Académique Documents

Professionnel Documents

Culture Documents

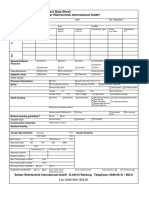

Acoplamiento Duraflex

Transféré par

scribdviviCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Acoplamiento Duraflex

Transféré par

scribdviviDroits d'auteur :

Formats disponibles

DURA-FLEX COUPLINGS

SECTION

F2

Patent No. 5,611,732

FEATURES

Designed from the ground up using finite element analysis to maximize flex life.

Easy two piece element installation. No need to move the hubs during replacement.

One spacer size to handle most different between shaft spacings.

Light weight element absorbs shock loading and torsional vibration.

Same hubs used on both spacer and standard elements.

No lubrication.

Good chemical resistance.

Stock bore-to-size (BTS), Sure-Grip bushed (QD) and Taper-Lock bushed (TL) Hubs.

The specially designed split-in-half element can be easily

replaced without moving any connected equipment.

Taper-Lock is a registered tradename of Rockwell Automation-Dodge.

F21

DURA-FLEX COUPLING SELECTION

A. Determine the Prime Mover Classification

Prime Mover

Class

Electric Motors (Standard duty), Hydraulic Motors, Turbines

Gasoline or Steam Engines (4 or more cylinders)

Diesel or Gas Engines, High Torque Electric Motors

A

B

C

B. Determine the Load Characteristics and the Service Factor

Typical Applications

Load

Agitators (pure liquids), Blowers (centrifugal, Can and Bottle

Filling Machines, Conveyors - uniformly loaded or fed (belt,

chain, screw), Fans (centrifugal), Generators (uniform load),

Pumps (centrifugal), Screens (air washing, water), Stokers

(uniform load), Woodworking Machines (planers, routers, saws)

Uniform

Characteristics

Even loads - no shock - non

reversing - infrequent starts (up

to 10 per hour) - low starting

torques

Beaters, Blowers (lobe, vane), Compressors (centrifugal, rotary), Moderate Uneven loads - moderate shock

Conveyors - non uniformly loaded or fed (belt, bucket, chain,

shock Infrequent reversing-moderate

screw), Dredge Pumps, Fans (forced draft, propeller), Kilns,

torques

Paper Mills (calendars, converting machines, conveyors, dryers,

mixers, winders), Printing Presses, Pumps (gear, rotary),

Shredders, Textile Machinery (dryers, dyers)

Cranes (bridge, hoist, trolley), Fans (cooling tower), Generators

(welding), Hammer Mills, Mills (ball, pebble, rolling, tube,

tumbling), Pumps (oil well), Wire Drawing Machines

Heavy

shock

Uneven loads - heavy shock frequent starts and stops - high

starting torques - high inertia

peak loads

Prime Mover

Class

A

B

C

1.0

1.5

2.0

1.5

2.0

2.5

2.0

2.5

3.0

Note: The above applications depict the generally accepted conditions encountered in industry. Conditions subject to extreme

temperatures, abrasive dusts, corrosive liquids, excessively high starting torques, etc., must be considered as extra heavy

shock loads. These conditions will increase service factors. Consult TB Woods for these selections.

C. Calculate Design Horsepower or Design Torque

If Prime Mover is a 1160, 1750, or 3500 rpm motor.

Design Hp = Prime Mover HP x Service Factor

Go to page F23 and reference the corresponding motor rpm column.

If Prime Mover is not one of the three speeds listed above.

Design HP @ 100 rpm = (Primer Mover Hp x Service Factor x 100) / Coupling RPM

Go to page F23 and reference HP @ 100 RPM column.

If Using Prime Mover Torque

Design Torque = Prime Mover Torque x Service Factor

Go to page F23 and reference Torque column.

D. Select Coupling (DURA-FLEX Couplings are sold by component)

A DURA-FLEX Assembly consists of one element (STD or Spacer) and two hubs (BTS or QD). Optional high speed rings may also

be ordered for spacer elements. Below is an ordering example for Dura-Flex Couplings.

