Académique Documents

Professionnel Documents

Culture Documents

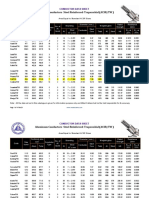

Ac Resistance Measurement of Connectors

Transféré par

Travis WoodCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ac Resistance Measurement of Connectors

Transféré par

Travis WoodDroits d'auteur :

Formats disponibles

OVERHEAD T&D

CHANNEL

ELECTRICAL

CONNECTORS

FOR OVERHEAD LINES

Evaluating assessment and test methodologies to improve quality

BY ALEX BABAKOV, CHRIS MORTON, HONG LI, Powertech Labs

& ROBYN PASCAL, CEATI International

tility distribution systems utilize a variety of connectors to

join and attach overhead conductors. These components

are simple and relatively inexpensive; however, due to their

critical function and the large number of components utilized in

the electrical system, they deserve some consideration from the

maintenance perspective.

Factors such as corrosion, improper installation, and

manufacturing defects can cause in-service failure of connectors

leading to safety risks to lineman crews and the public, and

compromising the reliability of the power supply.

Many utilities have experienced this problem and some have made

efforts to mitigate the risk. Due to the nature of the connector design,

the defects are typically hidden and cannot be detected easily. As a

result, blanket replacement sometimes is the only option, which can be

inefficient due to the large number of connectors replaced prematurely.

Thus, a need exists for an effective inspection tool that electric

utilities can use to provide information on the condition of the

connectors currently in service. This tool would allow utilities

to plan for the timely replacement of deteriorating connectors,

thereby reducing risks and costs in system operation.

In order to identify the most effective inspection tools, a study

titled, Assessment/Test Methodology of In-service Electrical Connectors

for Overhead Lines was conducted by Powertech Labs Inc., under

contract from the CEATI Distribution Assets Life Cycle Management

(DALCM) Interest Group, to review the electrical connector

assessment practices currently employed by utilities, as well as other

potentially applicable methods described in the technical literature.

Researchers tested the identified methods using connector samples

collected in the field and samples created in the lab to simulate

corrosion. Subsequently, researchers compared the collected

measurements to the actual condition of the connector samples.

22 | FALL 2015

STUDY APPROACH

The utility overhead distribution system uses numerous

connectors. These connectors vary in design and coupling

methods (that is, compression splices, automatic splices, and

clamps). Carl Tamm, a consultant with Classic Connectors,

considers connectors the weakest point of the overhead line.

The main objective of this study was to review and evaluate

the best practices for in-situ condition assessment and testing of

overhead electrical connectors. The study provides evaluation,

ranking, and recommendation of inspection techniques that

utilities can use to assess the condition of in-service electrical

connectors, giving quantitative information on their present

condition. These assessment methods would allow maintenance

personnel to plan prompt replacement times for deteriorating

connectors, thereby reducing the risks and cost of in-service

failures and premature replacements.

The scope of the project, established with the support of the

Distribution Assets program representing 37 North American

electric utilities, included a number of tasks (refer to Tasks for

Connector Project sidebar).

TASKS FOR CONNECTOR PROJECT

Identify most common connector types and features

Identify connector failure modes and causes

Review state-of-the-art connector condition assessment

methods through a technical literature review

Survey participating utilities practices and testing

methodologies currently used for connector inspection

Evaluate the most promising inspection methods through

laboratory tests

Summarize findings and provide recommendations, including

the most effective assessment approach, equipment,

and procedures as supported by verification results, and

suggestions for further research

FREE Subscription: www.electricity-today.com

Even though some connectors fail due to mechanical stress,

electrical failures appear to be more commonly reported.

CONNECTOR TYPES

Before considering the various connector assessment and test methodologies,

connector types, their features and failure mechanisms should be understood.

Researchers identified the four most common connector types: wedge, compression,

bolted, and automatic. These connector types differ in materials, design, and service

applications; however, the failure mechanisms appear to be common for all types.

Another major distinction in connector types is whether they are current carrying or not

(for example, dead-end connectors).

The connector type will indicate what possible stress and conditions the connector

will be exposed to and thus it can be used to assign a risk factor to the connector for the

purpose of asset management.

FAILURE MECHANISMS

Even though some connectors fail due to mechanical stress, electrical failures appear

to be more commonly reported. In these situations, the connector resistance increases

over time to a high enough value that a rapid deterioration of the connector occurs,

resulting in destruction due to electric overheating.

