Académique Documents

Professionnel Documents

Culture Documents

FactSheet Fiber Yarn Ring SpinningProcessing PDF

Transféré par

Prasad PotdarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FactSheet Fiber Yarn Ring SpinningProcessing PDF

Transféré par

Prasad PotdarDroits d'auteur :

Formats disponibles

Ring-spinning processing

Technical Bulletin 341104

Introduction

Blending, Opening and Cleaning

The sections that follow relate to the processing

bale laydown

of 1.5dtex 38 mm Ingeo PLA fiber intended for

Bales of Ingeo PLA weigh approximately 250 kg each

and should be used, where possible, sequentially

according to bale and lot/merge number.

conversion through the cotton or short staple

spinning route. The fiber has been engineered

specifically for ring spinning.

Fiber lengths other than 38 mm can be supplied

(for example 51 mm) where fiber blend or machinery

considerations are important. The information on

machinery settings is appropriate for such fibers but

some adjustments will be required for example, to

roller spacing in order to accommodate the different

fiber length. Additionally, roving twist, and possibly

yarn twist, will need adjustment.

Adherence to the recommended safety procedures

when opening bales is paramount. Suitable measures

should be taken to protect operators when automatic

systems are not in use. Bale wrappers should also

be disposed of according to local conditions.

While Ingeo PLA fiber has significantly less bale to

bale variation than cotton, as many bales as possible

should be used in each laydown. This will ensure that

fibers are thoroughly blended. Where continuous use

of Ingeo PLA fiber is anticipated, programmed use of

bales, from a range of deliveries, is recommended.

Ideally, fibers should be opened in a conditioned area

to allow the surface fibers to equilibrate and to

minimize the effects of condensation, particularly

where bales have been stored in a cold area. Transport

air should also be conditioned to ensure that the fibers

arrive at the card containing the appropriate amount of

moisture. Air conditions should be in the region of 2325 C,

50-60% RH.

Ring-spinning processing

blending

Both manual and automated systems can be used.

It is clear, however, that automated systems give

better, more intimate and controlled blending. The

open state of tufts of Ingeo PLA fiber makes for easy

bale skimming, with low increments (2-3 mm per slice).

Sandwich-type blenders can be used for additional

blending, particularly where manual feed systems

are employed or where blends with other fibers are

being used.

The use of Ingeo PLA fiber may necessitate

adjustments to volumetric feeds since the fiber has

good resilience and can be quite lofty on opening.

Settings similar to those for polyester or polyamide

are a good starting point.

Production rates will depend on the opening system

installation. However, a slower controlled rate is

preferable to large overfeeds and long stops. This gives

a more consistent feed to openers and cards.

Because of the open nature of Ingeo PLA fiber,

over trunking and excessive handling must be

avoided to reduce the possibility of inserting nep

and entangling fibers.

opening

The production of staple fibers made with Ingeo PLA

ensures that the filaments are not entangled and

that removal of foreign matter is not required. Hence

minimal opening is required to separate the fiber tufts

ready for carding. Waste removal is unnecessary and

fiber extraction should be minimal.

Only one opening point is recommended, preferably a

fully pinned beater. To avoid damage to the Ingeo PLA

fibers, settings and speeds should be similar to those

used for polyester or other man-made synthetics. Exact

settings and speeds will vary from machine to machine

according to the type.

(Note: Severe cotton opening systems must be avoided

to prevent the deterioration of yarn quality.)

It should be remembered that each additional machine

in the opening line will add nep and may even damage

the fibers, leading to a reduction in yarn strength and

an increase in yarn faults.

laps

To date, Ingeo PLA fiber has not been processed on

lap forming machinery. It is anticipated that settings

used for polyester or polyamide should be used as a

starting point should this route be needed.

spraying

Ingeo PLA fibers are finished with additives which

provide a balance of cohesion, lubrication and antistatic protection appropriate for the vast majority

of mills. Sprays are not needed on any installation

where carding and drawing equipment is less than

15 years old.

Before using oversprays please consult with

NatureWorks Technical Services to ensure that

these are really needed.

tinting

Tinting Ingeo PLA fiber is not recommended,

though work is continuing to identify safe

methods of application and removal.

Ring-spinning processing

Carding

The vast majority of short staple Ingeo PLA fiber used in

yarn manufacture is carded using chute feeds and

revolving flat cards.

chute feeding

Feed weights of between 500 and 900g are usual with

card drafts from 100 to 160. In general, older cards will

require lighter weights and lower drafts. Volumetric

settings as for bulky synthetic fibers are likely to

prove adequate.

card settings

Few changes to conventional card settings are required

to achieve even webs. Card wire should be suitable for

1.7dtex and finer fibers. Fig. 2 shows combinations of

wire types currently in commercial use. Wires designed

for man-made fibers are essential to give the best

performance and web quality. Aggressive cotton type

wires and settings will cause too much fiber damage

and must not be used.