Part #

Element (1)

Hubs (2)

HS Rings (1)

F22

WE2 - WE80

WES2 - WES80

WE[2-80] x Bore

WE[4-80] - Bushing

WE[3-80] - TL Bushing

WE[20-80]R

Description

Standard element, sizes 2 through 80

Spacer element, sizes 2 through 80

BTS hubs - stock bore (specify bore size)

QD hubs (sizes 4 through 80, bushing not included)

TL hubs (sizes 3 through 80, bushing not included)

High speed rings - sizes 20-80 (standard for sizes 2-10)

Size 20 Example

WE20

WES20

WE20H138

WE20H

WE20HTL

WE20R

DURA-FLEX COUPLING SELECTION

(continued)

COUPLING RATINGS (STD & SPACER)

3500

Torque

(IN LBS)

Stiffness

in lbs/

Radian

Standard

10.55

20.27

30.54

51.37

80.52

127.73

202.70

305.43

424.83

694.17

1229.20

2194.50

190

365

550

925

1450

2300

3650

5500

7650

12500

22125

39500

3170

4710

5370

9820

15800

27600

42200

65200

123000

167000

205000

305000

7500

7500

7500

7500

7500

6600

5800

5000

4200

3800

3600

2000

HP @ RPM

Coupling

Size

100

1160

1750

WE2

WE3

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

.30

.58

.88

1.48

2.30

3.65

5.79

8.85

12.14

19.84

35.12

62.70

3.50

6.72

10.12

17.02

26.69

42.33

67.18

101.23

140.80

230.07

407.39

727.32

5.28

10.13

15.27

25.68

40.26

63.86

101.35

152.72

212.42

347.08

614.60

1097.30

Maximum Rpm

Spacer*

Max. Misalignment

Parallel

Angular

1/16

1/16

1/16

1/16

1/16

3/32

3/32

3/32

3/32

1/8

1/8

1/8

4

4

4

4

4

3

3

3

3

2

2

2

7500

7500

7500

7500

7500

4800

4200

3600

3100

2800

2600

1800

*Maximum spacer RPM = Maximum standard RPM if using optional high speed rings. Operating temperature range is 40 F to 200 F.

BTS HUBS - STOCK BORES

BORE SIZE PRODUCT NO.*

1/2

12

5/8

58

3/4

34

7/8

78

15/16

15/16

1

1

1-1/16

1116

1-1/8

118

1-3/16

1316

1-1/4

114

1-5/16

1516

1-3/8

138

1-7/16

1716

1-1/2

112

1-9/16

1916

1-5/8

158

1-11/16

11116

1-3/4

134

1-7/8

178

1-15/16

11516

2

2

2-1/8

218

2-3/16

2316

2-1/4

214

2-3/8

238

2-1/2

212

2-5/8

258

2-3/4

234

2-7/8

278

3-3/8

338

3-3/4

334

3-7/8

378

4

4

4-3/8

438

4-7/8

478

MAX BORE

WE2H

O

X

XS

XS

WE3H

O

X

XS

XS

XS

XS

XS

XS

WE4H

WE5H

WE10H

WE20H

WE30H

WE40H

O

X

XS

XS

XS

XS

X

X

XS

XS

XS

XS

XS

XS

X

X

XS

X

S

X

XS

X

XS

XS

X

X

XS

X

XS

XS

XS

X

XS

XS

XS

WE50H

WE60H

WE70H

WE80H

OX

XS

X

XS

XS

X

X

X

XS

X

X

X

XS

X

XS

XS

X

X

XS

X

X

X

XS

X

X

XS

X

X

XS

XS

XS

X

X

XS

XS

O

X

XS

XS

XS

X

XS

X

X

X

XS

XS

XS

XS

XS

X

X

X

X

X

X

X

X

X

X

X

X

X

X

1-1/8

1-3/8

1-11/16

1-7/8

2-1/8

2-3/8

O NO KEYSEAT

X STANDARD KEYSEAT

S STEEL HUB OPTION

MAX. BORE INCLUDES STANDARD KEYSEAT

* PRODUCT NUMBER EXAMPLE

WE5H114 for WE5 x 1-1/4 HUB

WE5HS118 for WE5 x 1-1/8 STEEL HUB

2-7/8

3-3/8

3-5/8

4-1/2

X

6

BORE TOLERANCES (BTS)

BORE SIZE

UP TO AND INCLUDING 2

OVER 2

TOLERANCE

+.0005 to +.0015

+.0005 to +.0020

F23

DURA-FLEX BTS COUPLINGS

Assembly Dimensions for BTS Couplings.

(All dimensions in inches)

Minimum Shaft Spacing = .25

Dimensions Common to BTS Standard and Spacer Assemblies

SIZE

WE2

WE3

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

&

&

&

&

&

&

&

&

&

&

&

&

WES2

WES3

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

Max. Bore

3.70

4.24

4.52

5.40

6.48

7.36

8.41

9.71

11.34

12.53

14.00

16.00

1.85

2.32

2.6

3.13

3.65

4.48

5.42

6.63

8.13

8.75

9.25

11.3

0.94

1.50

1.69

1.75

1.88

2.06

2.31

2.50

2.75

3.25

3.62

4.87

1-1/8

1-3/8

1-5/8

1-7/8

2-1/8

2-3/8

2-7/8

3-3/8

3-5/8

4

4-1/2

6

Standard Element Assembly

Product

No.*

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

lbs.