The cause of an increase in electrical resistance is usually a combination of several factors:

High initial resistance due to improper assembly/installation or defective materials

Degradation of electrical interfaces in the connector through thermal cycling

Oxidation of electrical interfaces due to contaminants and environmental effects

For current-carrying connectors, electrical resistance appears to be the main factor in

determining the service life of a connector, provided it is appropriately designed and

installed to withstand electrical and mechanical stress loads normally seen in service.

Over time, the contact resistance of the connector will increase from its initial

nominal value at the time of assembly. Steffen Grossmann, Helmet Lobl, and Helmut

Portable Instruments for monitoring

Power Quality and Energy Consumption

PQPro

EnergyPro

Meter Base

Adaptor

PowerPro

FREE Subscription: www.electricity-today.com

FALL 2015 | 23

Resistance

Principle of connector resistance vs. time

inflection point

Figure 1

Rlimit

R(t=0)

After

Installation

Relative

Stability

Accelerated

Aging

Source: Steffen Grossmann, Helmet Lobl, and Helmut Bohmes study,

Contact lifetime of connections in electrical power systems

Bohme identify in their study, Contact Lifetime of Connections in

Electrical Power Systems three factors that influence the rate of

change of contact resistance (refer to Contact Resistance Changers

sidebar). Figure 1 shows the increase of connector resistance

with time and the three phases of the connector service life as

proposed by this theory.

Once the electrical resistance of the connector reaches a

critical value, progression to failure is quite rapid. Either a thermal

runaway process or arcing will occur. The material at the connector

to conductor interface will eventually soften or melt, destroying

the connection. Softening of the conductor will also affect its

mechanical strength. For connectors under tensile load, the end

failure mode might cause a mechanical separation of the connector

and the conductor.

The relationship between connector temperature and resistance

is interdependent. The connector temperature is a result of a balance

between the heat generated by the passage of current through the

connector, and the heat dissipated from the connector. Since the

resistivity of the connector material is temperature dependent, as the

temperature of the connector increases, more heat will generate at a

given current level.

However, since dead-end connectors do not carry current, the

resistance of the connector joint is not applicable as an indicator

of its condition. For these types of connectors, mechanical fatigue

is the primary failure mechanism associated with long-term aging.

Failures due to mechanical fatigue occur in connectors, including

dead-end varieties, subjected to mechanical loads. The cause of

this failure mechanism is typically attributed to problems with

design, installation, manufacturing, or in-service damage.

Additionally, mechanical failures can be caused by overloading.

Overloading occurs due to improper installation (for example, over

tensioning the line), using incorrectly rated connectors or due to

accidents or natural events such as windstorms and icing events. In

24 | FALL 2015

Time

general, there appears to be fewer reports of connector failures due to

mechanical fatigue and overloading compared to electrical failures.

CONTACT RESISTANCE CHANGERS

Factors that influence rate of change in contact

resistance

Rate of connector joint expansion/contraction due to

thermal and mechanical stress

Rate of conductor and connector oxidation/corrosion

Temperature of the connector

Source: Grossmann, Lobl, and Bohme study, Contact Lifetime

of Connections in Electrical Power Systems

Although connectors vary in the way they are connected to the

conductor, the failure mechanisms appear to be common for all

types. The most common failure mechanism appears to be the

long-term increase in electrical resistance; however, due to the

long-time scales of this process, most connectors are replaced

before they fail.

CONNECTOR INSPECTION METHODS

In reviewing the current technologies and the technical

literature, four established and widely used inspection methods

are prevalent: visual inspection, infrared (IR) temperature

measurements, resistance measurements, and radiographic

inspection. Each method has its own benefits and shortcomings.

A utility survey has found that some utilities have used the

aforementioned inspection methods with various degrees of

success. Based on responses, participating utilities considered the

in-situ resistance measurement technique as the most accurate

FREE Subscription: www.electricity-today.com

inspection method. However, only a few utilities have used this

technique due to its higher cost of implementation. In addition,

most utilities that experienced success in identifying degraded

connectors used several different inspection methods. The most

commonly used included resistance measurement, infrared

thermography, and visual or radiographic inspection.

In addition, the placement of the measurement tool should be

such that the length of conductor and connector included in the

measurement are consistent. Maintenance engineers should choose

test procedures and pass/fail criteria carefully, in conjunction with

a thorough calibration and validation process using aged field

samples or fabricated lab samples of known condition.

LAB TESTS

DIRECT TEMPERATURE MEASUREMENTS

Based on the results of the technical literature review and

Direct temperature measurements appear to provide a satisfactory

utility survey, researchers chose several condition assessment

correlation with connector condition. However, this test method

methods, including alternating current resistance measurements,

did not appear to detect deterioration or resistance measurements.

infrared thermography, direct temperature measurements, and

From a practical perspective, this method has the same limitations

radiographic inspection, for further evaluation in the lab. The

as resistance measurement as it also requires direct access to

purpose was to, first, confirm the findings

described in the previous sections and, second,

obtain more data on the practical application

of the aforementioned assessment methods.

