Académique Documents

Professionnel Documents

Culture Documents

C3. Paint Specification (WSS-M64J39-A1) v1

Transféré par

Chandrajeet ShelkeDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

C3. Paint Specification (WSS-M64J39-A1) v1

Transféré par

Chandrajeet ShelkeDroits d'auteur :

Formats disponibles

ENGINEERING MATERIAL SPECIFICATION

Material Name

Specification Number

PRIMER, WATERBORNE CATIONIC ELECTROCOAT,

LEAD-FREE, HIGH THROW POWER, EDGE

CORROSION RESISTANT, INITIAL FILL

WSS-M64J39-A1

MAKEUP FEED, WATERBORNE CATIONIC

ELECTROCOAT, LEAD-FREE, HIGH THROW

POWER, EDGE CORROSION RESISTANT, RESIN

WSS-M64J39-A2

MAKEUP FEED, WATERBORNE CATIONIC

ELECTROCOAT, LEAD-FREE HIGH THROW POWER,

EDGE CORROSION RESISTANT, PIGMENT

WSS-M64J39-A3

FLOW CONTROL ADDITIVE

WSS-M64J39-A4

MAKEUP FEED, WATERBORNE CATIONIC

ELECTROCOAT, LEAD-FREE, HIGH THROW POWER,

EDGE CORROSION RESISTANT, PRE-BLEND

WSS-M64J39-A5

1.

SCOPE

The materials defined by these specifications are the basic components

for lead-free, high-throw power, high-edge corrosion resistant cathodic

electrocoat primer.

2.

APPLICATION

These specifications were released originally for a paint system when

properly electrodeposited on vehicle bodies, sheet metal components or

small parts will provide good corrosion resistance, adhesion and enamel

appearance properties. These materials together make a paint system that

is lead-free with high-throw power and high-edge corrosion resistance.

WSS-M64J39-A1:

This material is the initial fill material and

represents

the

electrocoat

bath

during

production.

WSS-M64J39-A2:

This material is makeup feed material used to

replenish

the

resins

of

the

initial

fill

electrocoat bath.

Date

1998 03 24

WP 3948-a

Action

Activated

Changes

N. Chamberlain

G. Schuh

Page 1 of 7

ENGINEERING MATERIAL SPECIFICATION

3.

WSS-M64J39-A1-A5

WSS-M64J39-A3:

This material is makeup feed material used to

replenish the pigments of the initial fill

electrocoat bath.

WSS-M64J39-A4:

This material is makeup feed material used to

correct poor flow characteristics of the primer

which may develop when the bath ages.

This

additive is used only as recommended by the

supplier following ultrafiltrate purge or when

discontinuous operation of an electrocoat tank

results in evaporation of bath volatiles.

WSS-M64J39-A5:

This material is a pre-blended makeup feed

material used to replenish the resins and

pigments of the initial fill electrocoat bath.

The ratio of resin to pigment shall be agreed

upon by the supplier, the affected assembly

plant, Global Paint Engineering and Production

Purchasing prior to delivery of the material to

the assembly plant.

REQUIREMENTS

3.1

QUALITY SYSTEM REQUIREMENTS

Material suppliers and part producers must conform to Quality

System Requirements, QS-9000. Material specification requirements

are to be used for initial qualification of materials. A Control

Plan for ongoing production verification is required.

This plan

must be reviewed and approved by the relevant Ford Materials

activity and/or Ford Supplier Technical Assistance (STA) prior to

production parts submission. Appropriate statistical tools must be

used to analyze process/product data and assure consistent

processing of the materials.

Part producers using this material in their products, must use Ford

approved materials and must conform to a process control plan which

has been approved by STA and/or the relevant Materials Activity.

3.2

INFRARED SPECTROPHOTOMETRY AND/OR THERMAL ANALYSIS

Ford Motor Company, at its option, may conduct infrared and/or

thermal analysis of material/parts supplied to this specification.

The IR spectra and thermograms established for initial approval

shall constitute the reference standard and shall be kept on file

at the designated material laboratory. All samples shall produce IR

spectra and thermograms that correspond to the reference standard

when tested under the same conditions.

WP 3948-b

Page 2 of 7

ENGINEERING MATERIAL SPECIFICATION

3.3

WSS-M64J39-A1-A5

CONDITIONING AND TEST CONDITIONS

All test values indicated herein are based on material conditioned

in a controlled atmosphere of 23 +/- 2 C and 50 +/- 5 % relative

humidity for not less than 24 h prior to testing and tested under

the same conditions unless otherwise specified.

