Académique Documents

Professionnel Documents

Culture Documents

Product Guide - HCD600

Transféré par

Anonymous R9Lpd68FTATitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Product Guide - HCD600

Transféré par

Anonymous R9Lpd68FTADroits d'auteur :

Formats disponibles

PRODUCT INFORMATION

HCD Series

HCD-600

Desiccant Dehumidifier

MODULAR DEHUMIDIFIER UNITS

WITH OPTIONS

Advantages:

Weather-tight construction for

indoor or outdoor use

Low profile cassette design

Quick access for easy

maintenance

Easy duct connections

Modulating electric or steam

reactivation

Multiple blower orientations

Built-in bypass option

Add-on post-/pre-air treatment

options

Product Description

Process Air: Flow rates of 300-1125 scfm. Nominal moisture

removal: 16 lbs/hr at 75F, 50% RH at 600 scfm. Delivered air

moisture levels of -40F dewpoint and lower are attainable.

Contact Air Seals: Separate process and reactivation air at

pressures up to 8 W.G. with 5 years life expectancy.

Process & Reactivation Fans: Centrifugal, direct drive with

totally enclosed fan cooled motors.

Electrical Controls: Continuous automatic operation including motor starters, overload protective devices, programmable

logic controller with indicating lights and fault circuits. All

wiring to NEC codes.

Drive System: Simple drive belt arrangement, few moving

parts.

Reactivation Utility: Electric with solid state proportioning

control or steam with proportional air volume control.

Dehumidifier Housing: Process and reactivation air flow insulation. Durable air-dry polyurethane paint. All welded aluminum cabinet.

Desiccant Rotors

In the 1950s Munters invented modern industrial dehumidication when it introduced the

self-regenerating desiccant rotor, the heart of the

dehumidier.

Today, Munters offers rotors with ve desiccant

formulations and is the acknowledged expert in

the integration of rotors into dehumidication

systems and air handlers.

The Humidity Expert

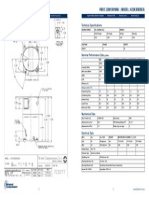

MODEL HCD- 600 EA (ELECTRIC)

General arrangement drawings for other steam or electric reactivation units available from your local representative or

factory. Below drawing for illustrative purposes, not for construction. Consult factory for certified drawings.

REACTIVATION

AIR INLET

914" x 914"

ELECTRICAL

CONTROLLER

MODULATION

REACTIVATION

HEATER

AIR FLOW

GAUGES

REACTIVATION

FILTER ACCESS

REACTIVATION

AIR OUTLET

5116" x 758"

REACTIVATION

INLET WEATHERHOOD

(OPTIONAL)

5714"

PROCESS

AIR INLET

16" x 25"

39"

DESICCANT

WHEEL ACCESS

PROCESS AIR

OUTLET

5116" x 758"

30"

30% FILTER

(OPTIONAL)

21"

2714"

INSPECTION

WINDOW

5712"

31"

67"

DIMENSIONS TABLE FOR EA (ELECTRIC) AND SA (STEAM) REACTIVATION

Typical External Static

Pressures (in. W.G.)

Max

Length (in.)

Max

Width (in.)

Max

Height (in.)

Max

Weight (lbs.)

Process

React

HCD-600 EA

58

31

56

400

3.5

2.75

HCD-600 SA

76

31

56

410

3.5

2.75

Model

Suggested Specification Guide:

Dehumidifier shall be of a type proven in

satisfactory operation for a minimum of ten

years. Dehumidifier shall be of the noncycling sorption type with a single desiccant

rotary structure. The casing will be fabricated as a unitized body with welded aluminum construction for maximum strength

and durability. Suitable access panels on

both sides of the unit shall allow access for

inspection or servicing without disconnecting ducting or electrical wiring. Airflow

balancing dampers to be furnished. The

dehumidifier shall be designed for continuous operation.

The rotary structure shall be a monolithic fabricated extended surface consisting

of inert silicates reinforced with uniform

diameter glass fibers for maximum strength.