Researchers selected connector test samples

from a number of aged field samples based on

visual and radiographic inspection. In order to

supplement the quantity of connectors in poor

condition, additional samples were prepared

in the lab to simulate connector corrosion

and improper installation. Figure 2 shows a

connector sample having several anodized

conductor strands in order to simulate

deterioration due to oxidation/corrosion.

Researchers evaluated the samples using

the aforementioned condition assessment

methods and then subjected the samples

to fault current tests. Subsequently, the

researchers dissected the samples to

determine their exact condition and to

decide if any correlation existed between the

condition assessment results. Researchers

made some notable observations during the

lab tests.

For example, a considerable challenge in

evaluating connector assessment methods

lies in obtaining connector test samples that

have a range of conditions, from excellent to

poor. This process is necessary to properly

judge the resolution and effectiveness of a

particular test method.

It is also important to have a sufficiently

large population size of samples so that

Outages due to animal contact are an estimated cost to the

the test results will have some statistical

United States of at least $18 billion in lost economy each year.

significance. A large number of samples will

also naturally provide variation in connector

Improve your power system reliability with Cantegas

parameters that researchers might not have

complete Greenjacket solution. Using a patent-pending 3D

considered during initial planning.

photogrammetry process, Cantega measures exact dimensions

Given that connector failures are a

of energized substation equipment. We manufacture animal

statistically rare occurrence, the main problem

of sample collection is finding field samples in

and bird protection covers that precisely fit the risk points in

worse than average and poor condition (refer

your substation distribution voltage equipment.

to Figure 3 on page 26). These types of samples

Because of the precise-fit, animal contact is prevented, your

are crucial to benchmarking the condition

assessment methods identified in the study.

system remains energized, and your reliability - and reputation -

Dont Let a Preventable

Outage Cost You

Your Reputation

RESISTANCE MEASUREMENTS

AC resistance measurements compared well

with sample conditions; however, when

making measurements on connectors that

join conductors of different size, the results

had to be interpreted with that fact in mind.

FREE Subscription: www.electricity-today.com

is protected. Get Greenjacket and install the highest standard

of animal contact prevention.

FALL 2015 | 25

Figure 2

Anodized conductor

the conductor, making it expensive and time consuming. In

addition, environmental conditions, line loading conditions, and

connector geometry will influence the temperature difference of

measurements and will increase inconsistency of the test results.

INFRARED THERMOGRAPHY

Infrared thermography (IR) inspection appears to be the least

expensive and most practical method. However, this technique

appears to be only effective for detecting severely deteriorated

connectors under favorable environmental conditions, with

appropriate line loading, adequate equipment, and properly

trained and experienced personnel.

Due to the difficulty in managing the number of variables

influencing infrared inspection, this method is unlikely to be

100-percent effective and, therefore, would not be reliable on its

own. Researchers observed both false positive and false negative

inspection resultseven in lab conditions. In addition, this

method is less reliable for new connectors and/or conductors

because of their low emissivity.

RADIOGRAPHIC INSPECTION

Radiographic inspection is useful in identifying problems

associated with improper installation, and since this is one of the

more common causes of connector failure, radiographic inspection

may have some potential. Additionally, utility personnel can use

this method to identify heavy corrosion in automatic splices (refer

to Figure 4 on page 28).

However, at this point, utility personnel cannot use radiographic

inspection to identify improper crimping of compression

connectors or bolted joints not fully tightened. As a result, the

techniques application is limited to detecting certain defects

such as misalignment or incomplete connector insertion. In other

words, utility personnel should consider radiographic inspection

only for specific applications.

STUDY CONCLUSIONS

Based on the information gathered in the technical literature,

the results of the utility survey and the observations from the

tests performed in the lab, AC resistance measurement appears

Figure 3

Cross-section of an automatic splice with heavy corrosion

26 | FALL 2015

FREE Subscription: www.electricity-today.com

to be the most reliable connector inspection method currently

available. However, the major drawback is the significant cost and

time associated with this method. Other assessment techniques

can be effective for specific applications. An approach that

combines several assessment methods such as AC resistance,

direct temperature measurements, and infrared temperature

measurement would be the most successful.

