Académique Documents

Professionnel Documents

Culture Documents

B3L01 - Detail 1

Transféré par

vikramjain66Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

B3L01 - Detail 1

Transféré par

vikramjain66Droits d'auteur :

Formats disponibles

Profis Anchor 2.6.

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

C925 Lift Shaft

Detail 1

9/5/2016

Specifier's comments:

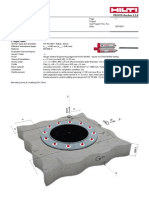

1 Input data

Anchor type and diameter:

HIT-HY 200-R + Rebar 28mm

Seismic/Filling set or any suitable annular gap filling solution

Effective embedment depth:

hef,opti = 515 mm (hef,limit = 560 mm)

Material:

B500B

Evaluation Service Report:

ETA 12/0084

Issued I Valid:

15/4/2015 | 15/4/2020

Proof:

SOFA design method + fib (07/2011) - after ETAG BOND testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 45 mm

Anchor plate:

S 355 (St 52); E = 210000.00 N/mm2; fyk = 355.00 N/mm2; gMs = 1.100

lx x ly x t = 600 mm x 600 mm x 45 mm; (Recommended plate thickness: calculated (43 mm))

Profile:

Square hollow; (L x W x T) = 150 mm x 150 mm x 10 mm

Base material:

cracked concrete, C30/37, fc = 30.00 N/mm2; h = 2000 mm, Temp. short/long: 30/30 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.5

www.hilti.com.sg

2

C925 Lift Shaft

Detail 1

9/5/2016

Page:

Project:

Sub-Project I Pos. No.:

Date:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

2 Load case/Resulting anchor forces

Load case: Design loads

Compression

1

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

0.000

3.856

-3.173

2

3.674

6.314

-3.173

3

15.364

9.286

-3.173

4

13.568

2.261

0.563

5

25.258

5.488

0.563

6

35.152

4.824

4.298

7

46.843

6.948

4.298

8

58.533

9.729

4.298

max. concrete compressive strain:

0.21 []

max. concrete compressive stress:

6.21 [N/mm2]

resulting tension force in (x/y)=(-3/-122):

198.393 [kN]

resulting compression force in (x/y)=(-205/241): 93.263 [kN]

Shear force y

2.190

5.459

8.727

2.190

5.459

2.190

5.459

8.727

Tension

6

3 Tension load SOFA (fib (07/2011), section 16.2.1)

Load [kN]

58.533

Capacity [kN]

242.143

Utilization bN [%]

25

Status

OK

Combined pullout-concrete cone failure**

198.393

306.367

65

OK

Concrete Breakout Strength**

198.393

220.744

90

OK

198.393

327.608

61

OK

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

339.000

gM,s

1.400

NRd,s [kN]

242.143

NSd [kN]

58.533

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

826709

A0p,N [mm2]

418133

yA,Np

1.977

2

tRk,ucr,25 [N/mm ]

10.00

scr,Np [mm]

647

yc

1.044

2

tRk,cr [N/mm ]

5.74

max tRk,cr [N/mm2]

10.88

yg,Np

2.015

yg,Np

1.468

ec1,N [mm]

22

yec1,Np

0.936

ec2,N [mm]

94

yec2,Np

0.775

ys,Np

0.839

N0Rk,p [kN]

260.140

NRk,p [kN]

459.551

gM,p

1.500

NRd,p [kN]

306.367

NSd [kN]

198.393

ccr,Np [mm]

323

cmin [mm]

150

yre,Np

1.000

3.3 Concrete Breakout Strength

Ac,N [mm2]

2440013

A0c,N [mm2]

2387025

yA,N

1.022

ccr,N [mm]

773

scr,N [mm]

1545

ec1,N [mm]

22

yec1,N

0.972

ec2,N [mm]

94

yec2,N

0.892

ys,N

0.758

N0Rk,c [kN]

492.904

gM,c

1.500

NRd,c [kN]

220.744

NSd [kN]

198.393

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

yre,N

1.000

k1

7.700

Profis Anchor 2.6.5

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

C925 Lift Shaft

Detail 1

9/5/2016

3.4 Splitting failure

Ac,N [mm2]

1416450

A0c,N [mm2]

1060900

yA,N

1.335

ccr,sp [mm]

515

scr,sp [mm]

1030

yh,sp

1.170

ec1,N [mm]

22

yec1,N

0.959

ec2,N [mm]