WE2

WE3

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

3.78

4.32

4.68

5.30

5.57

6.82

7.61

8.16

9.21

10.70

11.00

14.75

3.22

3.80

3.82

4.32

4.13

4.30

4.63

5.08

5.79

6.44

7.20

9.30

1.90

1.32

1.30

1.80

1.81

2.70

2.99

3.16

3.71

4.20

4.86

6.64

1.5

3.3

4.4

7.4

11.2

16.3

27.7

45.4

59.0

82.6

109.0

242.0

* Product number is element only.

Spacer Element Assembly

Product

No.*

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

lbs.

WES2

WES3

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

5.72

8.02

8.38

8.50

8.76

11.17

11.65

11.89

12.31

16.28

16.81

19.73

5.72

7.28

7.28

7.28

7.28

9.35

9.35

9.35

9.35

12.40

12.50

12.50

4.04

5.02

5.00

5.00

5.00

7.05

7.03

6.89

6.81

9.78

9.57

9.77

2.5

4.8

6.1

9.4

13.6

19.2

31.0

48.9

63.5

91.0

128

258

* Product number is element only.

Sizes WES2 through WES10 are furnished

with high speed rings. All larger sizes, rings

can be ordered as an option.

All weights shown are with MPB style hubs.

Shaft Spacing from 1/4 up to the MAX DBSE can be accomodated by positioning hubs IN or OUT or by using various existing hole

patterns. OAL - Over All Length does Not include bolt heads

F24

DURA-FLEX QD BUSHED COUPLINGS

Assembly Dimensions for QD Bushed Couplings.

(All dimensions in inches)

Minimum Shaft Spacing = .25

Dimensions Common to QD Bushed Standard and Spacer Assemblies

SIZE

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

&

&

&

&

&

&

&

&

&

&

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

Bushing

Max. Bore

4.52

5.40

6.48

7.36

8.41

9.71

11.34

12.53

14.00

16.00

2.60

3.13

3.65

4.48

5.42

6.63

8.13

8.75

9.25

11.3

1.00

1.25

1.31

1.88

2.00

2.63

2.63

3.63

4.50

6.75

JA

SH

SDS

SK

SF

E

E

F

J

M

1-1/4

1-11/16

2

2-5/8

2-15/16

3-1/2

3-1/2

4

4-1/2

5-1/2

Standard Element Assembly

Product

No.*

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

lbs.

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

3.88

4.50

4.95

6.37

5.94

6.75

7.88

8.88

10.47

14.72

3.24

4.24

3.83

4.38

5.43

6.50

6.61

8.68

10.12

13.97

1.88

1.88

2.31

2.62

2.19

1.74

2.89

1.96

1.72

1.47

3.8

6.0

8.8

15.9

25.1

47.0

48.0

79.4

124

268

* Product number is element only.

Spacer Element Assembly

Product

No.*

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

lbs.

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

7.58

7.71

8.14

10.72

9.98

10.48

10.98

14.46

15.41

17.85

7.28

7.28

7.28

9.35

9.35

9.35

9.35

12.40

12.50

14.35

5.58

5.08

5.50

6.97

6.23

5.47

5.99

7.54

6.65

4.60

5.5

8.0

11.2

18.8

28.4

50.5

52.5

106.8

143

284

* Product number is element only.

Sizes WES4 through WES10 are furnished

with high speed rings. All larger sizes, rings

can be ordered as an option.

All weights shown are with MPB bushings.

Shaft Spacing from 1/4 up to the MAX DBSE can be accomodated by positioning hubs IN or OUT or by using various existing hole

patterns. OAL - Over All Length does Not include bolt heads

F25

DURA-FLEX Taper-Lock BUSHED COUPLINGS

Assembly Dimensions for Taper-Lock Bushed Couplings.

(All dimensions in inches)

Minimum Shaft Spacing = .25

Dimensions Common to Taper-Lock Bushed Standard and Spacer Assemblies

SIZE

WE3

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

&

&

&

&

&

&

&

&

&

&

&

WES3

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

Bushing

Max. Bore

4.24

4.52

5.40

6.48

7.36

8.41

9.71

11.34

12.53

14.00

16.00

2.32

2.60

3.13

3.65

4.48

5.42

6.63

8.13

8.75

9.25

11.3

0.88

0.88

0.88

1.00

1.00

1.25

1.75

1.75

2.00

3.50

4.00

TL1008

TL1008

TL1108

TL1310

TL1610

TL2012

TL2517

TL2517

TL3020

TL3535

TL4040

1

1

1-1/8

1-7/16

1-11/16

2-1/8

2-11/16

2-11/16

3-1/4

3-15/16

4-7/16

Standard Element Assembly

Product

No.*

OAL

Maximum

DBSE

Weight

lbs.

