Académique Documents

Professionnel Documents

Culture Documents

2012 Tech Insp Review Part 1

Transféré par

Anonymous 4ot6aS9Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2012 Tech Insp Review Part 1

Transféré par

Anonymous 4ot6aS9Droits d'auteur :

Formats disponibles

A

TECHNICAL INSPECTORS GUIDE

TO THE

2012 FSAE RULES

PART 1

RULES CHANGE SUMMARY

&

ADMINISTRATIVE CHANGES

2012 FSAE Rules

Format

Index

Introduction

Part A - Administrative Regulations

Appendix S - SAE Technical Standards

Part B - Technical Regulations

Technical Drawings

o Appendix AF - Alternative Frame Rules

o Appendix B-1, Structural Equivalency Form (2 pages)

o Appendix B-2, Impact Attenuator Data Report (3 pages)

Part C - Static Event Regulations

o Appendix C-1 thru C-5 Cost Event Appendices

o Appendix C-6 Presentation Judging

o Appendix C-7 Design Judging

Part D - Dynamic Event Regulations

Rules Changes for 2012

For the benefit of the teams, below is a summary of the major rules changes for the 2012

Formula SAE competitions. It is not a complete list. If there are any differences between this

summary and the official Rules, the Rules will prevail. Therefore, it is the responsibility of the

competitors to read the Rules thoroughly.

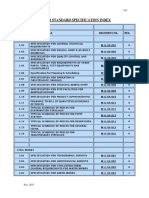

Rule

Number

System

Change

Forms

Standard forms have been relocated to www.fsaeonline.com

A.8.5 & A.8.6

Documentation

FSAE Michigan & Lincoln-many of documents & submissions

have to be submitted on line.

A.8.1

Forms

A Structural Equivalency Spreadsheet (SES) replaces the

Structural Equivalency Form (SEF)

B.3.4.5

Tubing

Extra bracing required for bent tubes in the Primary Structure

B.3.21.11

Std Attenuator

Diagonal or X-brace required with Standard IA.

B.24.3

Side Impact Str.

ALL of top tube must be between 300 & 350 mm above ground.

B.6.2

Ground Clearance

Exact dimension deleted. Must be sufficient. (No sliding skirts.)

B.6.6.2

Jacking Point

Must have unobstructed access from rear. (Relaxed aero rules.)

Rules Changes for 2012 (contd)

Rule

Number

System

Change

B.11.4

Batteries

Restrictions & requirements on batteries other than lead-acid.

B.15

Transponders

AMB 260 TraX260 units are now MYLAPS Car/Bike (name change)

B.17.5

Drivers Suits

Triple layer suits (SFI 3-2A/5 & FIA) now mandatory.

D.13.1.2 Vehicle Movement

Changes to requirements on how a car can be moved in paddock.

Article A - Administrative

Forms The standard forms that are required for documentation and

submissions at FSAE competitions have been relocated to

www.fsaeonline.com

A8.5 Web Based Submission FSAE Michigan and FSAE Lincoln

Only Many of the required documents must now be submitted online

through www.fsaeonline.com.

A8.6 Account Signup for Online Submission FSAE Michigan

and FSAE Lincoln Only Teams must comply with certain

requirements when registering at www.fsaeonline.com and submitting

documents online.

Article A8 - Vehicle Documentation, Deadlines &

Penalties

A8.1 Required Documents and Required Forms

The following documents supporting each vehicle must be submitted by the action

deadlines posted on each competition website or otherwise published by the

organizers.

B3.8 Structural Equivalency Spreadsheet (SES) and Appendix B-1 - Use

required form located at www.fsaeonline.com: or AF2 Structural Requirements

Certification Form (SRCF) - Use required form located at www.fsaeonline.com.

Note Teams must submit an SES unless using the AF Rules in which case the

SES is superseded by the SRCF. Submit either the SES or the SRCF as required,

but not both.

B3.21 Impact Attenuator Data Requirement - Use required form located at

www.fsaeonline.com.

