and form a weld line. This is

usually a slightly visible line and is often mistaken for a crack

in a part. Avoiding weld lines can be tricky, and sometimes an

alternative gating strategy can be implemented to alter the

flow of material in order to save a cosmetic or weaker surface.

Parts with multiple obstructions to material flow tend to

have more weld lines than others. Early design feedback can

certainly limit the presence of weld lines.

Page 8

Design For Manufacturing Analysis

12

2D Print Review

Although a 2D print is not required, it is always helpful,

especially if there are critical features that justify special

attention. Standard part tolerance expectations are +/- 0.005;

however, it is possible to achieve tighter tolerances on a

case-by-case basis. Drawings with such callouts are highly

encouraged, as an overwhelming majority of molders build

specifically off of the 3D CAD model. A thorough review of any

2D print via DFM analysis will provide a better understanding

of the expectations of both the customer and the supplier,

both of which will lead to a more streamlined process in

which the best product can be delivered.

With any molded part design, either in its infancy or nearing

its production release, Quickparts strongly encourages all

customers to submit their design for DFM. The earlier the

feedback, the easier it will be to optimize, which in turn will

make the injection molding process smoother, thus saving

time, money, and stress.

Contact us now to have your design evaluated. Our team of

experienced salespeople and engineers are happy to help, no

matter which stage of the program you find your design.

3D Systems Corporation | Quickparts Solutions | 301 Perimeter Center North, Suite 400 | Atlanta, GA 30346 | USA

Toll Free: +1 877.521.8683 | Tel: +1 770.901.3200 | quote@quickparts.com | www.3dsystems.com/quickparts

Page 9

Vous aimerez peut-être aussi

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3D'EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Pas encore d'évaluation

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2D'EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Pas encore d'évaluation

- Plastic Part DesignDocument10 pagesPlastic Part Designalidani_1Pas encore d'évaluation

- Design For Mouldability-UK092010Document16 pagesDesign For Mouldability-UK092010mjobson100% (1)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1D'EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Évaluation : 5 sur 5 étoiles5/5 (2)

- 9 Ejection System PDFDocument10 pages9 Ejection System PDFBa BuPas encore d'évaluation

- Chapter 2 Injection MoldsDocument83 pagesChapter 2 Injection MoldsRadia ElkhaniPas encore d'évaluation

- Runners and GatesDocument35 pagesRunners and Gatesbjdavies2010100% (2)

- Clamping Force & Tonnage CalculationDocument3 pagesClamping Force & Tonnage CalculationJyoti KalePas encore d'évaluation

- Theory of Moulds - ContentsDocument9 pagesTheory of Moulds - Contentsnagesh_sprao19275% (4)

- Moulding Technology: by Balraj TanwarDocument37 pagesMoulding Technology: by Balraj TanwarVinod KumarPas encore d'évaluation

- Tooling Standards Manual: MouldsDocument36 pagesTooling Standards Manual: Mouldsandre boniniPas encore d'évaluation

- Injection Molding SchematicDocument15 pagesInjection Molding SchematicSourav DipPas encore d'évaluation

- Mold Design FeasabilityDocument16 pagesMold Design FeasabilitySreedhar PugalendhiPas encore d'évaluation

- Injection Mold Design DetailsDocument43 pagesInjection Mold Design DetailsKen100% (1)

- Mould Starndard Parts PDFDocument13 pagesMould Starndard Parts PDFMohd Nazri SalimPas encore d'évaluation

- Techdesign Study: Plastic Mould Technology Duration: 30 DaysDocument14 pagesTechdesign Study: Plastic Mould Technology Duration: 30 DaysAnkit NaphadePas encore d'évaluation

- Injection Mould PDFDocument256 pagesInjection Mould PDFEdo KarmawiPas encore d'évaluation

- Mold and Die - PPTDocument110 pagesMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

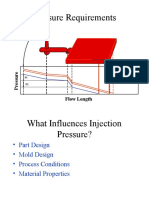

- Pressure Requirements: Flow LengthDocument43 pagesPressure Requirements: Flow Lengthanirudha_jewalikar1100% (2)

- Mould Theory PDFDocument35 pagesMould Theory PDFArunava Bala75% (4)

- 6 Plastic Part Defect - 0Document27 pages6 Plastic Part Defect - 0allrounder_mannPas encore d'évaluation

- Mold Spec GuideDocument25 pagesMold Spec Guidemrj27050% (2)

- Protomold - Design For Mold AbilityDocument16 pagesProtomold - Design For Mold Abilitylanning15Pas encore d'évaluation

- Feed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andDocument26 pagesFeed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andS Karthick KeyanPas encore d'évaluation

- Typical Plastic Design ChecklistDocument6 pagesTypical Plastic Design ChecklistAlex DobrescuPas encore d'évaluation

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85Pas encore d'évaluation

- Protomold Cube KeyDocument2 pagesProtomold Cube KeyMarius MarchisPas encore d'évaluation