WE3

WE4

WE5

WE10

WE20

WE30

WE40

WE50

WE60

WE70

WE80

3.44

3.44

3.94

4.06

4.50

5.06

5.88

6.50

7.31

9.38

11.75

1.69

1.69

2.19

2.06

2.50

2.56

2.38

3.00

3.31

2.38

3.75

1.8

2.6

4.0

6.0

9.0

13.6

21.8

31.5

46.6

66.7

82.0

* Product number is element only.

Spacer Element Assembly

Product

No.*

OAL

MAX

OAL

MIN

WES3

WES4

WES5

WES10

WES20

WES30

WES40

WES50

WES60

WES70

WES80

7.28

7.28

7.28

7.28

9.35

9.35

9.59

9.59

12.90

14.34

14.84

7.28

7.28

7.28

7.28

9.35

9.35

9.35

9.35

12.40

12.50

14.35

Maximum Weight

DBSE

lbs.

5.38

5.38

5.38

5.25

6.87

6.60

6.11

6.11

8.90

7.34

6.84

3.2

4.2

6.0

7.9

11.9

18.0

26.8

37.4

60.7

81.4

93.2

* Product number is element only.

Taper-Lock is a registered tradename of Rockwell Automation-Dodge.

F26

Sizes WES3 through WES10 are furnished

with high speed rings. All larger sizes, rings

can be ordered as an option.

All weights shown are with MPB bushings.

DURA-FLEX METRIC COUPLINGS

Patent No. 5,611,732

FEATURES

Metric Hardware

Designed from the ground up using finite element analysis to maximize flex life.

Easy two piece element installation. No need to move the hubs during replacement.

One spacer size to handle most different between shaft spacings.

Light weight element absorbs shock loading and torsional vibration.

Same hubs used on both spacer and standard elements.

No lubrication.

Good chemical resistance.

The specially designed split-in-half element can be easily

replaced without moving any connected equipment.

Taper-Lock is a registered tradename of Rockwell Automation-Dodge.

F27

DURA-FLEX METRIC COUPLING SELECTION

A. Determine the Prime Mover Classification

Prime Mover

Class

Electric Motors (Standard duty), Hydraulic Motors, Turbines

Gasoline or Steam Engines (4 or more cylinders)

Diesel or Gas Engines, High Torque Electric Motors

A

B

C

B. Determine the Load Characteristics and the Service Factor

Typical Applications

Agitators (pure liquids), Blowers (centrifugal, Can and Bottle

Filling Machines, Conveyors - uniformly loaded or fed (belt,

chain, screw), Fans (centrifugal), Generators (uniform load),

Pumps (centrifugal), Screens (air washing, water), Stokers

(uniform load), Woodworking Machines (planers, routers, saws)

Load

Uniform

Characteristics

Even loads - no shock - non

reversing - infrequent starts (up

to 10 per hour) - low starting

torques

Beaters, Blowers (lobe, vane), Compressors (centrifugal, rotary), Moderate Uneven loads - moderate shock

Conveyors - non uniformly loaded or fed (belt, bucket, chain,

shock Infrequent reversing-moderate

screw), Dredge Pumps, Fans (forced draft, propeller), Kilns,

torques

Paper Mills (calendars, converting machines, conveyors, dryers,

mixers, winders), Printing Presses, Pumps (gear, rotary),

Shredders, Textile Machinery (dryers, dyers)

Cranes (bridge, hoist, trolley), Fans (cooling tower), Generators

(welding), Hammer Mills, Mills (ball, pebble, rolling, tube,

tumbling), Pumps (oil well), Wire Drawing Machines

Heavy

shock

Uneven loads - heavy shock frequent starts and stops - high

starting torques - high inertia

peak loads

Prime Mover

Class

A

B

C

1.0

1.5

2.0

1.5

2.0

2.5

2.0

2.5

3.0

Note: The above applications depict the generally accepted conditions encountered in industry. Conditions subject to extreme

temperatures, abrasive dusts, corrosive liquids, excessively high starting torques, etc., must be considered as extra heavy

shock loads. These conditions will increase service factors. Consult TB Woods for these selections.

C. Calculate Design Horsepower or Design Torque

If Prime Mover is a 970, 1450, or 3000 rpm motor.

Design KW = Prime Mover KW x Service Factor

Go to page F29 and reference the corresponding motor rpm column.

If Prime Mover is not one of the three speeds listed above.