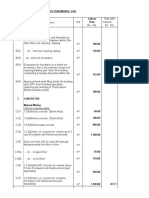

3.4

COMPOSITION

3.4.1

Density, kg/L at 25 C

(ASTM D 1475)

Initial Sample

+/- 0.05 %

3.4.2

Non-volatile, weight %

(FLTM BI 102-01)

Initial Sample

+/- 0.05 %

3.4.3

Weight Loss, max

(FLTM BI 120-15)

Initial Sample

+/- 0.05 %

Measure weight loss after 10 minutes at 182 +/- 2 C metal

temperature bake cycle.

3.4.4

Solvent Emissions, max

(ASTM D 3960)

0.096 kg/L of

wet paint

This requirement is as determined by the United States

Environmental Protection Agency Reference Method #24 but is

only applicable to materials used in the USA.

3.5

STABILITY

3.5.1

Pumping Stability, min

(FLTM BI 120-04)

21 days

After 21 day min agitation, the bath prepared from the

initial fill or feed materials shall meet all requirements

of the specification.

3.5.2

Storage Stability, min

2 months

During a storage of 2 months between 5 and 32 C temperature

the material as supplied shall not settle or cake.

3.6

PREPARATION OF TEST PANELS

Coating System I

- Electrocoat Only

Coating System II - Electrocoat and Primer Surfacer

Coating System III - Total Paint System

WP 3948-b

Page 3 of 7

ENGINEERING MATERIAL SPECIFICATION

3.6.1

WSS-M64J39-A1-A5

Substrates

Auto body steel, aluminum, pre-coated or electroplated zinc

or zinc alloy coated steel and zinc die casting or as

specified on Engineering documents.

3.6.2

Substrate Condition

Clean the surface by an automated process to ensure the

absence

of

oil

or

alkaline

residues,

fingerprints,

corrosion, dirt, moisture, and other foreign materials.

3.6.3

Coating Material

3.6.3.1

Zinc Phosphate (All Panels)

Zinc phosphate coating per WSS-M3P1-D for cold

rolled steel, pre-coated, electroplated zinc or

zinc alloy coated steel and zinc die castings.

Aluminum when processed alone should use chromium

oxide coating per WSK-M6P2-B.

If steel and

aluminum parts are processed concurrently, apply

zinc phosphate per WSS-M3P1-D. Do not exceed the

aluminum tolerance of the process.

Steel and

aluminum parts are to meet all requirements of

both WSS-M3P1-D and this specification.

3.6.3.2

Cathodic Electrocoat (Coating System I)

Ford Engineering approved current production

materials or material under evaluation.

Film

thickness requirements are based on current

production requirements or direction of materials

engineer. Baking requirements are 10 minutes at

165, 175 and 200 C metal temperature.

3.6.3.3

Electrocoat and Primer Surfacer

(Coating System II)

Ford Engineering

materials.

3.6.3.4

current

production

Total Paint System (Coating System III)

Ford Engineering

materials.

WP 3948-b

approved

approved

current

production

Page 4 of 7

ENGINEERING MATERIAL SPECIFICATION

3.7

WSS-M64J39-A1-A5

APPEARANCE

3.7.1

3.7.2

Color

(FLTM BI 109-01)

Initial Sample

Leveling

3.7.2.1

Smoothness

The surface of the electrocoat primer shall be

smooth without any structure and not more than a

min of orange peel when applied and baked as

required in Coating System I.

3.7.2.2

Gloss

(FLTM BI 110-01)

Initial Sample

+/- 5 %

Use a 60 deg glossmeter for gloss measurements.

3.7.3

Holdout

Apply the enamel color coat over unsanded electrocoat

primer. Failure is evidence of dulling or change in image

clarity compared to current approved production electrocoat

enamel (Coating System III).

3.8

RESISTANCE PROPERTIES

The material defined by this

requirements of WSS-M2P182-A.

3.9

specification

must

meet

the

MATERIAL COMPATIBILITY

The material must be compatible with all related materials, for

example, electrocoats, sealers, and adhesives. The supplier of this

material shall keep abreast of changes in technology of related

materials which may affect the compatibility and performance of

this product.

The supplier shall notify the appropriate Ford

Product

Materials

Engineering

Office

in

writing

when

incompatibility is anticipated.

3.10 SUPPLIER'S RESPONSIBILITY

All materials supplied to this specification must be equivalent in

all characteristics to the material upon which approval was

originally granted.

