Académique Documents

Professionnel Documents

Culture Documents

FPSO

Transféré par

Melissa LeeDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FPSO

Transféré par

Melissa LeeDroits d'auteur :

Formats disponibles

INSTITUT TEKNOLOGI BRUNEI

BRUNEI DARUSSALAM

Bachelor of Engineering (HONS) in Petroleum Engineering

Report on production platform analysis :

Floating Production Storage and Offloading (FPSO)

Course:

PCE1IPI Introduction to the Petroleum Industry

Submitted by :

Melissa Lee Jia Chie

Lecturer-in-Charge:

Mr Matthew Smith

Date of Submission:

30th October 2012

ABSTRACT

Floating Production Storage And Offloading (PFSO)

The Floating Production Storage and Offloading vessel is a ship-shaped

structure with several different mooring systems used by offshore oil and

gas industry. It is a type of floating tank system designed to produce,

refine and store oil or gas before being exported. The purpose of this

report is to understand how this system function, the situations and

conditions it can be used for and also the advantages and disadvantages

of the system. This report will explain how this type of off shore production

platform works, and also how certain designs of the vessel will affect the

system. This type of off shore production platform has been in use since

the seventies and over the past four decades has seen an increase in the

use of this system. With the many advantages such as cost efficient , it

has become a popular choice of offshore production platform by the oil

and gas industry.

ii

Floating Production Storage And Offloading (PFSO)

TABLE OF CONTENTS

ABSTRACT

ii

LIST OF FIGURES

. iv

Introduction

1

Brief History of FPSOs ...

. 2

How Does An FPSO Function

. 3

Turret Mooring System

. 5

Internal Turret Mooring System .

.. 7

External Turret Mooring System .

. 7

Double-hull Arrangements

11

Advantages and Disadvantages of FPSO

. 11

FPSO Spill Risk

13

Examples Of FPSOs In Different Countries

14

FPSO Castellon Delta 1987

.... 14

Girassol FPSO

.. 14

Floating Production Storage And Offloading (PFSO)

Seillean FPSO 1987

.. 14

Conclusion .

.. 15

References .

.. 16

iii

List of Figures

Figure 1(a) An early permanently moored FSO in a side-by-side export

arrangement,

1972 .............................................................................................................

..... 2

Figure 1(b) An early FPSO Castellon, in Spain, 1976

. 2

Figure 1(c) A modern FPSO with an external turret mooring in a tandem

export arrangement

............................................................................................................

....... 3

Figure 1(d) A modern FPSO with an internal turret mooring in a tandem

export arrangement

............................................................................................................

....... 3

Figure 2 Features of an FPSO ..

... 4

Floating Production Storage And Offloading (PFSO)

Figure 3 Components of an FPSO ..

.. 5

Figure 4 FPSO Components

.. 6

Figure 5 Submerged turret

...

6

Figure 6 An external turret mooring system

... 8

Figure 7 An internal turret mooring system

.... 8

Figure 8 A computer graphic of an example field layout .

9

Figure 9(a) Sample topsides layout of a ship-shaped offshore unit FPSO

with an accommodation forward and an internal turret

. 10

Figure 9(b) Sample topsides layout of a ship-shaped offshore unit FPSO

with an accommodation aft and an internal turret

. 10

Figure 10(a) Main offloading system at Girassol

........ 14

Figure 10(b) Girassol FPSO has a storage capacity of two million barrels of

crude oil . 14

Figure 11 Seillean FPSO

..

.. 15

iv

INTRODUCTION

Floating Production Storage And Offloading (PFSO)

FPSO, which stands for Floating Production Storage and Offloading unit, is

a floating vessel that is able to produce crude oil and gas. An FPSO system

consists of the following major parts:

-

Vessel (hull)

Topsides (processing system, accommodation, machinery space,

helideck)

Mooring system

Export system (offloading, shuttle tanker)

Subsea systems and flowlines

This report will explain the various aspects as stated below:

-

Brief history of the FPSO.

The technology used and engineering of the platform (i.e. how does

it function).

What situations and conditions can it be used for.

What are the advantages and disadvantages of the chosen platform.

Examples of FPSOs used in different countries.

BRIEF HISTORY OF FPSOs

Floating Production Storage And Offloading (PFSO)

Over the past 25 years, ship-shaped offshore unites have proven to be

reasonably reliable, cost-effective solutions for the development of

offshore fields in deep waters worldwide. They made a mark in the oil and

gas industry and are now a very important part of the industry.