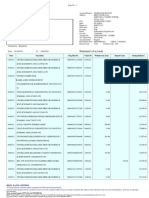

Fig. 2 Card Wire Types

Points (/sq in)

Angle

Speed (rpm)

Taker-in

40-60

90

650-750

Cylinder

640-800

70

300-400

Doffer

360-400

60-65

Flats

380-420

75-85

Full underscreens can be used since Ingeo PLA fibers

do not need to be cleaned. Where mote knives are

fitted, they should be adjusted to reduce fiber loss,

either by reducing the opening before the mote knife

or by opening the mote knife setting.

Flat strip removal can be carried out according to mill

requirements. However, as Ingeo PLA fiber is very

clean, only light strips need to be removed and these

should be discarded.

Different cards, production rates and quality

requirements may necessitate different settings,

but many spinners have not needed to change the

settings used for other synthetic fiber types of

similar dtex and staple length.

Depending on card type and production rates,

changes to the web and coiler tensions may be

required (particularly for speeds above 100 m/min).

Ingeo PLA fibers card and separate easily, and the

webs have good cohesion.

Web removal systems which feature belts or some form

of gathering improve carding efficiency, and

allow high, stable production rates. For the best

quality, however, the slowest carding rate compatible

with mill balance is recommended to reduce

imperfections and improve sliver consistency. The

majority of mills process 1.5dtex 38 mm Ingeo PLA at

between 25

and 35 kg/hr.

Sliver weights from 4 to 6 g/m are usual depending

on card and wire limitations. Ingeo PLA is compatible

with all autoleveling systems but, where possible,

the compression of the sliver should be minimized

to prevent the possibility of fibers self bonding,

particularly where surfaces may be hot. This is also

the case for calendar rollers in coilershigh calendar

roll pressures are not required to achieve good can

coiling and high can weights.

Sliver CV% depends on the feed and card type, but

values of under 4% are usual. Nep counts should be

extremely low, often zero, therefore testing is

considered unnecessary.

Overall carding efficiencies should be the same as

mill expectations, with low levels of waste and fly.

Atmospheric conditions of 23-270 C and 50-55%

RH are considered ideal.

Ring-spinning processing

Drawing

Roving

Ingeo PLA fiber processes easily at normal mill

production rates and sliver weights and on all types

of draw frames found currently in short staple mills.

Final sliver quality is dependent on the type and age

of the draw frame. Two passages of drawing are

commonly used.

In general, Ingeo PLA processes well on most roving

frames, with low break rates and good regularities.

Normally 6 ends, but up to 8 ends, may be creeled

per delivery, but care must be taken to ensure that

edge and creel guides are carefully aligned to prevent

overlapping of slivers. Excessive width should be

avoided since this can lead to roller lapping and frayed

sliver edges, particularly on second passage drawing.

Roller settings are less critical in the back drafting zone

but a nip to nip setting of 48 mm has been found to

give good performance. The front or main draft zone is

more critical with a minimum nip setting of 42 mm.

Drafts depend on sliver weight requirements, but back

zone drafts of 1.4 to 1.5 on both passages have given

good results on a wide range of draw frames.

The roller settings should be chosen to suit a nominal

38 mm fiber. On older systems the rollers should

be set as close as possible to 43 mm. With SKF

PK1500 series drafting systems, the short cradle should

be used in the main zone. The rear zone

setting is less critical.

The choice of spacers in the main drafting zone will

depend on the draft and roving weight, and should be

confirmed by experiment. On SKF systems the use of

a green or blue spacer is advised initially.

Front roll (floating) condensers are beneficial. The

width should be chosen carefully to control the

spread of fibers (9-12 mm spacing is normal).

Fig. 3 Initial Settings for PK1500 Series

Drafting Systems on Roving Frames

Tension drafts should be checked after the front roller

to obtain the best regularity. Roller pressure after

drafting should be low to prevent any bonding of fibers.

For sliver monitoring systems using tongue and groove

rollers, pressures should be reduced to a minimum

where possible.

Overall draft

Minimum 6, preferably 8-10

Back zone draft

1.15-1.20

Some adjustment to coilers may be needed to ensure

that coils are laid correctly in the can. Smaller coilers

are more likely to need adjustment and in some cases

different coiler plate surfaces may be needed.