Article B.3.4 Alternative Tubing and Materials General

B.3.4.5

If a bent tube is used anywhere in the primary structure, other than

the front and main roll hoops, an additional tube must be attached

to support it. The attachment point must be the position along the

tube where it deviates farthest from a straight line connecting both

ends. The support tube must have the same diameter and

thickness as the bent tube. The support tube must terminate at a

node of the chassis.

Article B.3.4 Alternative Tubing and Materials General

B.3.4.5

If a bent tube is used anywhere in the primary structure, other than

the front and main roll hoops, an additional tube must be attached

to support it. The attachment point must be the position along the

tube where it deviates farthest from a straight line connecting both

ends. The support tube must have the same diameter and

thickness as the bent tube. The support tube must terminate at a

node of the chassis.

Article B.3.21.11 Standard Attenuator

B.3.21.11 Standard Attenuator

An officially approved impact attenuator can be found at http://

www.fsaeonline.com/home/page.aspx?pageid=193613e4fff1-4ea9-97ec-eb1c07fbe3c0 .

Teams may choose to use that style of impact attenuator and need not

submit test data with their IAD Report. The other requirements of the

IAD Report must still be submitted including, but not limited to, photos

of the teams actual attenuator with evidence that it meets the design

criteria given on the website.

However,

The attenuator itself is unchanged from 2011 but requires either the

diagonal or an x-brace in the front bulkhead. Teams can use this

attenuator and test their front bulkhead without the diagonal, but all the

requirements for a student designed attenuator would apply and they

would have to submit the IA data submission like normal.

B.3.21 - Impact Attenuator Testing

B.3.21.9

During the test, the attenuator must be attached to the anti

intrusion plate using the intended vehicle attachment method.

The anti-intrusion plate must be spaced at least 50 mm (2

inches) from any rigid surface.

No part of the anti-intrusion plate may permanently deflect

more than 25.1 mm (1 inch)beyond the position of the antiintrusion plate before the test.

Note: The 25.4 mm (1 inch) spacing represents the front

bulkhead support and insures that the plate does not intrude

excessively into the cockpit

Article B.3.24 Side Impact Structure for Tube Frame

Cars

B.3.24.3

The locations for the three (3) required tubular members are as follows:

The upper Side Impact Structural member must connect the Main Hoop and the Front Hoop.

With a 77kg (170 pound) driver seated in the normal driving position all of the member must

be at a height between 300 mm (11.8 inches) and 350 mm (13.8 inches) above the ground.

The upper frame rail may be used as this member if it meets the height, diameter and

thickness requirements.

The lower Side Impact Structural member must connect the bottom of the Main Hoop and the

bottom of the Front Hoop. The lower frame rail/frame member may be this member if it meets

the diameter and wall thickness requirements.

The diagonal Side Impact Structural member must connect the upper and lower Side Impact

Structural members forward of the Main Hoop and rearward of the Front Hoop.

Article B.6.2 Ground Clearance

B.6.2 Ground Clearance

Ground clearance must be sufficient to prevent any portion of the car,

other than the tires, from touching the ground during track events.

Intentional or excessive ground contact of any portion of the car other

than the tires will forfeit a run or an entire dynamic event.

Comment: The intention of this rule is that sliding skirts or other devices

that by design, fabrication or as a consequence of moving, contact the

track surface are prohibited and any unintended contact with the ground

which either causes damage, or in the opinion of the dynamic event

organizers could result in damage to the track, will result in forfeit of a

run or an entire dynamic event

Article B.6.6.2 Jacking Point

B.6.6.2 Jacking Point

The jacking point is required to be:

Visible to a person standing 1 meter (3 feet) behind the car.

Painted orange.

Oriented horizontally and perpendicular to the centerline of the car

Made from round, 25 29 mm (1 1 1/8 inch) O.D. aluminum or steel tube

A minimum of 300 mm (12 inches) long

Exposed around the lower 180 degrees (180) of its circumference over a

minimum length of 280 mm (11 in)

The height of the tube is required to be such that:

- There is a minimum of 75 mm (3 in) clearance from the bottom of the tube to

the ground measured at tech inspection.