The fabricated structure shall be smooth

and continuous in the direction of airflow

without interruptions or sandwich layers

which restrict airflow or create a leakage

path at joining surfaces. Desiccant shall not

channel, cake or fracture due to repeated

temperature and moisture cycling. The

materials of construction shall be non-toxic

and NFPA 255-ASTM E84 compliant.

The desiccant wheel shall be a single piece

for fast removal and simple handling. The

desiccant wheel shall be supported by four

rollers at the base of the unit so the wheel

can be easily removed for maintenance by

lifting it over the rollers using the drive belt.

Center-axle support or any arrangement

which requires disassembly of the support

structure for wheel removal shall not be

acceptable.

Design shall be modular in approach to

readily allow connection to accessories such

as face & bypass, pre- or post-cool modules.

Electrical components shall be UL/

CSA recognized and wiring methods in

accordance with the latest edition of the

National Electric Code. Power supply shall

be ___Volts/3 Phase/___ Hertz.

Full face contact pressure seals shall

be provided to separate the process and

reactivation air streams and eliminate detrimental leakage of air or moisture with static

pressure differentials of up to 8 of water

gauge.

Dehumidifier shall be factory assembled, fully automatic, complete with

HoneyCombe desiccant wheel, reactivation heaters, reactivation energy control

system, roughing filters, motors, fans, nonracheting desiccant drive unit, automatic

controller and all components auxiliaries.

Dehumidifier shall be functionally tested

at the manufacturers factory and shipped

complete with all components necessary to

maintain normal operation.

*Continual engineering and research for product

improvement may result in design and specification

changes. Consult factory for certified technical data.

Technical Specifications*

Utilities: 208, 230, 460 or 575 Volts

Reactivation Heaters:

EA-Electric: 208-575 volts.

SA-Steam: 10-150 psig.

Max Reactivation Air Volume: 230 scfm

Reactivation Filter: Permanent and

washable

Electric Controller: NEMA 4

Installation: Indoors or outdoors

Options: On/Off or modulating

humidity control, internal or external

bypass, skids, weatherhoods, pre- and

post-air treatment modules can include

filtration, cooling and heating.

Typical Energy Consumption:

MODEL EA

VOLTAGE

HEATER

KW

UNIT

AMPS

208

13.5

51

230

13.5

45

460

13.5

23

575

13.5

18

Munters Corporation

Dehumidification Division - Industrial

79 Monroe Street

Amesbury, MA 01913

Tel: (978) 241-1100 or (800) 843-5360

Fax: (978) 241-1214

www.munters.us

M162008 Rev. 5 10/07

2007 Munters Corporation

HoneyCombe is a registered trade name of Munters Corporation

The Humidity Expert

Vous aimerez peut-être aussi

- AHU Owners ManualDocument84 pagesAHU Owners ManualTom MurphyPas encore d'évaluation

- C-PAC Gas R22Document22 pagesC-PAC Gas R22Leed ENPas encore d'évaluation

- Technical Sales Guide-1Document42 pagesTechnical Sales Guide-1Amer GaladPas encore d'évaluation

- RTP 3 25 TR For Rooftoppackage 1Document52 pagesRTP 3 25 TR For Rooftoppackage 1GeorgePas encore d'évaluation

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- FOCSWATER.C Water Cooled Chiller - R134aDocument8 pagesFOCSWATER.C Water Cooled Chiller - R134antt_121987Pas encore d'évaluation

- M52 Controller - Simplicity by DesignDocument6 pagesM52 Controller - Simplicity by Designluis pardo solano100% (1)

- AC EZ (PQCSZ250S0) Installation and User Manual PDFDocument56 pagesAC EZ (PQCSZ250S0) Installation and User Manual PDFPrabhjeet Singh ChannaPas encore d'évaluation

- High Efficiency High AmbientGeneral Sales BrochureDocument30 pagesHigh Efficiency High AmbientGeneral Sales BrochureJosue Alvarez GomezPas encore d'évaluation

- H23A383DBEADocument1 pageH23A383DBEABruno Monteiro0% (1)

- GS3BA Series High Efficiency Air Conditioner: Technical SpecificationsDocument4 pagesGS3BA Series High Efficiency Air Conditioner: Technical Specificationstrien15Pas encore d'évaluation