94

yec2,N

0.846

ys,N

0.787

yre,N

1.000

N0Rk,c [kN]

492.904

gM,sp

1.500

NRd,sp [kN]

327.608

NSd [kN]

198.393

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

k1

7.700

Profis Anchor 2.6.5

www.hilti.com.sg

Page:

Project:

Sub-Project I Pos. No.:

Date:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

4

C925 Lift Shaft

Detail 1

9/5/2016

4 Shear load SOFA (fib (07/2011), section 16.2.2)

Load [kN]

9.729

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

112.667

Utilization bV [%]

9

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

40.650

409.530

10

OK

Concrete edge failure in direction x+**

17.976

64.384

28

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

169.000

gM,s

1.500

VRd,s [kN]

112.667

VSd [kN]

9.729

4.2 Pryout Strength (Concrete Breakout Strength controls)

Ac,N [mm2]

2475013

A0c,N [mm2]

2387025

yA,N

1.037

ccr,N [mm]

773

scr,N [mm]

1545

k4

2.000

ec1,V [mm]

178

yec1,N

0.813

ec2,V [mm]

20

yec2,N

0.975

ys,N

0.758

yre,N

1.000

N0Rk,c [kN]

492.904

gM,c,p

1.500

VRd,c1 [kN]

409.530

VSd [kN]

40.650

4.3 Concrete edge failure in direction x+

lf [mm]

224

dnom [mm]

28.0

kV

1.700

a

0.067

c1 [mm]

500

Ac,V [mm2]

1425000

A0c,V [mm2]

1125000

yA,V

1.267

ys,V

1.000

yh,V

1.000

ya,V

1.479

ec,V [mm]

105

yec,V

0.877

V0Rk,c [kN]

176.352

n1

3

gM,c

1.500

VRd,c [kN]

64.384

VSd [kN]

17.976

b

0.056

yre,V

1.000

y90,V

2.500

Note: Resistance limit acc. to fib (07/2011) Eq. (10.2-6) is governing

5 Combined tension and shear loads SOFA (fib (07/2011), section 10.3)

steel

concrete

a

bN

a

bV

bN

0.242

bV

0.086

a

2.000

Utilization bN,V [%]

7

Status

OK

0.899

0.279

1.500

100

OK

<= 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

43.358 [kN]

dN

0.144 [mm]

VSk

7.206 [kN]

dV

0.216 [mm]

dNV

0.260 [mm]

Long term loading:

NSk

43.358 [kN]

dN

0.211 [mm]

VSk

7.206 [kN]

dV

0.288 [mm]

dNV

0.357 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.5

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

C925 Lift Shaft

Detail 1

9/5/2016

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Bore hole cleaning must be performed according to instructions for use (blow twice with oil-free compressed air (min. 6 bar), brush twice,

blow twice with oil-free compressed air (min. 6 bar)).

Characteristic bond resistances depend on short- and long-term temperatures.

The design method fib (07/2011) assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by

filling the gap with mortar of sufficient compressive strength (e.g. by using the HILTI Seismic/Filling set) or by other suitable means

The compliance with current standards (e.g. EC3) is the responsibility of the user

Checking the transfer of loads into the base material is required in accordance with fib (07/2011)!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.5

www.hilti.com.sg

6

C925 Lift Shaft

Detail 1

9/5/2016

Page:

Project:

Sub-Project I Pos. No.:

Date:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

8 Installation data

Anchor plate, steel: S 355 (St 52); E = 210000.00 N/mm2; fyk = 355.00 N/mm2 Anchor type and diameter: HIT-HY 200-R + Rebar 28mm

Profile: Square hollow; 150 x 150 x 10 mm

Installation torque: Hole diameter in the fixture: df = 28 mm

Hole diameter in the base material: 35 mm

Plate thickness (input): 45 mm

Hole depth in the base material: 515 mm

Recommended plate thickness: calculated (43 mm)

Minimum thickness of the base material: 585 mm

Drilling method: Hammer drilled

Cleaning: Compressed air cleaning of the drilled hole according to instructions for use is required

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

Setting

Dispenser including cassette and mixer

For deep installations, a piston plug is

necessary

Seismic/Filling set

Torque wrench

y

220

300

100

300

200

300

300

200

100

100

175

175

150

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

-200

-25

150

-200

y

200

200

200

0

c-x

-

c+x

500

325

150

500

c-y

-

c+y

-

Anchor

5

6

7

8

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

x

-25

-200

-25

150

y

0

-200

-200

-200

c-x

-

c+x

325

500

325

150

c-y

-

c+y

-

Profis Anchor 2.6.5

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Vasu Chartered Engineers Pte Ltd