Given the large number of connectors in the distribution system,

it would be cost prohibitive to perform resistance measurements

on all connectors or even a significant portion. An inspection

approach that combines several of the discussed methods to

sample the population and provide statistical input for analysis

based on a reliability criteria and lifecycle cost analysis would likely

be the most successful. An appropriately structured program that

uses documented guidelines and procedures together with a data

management system will provide a clearer picture of connector

condition in the power grid. Based on the results of the utility

survey, it appears that several utilities are achieving success with

this approach.

FREE Subscription: www.electricity-today.com

A more

commprehensive

investigation evaluating

the effects of resistance

measurements on different

connector types is necessary.

FALL 2015 | 27

Figure 4

X-ray of an automatic splice with heavy internal corrosion

Researchers provided the following additional conclusions and

recommendations based on the results of the laboratory tests,

utility survey, and technology review.

A need exists for a comprehensive field study of the AC

resistance test method, supported by statistically significant field

data to give utilities confidence to utilize this assessment method.

An inspection using infrared thermography is only effective in

detecting severely deteriorated connectors under favourable

environmental conditions, with appropriate line loading, adequate

equipment, and properly trained and experienced personnel.

A more comprehensive investigation evaluating the effects

of resistance measurements on different connector types is

necessary.

28 | FALL 2015

The condition assessment methodologies evaluated in

this study are applicable to connectors used in both the

distribution system as well as the transmission system. Electric utilities

can further develop their condition assessment methods more

effectively by pooling resources from both systems together. ET

Alex Babakov, Chris Morton, and Hong Li, are electrical engineers

working with Powertech Labs. Alex works on projects and research

activities specializing in testing and condition assessment of T&D

utility equipment. Chris specializes in laboratory testing and failure

analysis work on electrical equipment. Hong Li has extensive

experience and knowledge in asset management of T&D structures

and components. Robyn Pascal is the Program Manager for

Distribution programs at CEATI International.

FREE Subscription: www.electricity-today.com

Vous aimerez peut-être aussi

- Re Voltage StabilityDocument27 pagesRe Voltage StabilityTravis WoodPas encore d'évaluation

- Anandaram BaruaDocument1 pageAnandaram BaruaTravis WoodPas encore d'évaluation

- 1363 Bolts and Nut Standard PDFDocument7 pages1363 Bolts and Nut Standard PDFTravis WoodPas encore d'évaluation

- Ceramic Manufacturing PDFDocument41 pagesCeramic Manufacturing PDFTravis WoodPas encore d'évaluation

- KSEB Technical SPec PDFDocument279 pagesKSEB Technical SPec PDFTravis WoodPas encore d'évaluation

- Unidirectional Corona RingDocument2 pagesUnidirectional Corona RingTravis WoodPas encore d'évaluation

- Gear Design For Quiet Reduction GearDocument8 pagesGear Design For Quiet Reduction GearTravis WoodPas encore d'évaluation

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 pagesAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodPas encore d'évaluation

- April Is The Cruellest MonthDocument1 pageApril Is The Cruellest MonthTravis WoodPas encore d'évaluation

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 pagesAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodPas encore d'évaluation

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Document6 pagesEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodPas encore d'évaluation

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385Pas encore d'évaluation

- Study of Single and Double Sampling PlansDocument14 pagesStudy of Single and Double Sampling PlansTravis WoodPas encore d'évaluation

- Double Sampling-Wha It Means PDFDocument17 pagesDouble Sampling-Wha It Means PDFTravis WoodPas encore d'évaluation

- Transformer Factory Assembly Area LayoutDocument55 pagesTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosPas encore d'évaluation

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodPas encore d'évaluation

- Ehv Disconnectors For Smart GridDocument2 pagesEhv Disconnectors For Smart GridTravis WoodPas encore d'évaluation

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pages3 Sec-III-Hardware Fittings & AccessoriesTravis WoodPas encore d'évaluation

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodPas encore d'évaluation

- Spacer Damper IssuesDocument5 pagesSpacer Damper IssuesTravis WoodPas encore d'évaluation

- Fretting Fatigue in Overhead ConductorsDocument16 pagesFretting Fatigue in Overhead ConductorsTravis WoodPas encore d'évaluation

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzPas encore d'évaluation

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodPas encore d'évaluation

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodPas encore d'évaluation

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodPas encore d'évaluation

- ElectricalDocument34 pagesElectricalTravis WoodPas encore d'évaluation

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 pagesAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodPas encore d'évaluation

- An Introduction To Conway's Games and NumbersDocument30 pagesAn Introduction To Conway's Games and NumbersSilentSparrow98Pas encore d'évaluation