- Sollaren 4.0 2021Document4 pagesSollaren 4.0 2021Claudio SollarenPas encore d'évaluation

- York Yoea36fs36adhDocument20 pagesYork Yoea36fs36adhjean_carlos_abreu_rPas encore d'évaluation

- Split System Heat Pump Product & Performance Data: SSP-PRC013-ENDocument64 pagesSplit System Heat Pump Product & Performance Data: SSP-PRC013-ENJoel Pat ChesneyPas encore d'évaluation

- SU BrochureDocument4 pagesSU BrochureOreolPas encore d'évaluation

- LEC1Document17 pagesLEC1christophermrequintoPas encore d'évaluation

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersHải TrầnPas encore d'évaluation

- Aerofoil Climafan Brochure 50Hz (ENG) For RefDocument58 pagesAerofoil Climafan Brochure 50Hz (ENG) For RefAnonymous BbZceWkVnPas encore d'évaluation

- Copeland LubricantsDocument2 pagesCopeland LubricantsDanLorenaPas encore d'évaluation

- 30XA Product Data PDFDocument36 pages30XA Product Data PDFanoopkumar1231150100% (2)

- BAC - VXC-S - Technical Data SheetsDocument12 pagesBAC - VXC-S - Technical Data SheetsMahmoud AliPas encore d'évaluation

- C-PAC Gas R22 PDFDocument22 pagesC-PAC Gas R22 PDFngocdhxd92Pas encore d'évaluation

- Catalogo Tecnico Split Ducto Baja SiluetaDocument120 pagesCatalogo Tecnico Split Ducto Baja SiluetaPavlo Rodriguex100% (2)

- Carrier Serie 50TC (15-27.5 Ton) PDFDocument98 pagesCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoPas encore d'évaluation

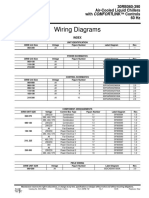

- Wiring Diagram Schema Electrique: 30RH 120 B0511 PEE 0000268283Document13 pagesWiring Diagram Schema Electrique: 30RH 120 B0511 PEE 0000268283Nha TrangPas encore d'évaluation

- Blue Star AHU DetailsDocument5 pagesBlue Star AHU DetailsdheerajdorlikarPas encore d'évaluation

- Catalog VRV IV - 2016Document62 pagesCatalog VRV IV - 2016VietHienPas encore d'évaluation

- Siemens Energy Turblex Full Line BulletinDocument6 pagesSiemens Energy Turblex Full Line BulletinKunming WangPas encore d'évaluation

- AERCO Boiler Benchmark 3.0Document129 pagesAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Canatal Modulo Web - m52 - Web - Interface - DatasheetDocument11 pagesCanatal Modulo Web - m52 - Web - Interface - DatasheetcandaruchoPas encore d'évaluation

- Radical Centrifugal Fans en PDFDocument184 pagesRadical Centrifugal Fans en PDFMohd AidilPas encore d'évaluation

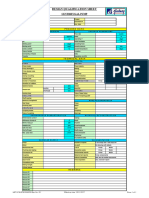

- Datasheet Kirim Item 1Document2 pagesDatasheet Kirim Item 1Muhammad RidoPas encore d'évaluation

- FGC Communication Module. Installation ManualDocument32 pagesFGC Communication Module. Installation ManualAfsar's SonPas encore d'évaluation

- AIRTORQUEDocument20 pagesAIRTORQUEPaula MendesPas encore d'évaluation

- Catalogue Air Cooled Chiller Uaa-St3m (R134) PDFDocument9 pagesCatalogue Air Cooled Chiller Uaa-St3m (R134) PDFNanda AulianaPas encore d'évaluation

- NA592 - Powerciat LX R134aDocument57 pagesNA592 - Powerciat LX R134apaldopalPas encore d'évaluation

- Model 42 RotofeederDocument85 pagesModel 42 RotofeederhauPas encore d'évaluation

- Product Data: 50HJQ Single-Package Rooftop High Efficiency Heat Pump UnitsDocument52 pagesProduct Data: 50HJQ Single-Package Rooftop High Efficiency Heat Pump UnitsfjeroPas encore d'évaluation