Design KW @ 100 rpm = (Primer Mover KW x Service Factor x 100) / Coupling RPM

Go to page F29 and reference KW @ 100 RPM column.

If Using Prime Mover Torque

Design Torque = Prime Mover Torque x Service Factor

Go to page F29 and reference Torque column.

F28

DURA-FLEX METRIC COUPLING

SELECTION (continued)

D. DURA-FLEX Couplings are sold by component

A DURA-FLEX Assembly consists of one element (STD or Spacer) and two hubs (BTS or QD). Optional high

speed rings may also be ordered for spacer elements. Below is an ordering example for Dura-Flex Couplings.

Part #

Description

Size 20 Example

Element (1)

WE2M WE80M

WES2M WES80M

Standard Metric Element, sizes 2 through 80

Spacer Metric Element, sizes 2 through 80

WE20M

WES20M

Hubs (2)

WE[2-80] MPB

WE[3-80] TL Bushing

BTS Hubs MPB suitable to rebore

TL Hubs (sizes 3 through 80, bushing not included)

WE20MMPB

WE20MTL

HS Rings (1)

WE[20-80]R

High speed rings sizes 20-80 (standard for sizes 2-10)

WE20RM

COUPLING RATINGS (STD & SPACER)

Coupling

Size

KW @ RPM

100

970

1450

3000

WE2M

0.22

2.17

3.24

6.71

WE3M

0.43

4.20

6.27

12.98

WE4M

.66

6.37

9.52

19.69

WE5M

1.10 10.71 16.00

33.11

WE10M 1.72 16.64 24.87

51.45

WE20M 2.72 26.40 39.47

81.65

WE30M 4.32 41.88 62.61 129.53

WE40M 6.60 64.01 95.69 197.98

WE50M 9.05 87.81 131.27 271.58

WE60M 14.79 143.51 214.52 443.84

WE70M 26.19 254.03 379.74 785.67

WE80M 46.76 453.53 677.95 1402.66

Torque Stiffness

(Nm) NM/RAD

21.47

41.24

62.14

104.5

163.8

259.9

412.4

621.4

864.3

1412

2500

4463

358

532

607

1110

1790

3120

4770

7370

13900

18900

23200

34500

Maximum Rpm

Standard Spacer*

7500

7500

7500

7500

7500

6600

5800

5000

4200

3800

3600

2000

7500

7500

7500

7500

7500

4800

4200

3600

3100

2800

2600

1800

Max. Misalignment

Parallel

(MM)

1.6

1.6

1.6

1.6

1.6

2.4

2.4

2.4

2.4

3.2

3.2

3.2

Angular

4

4

4

4

4

3

3

3

3

2

2

2

*Maximum spacer RPM = Maximum standard RPM if using optional high speed rings

F29

DURA-FLEX METRIC BTS COUPLINGS

Assembly Dimensions for BTS Couplings.

(All dimensions in millimeters)

Minimum Shaft Spacing = 6.35mm

Dimensions Common to BTS Standard and Spacer Assemblies

SIZE

Max Bore

WE2M & WES2M

WE3M & WES3M

WE4M & WES4M

WE5M & WES5M

WE10M & WES10M

WE20M & WES20M

WE30M & WES30M

WE40M & WES40M

WE50M & WES50M

WE60M & WES60M

WE70M & WES70M

WE80M & WES80M

94

108

115

137

165

187

214

247

288

318

356

406

47

59

66

80

93

114

138

168

207

222

235

287

24

38

43

44

48

52

59

64

70

83

92

124

29

35

41

48

54

60

73

86

92

102

114

152

Standard Element Assembly

Product

No.

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

kg

WE2M

WE3M

WE4M

WE5M

WE10M

WE20M

WE30M

WE40M

WE50M

WE60M

WE70M

WE80M

96

110

119

135

141

173

193

207

234

272

279

375

82

97

97

110

105

109

118

129

147

164

183

236

48

34

33

46

46

69

76

80

94

107

123

169

.07

1.5

2.0

3.4

5.1

7.4

12.6

20.6

26.8

37.5

49.4

110

* Product number is element only.

Spacer Element Assembly

Product

No.

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

kg

WES2M

WES3M

WES4M

WES5M

WES10M

WES20M

WES30M

WES40M

WES50M

WES60M

WES70M

WES80M

145

204

213

216

223

284

296

302

313

414

427

501

145

185

185

185

185

237

237

237

237

315

318

318

103

128

127

127

127

180

180

175

173

248

243

248

1.1

2.2

2.8

4.3

6.2

8.7

14.1

22.2

28.8

41.3

58.1

117

Sizes WES2M through WES10M are

furnished with high speed rings. All larger

sizes, rings can be ordered as an option.