Floating production can be traced to 1974, when Hamilton Brothers

converted the semisubmersible drill rig Transworld 58 to a floating

production unit for use on the Argyll field in the North Sea. The unit was

placed in 79 meters water depth and operated for 16 years. The first ship

shape floating production unit is traced to 1977, when Shell converted a

60,000 dwt tanker to an FPSO vessel with 20,000 b/d processing capacity

for use on the Castellon field offshore Spain. It operated in 115 meters

water depth.

But the commercializing and early expansion of floating production

technology can be attributed to Petrobras. The operator saw floating

production as an excellent, relatively low cost solution for producing crude

oil in the deepwater fields of Campos Basin. Petrobras began using

converted rigs as production semisubmersibles in 1977, and within 10

years had 11 floating production units operating offshore Brazil.

FPSOs have been used in offshore production since the 1970s in places

like the North Sea, offshore Brazil, Asia Pacific, the Mediterranean Sea and

offshore

West Africa.

Floating Production Storage And Offloading (PFSO)

Fig.1(a) An early

permanently moored FSO

in a side-by-side export

arrangement, 1972

Fig.1(b) An early FPSO

Castellon, in Spain, 1976

Floating Production Storage And Offloading (PFSO)

Fig. 1(c) A modern FPSO

with an external turret

mooring in a tandem

export arrangement

Fig. 1(d) A modern FPSO

with an internal turret

mooring in a tandem

export arrangement

HOW DOES AN FPSO

Production :

The P in the FPSO stands for production. Production means evolving the

crude oil obtained from the deeper parts of the ocean. The FPSO is

enabled and fitted with equipments that would act as a refinery of sort to

distil the oil obtained from the ocean along with the gases that are

emitted. This is the main feature of a FPSO as only with the help of this

feature can a FPSO attain the reliability that it enjoys in todays times.

3

Floating Production Storage And Offloading (PFSO)

Storage :

This is the second most important feature and the S in the acronym

FPSO. Second-most important because just as it is important to filter the

excavated oil from its oceanic reservoirs, it is equally important to store it

well. For this purpose, the FPSO is built in such a way that the tubes and

the pipes and the tanks are perfect for storing the distilled product from

the crude raw-material. They are safe and sturdy so as to resist any

chances of unwanted oil spillage and thus contamination of the marine

life-forms.

Offloading :

This is O in the concept of FPSO. The offloading aspect is important when

the FPSO has to transfer its contents into ships designed as oil carriers or

to pipelines that act as transfer agents. In simple terms, offloading refers

to removing the cargo in a FPSO and transferring it to another cargocarrying vessel or equipment. The offloading part is very tricky as the

process is carried out in the middle of the sea and thus requires a lot of

concentration and focus in order to avoid any sort of spillage.

Fig. 2 Features of an FPSO

FPSOs house both processing equipment and storage for produced

hydrocarbons. The basic design of most FPSOs encompasses a shipshaped vessel, with processing equipment, or topsides, aboard the

vessels deck and hydrocarbon storage below in the double hull. After

Floating Production Storage And Offloading (PFSO)

processing, an FPSO stores oil or gas before offloading periodically to

shuttle tankers or transmitting processed petroleum via pipelines.

4

Usually tied to multiple subsea wells, FPSOs gather hydrocarbons from

subsea production wells through a series of in-field pipelines. Once tapped

by subsea wells, hydrocarbons are transmitted through flowlines to risers,

which transport the oil and gas from the seafloor to the vessels turret and

then to the FPSO on the waters surface.

Fig. 3 Components of an FPSO

Moored in place by various mooring systems, FPSOs are effective

development solutions for both deepwater and ultra-deepwater fields. A

central mooring system allows the vessel to rotate freely to best respond

to changes in weather conditions, while spread-mooring systems anchor

the vessel from various locations on the seafloor.

There are two types of FPSOs :

-

A converted oil tanker

A custom built

TURRET MOORING SYSTEM

One type of mooring system is a turret mooring system. It consists of a

geostatic part attached to the seabed and a rotating part integrated in the

hull, which are connected and allow the ship to weathervane around the

turnet.

Floating Production Storage And Offloading (PFSO)

Fig. 4 FPSO

Components

Fig. 5 Submerged turret

Components of a turret mooring system :

-

Turret and spider

Turret casing

Turntable

Anchor arrangement

Product transfer system

Floating Production Storage And Offloading (PFSO)

The turret mooring system consists of a (geo)static part attached to the

seabed and a rotating part integrated within the FPSO hull. The geostatic

part is called turret and the rotating part is the turret casing. The two

parts are connected via a bearing arrangement, which allows rotation

between them, and hence allows the FPSO to freely weathervane around

the turnet.