WP 3948-b

Page 5 of 7

ENGINEERING MATERIAL SPECIFICATION

WSS-M64J39-A1-A5

Prior to making any change in the properties, composition,

construction, color, processing or labeling of the material

originally approved under this specification, whether or not such

changes affect the material's ability to meet the specification

requirements, the Supplier shall notify Purchasing, Toxicology and

the affected Materials Engineering activity of the proposed changes

and obtain the written approval of the Materials Engineering

activity. Test data, test samples and a new code identification are

to be submitted with the request.

Substance restrictions imposed by law, regulations or Ford, apply

to the materials addressed by this document. The regulations are

defined in Engineering Materials Specification WSS-M99P9999-A1.

4.

APPROVAL OF MATERIALS

Materials defined by this specification must have prior approval by the

responsible Materials Engineering activity. Suppliers desiring approval

of their materials shall first obtain an expression of interest from the

affected Purchasing, Design and Materials Engineering activity.

Upon

request, the Supplier shall submit to the affected Materials Engineering

activity a completed copy of their laboratory test reports, signed by a

qualified

and

authorized

representative

of

the

test

facility,

demonstrating full compliance with all the requirements of this

specification

(test

results,

not

nominal

values),

the

material

designation and code number, and test specimens for Ford evaluation.

Ford's engineering approval of a material will be based on its

performance to this specification and on an assessment of suitability

for intended processes and/or applications. Upon approval, the material

will be added to the Engineering Material Approved Source List.

5.

GENERAL INFORMATION

The information given below is provided for clarification and assistance

in meeting the requirements of this specification.

The corrosion resistance required in this specification is the basis of

corrosion protection of vehicle body steel. Test Panels and parts which

meet

this

specification

will

also

conform

with

the

corrosion

requirements of WSS-M2P180-A.

5.1

Panel Information

5.1.1

Standard Steel Panels

Standard steel panels are laboratory quality mild coal

rolled steel available clean or zinc phosphated. Qualified

coil stock is available from Advanced Coating Technologies,

Inc.*

OR

WP 3948-b

Page 6 of 7

ENGINEERING MATERIAL SPECIFICATION

WSS-M64J39-A1-A5

Use panels prepared in accordance with Ford Manufacturing

Standard U-MA001-8001.

5.1.2

Electrogalvanized Steel

50 - 80 g/m2

Qualified coil stock is available from Advanced Coating

Technologies, Inc.*

OR

Use panels complying with relevant grades of WSB-M1A250-C3

and WSB-M1A311-B2.

5.1.3

Aluminum Panels

Aluminum panels (AA6111) can

Coating Technologies, Inc.*

5.2

be

obtained

from

Advanced

Panel Preparation

Panels can be prepared and or tested at:

* Advanced Coating Technologies, Inc.

PO Box 735

273 Industrial Dr.

Hillsdale, Michigan 49242

(517) 439-1485

WP 3948-b

Page 7 of 7

Vous aimerez peut-être aussi

- FLTM Bi 160-01 Florida and Arizona Outdoor Exposure TestDocument5 pagesFLTM Bi 160-01 Florida and Arizona Outdoor Exposure TestJuan Angel DechimaPas encore d'évaluation

- Din en Iso 20566-2005Document16 pagesDin en Iso 20566-2005ADILSON FCO SILVAPas encore d'évaluation

- 49-00023 Rev LDocument14 pages49-00023 Rev LJose Cuellar100% (1)

- Iso 11997-1 - 2005Document8 pagesIso 11997-1 - 2005Khin Khin Thaw100% (2)

- Hand Out To Borbet GMBH: Coating Adhesion TestDocument8 pagesHand Out To Borbet GMBH: Coating Adhesion Testferhat aydoganPas encore d'évaluation

- Scope TestsDocument4 pagesScope TestsGonzalo TelleríaPas encore d'évaluation

- ATE N 553 81.09 (En)Document11 pagesATE N 553 81.09 (En)Miguel QueirosPas encore d'évaluation

- M0007 - 2014-1 Testing Method For Automotive PaintDocument164 pagesM0007 - 2014-1 Testing Method For Automotive PaintErick Hernández0% (1)

- D451333 eDocument15 pagesD451333 eMaddalena PezzaniPas encore d'évaluation

- Surface Surface Vehicle Vehicle Recommended Recommended Practice PracticeDocument19 pagesSurface Surface Vehicle Vehicle Recommended Recommended Practice PracticeGustavo figueiredoPas encore d'évaluation