- Bolt InterlocksDocument5 pagesBolt InterlocksTravis WoodPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Forged Gate, Globe and Check Valves CatalogDocument80 pagesForged Gate, Globe and Check Valves CatalogSulist N WahyudiePas encore d'évaluation

- IBIS Hotel Key Design and Construction CriteriaDocument2 pagesIBIS Hotel Key Design and Construction Criteriachien100% (1)

- Design and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesDocument9 pagesDesign and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesmrezaianPas encore d'évaluation

- An Architect Reviews Brigade Gateway Architecture IdeasDocument13 pagesAn Architect Reviews Brigade Gateway Architecture Ideasbala0% (1)

- 5-Clamping Principles & Clamps.Document69 pages5-Clamping Principles & Clamps.Karthigeyan MurugesanPas encore d'évaluation

- ISA RP60.3 Human Engineering For Control CentersDocument22 pagesISA RP60.3 Human Engineering For Control CentersDaniel Arrieta DarrásPas encore d'évaluation

- G-code Programming Language GuideDocument16 pagesG-code Programming Language GuideArnold NagyPas encore d'évaluation

- SG 247777Document862 pagesSG 247777ieatbeesPas encore d'évaluation

- EpicorSLS10 MigrateGuide SQL 10.2.100.505100Document219 pagesEpicorSLS10 MigrateGuide SQL 10.2.100.505100Marianne Hernandez MendietaPas encore d'évaluation

- Airworks TeaserDocument8 pagesAirworks TeaserNavin GuptaPas encore d'évaluation

- Project Title: Simple Cafe Billing System: Rajokari Institute of TechnologyDocument8 pagesProject Title: Simple Cafe Billing System: Rajokari Institute of TechnologyVinodPas encore d'évaluation

- Strategic Management g9 Elon Musk BetsDocument5 pagesStrategic Management g9 Elon Musk BetsJaya Neelanshi SethPas encore d'évaluation

- Rajasthan Power Sector Reforms Act 1999Document41 pagesRajasthan Power Sector Reforms Act 1999Latest Laws TeamPas encore d'évaluation

- The Envelopes of The Arts Centre in SingaporeDocument12 pagesThe Envelopes of The Arts Centre in SingaporeAndriPas encore d'évaluation

- How To Create Simple CDC in Oracle ODI 11GDocument10 pagesHow To Create Simple CDC in Oracle ODI 11GAlina MamayevPas encore d'évaluation

- Fabrication Processes: Cold Working Hot Working Castings Powder Metallurgy Machining Joining/WeldingDocument41 pagesFabrication Processes: Cold Working Hot Working Castings Powder Metallurgy Machining Joining/WeldingVenai SeelochanPas encore d'évaluation

- Presentation ON Rural Marketing Mix: Presented By: Aradhana Bhopte Ravneet KaurDocument23 pagesPresentation ON Rural Marketing Mix: Presented By: Aradhana Bhopte Ravneet KaurRavneet Kaur100% (1)

- Xerox Management Failed To See The Opportunities Afforded by Many of The Innovations at ParcDocument2 pagesXerox Management Failed To See The Opportunities Afforded by Many of The Innovations at Parcambrosialnectar50% (2)

- Lookbook 2019 High ResolutionDocument74 pagesLookbook 2019 High ResolutionAis Mktg100% (1)

- The Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationDocument15 pagesThe Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationSatya Sai KiranPas encore d'évaluation

- DB Cylinder Pressure Sensor enDocument2 pagesDB Cylinder Pressure Sensor enjulien17Pas encore d'évaluation

- Brochure Al Osais International Holding CompanyDocument4 pagesBrochure Al Osais International Holding CompanyhafezasadPas encore d'évaluation

- Drill Off Test OptimizationDocument9 pagesDrill Off Test OptimizationAmar BenAmarPas encore d'évaluation

- Nota - 2245047 - Pre Manual Implementation StepsDocument13 pagesNota - 2245047 - Pre Manual Implementation StepsCarlos Manoel SouzaPas encore d'évaluation

- The Six Big Losses in Manufacturing - EvoconDocument23 pagesThe Six Big Losses in Manufacturing - Evoconarvin john cabralPas encore d'évaluation

- Sudhakar ProjDocument71 pagesSudhakar ProjsureshexecutivePas encore d'évaluation

- Aviation Paperbacks 2012Document4 pagesAviation Paperbacks 2012tomas.kujal8455Pas encore d'évaluation

- EA - Maturity ModelDocument12 pagesEA - Maturity ModelAntonius SonyPas encore d'évaluation

- DESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Document5 pagesDESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Tanishq ShettyPas encore d'évaluation