- With the bottom of the tube 200 mm (7.9 in) above ground, the wheels do

not touch the ground when they are in full rebound.

Access from the rear of the tube must be unobstructed for at least 300mm of

its length

Article B.11.4 Batteries

B.11.4.3 The hot (ungrounded) terminal must be insulated.

B.11.4.5 Battery packs based on Lithium Chemistry other than LiFePo:

a. must be commercially manufactured items

b. must have over voltage, under voltage, short circuit and over

temperature cell protection

B.11.4.6 All batteries using chemistries other than lead acid must be

presented at technical inspection with markings identifying it for

comparison to a datasheet or other documentation proving the pack

and supporting electronics meet all rules requirements

Article B.15 Transponders

B15.1.3

All vehicles must be equipped with at least one MYLAPS Car/

Bike Rechargeable Power Transponder or MYLAPS Car/Bike

Direct Power Transponder.

Note:

Except for their name, AMB TranX260 transponders are

identical to MYLAPS Car/Bike Transponders and fully comply

with this rule. If you own a functional AMB TranX260 it does

not need to be replaced.

Article B.17 Drivers Equipment

B.17.2 Helmets

A well-fitting, closed face helmet that meets one of the following

certifications and is labeled as such:

- Snell K2000, K2005, K2010, M2000, M2005, M2010, SA2000,

SA2005, SA2010

- SFI 31.2A, SFI 31.1/2005

- FIA 8860-2004

- British Standards Institution BS 6658-85 Type A/FR rating

(Types A and B are not accepted)

Article B.17 Drivers Equipment

B.17.5 Suit

- SFI 3-2A/5 (or higher)

Article B.17 Drivers Equipment

B.17.5 Suit

- SFI 3-2A/5 (or higher)

This picture is of the label for a single layer 3-2A/1 suit!

B.6.8 Skid Pad Scoring

D6.8.3

The following equation is used to determine the scores for the skidpad event:

SKID PAD SCORE = (47.5 x (Tmax/Tyour) -1) / ((Tmax/Tmin) -1) +

2.5

Where:

Tyour is the average of the left and the right timed laps on your

best run including penalties.

Tmin is the elapsed time of the fastest car

Tmax is 125% of Tmin

D.13.1 Vehicle Movement

D.13.1.2

Off track vehicles must be pushed at a normal walking pace by

means of a Push Bar, (See D13.2) and with a driver in the

cockpit and with another team member walking beside the car.

The team has the option to move the car either with

(a) all four (4) wheels on the ground or with

(b) the rear wheels supported on dollies, by push bar mounted

wheels, or other means as long as the person in the cockpit has

full control of vehicle movement and can steer and brake

normally. The external wheels supporting the rear of the car must

be non-pivoting so the vehicle travels only where the front wheels

are steered. The driver must always be able to steer and brake

the car normally.

Questions?

Vous aimerez peut-être aussi

- Toca NGTC Build Manual 01-02-12Document22 pagesToca NGTC Build Manual 01-02-12PericlesleitePas encore d'évaluation

- InterClean Hybrid Transit Bus Wash With RecyclingDocument21 pagesInterClean Hybrid Transit Bus Wash With Recyclingmelgarcia829100% (1)

- Cleveland Wheel & Brakes Technician Service Guide AWBTSG0001Document28 pagesCleveland Wheel & Brakes Technician Service Guide AWBTSG0001Richard MayPas encore d'évaluation

- Brake Technicians Service Guide PDFDocument28 pagesBrake Technicians Service Guide PDFleonardo cardenasPas encore d'évaluation

- EPA 2010 Exhaust and Aftertreatment System Modification GuidelinesDocument30 pagesEPA 2010 Exhaust and Aftertreatment System Modification GuidelinesRodolfo Alberto Muñoz CarcamoPas encore d'évaluation