6

The FPSO will find a stable position, according to prevailing wind, waves,

and currents, which minimizes the loads on the FPSO. This makes it

possible to use fewer and smaller chains and anchors than with spread

mooring.

The turret fulfils more functions than weathervaning; it also hangs off the

production or injection risers, supports the (multi pass) fluid swivel and

forms the interface between sub sea facilities and topsides. Next to this all

fluids and information communication systems pass through the turnet.

This includes well fluids, injection water and gas, and the electrical

connections and controls for the sub sea systems.

As all risers pass through the inside of the turret bearing, it is considered

as a limiting factor for the number of risers. It therefore also influences the

possible production rate for a field. With a turret the offloading can be

executed in tandem to the FPSO with shuttle tankers. This provides a more

operational uptime and less risk of tanker collision compared with spreadmoored FPSOs.

Several systems have been developed for a turret connection.

-

Internal turret mooring system :

It is located in the front end of a vessel. It can sometimes be found

in the middle. The internal turret is supported by a large roller

bearing in a moonpool. This can be found either at the bottom of the

vessel, or at deck level. As the internal turret is appropriate for a

large number of risers, it has good fluid transfer capabilities. Internal

turret mooring systems also allow vessels to remain on location

permanently. This holds even in the most harsh environments. An

advantage of the internal turret in comparison to the external turret

is that mooring forces can be transferred more easily into the hull.

External turret mooring system :

This system is similar to an internal turret mooring. An external

turret is however located outside the ships hull. It comprises a steal

box located at the bow or stern of the vessel, which provides a

foundation for the bearing and turret. The turret is mostly set-up

Floating Production Storage And Offloading (PFSO)

above the waterline, but sometimes also under. The bearing

provides a fixed chain table to which mooring chains and fluid

transfer hoses are attached. Chain legs are anchored to the seabed

either by anchors or piles. A swivel provides a product and utility

connections between the tanker facilities and the seabed.

Because the external turret is located outside the ships hull, it

requires less modification for conversion than an internal turret. As

the effective depth of the mooring system is increased, the storage

capacity of the hull can be maximised. On the other hand an

external location limits the risers to one or a few units. As the

7

chain table of an external turret mooring system is usually located

above water level (in contrary to internal turrets), the system is

suitable for shallow waters. An external turret mooring can resist

extreme sea conditions, as the vessel can "weathervane" freely over

360 degrees, just like the internal turret. One advantage of the

external turret to internal systems, is that it is less expensive.

The fabrication takes a shorter period of time. Next to this the

compacter turret allows a saving on steel.

Fig.6 An external turret mooring system

Floating Production Storage And Offloading (PFSO)

Fig.7 An internal turret mooring system

8

The processing equipment aboard the FPSO is similar to what would be

found atop a production platform. Usually built in modules, FPSO

production equipment can consist of water separation, gas treatment, oil

processing, water injection and gas compression, among others.

Hydrocarbons are then transferred to the vessels double-hull for storage.

Crude oil that is stored onboard is frequently transferred to shuttle tankers

or ocean barges going ashore, via a loading hose. Loading oil from the

stern of the FPSO to the bow of the shuttle tanker is known as tandem

loading. While gas is many times transferred to shore via pipeline or reinjected into the field to boost production.

Floating Production Storage And Offloading (PFSO)

Fig.8 A computer graphic of an example field layout

Floating Production Storage And Offloading (PFSO)

(a)

(b)

Fig.9 Sample topsides layout of a ship-shaped offshore unit FPSO : (a) with

an accommodation forward and an internal turret; (b) with an

accommodation aft and an internal turret.

Figure 8 shows an example of the overall field layout involving both oil

and gas. Figure 9 shows typical layouts of an FPSO topsides facility. The

accommodation is located in the bow area as shown in Figure 9(a) or in

the stern area as shown in Figure 9(b). The vessel layout is designed so

that the separation between the accommodation (including the principal

evacuation systems) and the major hydrocarbon hazards should be

maximized. The accommodation and the turret are separated as far away

as possible when a turret-mooring system is adopted with risers and

mooring facilities located at the bow; refer to Figure 9(b).

This configuration is beneficial also because turret motions can be

minimized while weathervaning capacity can be maximized. Also, when

the accommodation with a helideck is located at the stern in a conversion,

the proximity so achieved, to the engine room that contains many of the

major vessel systems including utility systems, can be an advantage.