Production speeds will depend on machinery type

but, as with other fibers, the slowest possible speed

commensurate with mill balance will give the best

results. Speeds of 400 m/min are commonly used

with sliver weights typically between 4 and 5 g/m,

except for very coarse or very fine yarn counts.

Resultant sliver regularities are around 2.5 CV.

Back zone setting

55-65 mm

Cradle type

Short

Spacer clip

<400 tex-black

>400 tex green or blue

Condenser

9-12 mm depending on count

Roller loading

High (red)

Twist levels similar to those used for polyester or

polyamide (e.g., around 0.8TM or AlphaM of 24).

Generally, roving spindle speeds of up to 1200 rpm

are used, although better roving quality is achieved at

lower speeds. Roving weights can vary from 400 to 800

tex depending on final yarn counts. Regularities should

be good 4-4.5 CV% or better should be easily achieved.

Ring-spinning processing

Ring Spinning

introduction

Fig. 4 Initial settings for PK200 Series Drafting System

In ring spinning, Ingeo PLA fibers produce yarns of

high elongation, good regularity and few imperfections.

Ring frame settings are chosen mainly to reduce yarn

hairiness and the risk of glazing or melting the fiber,

particularly when considering twist and traveler

selection.

Overall draft

drafting

Back zone drafts should be between 1.12 and 1.20,

although the roller setting is not critical on SKF type

double apron drafting systems. For other systems,

a close rear zone setting may improve yarn regularity.

Roller settings should be as indicated in SKF manuals

for synthetic fibers.

Main drafts should be higher than 15, and around 30

is the most common. Spacers and guides are chosen

to suit the drafting system and yarn count.

Apron types recommended by the main

manufacturers for short staple man-made fibers

are usually acceptable, but they should not be

mixed top and bottom.

Soft top rollers, as low as 65 Shore, will

undoubtedly give the best yarn quality, but they

are more susceptible to wear and damage. 70-75

Shore is an excellent compromise between quality

and durability. Ingeo PLA has a low rate of roller

lapping, and end break rates below 10/1000 spindle

hours should be expected on modern machinery.

High roller pressure is commonly used for coarse

counts and low drafts, but this is unnecessary for

finer counts.

Minimum 15, preferably 25 - 35

Back zone draft

1.12 - 1.20

Back zone setting

45 - 55 mm

Cradle type

OH132

Spacer clip

<20 tex - yellow

20 - 50 tex - black - confirm by trial

>50 tex - green

Roller loading

High (red) on coarse counts

twist

Ingeo PLA yields reasonably strong yarns and only in

exceptional cases will the twist level be chosen to give

maximum strength. Usually an alphaM of 110 (3.6TF)

or above is recommended for knit applications, with

116 (3.85TF) for woven applications, especially warps.

travelers

Yarns made with Ingeo PLA can be produced at rates

similar to those for the majority of man-made fibers.

A traveler speed of about 30 m/sec maximum (about

12,000 rpm on a 48 mm diameter ring) is typical for a

50-70 Nm (30-40 Ne) yarn.

The traveler weight is dependent on speed, tube size,

lift, etc. but different weights can reduce hairiness.

Traveler style will vary from mill to mill though usually

drw (half round wide) types are used. Any traveler

finish can be used and traveler wear is normal.

The low melting point of the fiber must also be kept in

mind when considering the choice of traveler and

actual production rates. New ring frames with

programmed speed controls at the start and end of the

spin cycle

are clearly advantageous in this respect.

Ring-spinning processing

atmospheric conditions

Atmospheric conditions of 23-28 C and 45-50%

RH give the best processing performance.

Air-jet Spinning

Ingeo PLA has been spun successfully on air-jet

spinning machinery (specifically Murata MJS) during

trials at the machinery manufacturer, though at this

stage should be considered as still under development.

Rotor spinning

Ingeo PLA fiber has been spun for development

purposes on OE (rotor) machinery, but as yet this

route and the fiber for it are still under development.

Compact Spinning

This extension of ring spinning technology is growing

and Ingeo PLA is being assessed currently through this

process route. Initial trials indicate that there should be

no difficulties on the commercial systems available for

synthetic fibers.

Yarn Steaming

Steaming of fibers, including Ingeo PLA fiber, affects

a number of fiber and yarn properties: fiber dye affinity

and yarn twist liveliness particularly. The effects are

variable, depending on the steaming conditions;

therefore care should be exercised in the

steaming operation.