- Plastic Injection Molding Write UpDocument16 pagesPlastic Injection Molding Write UpVishal MahajanPas encore d'évaluation

- Molding CavityDocument7 pagesMolding CavitySudarno BaraPas encore d'évaluation

- PIM 101 Ebook-1Document33 pagesPIM 101 Ebook-1agniflamePas encore d'évaluation

- Injection Molding Defect OzDocument12 pagesInjection Molding Defect Oztopkaya100% (1)

- Introduction To Plastic Part DesignDocument61 pagesIntroduction To Plastic Part DesignVIGNESHPas encore d'évaluation

- Mould Design Part OneDocument15 pagesMould Design Part Oneazizmaarof100% (3)

- Injection Molded Part Problems & Solutions With: SkillbuilderDocument2 pagesInjection Molded Part Problems & Solutions With: SkillbuilderradzPas encore d'évaluation

- Blow Molding Design GuidlinesDocument13 pagesBlow Molding Design Guidlinesmayank123Pas encore d'évaluation

- Snap Fit DesignDocument4 pagesSnap Fit DesignJagadish_kPas encore d'évaluation

- PS Injection Mold Tool StandardsDocument107 pagesPS Injection Mold Tool StandardsНикола МедићPas encore d'évaluation

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyPas encore d'évaluation

- C8ff2ca9 7642 4e7c Bbf0 8231c2f9c870 - RT - 1317 - Us Ejection, Venting and CoolingDocument23 pagesC8ff2ca9 7642 4e7c Bbf0 8231c2f9c870 - RT - 1317 - Us Ejection, Venting and CoolingEdenilson FadekPas encore d'évaluation

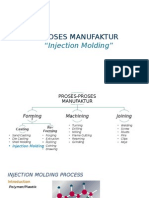

- Injection MoldingDocument23 pagesInjection MoldingAditya DhikaPas encore d'évaluation

- Injection Molding Troubleshooting Flash BurnmarksDocument60 pagesInjection Molding Troubleshooting Flash Burnmarkswawawa1100% (1)

- Injection Moulding REPORT PDFDocument10 pagesInjection Moulding REPORT PDFmiraPas encore d'évaluation

- POM - Delrin Molding Guide-1Document48 pagesPOM - Delrin Molding Guide-1Ana Claudia Machado100% (1)

- Misumi Press Die StandardDocument72 pagesMisumi Press Die StandardthanhvutsmvnPas encore d'évaluation

- Design Guide For Reaction Injection Molded Plastic PartsDocument26 pagesDesign Guide For Reaction Injection Molded Plastic Partsxeron7126Pas encore d'évaluation

- Two Plate Three PlateDocument15 pagesTwo Plate Three PlateHarshvardhan KharatPas encore d'évaluation

- Injection Mold Standards 80 Eng D 20Document21 pagesInjection Mold Standards 80 Eng D 20Deep ShahPas encore d'évaluation

- Joining Methods: Tolerances: Fit Between PartsDocument11 pagesJoining Methods: Tolerances: Fit Between PartsChiara RipaltiPas encore d'évaluation

- Injection Molding MethodsDocument23 pagesInjection Molding MethodsKi SeyPas encore d'évaluation

- Cavity Mold Cooling Construction DesignDocument141 pagesCavity Mold Cooling Construction DesignJayson Serato50% (2)

- Injection MouldinDocument32 pagesInjection MouldinKarthick KarthickPas encore d'évaluation

- Seminar On Split Cavity MouldDocument43 pagesSeminar On Split Cavity MouldasgrutuPas encore d'évaluation

- Injection Mold Design Engineering Complete Self-Assessment GuideD'EverandInjection Mold Design Engineering Complete Self-Assessment GuidePas encore d'évaluation

- Resume That Gets Results PresentationDocument21 pagesResume That Gets Results Presentationanjal22Pas encore d'évaluation

- Van EssenDocument26 pagesVan Essenanjal22Pas encore d'évaluation

- 1) WhatDocument190 pages1) Whatanjal22Pas encore d'évaluation

- DX5100 Manual V3.37Document56 pagesDX5100 Manual V3.37anjal22Pas encore d'évaluation

- DX5100 Manual V3.37Document56 pagesDX5100 Manual V3.37anjal22Pas encore d'évaluation

- Creep Analysis With SolidworksDocument3 pagesCreep Analysis With Solidworksanjal22Pas encore d'évaluation

- Tablecurve2d 5 01 BrochureDocument4 pagesTablecurve2d 5 01 Brochureanjal22Pas encore d'évaluation

- BS en 16729-1Document40 pagesBS en 16729-1Anonymous ihanyMJPas encore d'évaluation

- Some Information About Edm EBM and LBMDocument6 pagesSome Information About Edm EBM and LBMRuchin ChahwalaPas encore d'évaluation