Floating Production Storage And Offloading (PFSO)

10

As shown in Figure 9(b), a turret is often located as far forward as possible,

although the accommodation with the helideck must usually be sited aft,

with the process modules and power generation in the cargo length and

flare tower in the forward area. By placing the turret location as far

forward as possible, it makes active heading control by thrusters easier.

The topsides facilities are located above the main deck in between the

turret and the accommodation. The main deck needs to be strong enough

for the support columns of topsides modules and also have space for the

required piping for cargo loading/offloading, inerting and venting, and

hatches for access to the tanks. It will also contain the main cranes,

perhaps two, one on the port side and one on the starboard side.

The topsides may be divided into the process area and the utility area.

The process area includes spaces for hydrocarbon-containing equipment,

flare tower, compression equipment, and separation equipment. The

utility area includes spaces for utility equipment and power-generation

equipment.

DOUBLE-HULL

An aspect that needs to be considered for design and operation of an

FPSO is the protection of cargo tanks from damage caused by collisions

with shuttle tankers, particularly when a side-by-side configuration is to be

used for exporting cargo. A new-build FPSO hull usually has double sides,

but the bottom is not necessarily double-skinned.

Double bottoms are generally not required because damage from hull

grounding is unlikely. However, if the FPSO is a disconnectable type and

may need to leave the station from time to time under its own power, a

double bottom may be required by regulation. Also, if the FPSO is located

in a very shallow location with some chance of contact with the sea

bottom, a double bottom may be necessary.

ADVANTAGES AND

DISADVANTAGES OF FPSO

FPSOs are the most common type of floating production system. They

represent 61 percent of the production units now in operation and 70

Floating Production Storage And Offloading (PFSO)

percent of the production units on order. They are located in all major

offshore areas, except the Gulf of Mexico.

11

Advantages :

1) Can be built in a shorter time => quicker profits

The average semi-submersible oil rig takes 3-4 years to build, and a

jack-up rig 2-3 years. From laying the keel in dry dock to first launch,

an FPSO could be rolled out in months to a year, or even less if an

existing vessel is simply being modified into an FPSO.

2) FPSOs do not have to be custom built

Unlike their fixed platform and semi-submersible counterparts, an

FPSO does not have to start its life as an FPSO. The first ever FPSO,

BPs Castellon, was an oil tanker in a former life, and many of its

descendants are also vessels that have been converted from

transporters to harvesters of hydrocarbons. Recycling assets in

this way saves a lot of costs.

3) FPSOs can evade harsh weather

FPSOs are mobile units and hence are able to navigate away from

potentially perilous weather conditions. Permanent installations

would be vulnerable in the hurricane-riddled Gulf of Mexico, cyclonic

activity zones like the South China Sea and iceberg-infested waters

around the Arctic circle, whereas FPSOs are able to relocate and

elude these dangers.

4) FPSOs can move from field to field

FPSOs were conceived as the perfect solution to develop marginal

fields and so find themselves ideally disposed to a world with

rapidly exhausting conventional reserves. Once the source of

hydrocarbons has plateaued in a specific site, an FPSO unit can

then move on to its next target. In this way, owner/operators are

dispensing with the need to build and maintain costly platforms in

economically dubious situations, whilst retaining value with the

employment of a reusable unit.

5) Abandonment costs are less than for fixed platforms.

When a well becomes economically unviable due to underproduction or depletion, the removal of equipment, capping of the

well and any environmental clean up, that has to be enacted before

Floating Production Storage And Offloading (PFSO)

the well can be abandoned, could reach into the hundreds of

millions of dollars. An FPSO considerably minimizes this expenditure

as little permanent infrastructure has to be considered.

12

6) FPSOs are ideal for deep water drilling

With operators having to drill deeper than ever before to hit the

black gold, deep and ultra-deep water plays like the Santos Basin,

the US Gulf Lower Tertiary and the Arctic region are becoming more

plausible choices for an oil-thirsty world. In areas such as these,

where subsurface pipelines would be logistically challenging and

export by shuttle tankers is increasingly expensive, an FPSO is the

best choice as a tailored upstream and midstream unit rolled into

one.

7) FPSOs eliminate the need for costly and expansive underwater

infrastructure

In a situation where laying pipelines is not a cost-effective solution,

the FPSO is particularly well-adapted. FPSOs tap in to existing well

centres with its retractable risers, negating the need for extensive

undersea hydrocarbon transportation.

8) FPSOs are more environmentally friendly than rigs

While many rigs have been in operation for several decades and

have a permanent ecological footprint, an FPSO can be designed

and redesigned for more environmentally friendly field operations.

Disadvantages :

1) The subsea tiebacks associated with FPSOs generally bring higher

well maintenance costs.