- FR20 Nomenclature 09 FR V1 01Document57 pagesFR20 Nomenclature 09 FR V1 01Octavio LópezPas encore d'évaluation

- Awbtsg0001 9Document28 pagesAwbtsg0001 9EleazarPas encore d'évaluation

- #08207A: Customer Satisfaction - Sunroof Water Leak - Install Drain Tube Extensions - (Sep 15, 2008)Document12 pages#08207A: Customer Satisfaction - Sunroof Water Leak - Install Drain Tube Extensions - (Sep 15, 2008)lamping_ap100% (1)

- Aeb02132Exhaust Systems - InstallationDocument19 pagesAeb02132Exhaust Systems - Installationacere18Pas encore d'évaluation

- Baja SAE Tech Inspection Sheet 2014-2015Document12 pagesBaja SAE Tech Inspection Sheet 2014-2015FoureyeddjPas encore d'évaluation

- VSB6 SectionH ChassisDocument73 pagesVSB6 SectionH ChassisaswarPas encore d'évaluation

- Semi Trailer / Runing Gear For Vitts: Design Code and RegulationsDocument34 pagesSemi Trailer / Runing Gear For Vitts: Design Code and Regulationssandy riadiPas encore d'évaluation

- QCS 2010 Part 07 Vehicle Crash BarriersDocument13 pagesQCS 2010 Part 07 Vehicle Crash BarriersRotsapNayrbPas encore d'évaluation

- Hindustan Petroleum CorporationDocument39 pagesHindustan Petroleum CorporationSrinivasan RajenderanPas encore d'évaluation

- AWBTSG0001Document28 pagesAWBTSG0001Александр ГладкийPas encore d'évaluation

- HVAC Pumps and Specialties GuideDocument5 pagesHVAC Pumps and Specialties Guidenestor159357Pas encore d'évaluation

- Uputstvo Za Beton PumpuDocument155 pagesUputstvo Za Beton PumpuPredrag StojanovicPas encore d'évaluation

- FordInstShtM 6017 A504VDocument21 pagesFordInstShtM 6017 A504V2791957Pas encore d'évaluation

- 60 - 15540 - HVAC Pumps and SpecialtiesDocument4 pages60 - 15540 - HVAC Pumps and Specialtiesnestor159357Pas encore d'évaluation

- Pumps: Suggested Specifications Submersible Sump Pump Type SMDocument4 pagesPumps: Suggested Specifications Submersible Sump Pump Type SMloveanbu24Pas encore d'évaluation

- Port Royal Speedway 2021 Limited Late Model Rules SummaryDocument18 pagesPort Royal Speedway 2021 Limited Late Model Rules SummaryWyliePas encore d'évaluation

- Installation Instructions: PART NUMBER: 21-436Document10 pagesInstallation Instructions: PART NUMBER: 21-436Roberto ChangPas encore d'évaluation

- REHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFDocument18 pagesREHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFvoivod6Pas encore d'évaluation

- Victory Rig - LB50-3 ManualDocument75 pagesVictory Rig - LB50-3 ManualLuis CastelanPas encore d'évaluation

- Project Standard Specification: Sump Pumps 15446 - Page 1/10Document10 pagesProject Standard Specification: Sump Pumps 15446 - Page 1/10adel rihanaPas encore d'évaluation

- SAEJ198 V 001Document12 pagesSAEJ198 V 001Nijanthan G. VasudevanPas encore d'évaluation

- Autocross Technical Inspection ProceduresDocument5 pagesAutocross Technical Inspection ProceduresRajat NanchahalPas encore d'évaluation

- Maintain Gas Engines GuideDocument13 pagesMaintain Gas Engines Guidebmgeisler0% (1)

- Submersible Pumps and Motors For Water Well and Offshore ServiceDocument12 pagesSubmersible Pumps and Motors For Water Well and Offshore ServiceTijo ThomasPas encore d'évaluation