- Air Torque Pneumatic Actuator ManualDocument1 pageAir Torque Pneumatic Actuator ManualAmit AGRAWALPas encore d'évaluation

- 30GT226 - Product Data Supplement 2Document12 pages30GT226 - Product Data Supplement 2Hani SaidPas encore d'évaluation

- AesvDocument32 pagesAesvKhusnulPas encore d'évaluation

- Total Flow Control SolutionsDocument40 pagesTotal Flow Control SolutionsKamillAL-akhrasPas encore d'évaluation

- 30rb 1wDocument24 pages30rb 1wmlozadabastPas encore d'évaluation

- SST Series Engineering Manual 413a-Sem 0Document52 pagesSST Series Engineering Manual 413a-Sem 0Gerber GarciaPas encore d'évaluation

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 pagesTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasPas encore d'évaluation

- Service Manual MU-GF20VA MU-GF25VA MU-GF35VA MU-GF50VA - MU-GF60VA - MU-GF80VADocument40 pagesService Manual MU-GF20VA MU-GF25VA MU-GF35VA MU-GF50VA - MU-GF60VA - MU-GF80VABayu IbrahimPas encore d'évaluation

- Refrig LBDocument8 pagesRefrig LBMuhammad HafeezPas encore d'évaluation

- Hallscrew Replacement Parts List: July 2006Document8 pagesHallscrew Replacement Parts List: July 2006Annika Cass100% (1)

- Rcu2e Ag2 & Rhu2e Ag2 PDFDocument192 pagesRcu2e Ag2 & Rhu2e Ag2 PDFKostas AstrinisPas encore d'évaluation

- Derakane Momentum 411-350 TDSDocument5 pagesDerakane Momentum 411-350 TDSGautamPas encore d'évaluation

- Water in Air Calculator - Version 3Document7 pagesWater in Air Calculator - Version 3Neelakandan DPas encore d'évaluation

- Boosterpaq Grundfos Cr-Booster Systems 60 HZDocument40 pagesBoosterpaq Grundfos Cr-Booster Systems 60 HZNShebertPas encore d'évaluation

- Canatal Series 6 - BrochureDocument8 pagesCanatal Series 6 - BrochureOscar A. Pérez MissPas encore d'évaluation

- Tecs HF 0251 1954 200910 GB PDFDocument43 pagesTecs HF 0251 1954 200910 GB PDFLeuce LaviniuPas encore d'évaluation

- Carrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersDocument13 pagesCarrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersvickersPas encore d'évaluation

- Ingersoll Rand M37 & M45 Ops & Maint ManualDocument31 pagesIngersoll Rand M37 & M45 Ops & Maint ManualjiangshencaoPas encore d'évaluation

- 2009 MRVII-C Service Manual (GWL)Document552 pages2009 MRVII-C Service Manual (GWL)Nha TrangPas encore d'évaluation

- Product Guide - HCD600Document2 pagesProduct Guide - HCD600Jorge Mario PérezPas encore d'évaluation

- Desumidificador Munters Modelo HCD1125 PDFDocument2 pagesDesumidificador Munters Modelo HCD1125 PDFRobert DanielsPas encore d'évaluation

- AP5027-30/AP5208-30/AP5210-30 Airflow Differential Pressure SwitchesDocument2 pagesAP5027-30/AP5208-30/AP5210-30 Airflow Differential Pressure SwitchesAnonymous R9Lpd68FTAPas encore d'évaluation

- Käyttöohje JLG E3-SarjaDocument70 pagesKäyttöohje JLG E3-SarjaAnonymous R9Lpd68FTAPas encore d'évaluation

- PDP PRT 4sr Well Sub PartsDocument120 pagesPDP PRT 4sr Well Sub PartsAnonymous R9Lpd68FTAPas encore d'évaluation

- Páginas DesdeRadio Electronics April 1985-2-2Document1 pagePáginas DesdeRadio Electronics April 1985-2-2Anonymous R9Lpd68FTAPas encore d'évaluation

- Applied Mechanics Lab ManualDocument23 pagesApplied Mechanics Lab ManualEr Anoop SinghPas encore d'évaluation