- Geometric dimensioning and tolerancing Second EditionD'EverandGeometric dimensioning and tolerancing Second EditionPas encore d'évaluation

- ASTM E 505 Die Casting Reference RadiographsDocument3 pagesASTM E 505 Die Casting Reference RadiographsMario Moura JrPas encore d'évaluation

- E1329-Withdrawn 4257Document12 pagesE1329-Withdrawn 4257delta lab sangliPas encore d'évaluation

- Astm B765Document4 pagesAstm B765Purushottam Sutar100% (2)

- Iso 1-2016Document7 pagesIso 1-2016ProfRyu11100% (1)

- Iso 12004 1Document16 pagesIso 12004 10511018Pas encore d'évaluation

- GMW14872 - Cyclic Corrosion Laboratory TestDocument22 pagesGMW14872 - Cyclic Corrosion Laboratory TestZAPSEPas encore d'évaluation

- Astm A582-A582m-05Document3 pagesAstm A582-A582m-05NadhiraPas encore d'évaluation

- Astm E-18Document38 pagesAstm E-18Kiran100% (1)

- Astm A228Document2 pagesAstm A228Rakesh S IndiaPas encore d'évaluation

- Oxygen-Free Copper in Wrought Forms For Electron DevicesDocument6 pagesOxygen-Free Copper in Wrought Forms For Electron DevicesErick Vargas100% (1)

- GMW3059 - Material Specification PDFDocument7 pagesGMW3059 - Material Specification PDFJuanPeriquitan100% (2)

- Aisi 1018Document1 pageAisi 10188085roPas encore d'évaluation

- Iso 178 PDFDocument19 pagesIso 178 PDFLAL KRISHPas encore d'évaluation

- D 5628 - 96 R01 - Rdu2mjg - PDFDocument10 pagesD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaPas encore d'évaluation

- D1153 - 12 Standard Specification For Methyl Isobutyl Ketone PDFDocument2 pagesD1153 - 12 Standard Specification For Methyl Isobutyl Ketone PDFJacques BlueqPas encore d'évaluation

- Quality Evaluation StandardDocument7 pagesQuality Evaluation Standardsatish_trivediPas encore d'évaluation

- A623Document36 pagesA623Aleksei AvilaPas encore d'évaluation

- IEC 15415-2006 EenDocument61 pagesIEC 15415-2006 EenAlaeddine AbidPas encore d'évaluation

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument4 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuPas encore d'évaluation

- D 333 - 96Document6 pagesD 333 - 96PoyoeberPas encore d'évaluation

- ASME B1.20.5 Rosca NPTDocument63 pagesASME B1.20.5 Rosca NPTdopcncPas encore d'évaluation

- Surface RoughnessDocument35 pagesSurface Roughnessds_srinivasPas encore d'évaluation

- ISO 3497 X Ray Mthod CoatingDocument8 pagesISO 3497 X Ray Mthod CoatingAmandeep SinghPas encore d'évaluation

- 13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderDocument21 pages13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Publication Date OrderGabriel RoquePas encore d'évaluation

- ASTM-D991 Usa Standard 2004Document5 pagesASTM-D991 Usa Standard 2004DenisTarasPas encore d'évaluation

- Rust Protection by Metal Preservatives in The Humidity CabinetDocument9 pagesRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxPas encore d'évaluation

- Astm D6344-98 PDFDocument4 pagesAstm D6344-98 PDFRajeshPas encore d'évaluation

- International Standard: Stainless Steels For Springs - WireDocument8 pagesInternational Standard: Stainless Steels For Springs - WireAfzal ImamPas encore d'évaluation

- Tabla Ajustes ISO286 2Document45 pagesTabla Ajustes ISO286 2Shawn MoorePas encore d'évaluation

- Astm B240-09 PDFDocument4 pagesAstm B240-09 PDFRaúlPas encore d'évaluation

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926Pas encore d'évaluation

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- Iso 105 B06Document8 pagesIso 105 B06Hugo Jimenez FalconPas encore d'évaluation

- PWPT001 H Interior-Exterior Plastic Parts For DecorationDocument28 pagesPWPT001 H Interior-Exterior Plastic Parts For Decorationmohammad yazdanpanahPas encore d'évaluation

- Iso 14273-2000Document14 pagesIso 14273-2000Dhatchana moorthy.SPas encore d'évaluation