- Access Control SPECSDocument12 pagesAccess Control SPECSSyed JahangirPas encore d'évaluation

- Bosh Gear PumpDocument96 pagesBosh Gear Pumpkavadarci14Pas encore d'évaluation

- Bosch Gear PumpDocument57 pagesBosch Gear PumpMaximus Maxis0% (1)

- Eaton Clutch Service Bulletin Clib0035Document8 pagesEaton Clutch Service Bulletin Clib0035Levarda Bogdan100% (1)

- Plan Electrique Ducato 2017Document220 pagesPlan Electrique Ducato 2017DylanPas encore d'évaluation

- DR 633 833 1233 (1) BarraDocument15 pagesDR 633 833 1233 (1) BarraJhonatan Bejarano BazanPas encore d'évaluation

- Webco ABS Sensor TestsDocument4 pagesWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- Remote vacuum servo installation guideDocument8 pagesRemote vacuum servo installation guidejblodwellPas encore d'évaluation

- OSHA 1910.66 App A - Guidelines (Advisory)Document4 pagesOSHA 1910.66 App A - Guidelines (Advisory)Gunnie PandherPas encore d'évaluation

- A/C-Heater System Uniform Inspection Guidelines Article TextDocument19 pagesA/C-Heater System Uniform Inspection Guidelines Article TextLenny VirgoPas encore d'évaluation

- Sewage Pumps SpecificationDocument12 pagesSewage Pumps SpecificationRaaannPas encore d'évaluation

- 21.32 Exhaust System - Installation RequirementDocument14 pages21.32 Exhaust System - Installation Requirementvinay guptaPas encore d'évaluation

- 2018 Specific Technical Regulation For RallyingDocument5 pages2018 Specific Technical Regulation For RallyingashishPas encore d'évaluation

- 80 - 15540 - HVAC Pumps and SpecialtiesDocument5 pages80 - 15540 - HVAC Pumps and Specialtiesnestor159357Pas encore d'évaluation

- Western Star Maintenance ManualDocument164 pagesWestern Star Maintenance Manualtransteven9383% (6)

- TB 9-2300-247-40 This Bulletin Supersedes TB 9-2300-247-40, 23 February 1971Document51 pagesTB 9-2300-247-40 This Bulletin Supersedes TB 9-2300-247-40, 23 February 1971Rolando DaclanPas encore d'évaluation

- A/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Document6 pagesA/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Carlos CuellarPas encore d'évaluation

- BW177-213-226 Series 4 Service TrainingDocument182 pagesBW177-213-226 Series 4 Service Trainingze_fcc77% (22)

- Machinery Component Maintenance and RepairD'EverandMachinery Component Maintenance and RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- HVAC Guide Specifications 39M Total Energy Recovery Wheel SectionDocument7 pagesHVAC Guide Specifications 39M Total Energy Recovery Wheel Sectionhardik033Pas encore d'évaluation

- Manual Mtto Roper 3600HBDocument43 pagesManual Mtto Roper 3600HBjairoPas encore d'évaluation

- Manual Bomba RoperDocument43 pagesManual Bomba RoperFranco Alejandro Olivares Alvarez100% (2)

- Mainenace Guidelines For LHB Cocahes.Document7 pagesMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- Transsmission Driveline AdaptationDocument16 pagesTranssmission Driveline Adaptationamin chaabenPas encore d'évaluation

- Subject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDocument10 pagesSubject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDavid Samaniego PánchezPas encore d'évaluation

- Sid97 3GDocument28 pagesSid97 3GdzakubPas encore d'évaluation

- Pump Installation GuideDocument21 pagesPump Installation Guidekarioke mohaPas encore d'évaluation

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideD'EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BD'EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BPas encore d'évaluation

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsD'EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsÉvaluation : 5 sur 5 étoiles5/5 (5)

- TOTX1350 (F) : General Purpose Optical Transmitting ModuleDocument6 pagesTOTX1350 (F) : General Purpose Optical Transmitting ModuleAnonymous 4ot6aS9Pas encore d'évaluation