- PC-DMIS EDM Preset and Measure Brochure - enDocument4 pagesPC-DMIS EDM Preset and Measure Brochure - enAntonio CristianoPas encore d'évaluation

- NADCAP Checklist ListingDocument6 pagesNADCAP Checklist ListingMajid Shakeel100% (2)

- Epri 501a-DDocument154 pagesEpri 501a-DEKKACHAI PRABNAKORN100% (2)

- 1 s2.0 S0141635914002025 Main PDFDocument6 pages1 s2.0 S0141635914002025 Main PDFMark JamesPas encore d'évaluation

- Wire CutDocument3 pagesWire CutMahmoud ElsayedPas encore d'évaluation

- 18 International Metallurgy and Materials Congress: Beyond 45Document12 pages18 International Metallurgy and Materials Congress: Beyond 45levent oncelPas encore d'évaluation

- Objective Question Bank AMPDocument16 pagesObjective Question Bank AMPSANJAY KUMAR YADAV MtechPas encore d'évaluation

- CONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFDocument4 pagesCONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFjjzoranPas encore d'évaluation

- Square Hole Drilling MachineDocument4 pagesSquare Hole Drilling Machineedisonmech_erfPas encore d'évaluation

- List of Tesda Training Regulations As of 2020Document5 pagesList of Tesda Training Regulations As of 2020Aljon BalanagPas encore d'évaluation

- CIRP Annals - Manufacturing Technology: X. Cheng, K. Nakamoto, M. Sugai, S. Matsumoto, Z.G. Wang, K. YamazakiDocument6 pagesCIRP Annals - Manufacturing Technology: X. Cheng, K. Nakamoto, M. Sugai, S. Matsumoto, Z.G. Wang, K. YamazakiAmália EirezPas encore d'évaluation

- Aerospace ComponentsDocument16 pagesAerospace Componentsvigneshkumar rajan0% (1)

- Automation CIM Groover 4th Edition - PDF - by EasyEngineering - Net-2Document28 pagesAutomation CIM Groover 4th Edition - PDF - by EasyEngineering - Net-2Rishabh SrivastavaPas encore d'évaluation

- CFD Analysis of Flow PatternDocument100 pagesCFD Analysis of Flow Patternramkumar121Pas encore d'évaluation

- ME8073 - Unconventional Machining Process (Ripped From Amazon Kindle Ebooks by Sai Seena)Document260 pagesME8073 - Unconventional Machining Process (Ripped From Amazon Kindle Ebooks by Sai Seena)Johnson JohnsonPas encore d'évaluation

- DFM Injection Molding Analysis 0614Document9 pagesDFM Injection Molding Analysis 0614anjal22Pas encore d'évaluation

- An Empirical Study of Parameters in AbrasiveDocument9 pagesAn Empirical Study of Parameters in AbrasiveAneesh Kumaar IyyapphanPas encore d'évaluation

- Reference Standards Calibration Blocks: NDT IndustryDocument46 pagesReference Standards Calibration Blocks: NDT IndustryNaik Kiran GopiPas encore d'évaluation

- VTU SEM 1 Scheme of Evaluation and SyllabusDocument13 pagesVTU SEM 1 Scheme of Evaluation and SyllabusAdilHEngineerPas encore d'évaluation

- Materials Today: Proceedings: N.E. Arun Kumar, N. Sathishkumar, E. Raviraj, M. Pathri Narayanan, Roderik EugeneDocument8 pagesMaterials Today: Proceedings: N.E. Arun Kumar, N. Sathishkumar, E. Raviraj, M. Pathri Narayanan, Roderik EugeneGopinath GangadhariPas encore d'évaluation

- MicroMachiningTechAssessment 0209 TECHDocument239 pagesMicroMachiningTechAssessment 0209 TECHds_srinivasPas encore d'évaluation

- SARIXF SX 3D e 05Document2 pagesSARIXF SX 3D e 05regil01Pas encore d'évaluation

- Non Traditional MachiningDocument17 pagesNon Traditional MachiningLeo Dev WinsPas encore d'évaluation

- EDM Today, September/October 2009 IssueDocument4 pagesEDM Today, September/October 2009 Issuefeni4kaPas encore d'évaluation

- Mech3002y 3 2015 2Document7 pagesMech3002y 3 2015 2Keshav GopaulPas encore d'évaluation

- MT System Technical Manual PDFDocument56 pagesMT System Technical Manual PDFsowjanya gaddalaPas encore d'évaluation

- Department of Mechanical Engineering Question Bank 15ume911 Unconventional Machining Processes Unit - I Part ADocument6 pagesDepartment of Mechanical Engineering Question Bank 15ume911 Unconventional Machining Processes Unit - I Part ANagarajPas encore d'évaluation

- MetalSamples General Catalog XIIIDocument40 pagesMetalSamples General Catalog XIIIDavid Cruz ZamoraPas encore d'évaluation