2) Internal turret requires dry-docking and are more expensive than

external turret designs and it takes a longer period of time to be

built.

3) FPSOs are sensitive to motions.

4) High turret/fluid swivel costs.

5) High maintenance costs.

FPSO SPILL RISK

Floating Production Storage And Offloading (PFSO)

The highest crude oil spill risks in FPSO vessel operations in deepwater

come from the transport function, not the production function. Excluding

conventional offloading and shuttle tanker spills, FPSO-unique spill risks

comprise only 5 percent of the total risk. The remaining 95 percent of oil

spills are not FPSO related and are equally likely to occur with a tension

leg platform or other types of platform.

13

Risk analysis shows that only 1.8 percent of crude oil volumes lost during

all phases of FPSO operations would take place during the transfer of oil

from the vessel to the shuttle tanker.

EXAMPLES OF FPSOs IN

1) FPSO Castellon

Delta 1977 COUNTRIES

DIFFERENT

-

The first FPSO in the world

Shell operated conversion 65km offshore Tarragona, Spain

2) Girassol FPSO

- Worlds largest FPSO vessel

- Constructed in Korea and has been constructed as a joint venture

between Bouygues Offshore and Stolt Offshore within a period of 21

months

- The vessel has a production capacity of 200,000 barrels per day and

a storage capacity of 2,000,000 barrel storage capacity

Fig. 10 (a) Main offloading

system at Girassol

Fig. 10 (b) Girassol FPSO

has a storage capacity of

two million barrels of crude

oil

Floating Production Storage And Offloading (PFSO)

3) Seillean FPSO 1987

- Worlds only dynamically positioned, self-propelled deepwater FPSO

that extracts oil via a rigid riser system

- This allows Seillean to mobilize to deepwater locations and quickly

connect to subsea wells and commence production without the

assistance of offshore support vessels

- Operated by Petrobras since late 1988

- Storage capacity : 310,000 barrels

- Production capacity : 3,000 25,000 barrels per day

14

Fig. 11 Seillean FPSO

CONCLUSION

The trend of offshore oil and gas development has been shifting from

fields in shallow and medium waters to fields in deeper waters. Shipshaped offshore units such as FPSOs have been recognized as one of the

most reliable, economical solutions to develop offshore oil and gas

reserves in deep water areas.

Although FPSOs have been in existence since the late 1970s, their

complexity and size have been gradually increasing, and there are still a

number of problem areas related to designing, building, and operating

these units that must be resolved for achieving the high integrity in terms

of safety, health, the environment, and economics/financial expenditures.

Floating Production Storage And Offloading (PFSO)

15

REFERENCES

1. Anish, 2011 January 16, What is FPSO (Floating Production Storage

and Offloading) System? URL:

http://www.marineinsight.com/marine/types-of-ships-marine/what-isfpso-floating-production-storage-and-offloading-system/ Date

accessed : 2012 October 21

2. Tim Hadar, 2011 December 22, 10 Reasons Why FPSOs Are The

Future Of Oil And Gas. URL : http://www.oilandgasiq.com/strategymanagement-and information/articles/ten-reasons-why-fpsos-arethe-future-of-oil-and-ga/ . Date accessed : 2012 October 21

3. How Do FPSOs Work? URL:

http://www.rigzone.com/training/insight.asp?

insight_id=299&c_id=12. Date accessed : 2012 October 21

4. FLOATING TECHNOLOGY: Tanker lightering, transport leaks carry

highest risk in FPSO operations URL : http://www.offshoremag.com/articles/print/volume-60/issue-11/news/floatingtechnology-tanker-lightering-transport-leaks-carry-highest-risk-infpso-operations.html . Date accessed : 2012 October 21

5. Luk. W, 1.4 A Brief History of the FPSO Installations, URL :

http://www.scribd.com/doc/50405874/1-4-A-Brief-History-of-theFPSO-Installations date accessed : 2012 October 21

6. Aziz.A, 2011 May 4, Offshore Structures, URL :

http://offshoreengineeringstudy.blogspot.com/ Date accessed : 2012

October 21

7. Dr.ir. S.A. Miedema, Turret Mooring, URL:

http://www.offshoremoorings.org/moorings/2006/Groep6/Real

%20page/Turret_main.htm

Date accessed : 2012 October 21

Floating Production Storage And Offloading (PFSO)

8. Dushant, How and why to join merchant navy? URL:

http://dushant.wordpress.com/how-to-join-merchant-navy/ date

accessed : 2012 October 21

16

Vous aimerez peut-être aussi

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityD'EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityPas encore d'évaluation