- FSAE Student HandbookDocument88 pagesFSAE Student HandbookAadarsh DasPas encore d'évaluation

- Exam 1 Review F15Document22 pagesExam 1 Review F15Anonymous 4ot6aS9Pas encore d'évaluation

- Em302 HW1 F15Document2 pagesEm302 HW1 F15Anonymous 4ot6aS9Pas encore d'évaluation

- Hitchhiker's Guide ReflectionDocument2 pagesHitchhiker's Guide ReflectionAnonymous 4ot6aS9Pas encore d'évaluation

- European Design Guide For Tensile Surface StructuresDocument16 pagesEuropean Design Guide For Tensile Surface StructuresAngel Sullyvan100% (1)

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Ncert Summary Class 12th PhysicsDocument29 pagesNcert Summary Class 12th Physicsmeghraj.socialPas encore d'évaluation

- Makerere University Civil Engineering Assignment on Nalubaale DamDocument8 pagesMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiPas encore d'évaluation

- New Wiring Diagram Electric EMS2-tad1640ge PDFDocument2 pagesNew Wiring Diagram Electric EMS2-tad1640ge PDFVanHoang95% (22)

- Checklist Water Audit v1Document19 pagesChecklist Water Audit v1hammad.phistreamPas encore d'évaluation

- 6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Document18 pages6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Stefan IstratescuPas encore d'évaluation

- LT AB Cable GTPsDocument3 pagesLT AB Cable GTPsnishant sainiPas encore d'évaluation

- Adelino Horizontal Multistage PumpDocument13 pagesAdelino Horizontal Multistage PumpJaved HasanPas encore d'évaluation

- IGBTDocument22 pagesIGBTumeshgangwar100% (1)

- Chlorosorb Ultra Case StudiesDocument5 pagesChlorosorb Ultra Case StudiesWitta Kartika RestuPas encore d'évaluation

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyPas encore d'évaluation

- Energy Conservation Oppurtunities in Boiler SystemDocument34 pagesEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- KPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75Document9 pagesKPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75sreevasanthPas encore d'évaluation

- Operation Manual - WSRF-50Document175 pagesOperation Manual - WSRF-50eduardo100% (2)

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChilePas encore d'évaluation

- Sub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)Document2 pagesSub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)estelauPas encore d'évaluation

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסPas encore d'évaluation

- EDM Technologies: Electrical Discharge Machining ServicesDocument8 pagesEDM Technologies: Electrical Discharge Machining Servicesfarahin_selamatPas encore d'évaluation

- Ama Drainer & Ama Porter: Vertical Monobloc Dewatering PumpsDocument2 pagesAma Drainer & Ama Porter: Vertical Monobloc Dewatering Pumpssmita reddyPas encore d'évaluation

- Electrical Properties of Materials Mod-1Document18 pagesElectrical Properties of Materials Mod-1Darshan rajPas encore d'évaluation

- Quality Policy and Quality ObjectivesDocument2 pagesQuality Policy and Quality ObjectivesrabiulfPas encore d'évaluation

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.Pas encore d'évaluation

- General Principles of Freeze Drying (The Lyophilization Process)Document9 pagesGeneral Principles of Freeze Drying (The Lyophilization Process)Shefali PawarPas encore d'évaluation

- Siemens Actuator M3K20FXNDocument10 pagesSiemens Actuator M3K20FXNbasil christopherPas encore d'évaluation

- Hydrographic SurveyDocument24 pagesHydrographic SurveyKamal Veer100% (1)

- 2013 Renault ZOE PresskitDocument34 pages2013 Renault ZOE PresskitDidelisPas encore d'évaluation

- Wind Energy - University QuesDocument2 pagesWind Energy - University QuesKsn Hari100% (2)

- ECU Mount-On-Engine Vibration StudyDocument6 pagesECU Mount-On-Engine Vibration StudyElroy LeePas encore d'évaluation