- Wss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Document5 pagesWss-m2p177 - Paint Performance, Chassis Low Level Visible - A1 A A5Fab CarvalPas encore d'évaluation

- (BS en ISO 3611-2010) - Geometrical Product Specifications (GPS) - Dimensional Measuring Equipment. Micrometers For External Measurements. Design and Metrological CharacteristDocument30 pages(BS en ISO 3611-2010) - Geometrical Product Specifications (GPS) - Dimensional Measuring Equipment. Micrometers For External Measurements. Design and Metrological CharacteristAugusto MauryPas encore d'évaluation

- R 021 R 2 A 1 eDocument24 pagesR 021 R 2 A 1 egsuoag100% (1)

- As 60068.2.55-2003 Environmental Testing Tests - Test Ee and Guidance - BounceDocument8 pagesAs 60068.2.55-2003 Environmental Testing Tests - Test Ee and Guidance - BounceSAI Global - APACPas encore d'évaluation

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiPas encore d'évaluation

- Worldwide Engineering Standards: Low Carbon Sheet SteelDocument13 pagesWorldwide Engineering Standards: Low Carbon Sheet SteelaldairlopesPas encore d'évaluation

- Es-091 - W Passivation Treatment For Corrosion-Resistant Steel (Immunization)Document12 pagesEs-091 - W Passivation Treatment For Corrosion-Resistant Steel (Immunization)Rubén Eduardo Galindo CarmonaPas encore d'évaluation

- Why Intensity Isn’t Dependent on Exposure TimeDocument1 pageWhy Intensity Isn’t Dependent on Exposure TimeUmit AytarPas encore d'évaluation

- GMW3001Document1 pageGMW3001skgolban0% (1)

- E M0140 2009-N PDFDocument11 pagesE M0140 2009-N PDFAna Georgina Vidrio Longoria75% (4)

- 98d033a3 PDFDocument3 pages98d033a3 PDFergun tutukPas encore d'évaluation

- CW6 Part 1Document44 pagesCW6 Part 1Steve CowanPas encore d'évaluation

- MS-4005 - Rev - DDocument5 pagesMS-4005 - Rev - DEngenharia APedroPas encore d'évaluation

- 10080-1-SS-PP-019Document34 pages10080-1-SS-PP-019SURAJ PRSADPas encore d'évaluation

- CES S MANF 18 - r7 PDFDocument22 pagesCES S MANF 18 - r7 PDFChandrajeet ShelkePas encore d'évaluation

- Input Length CalculationDocument7 pagesInput Length CalculationChandrajeet ShelkePas encore d'évaluation

- CEIA InductionHeatingPrinciples FC040K0068v1ukDocument29 pagesCEIA InductionHeatingPrinciples FC040K0068v1ukariffzakaria63Pas encore d'évaluation

- CAR 5 User GuideDocument34 pagesCAR 5 User GuideChandrajeet ShelkePas encore d'évaluation

- AWS C3.5 Induction BrazingDocument16 pagesAWS C3.5 Induction BrazingChandrajeet Shelke0% (1)

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Silverbraze 50ni2 BAg-24 AMS 4788 TDSDocument2 pagesSilverbraze 50ni2 BAg-24 AMS 4788 TDSChandrajeet ShelkePas encore d'évaluation

- Ackme Tools Pin ChartDocument1 pageAckme Tools Pin ChartChandrajeet ShelkePas encore d'évaluation

- Lec 7 Fe C DiagramDocument45 pagesLec 7 Fe C DiagramAdnan MehmoodPas encore d'évaluation

- Faurecia Pr170614 Tdifoam English FinalDocument2 pagesFaurecia Pr170614 Tdifoam English FinalChandrajeet ShelkePas encore d'évaluation

- ElvDocument77 pagesElvRadu Victor TapuPas encore d'évaluation

- Din en 10149-2 (Only For Reference)Document31 pagesDin en 10149-2 (Only For Reference)Chandrajeet Shelke50% (2)

- Engineering Material Specification: Printed Copies Are UncontrolledDocument6 pagesEngineering Material Specification: Printed Copies Are UncontrolledChandrajeet ShelkePas encore d'évaluation

- Is 3074 2005Document16 pagesIs 3074 2005Kuldeep SinghPas encore d'évaluation

- Technical Info - Automotive Cushioning Through The AgesDocument64 pagesTechnical Info - Automotive Cushioning Through The Agescripi79Pas encore d'évaluation