- FPSODocument18 pagesFPSOCarly Rheman100% (3)

- FPSODocument6 pagesFPSONatanael ZangerolamoPas encore d'évaluation

- 788 TP FPSO ApplicationsDocument23 pages788 TP FPSO ApplicationsRicardo Argentton FicanhaPas encore d'évaluation

- FPSODocument2 pagesFPSOLesley Simpas GalvezPas encore d'évaluation

- OTC 16198 Design and Conversion of FPSO MystrasDocument18 pagesOTC 16198 Design and Conversion of FPSO Mystrassegunoyes100% (1)

- Safety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsDocument19 pagesSafety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsFoyez AhmadPas encore d'évaluation

- FPSO/FSO State of the Art ReviewDocument12 pagesFPSO/FSO State of the Art Reviewjsouza16Pas encore d'évaluation

- Hwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSODocument8 pagesHwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSOVeeraiah AnbuPas encore d'évaluation

- FPSO - PresentationDocument98 pagesFPSO - PresentationAnonymous WCG2HjPybJ100% (1)

- Intoduction of FPSO 01Document8 pagesIntoduction of FPSO 01muhammad hanifPas encore d'évaluation

- Fpso Con03Document16 pagesFpso Con03Burose KhanPas encore d'évaluation

- FPSO CourseDocument571 pagesFPSO CourseDigitalVault Enterprise100% (1)

- FPSO Facilities: Processing Oil and Gas OffshoreDocument30 pagesFPSO Facilities: Processing Oil and Gas OffshoreJogi100% (1)

- FPSO BrochureDocument12 pagesFPSO BrochuredonyaPas encore d'évaluation

- Statoil PPT On Fpso DesignDocument44 pagesStatoil PPT On Fpso Designcxb0716467% (3)

- FPSO Overall DesignDocument8 pagesFPSO Overall DesignZee Chien ChewPas encore d'évaluation

- 2015 15 OTC Subsea StructuresDocument7 pages2015 15 OTC Subsea StructuresAlberto darianPas encore d'évaluation

- Fpso Hull Integrity: MurdjitoDocument38 pagesFpso Hull Integrity: MurdjitoNoor Virliantarto100% (1)

- Fpso Redeployment StudyDocument23 pagesFpso Redeployment StudyMadhana GopalPas encore d'évaluation

- FPSO Design & Processing SystemsDocument20 pagesFPSO Design & Processing SystemsHtin Lin AungPas encore d'évaluation

- Turret MooringsDocument3 pagesTurret Mooringsjo0% (1)

- Targeting Deep Water in the Gulf of Mexico with Sevan FPSO ConceptDocument38 pagesTargeting Deep Water in the Gulf of Mexico with Sevan FPSO ConceptthunderPas encore d'évaluation

- Introduction To Fpso DesignDocument127 pagesIntroduction To Fpso DesignS S Nanthavarman Subramaniam100% (2)

- LR FPSO DesignDocument34 pagesLR FPSO Designcxb07164Pas encore d'évaluation

- Subsea EngineeringDocument2 pagesSubsea Engineeringgupta_hemanshu1986252100% (1)

- An Introduction To Floating Production Storage and Offloading (FPSO) VesselsDocument31 pagesAn Introduction To Floating Production Storage and Offloading (FPSO) VesselsGeorge Gougoulidis86% (7)

- General FPSODocument22 pagesGeneral FPSOaravind grandhi100% (2)

- FPSO Hazard IssuesDocument33 pagesFPSO Hazard IssuesJagan Bose100% (2)

- FPSO InformationDocument24 pagesFPSO Informationzorro21072107Pas encore d'évaluation

- FPSO Design and Conversion A Designer Approach PDFDocument21 pagesFPSO Design and Conversion A Designer Approach PDFJezzPas encore d'évaluation

- Esdep Offshore Structures General IntroductionDocument187 pagesEsdep Offshore Structures General Introductiondfal13Pas encore d'évaluation

- FPSOs - Design Considerations For The Structural Interface Hull and TopsidesDocument7 pagesFPSOs - Design Considerations For The Structural Interface Hull and TopsidesLuong Bang Giang67% (3)

- 0711 DSME Lessons Learned FPSO JIP Public Rev.1Document22 pages0711 DSME Lessons Learned FPSO JIP Public Rev.1Anonymous WCG2HjPybJPas encore d'évaluation

- Fundamentals of FPSO PDFDocument4 pagesFundamentals of FPSO PDFSamuel Mawutor Gamor25% (4)