All weights shown are with MPB style hubs.

* Product number is element only.

Shaft Spacing from 6.35 mm up to the MAX DBSE can be accomodated by positioning hubs IN or OUT or by using various existing

hole patterns. OAL Over All Length does Not include bolt heads.

F210

DURA-FLEX METRIC Taper-Lock

BUSHED COUPLINGS

Assembly Dimensions for Taper-Lock Bushed Couplings.

(All dimensions in millimeters)

Minimum Shaft Spacing = 6.35 mm

Dimensions Common to Taper-Lock Bushed Standard and Spacer Assemblies

SIZE

Bushing

Max Bore

WE3M & WES3M

WE4M & WES4M

WE5M & WES5M

WE10M & WES10M

WE20M & WES20M

WE30M & WES30M

WE40M & WES40M

WE50M & WES50M

WE60M & WES60M

WE70M & WES70M

WE80M & WES80M

108

115

137

165

187

214

247

288

318

356

406

59

66

80

93

114

138

168

207

222

235

287

22

22

22

25

25

32

44

44

51

89

102

TL1008

TL1008

TL1108

TL1310

TL1610

TL2012

TL2517

TL2517

TL3020

TL3535

TL4040

26

26

29

36

44

55

68

68

82

100

113

Standard Element Assembly

Product

No.

OAL

Maximum

DBSE

Weight

kg

WE3M

WE4M

WE5M

WE10M

WE20M

WE30M

WE40M

WE50M

WE60M

WE70M

WE80M

87

87

100

103

114

129

149

165

186

238

298

43

43

56

52

64

65

60

76

84

60

95

0.8

1.2

1.8

2.7

4.1

6.2

9.9

14.3

21.1

30.3

37.2

* Product number is element only.

Spacer Element Assembly

Product

No.

OAL

MAX

OAL

MIN

Maximum

DBSE

Weight

kg

WES3M

WES4M

WES5M

WES10M

WES20M

WES30M

WES40M

WES50M

WES60M

WES70M

WES80M

185

185

185

185

237

237

244

244

328

364

377

185

185

185

185

237

237

237

237

315

318

318

137

137

137

133

174

168

155

155

226

186

174

1.5

1.9

2.7

3.6

5.4

8.2

12.2

17.0

27.5

36.9

42.3

Sizes WES3M through WES10M are

furnished with high speed rings. All larger

sizes, rings can be ordered as an option.

All weights shown are with MPB bushings.

* Product number is element only.

Taper-Lock is a registered Trademark of Rockwell Automation - Dodge

Shaft Spacing from 6.35 mm up to the MAX DBSE can be accomodated by positioning hubs IN or OUT or by using various existing

hole patterns. OAL Over All Length does Not include bolt heads.

F211

We Have A Product for ALL Your Coupling Needs

Besides the full line of stock DURA-FLEX couplings

Woods has other stock coupling lines that may fill your application.

Sure-Flex

Operates in shear

No lubrication

Four-way flexibility

Easy installation

Up to 115 HP

@ 100 rpm

Gear Couplings

High Torque Capacity

Torsionally Stiff

Good Inherent Balance

Rated for Higher Speeds

Many Types and Configurations

Up to 2714 HP

@ 100 rpm

Jaw Couplings

Form-Flex

All metal construction

No lubrication

Wide temperature range

Zero backlash

API offering

Economical

No maintenance

Industry standard

Large inventories

Up to 3175 HP

@ 100 rpm

Up to 30 HP

@ 100 rpm

Vous aimerez peut-être aussi

- Dura Flex公制Document8 pagesDura Flex公制liyuping200809Pas encore d'évaluation

- Sec f2Document12 pagesSec f2saul ospinoPas encore d'évaluation

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 pagesThomson Super Metric Ball Bushing Bearings SpecsheetElectromatePas encore d'évaluation

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123Pas encore d'évaluation

- Cabaccat2012k RITZDocument28 pagesCabaccat2012k RITZKosong SudahanPas encore d'évaluation

- Jaw Coupling PDFDocument4 pagesJaw Coupling PDFhibhavuPas encore d'évaluation

- HVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EDocument5 pagesHVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EChristopher GarciaPas encore d'évaluation

- Duff-Norton Actuator Product GuideDocument12 pagesDuff-Norton Actuator Product GuideDeepu RockzzPas encore d'évaluation

- E211.21 Usl Catalogo Tpi Veot-Veos TrenchDocument8 pagesE211.21 Usl Catalogo Tpi Veot-Veos TrenchMario Eduardo Najera RamosPas encore d'évaluation