- Running Casing With Weatherford Overdrive System - Best PracticesDocument1 pageRunning Casing With Weatherford Overdrive System - Best PracticesYougchu LuanPas encore d'évaluation

- Detailed Lesson PlanDocument9 pagesDetailed Lesson PlancaifiPas encore d'évaluation

- RealmctubeDocument15 pagesRealmctubeToM100% (6)

- Kawasaki PumpsDocument32 pagesKawasaki PumpsRemzi Ceren100% (1)

- Specs PyroLance L 1000 WG Sept 2015Document9 pagesSpecs PyroLance L 1000 WG Sept 2015Forum PompieriiPas encore d'évaluation

- 4basics of LEDDocument3 pages4basics of LEDshaikh a nPas encore d'évaluation

- Computer Hardware Repairing Institute - Computer Hardware Repairing InstituteDocument4 pagesComputer Hardware Repairing Institute - Computer Hardware Repairing Institutesahil kumarPas encore d'évaluation

- Lab 3Document4 pagesLab 3Caramel KarebearPas encore d'évaluation

- D3 Remote ManualDocument2 pagesD3 Remote ManualbobanmiPas encore d'évaluation

- Broach Rotary Hassay NTDocument40 pagesBroach Rotary Hassay NTjlbrasco2Pas encore d'évaluation

- Penawaran AC LG - GD Checkup Laborat RS PHCDocument1 pagePenawaran AC LG - GD Checkup Laborat RS PHCaisyahbrillianaPas encore d'évaluation

- Locon32 eDocument88 pagesLocon32 eyoooo_74Pas encore d'évaluation

- Gts-150 Operation Manual 08 VerDocument329 pagesGts-150 Operation Manual 08 VersunhuynhPas encore d'évaluation

- 977205PDocument49 pages977205PChu QuynhPas encore d'évaluation

- APC SRC Installation ManualDocument30 pagesAPC SRC Installation Manualsanizam79Pas encore d'évaluation

- ABB RELT 9AKK107991A2520-RELT Setup and Testing Guide - Rev05132021 - 1Document30 pagesABB RELT 9AKK107991A2520-RELT Setup and Testing Guide - Rev05132021 - 1dougyuPas encore d'évaluation

- FADZXcv SXDocument1 pageFADZXcv SXMohamed SelimPas encore d'évaluation

- RC Helicopter Instruction ManualDocument12 pagesRC Helicopter Instruction Manualanon_528622415Pas encore d'évaluation

- 30-10 Solenoid ValvesDocument31 pages30-10 Solenoid ValvesadrianioantomaPas encore d'évaluation

- General Outline of Inventory in StockDocument10 pagesGeneral Outline of Inventory in Stocksalhi9676Pas encore d'évaluation

- Certificate of Conformity: SGS Tecnos, S.ADocument1 pageCertificate of Conformity: SGS Tecnos, S.Afiras abou sharafPas encore d'évaluation

- Information Sheet ERC216: Relay 16A, 2NO, 230V 50HzDocument2 pagesInformation Sheet ERC216: Relay 16A, 2NO, 230V 50HztongaiPas encore d'évaluation

- Hazard Study 4 - Compress AirDocument12 pagesHazard Study 4 - Compress AirSaran rasayaPas encore d'évaluation

- Mosquito KillerDocument15 pagesMosquito KillerTecheureka SolutionsPas encore d'évaluation

- Defence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Document2 pagesDefence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Aamir ArainPas encore d'évaluation

- Multi-Door Compact Type Controller (V4A) - Multi-Door Controller - ACS - SYRIS Technology Corp. (The RFID Total Solution.) - Powered by SYRISDocument2 pagesMulti-Door Compact Type Controller (V4A) - Multi-Door Controller - ACS - SYRIS Technology Corp. (The RFID Total Solution.) - Powered by SYRISSusheel GuptaPas encore d'évaluation

- VR6Document20 pagesVR6sareluis30Pas encore d'évaluation

- Quick Guide PDFDocument308 pagesQuick Guide PDFwilker2Pas encore d'évaluation

- XL4015Document9 pagesXL4015Jose M PeresPas encore d'évaluation

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)