Best practices for autoclaves should always

be followed:

dry (supersaturated) steam should always

be used

as high a vacuum as possible should be

applied prior to steaming

consistent conditions should be applied from

lot to lot

the autoclave should not be used cold

dye affinity

The dye affinity of almost all yarns is affected by

subjecting the fiber to steam. The effect is variable

depending on the conditions applied, especially by

time and temperature. With Ingeo PLA, work in this

area is still in progress. Therefore steaming

should only be carried out when it is

necessary.

Current recommendations are to use 600 C with a

time of 20 mins to ensure good control from lot to lot.

Winding

The winding of yarns made with Ingeo PLA from ring

tube can be carried out on any winder, including both

manual and automatic and onto any package.

Care should be taken to minimize contact between the

yarn and stationary objects to reduce abrasion on yarn.

Ingeo PLA yarns provide a firm package which does not

slough easily, and normal package sizes can be

produced. Some decrease in yarn tension may be

needed to reduce the hardness of the package.

Winding speeds will be as normal for the mill, up

to 1200 m/min. Slower winding speeds give better

final yarn appearance.

ring-spinning processing

clearing

Yarn Properties

Clearing will be as normal for other yarns of similar

count and quality standards. On capacitive systems

a polyester setting should be used. Stops for clearing

should be in line with mill norms.

The following ring spun yarn data is based on

both commercial spinning and trials carried out by

Ingeo PLA and will of course depend on age and

type of machinery and overall production rates.

waxing

Conventional waxing systems and waxes can be

used with no special precautions, though a lower

melting point wax is generally preferred.

splicing

This area is critical to the performance in fabric

making. Initial work has indicated no major concerns

in splicing, with chambers and settings used for

polyester being used as an initial guide.

The strength of the splice should be about 85% of

the parent yarn strength (slightly higher for fine yarns

and slightly less for coarse yarns). The minimum

strength of the splice should be at least 60% of the

parent yarn strength. Splices should be checked

carefully for consistency.

1.5dtex 38mm PLA Fiber-Ring Spun Yarn PropertiesCones

Count (Ne)

10

20

30

40

Tenacity (cN/tex)

19 - 20

18 - 19

16.5 - 18.5

14.5 - 16

Elongation (%)

30 - 32

28 - 30

25 - 27

24 - 26

CV% (UT3/4)

8 - 8.5

10.2 - 11

12 - 13

14 - 15

Thins -50%

0-1

5 - 25

Thicks +50%

1-2

2-4

10 - 15

25 - 40

Neps +200%

1-2

2-4

15 - 25

30 - 50

Twisting (Folding)

Ingeo PLA can be twisted either in 100% form or

with other yarns using any of the normal methods

of twisting and folding.

Only limited work on folding has been done to date

and particular care should be taken to ensure that the

correct lubrication is used and the fiber surfaces are

not damaged through excessive frictional heat.

Ingeo Worldwide Offices

Amsterdam, Hong Kong, London,

Milan, Minneapolis, New York and Tokyo

www.ingeofibers.com

Contact

1 800 66 INGEO (USA only)

+1 989 633 1746 (Worldwide)

Ingeo and the EcoPLA design are trademarks of NatureWorks LLC 2005

15305 Minnetonka Blvd., Minnetonka MN 55345

GSFIB034110305V2

No freedom from any patent of NatureWorks LLC or others is to be inferred. Because use conditions and applicable laws may differ

from one location to another and may change with time, NatureWorks customers are responsible for determining whether the products

and information in this document are appropriate for the customers use and for ensuring that the customers workplace and disposal

practices are in compliance with applicable laws and regulations. NatureWorks assumes no obligation or liability for the information in

this document. NO WARRANTIES ARE GIVEN: ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Vous aimerez peut-être aussi

- Anti Static OilDocument1 pageAnti Static OilPrasad PotdarPas encore d'évaluation

- The Rieter Manual of Spinning Vol. 7 2451-V1 en Original 68509Document78 pagesThe Rieter Manual of Spinning Vol. 7 2451-V1 en Original 68509Prasad Potdar50% (2)

- Irregularity and Imperfections in Ring-Spun: YarnsDocument4 pagesIrregularity and Imperfections in Ring-Spun: YarnsPrasad PotdarPas encore d'évaluation

- Assignment 1Document2 pagesAssignment 1Prasad PotdarPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Complaint-Affidavit THE UNDERSIGNED COMPLAINANT Respectfully Alleges: I, MR. NAGOYA, of Legal Age, Filipino, Single, and A Resident of Baguio CityDocument2 pagesComplaint-Affidavit THE UNDERSIGNED COMPLAINANT Respectfully Alleges: I, MR. NAGOYA, of Legal Age, Filipino, Single, and A Resident of Baguio CityNarz SabangPas encore d'évaluation