- Polyurethane Foams Improve Passenger Comfort by Reducing Noise and VibrationsDocument13 pagesPolyurethane Foams Improve Passenger Comfort by Reducing Noise and VibrationsChandrajeet ShelkePas encore d'évaluation

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkePas encore d'évaluation

- 0786GL11415Price List - Proto Molds-Magna Seating PDFDocument1 page0786GL11415Price List - Proto Molds-Magna Seating PDFChandrajeet ShelkePas encore d'évaluation

- Tool Engineering CalculatorDocument29 pagesTool Engineering Calculatorkannan90% (10)

- Wa0054Document38 pagesWa0054het pandyaPas encore d'évaluation

- Sheduled of Rates, PWD - MizoramDocument2 pagesSheduled of Rates, PWD - Mizoramswarlu63% (8)

- Protective Industrial Enamel CoatingDocument4 pagesProtective Industrial Enamel CoatingAna CabreraPas encore d'évaluation

- Hempadur Avantguard 550Document4 pagesHempadur Avantguard 550bondsivamaniPas encore d'évaluation

- Cage by Design BirdsDocument24 pagesCage by Design BirdsShanethebigkid PritchardPas encore d'évaluation

- BS 4756Document9 pagesBS 4756Umange Ranasinghe100% (1)

- Mohammad Ubaid: Chemical EngineerDocument1 pageMohammad Ubaid: Chemical EngineerShahzaib GulzarPas encore d'évaluation

- Glass Coloration Made EasyDocument7 pagesGlass Coloration Made Easyshashwat6789Pas encore d'évaluation

- 405HTR - EnvirolineDocument4 pages405HTR - EnvirolineEdinsonPas encore d'évaluation

- ParticleSizeAnalysis GuidebookDocument32 pagesParticleSizeAnalysis GuidebookLinhPas encore d'évaluation

- Learn To Paint A Portrait - Little Girl EnglishDocument25 pagesLearn To Paint A Portrait - Little Girl Englishsasbng100% (1)

- 285-700 Glasurit® Primer FillerDocument2 pages285-700 Glasurit® Primer FillerJordanPas encore d'évaluation

- Hempel Book DecoDocument97 pagesHempel Book DecommkattaPas encore d'évaluation

- Super Gelkyd 6006 Wda 55Document2 pagesSuper Gelkyd 6006 Wda 55monrmPas encore d'évaluation

- Ad 0673191Document149 pagesAd 0673191Genes CristinelPas encore d'évaluation

- Painting Inspection Procedure PDFDocument1 pagePainting Inspection Procedure PDFPhạm Văn Đảng67% (3)

- Sigmatherm™ 540: Product Data SheetDocument4 pagesSigmatherm™ 540: Product Data SheetSubodh KulkarniPas encore d'évaluation

- Brochure - SILIKOPHEN P 50XDocument40 pagesBrochure - SILIKOPHEN P 50XrndmenggapaiimpianbersamaPas encore d'évaluation

- Asian Paints Apcothane CF 674Document1 pageAsian Paints Apcothane CF 674Nagendra Kumar0% (1)

- Simazinc Silicate MC: Product Data SheetDocument3 pagesSimazinc Silicate MC: Product Data SheetMuhammad Mulya JatiPas encore d'évaluation

- 560 XF Anticondensation Tds - rv2.01022019Document2 pages560 XF Anticondensation Tds - rv2.01022019August WitjakPas encore d'évaluation

- BOQ Estimate For HouseDocument14 pagesBOQ Estimate For HouseElezer BatchoPas encore d'évaluation

- Hardtop XPL AGDocument6 pagesHardtop XPL AGHung NGUYEN SYPas encore d'évaluation

- Rate 2012 CecbDocument254 pagesRate 2012 CecbChathuranga PriyasamanPas encore d'évaluation

- VDA 16 AppendixDocument22 pagesVDA 16 Appendixserchecko1Pas encore d'évaluation

- How To Paint ElrondDocument5 pagesHow To Paint ElrondHenry Marshall100% (1)

- German Military ColoursDocument3 pagesGerman Military ColoursJan-Wouter Hasselaar100% (1)

- GPCB Category of IndustriesDocument3 pagesGPCB Category of IndustriestanayasahaPas encore d'évaluation

- Checklist For External Painting R1Document1 pageChecklist For External Painting R1hkshyla89Pas encore d'évaluation

- Sokalan CP9: Technical InformationDocument4 pagesSokalan CP9: Technical Informationomer reisPas encore d'évaluation