- FPSO Lessons LearntDocument21 pagesFPSO Lessons LearntAnant Arvind Kulkarni100% (6)

- Group 3 - FpsoDocument36 pagesGroup 3 - FpsoAzka Roby AntariPas encore d'évaluation

- FPSO Design and Conversion-A Designer ApproachDocument21 pagesFPSO Design and Conversion-A Designer ApproachDzakyHaidar100% (1)

- Benefits of Cylindrical FPOsDocument40 pagesBenefits of Cylindrical FPOsGaurav SinghalPas encore d'évaluation

- Integrated Subsea Facilities Design, Construction and Training ContractorsDocument7 pagesIntegrated Subsea Facilities Design, Construction and Training ContractorsUyavie Obonna0% (1)

- DeepC FPSO TutorialDocument33 pagesDeepC FPSO TutorialZou Jiawei100% (1)

- Conversion Tanker A FsoDocument15 pagesConversion Tanker A FsoFarihna Jose100% (1)

- SBM FPSO RecordDocument32 pagesSBM FPSO RecordgpriohardonoPas encore d'évaluation

- FPSODocument143 pagesFPSORagunath KarthickPas encore d'évaluation

- FPSO ToolkitDocument28 pagesFPSO ToolkitNathachai LeewathanakijPas encore d'évaluation

- FPSODocument7 pagesFPSOjohn_tigerPas encore d'évaluation

- LR FPSO Basic Principle TrainingDocument75 pagesLR FPSO Basic Principle TrainingBenjamin Yohan100% (4)

- O&M Contracts For FPSO FPSO ContractsDocument6 pagesO&M Contracts For FPSO FPSO Contractsagarwal.rm100% (1)

- Tanker Conversions To FPSODocument32 pagesTanker Conversions To FPSOtambokPas encore d'évaluation

- Notes On FPSO and FatigueDocument6 pagesNotes On FPSO and Fatiguedtr17Pas encore d'évaluation

- FPSO Hystory Old&NewDocument31 pagesFPSO Hystory Old&NewDaniel Mihailescu100% (3)

- Floating Production Storage and Offloading Units and Topside FacilitiesDocument18 pagesFloating Production Storage and Offloading Units and Topside FacilitiesPonnaiah SathiyaprabhuPas encore d'évaluation

- Floating Production Storage and Offloading Units and Topside FacilitiesDocument19 pagesFloating Production Storage and Offloading Units and Topside FacilitiesOlumuyiwa FasehunPas encore d'évaluation

- FPSO services agreements overviewDocument17 pagesFPSO services agreements overviewsachin_nemanePas encore d'évaluation

- FPSO - Floating Production Storage and OffloadingDocument3 pagesFPSO - Floating Production Storage and OffloadingcrisafutuPas encore d'évaluation

- GULFDocument33 pagesGULFJORDAN FREEPas encore d'évaluation

- FloatingDocument33 pagesFloatingJORDAN FREEPas encore d'évaluation

- How Do FPSOs WorkDocument3 pagesHow Do FPSOs WorkAnonymous cekPJylABoPas encore d'évaluation

- Offshore StructureDocument8 pagesOffshore StructureTHANGAVELU SIVAKUMARPas encore d'évaluation

- Development of A Gas Field Offshore Thailand Using An FPSO: C. Davison, Single Buoy Moorings IncDocument7 pagesDevelopment of A Gas Field Offshore Thailand Using An FPSO: C. Davison, Single Buoy Moorings Incthlim19078656Pas encore d'évaluation

- Venice 213 ParticularsDocument1 pageVenice 213 ParticularsMohamed SOPas encore d'évaluation

- Rev Cargo Doc - Id7 Voy.w66b WedaDocument8 pagesRev Cargo Doc - Id7 Voy.w66b Wedam.rifqianwarPas encore d'évaluation

- Memorandum of Understanding - Hosanna Fisheries Consult 2023Document5 pagesMemorandum of Understanding - Hosanna Fisheries Consult 2023victor chukwukaPas encore d'évaluation

- Rhumb Line SailingDocument2 pagesRhumb Line SailingHarinder PalPas encore d'évaluation

- 2008 International Tornado Class RulesDocument44 pages2008 International Tornado Class Rulesambs096172Pas encore d'évaluation

- Sm-411 14000 HP BHP Ahts Gerard Jordan 20171017Document2 pagesSm-411 14000 HP BHP Ahts Gerard Jordan 20171017StasPas encore d'évaluation

- List of Rogue WavesDocument6 pagesList of Rogue WavesdescataPas encore d'évaluation