- 96boards Iot Edition: Low Cost Hardware Platform SpecificationDocument15 pages96boards Iot Edition: Low Cost Hardware Platform SpecificationSapta AjiePas encore d'évaluation

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocument1 pageNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comPas encore d'évaluation

- Product Data Sheet: Description: TionaDocument1 pageProduct Data Sheet: Description: TionaOpox Diavolo PiccoloPas encore d'évaluation

- Suraya Binti Hussin: Kota Kinabalu - T1 (BKI)Document2 pagesSuraya Binti Hussin: Kota Kinabalu - T1 (BKI)Sulaiman SyarifuddinPas encore d'évaluation

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument3 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceHiten AhirPas encore d'évaluation

- Thermal Physics Assignment 2013Document10 pagesThermal Physics Assignment 2013asdsadPas encore d'évaluation

- ASME Steam Table PDFDocument32 pagesASME Steam Table PDFIsabel Pachucho100% (2)

- Philippine Health Care Providers, Inc. Vs CIR Case DigestDocument2 pagesPhilippine Health Care Providers, Inc. Vs CIR Case DigestJet jet NuevaPas encore d'évaluation

- About General Aung SanDocument18 pagesAbout General Aung SanThoon Yadanar ShanPas encore d'évaluation

- Claim Form - Part A' To 'Claim Form For Health Insurance PolicyDocument6 pagesClaim Form - Part A' To 'Claim Form For Health Insurance Policyanil sangwanPas encore d'évaluation

- Manu Social Order and LawsDocument13 pagesManu Social Order and LawsAmit KumarPas encore d'évaluation

- Shah Abdul Latif University, Khairpur: ST NDDocument9 pagesShah Abdul Latif University, Khairpur: ST NDsaqib maharPas encore d'évaluation

- Henna Residence BriefDocument56 pagesHenna Residence BrieffendeysanPas encore d'évaluation

- Gentlemen of The JungleDocument2 pagesGentlemen of The JungleClydelle Garbino PorrasPas encore d'évaluation

- GE 103 Lecture 4Document13 pagesGE 103 Lecture 4aljonPas encore d'évaluation

- Intel Core I37100 Processor 3M Cache 3.90 GHZ Product SpecificationsDocument5 pagesIntel Core I37100 Processor 3M Cache 3.90 GHZ Product SpecificationshexemapPas encore d'évaluation

- United States v. David Fields, 39 F.3d 439, 3rd Cir. (1994)Document13 pagesUnited States v. David Fields, 39 F.3d 439, 3rd Cir. (1994)Scribd Government DocsPas encore d'évaluation

- Quiz No 1Document8 pagesQuiz No 1LJ ValdezPas encore d'évaluation

- Ambrose Letter 73 To IrenaeusDocument4 pagesAmbrose Letter 73 To Irenaeuschris_rosebrough_1Pas encore d'évaluation

- Scope of Inspection For Ammonia TankDocument3 pagesScope of Inspection For Ammonia TankHamid MansouriPas encore d'évaluation

- HDFCDocument3 pagesHDFCJoseph ThompsonPas encore d'évaluation

- The Endgame of Treason - Doyle - ThesisDocument237 pagesThe Endgame of Treason - Doyle - Thesisdumezil3729Pas encore d'évaluation

- SurrogacyDocument17 pagesSurrogacypravas naikPas encore d'évaluation

- Chapter 13Document30 pagesChapter 13Michael Pujalte VillaflorPas encore d'évaluation

- Belgica Vs OchoaDocument5 pagesBelgica Vs OchoaDax MonteclarPas encore d'évaluation

- Internship Report On Dhaka BankDocument78 pagesInternship Report On Dhaka Bankparvin akhter evaPas encore d'évaluation

- IT Security Threats Vulnerabilities and CountermeasuresDocument35 pagesIT Security Threats Vulnerabilities and Countermeasureschristian may noqueraPas encore d'évaluation

- Copyreading and Headline Writing Exercise 2 KeyDocument2 pagesCopyreading and Headline Writing Exercise 2 KeyPaul Marcine C. DayogPas encore d'évaluation

- Renter Information Rental Information Charge Information: Biswadeep Das Time ChargesDocument1 pageRenter Information Rental Information Charge Information: Biswadeep Das Time ChargesBiswadeep DasPas encore d'évaluation