- Type Veot and VeosDocument8 pagesType Veot and VeosBalu M100% (1)

- Type Veot and VeosDocument8 pagesType Veot and VeosMahmoud WalyPas encore d'évaluation

- Arvis Brochure Plain BearingsDocument28 pagesArvis Brochure Plain BearingsJavierPas encore d'évaluation

- Catalogo Giunti Samiflex - GB PDFDocument8 pagesCatalogo Giunti Samiflex - GB PDFDANE80Pas encore d'évaluation

- Well HandyDocument6 pagesWell HandymtonellyPas encore d'évaluation

- ShaftClampEls LowDocument20 pagesShaftClampEls LowBaneMarkovicPas encore d'évaluation

- Exploiting of Coiled TubingDocument298 pagesExploiting of Coiled Tubingbelahmeurs86% (7)

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800Pas encore d'évaluation

- Castel Globe ValveDocument17 pagesCastel Globe Valveroy fadliPas encore d'évaluation

- Tratos Flex000Document64 pagesTratos Flex000twinvbooksPas encore d'évaluation

- TERA Joint BrochureDocument16 pagesTERA Joint BrochureraigoukiPas encore d'évaluation

- MHD55148 BOP Catalog 052008Document20 pagesMHD55148 BOP Catalog 052008jlmunozv100% (4)

- Enerpac Hydratight Powergen CapabilitiesDocument81 pagesEnerpac Hydratight Powergen CapabilitiesAhmed El TayebPas encore d'évaluation

- Transformer Manual GuideDocument35 pagesTransformer Manual Guidejiguparmar1516100% (1)

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosPas encore d'évaluation

- Desalination pump design bookletDocument14 pagesDesalination pump design bookletBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- RUDDER AND RUDDER STOCK INSPECTION GUIDEDocument12 pagesRUDDER AND RUDDER STOCK INSPECTION GUIDEJORGEPas encore d'évaluation

- PSK GET 9th v2Document827 pagesPSK GET 9th v2Luis PozoPas encore d'évaluation

- STAR - Linear Bushings and Shafts, Miniature Version OverviewDocument64 pagesSTAR - Linear Bushings and Shafts, Miniature Version Overviewgiu_gloPas encore d'évaluation

- Submersible Sand Pumps for Foundation WorksDocument5 pagesSubmersible Sand Pumps for Foundation WorksGuilherme CamposPas encore d'évaluation

- Thomson Roundrail 2DA Modular SpecsheetDocument2 pagesThomson Roundrail 2DA Modular SpecsheetElectromatePas encore d'évaluation

- 22 1739 04 - 02012010XXDocument16 pages22 1739 04 - 02012010XXMartinez MarPas encore d'évaluation

- Terex Priključki PDFDocument12 pagesTerex Priključki PDFnivaman03Pas encore d'évaluation

- Quick Release Hooks and CapstansDocument8 pagesQuick Release Hooks and CapstansRaul Strugar100% (1)

- SS2 Agv200 0300 01Document12 pagesSS2 Agv200 0300 01RaymondIlyasPas encore d'évaluation

- Ebac Bushing: Ansi Standard IEEE C57.19.01-2000Document8 pagesEbac Bushing: Ansi Standard IEEE C57.19.01-2000ElectrificationPas encore d'évaluation

- Fluid Tech-Info enDocument17 pagesFluid Tech-Info enadhityaPas encore d'évaluation

- Re77502 2004-05Document20 pagesRe77502 2004-05pamururamuPas encore d'évaluation

- Curve Jaw Type Coupling LOVEJOY PDFDocument17 pagesCurve Jaw Type Coupling LOVEJOY PDFRafo Vega GuerovichPas encore d'évaluation

- C 107 Pulley Catalog 11 05 LowDocument42 pagesC 107 Pulley Catalog 11 05 LowMauricio MpintoPas encore d'évaluation

- Drill Stem Components GuideDocument28 pagesDrill Stem Components Guidechonubobby100% (1)

- Falk Coupling SGDocument16 pagesFalk Coupling SGJorge Ernesto PinzonPas encore d'évaluation

- MAN YLD01C Chain Hoists eDocument44 pagesMAN YLD01C Chain Hoists eJohannesJacobsPas encore d'évaluation

- H 04437Document4 pagesH 04437E_Amr_SorourPas encore d'évaluation

- G2DT-21 2HP-230V-60HZ-1FDocument8 pagesG2DT-21 2HP-230V-60HZ-1FDaniel AbantoPas encore d'évaluation

- Belt and Chain DrivesDocument10 pagesBelt and Chain DrivesJagdip ShethPas encore d'évaluation

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDocument24 pagesRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioPas encore d'évaluation