- The Fastest Growing Sector in TravelDocument24 pagesThe Fastest Growing Sector in Traveljhyka mae BandolaPas encore d'évaluation

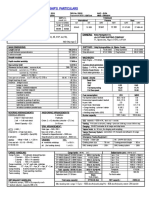

- Ship'S Particulars: Class DNV GL: OwnersDocument1 pageShip'S Particulars: Class DNV GL: OwnersDāvis DzērvePas encore d'évaluation

- Fixturenote - General CargoDocument6 pagesFixturenote - General Cargotoxu5532Pas encore d'évaluation

- Akel 5e60f89f49e91Document29 pagesAkel 5e60f89f49e91PedroPas encore d'évaluation

- marinegyaannn.comDocument1 pagemarinegyaannn.comAnoopPas encore d'évaluation

- 1944 - September - South West Pacific Anti Submarine Report PDFDocument28 pages1944 - September - South West Pacific Anti Submarine Report PDFEmmanuelleLizéPas encore d'évaluation

- Questions for the Rank of Officer of the WatchDocument57 pagesQuestions for the Rank of Officer of the WatchHoài Thanh100% (4)

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocument22 pagesRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunPas encore d'évaluation

- USS Oregon BB3: Epic 74-Day Cruise in Spanish-American WarDocument25 pagesUSS Oregon BB3: Epic 74-Day Cruise in Spanish-American WarbamboobuckPas encore d'évaluation

- Automatic Identification SystemDocument50 pagesAutomatic Identification SystemsaPas encore d'évaluation

- CharltonDocument6 pagesCharltonStephen SmithPas encore d'évaluation

- 3100 LM: Highly Flexible RoPax for Over 3,000 Lane MetersDocument1 page3100 LM: Highly Flexible RoPax for Over 3,000 Lane MetersChahbi RamziPas encore d'évaluation

- Collision Between Bulk Carrier Huayang Endeavour and Oil Tanker SeafrontierDocument3 pagesCollision Between Bulk Carrier Huayang Endeavour and Oil Tanker SeafrontierstamatisPas encore d'évaluation

- BCG Boats 2022-08-02Document5 pagesBCG Boats 2022-08-02Mrityunjoy MazumdarPas encore d'évaluation

- DG Shipping-2nd Mates Syllabus (STCW 2010) : SourceDocument10 pagesDG Shipping-2nd Mates Syllabus (STCW 2010) : SourceSebin C S0% (1)

- Draft Survey Pac AquilaDocument60 pagesDraft Survey Pac AquilaAldo TrinovachaesaPas encore d'évaluation

- Ship Knowledge 3Document124 pagesShip Knowledge 3vedran_katić100% (6)

- Offshore Subsea Construction Vessel Skandi SantosDocument2 pagesOffshore Subsea Construction Vessel Skandi SantosAlexPas encore d'évaluation

- Model CV QLDocument4 pagesModel CV QLTavi CuleaPas encore d'évaluation

- Interview Question - C.ODocument18 pagesInterview Question - C.OHoài ThanhPas encore d'évaluation

- INCOTERMS 2000 - Chart of ResponsibilityDocument3 pagesINCOTERMS 2000 - Chart of ResponsibilityManoj BansalPas encore d'évaluation

- Documentation of Iranian-Linked Ships - Inmarsat's Ship DirectoryDocument40 pagesDocumentation of Iranian-Linked Ships - Inmarsat's Ship DirectoryShurat HaDin - Israel Law CenterPas encore d'évaluation

- Port Logistics: The Role of Ports in Supply Chain ManagementDocument37 pagesPort Logistics: The Role of Ports in Supply Chain ManagementJOSEPH RASIEL ARANA SALDIVARPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsD'EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsPas encore d'évaluation

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilD'EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilPas encore d'évaluation

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisD'EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisPas encore d'évaluation

- Pipeline Integrity: Management and Risk EvaluationD'EverandPipeline Integrity: Management and Risk EvaluationÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesD'EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesPas encore d'évaluation

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsD'EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fire in the Night: The Piper Alpha DisasterD'EverandFire in the Night: The Piper Alpha DisasterÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Subsea Valves and Actuators for the Oil and Gas IndustryD'EverandSubsea Valves and Actuators for the Oil and Gas IndustryÉvaluation : 5 sur 5 étoiles5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignD'EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationD'EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisD'EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Corrosion Control in the Oil and Gas IndustryD'EverandCorrosion Control in the Oil and Gas IndustryÉvaluation : 4 sur 5 étoiles4/5 (12)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesD'EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertÉvaluation : 3 sur 5 étoiles3/5 (2)