- KSB B Deep Well Turbine Pump Technical DataDocument36 pagesKSB B Deep Well Turbine Pump Technical DataKishore Krishna0% (1)

- CDA - Elecon Flexible CouplingDocument5 pagesCDA - Elecon Flexible CouplingMohit GuptaPas encore d'évaluation

- Bulletin 190-B Solutions for Construction TestingDocument70 pagesBulletin 190-B Solutions for Construction TestingMarcelo SánchezPas encore d'évaluation

- Operating LIC: Manual JARDocument7 pagesOperating LIC: Manual JARDanciulescu Mircea GabrielPas encore d'évaluation

- MS 01 179Document12 pagesMS 01 179Billy ZununPas encore d'évaluation

- ID Fan Dodge BRGDocument4 pagesID Fan Dodge BRGjhanduPas encore d'évaluation

- Bettis CBA 725Document16 pagesBettis CBA 725kutts76100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- EnRD ECO CENTER PDFDocument56 pagesEnRD ECO CENTER PDFMhare Oroceo CasanovaPas encore d'évaluation

- Bar Screening Environmental EngineeringDocument11 pagesBar Screening Environmental EngineeringRajat Kushwaha100% (1)

- Epoxy Grout for ConstructionDocument3 pagesEpoxy Grout for Constructionarunjacobn100% (2)

- Delco Remy - Manual de DiagnósticoDocument32 pagesDelco Remy - Manual de Diagnósticosanches pita100% (1)

- Saes H 101VDocument83 pagesSaes H 101Vacolombel100% (2)

- Lennox G26 Installation InstructionsDocument31 pagesLennox G26 Installation Instructionslinkheating100% (1)

- Application of NanotubesDocument28 pagesApplication of Nanotubesarian2arian2Pas encore d'évaluation

- Plano de Una Mesa para SoldarDocument1 pagePlano de Una Mesa para SoldarHugo Alfredo Ordóñez Chocano86% (7)

- M&E MeasurementDocument6 pagesM&E MeasurementDar RylPas encore d'évaluation

- Firecel General Catalogue - 100-4Document32 pagesFirecel General Catalogue - 100-4dinesh_kp7647Pas encore d'évaluation

- ProTrack I ManualDocument203 pagesProTrack I ManualhishamuddinohariPas encore d'évaluation

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaPas encore d'évaluation

- Environmental Product Declaration: Interpon D2000 Powder CoatingsDocument22 pagesEnvironmental Product Declaration: Interpon D2000 Powder CoatingsmaPas encore d'évaluation

- PMI Procedure PDFDocument10 pagesPMI Procedure PDFMohammed Abdul Majid IrfanPas encore d'évaluation

- Nitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes RapidlyDocument14 pagesNitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes Rapidlyapi-25909541Pas encore d'évaluation

- Mcs 2010Document196 pagesMcs 2010rvillgPas encore d'évaluation

- An Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped PartDocument4 pagesAn Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped Partparag7676Pas encore d'évaluation

- Interactions Between Base Paper and Coating Color in Metered Size Press CoatingDocument99 pagesInteractions Between Base Paper and Coating Color in Metered Size Press CoatingHuy NguyenPas encore d'évaluation

- Indium Tin Oxide PDFDocument25 pagesIndium Tin Oxide PDFadhityaPas encore d'évaluation

- Reducing Fabric Waste in Cutting Through Marker EfficiencyDocument43 pagesReducing Fabric Waste in Cutting Through Marker EfficiencyMênfës Mgb GèdēchãPas encore d'évaluation

- Door Built Up RateDocument6 pagesDoor Built Up RateSebb seebPas encore d'évaluation

- Sub Title IodoformDocument3 pagesSub Title IodoformReni whynPas encore d'évaluation

- Atrita Pulverizer Products and ServicesDocument36 pagesAtrita Pulverizer Products and ServicesYousuf AliPas encore d'évaluation

- Sampling Procedure For Impact Testing of Structural SteelDocument5 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultomPas encore d'évaluation

- Unit 2 Me1203Document20 pagesUnit 2 Me1203Muthuvel MPas encore d'évaluation

- Magnetic Effects of Electric Current ( (Term I)Document15 pagesMagnetic Effects of Electric Current ( (Term I)Tapas BanerjeePas encore d'évaluation

- Cement Kiln ReportDocument22 pagesCement Kiln Reportamir100% (1)

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaPas encore d'évaluation

- Circuit Breaker SF6Document6 pagesCircuit Breaker SF6GautamPas encore d'évaluation

- Haas Mill WIPS Probe Training ManualDocument44 pagesHaas Mill WIPS Probe Training ManualpocerilloPas encore d'évaluation