VJ

6 Ubi Road 1

+65- 6479 0365/4761 | +65- 6742 9262

vasuchartered@gmail.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

7

C925 Lift Shaft

Detail 1

9/5/2016

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Vous aimerez peut-être aussi

- Spot Welding Interview Success: An Introduction to Spot WeldingD'EverandSpot Welding Interview Success: An Introduction to Spot WeldingPas encore d'évaluation

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguPas encore d'évaluation

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Machine RoomDocument6 pagesMachine RoomRonnie De Joya AguirrePas encore d'évaluation

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterPas encore d'évaluation

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 pagesPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiPas encore d'évaluation

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterPas encore d'évaluation

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981Pas encore d'évaluation

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirrePas encore d'évaluation

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanPas encore d'évaluation

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Pas encore d'évaluation

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayPas encore d'évaluation

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguPas encore d'évaluation

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliPas encore d'évaluation

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Pas encore d'évaluation

- 1 Input Data: Profis Anchor 2.5.2Document5 pages1 Input Data: Profis Anchor 2.5.2jasekan.dcPas encore d'évaluation

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiPas encore d'évaluation

- ETV Block 9 (Pressure)Document16 pagesETV Block 9 (Pressure)Sibi SamPas encore d'évaluation

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09Pas encore d'évaluation

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguPas encore d'évaluation

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterPas encore d'évaluation

- Hilti AnchorDocument6 pagesHilti AnchorantonioPas encore d'évaluation

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenPas encore d'évaluation

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderPas encore d'évaluation

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenPas encore d'évaluation

- PES Hilti M10 HSA ReportDocument4 pagesPES Hilti M10 HSA ReportCollin NguPas encore d'évaluation

- Anchor Calculations For Roof Top TowerDocument46 pagesAnchor Calculations For Roof Top TowerRoseLockerPas encore d'évaluation

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiPas encore d'évaluation

- Hilti Connection ReportDocument7 pagesHilti Connection ReportFrancisco BonillaPas encore d'évaluation

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinPas encore d'évaluation

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 page4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitPas encore d'évaluation

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliPas encore d'évaluation

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PPas encore d'évaluation

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenPas encore d'évaluation

- TOVP - Rebar - May 12, 2023Document20 pagesTOVP - Rebar - May 12, 2023prabhash kumarPas encore d'évaluation

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimPas encore d'évaluation

- Hollow Core Concrete DetailingManualDocument41 pagesHollow Core Concrete DetailingManualJevgenijsKolupajevs100% (2)

- Hollow CoreDocument41 pagesHollow Corepaulo_arrieiroPas encore d'évaluation

- Connection d01 1Document6 pagesConnection d01 1Win ThanPas encore d'évaluation

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiPas encore d'évaluation

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarPas encore d'évaluation

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliPas encore d'évaluation

- Thermosorb Paint ThicknessDocument5 pagesThermosorb Paint ThicknessKawser HossainPas encore d'évaluation

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiPas encore d'évaluation

- 1 Input Data: WWW - Hilti.aeDocument16 pages1 Input Data: WWW - Hilti.aeEren BoyaciPas encore d'évaluation

- SQN-051-Driven Piles Penetration Length at POB2 (Southbound)Document16 pagesSQN-051-Driven Piles Penetration Length at POB2 (Southbound)Wr ArPas encore d'évaluation

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankPas encore d'évaluation

- Channel at End of SlabDocument10 pagesChannel at End of SlabOecoep IteemPas encore d'évaluation

- Beam Spb01 - Length 5430mm - Pa2Document6 pagesBeam Spb01 - Length 5430mm - Pa2phuckha2012Pas encore d'évaluation

- OXY Mukhaizna Airport Daily Report 010413pdf PDFDocument3 pagesOXY Mukhaizna Airport Daily Report 010413pdf PDFonspsnonsPas encore d'évaluation

- Fields - Concrete - Jan 8, 2021Document4 pagesFields - Concrete - Jan 8, 2021IlirQosjaPas encore d'évaluation

- Hilti - Profis Anchor Design Report 594Document5 pagesHilti - Profis Anchor Design Report 594Madhu GuptaPas encore d'évaluation

- ReportDocument2 pagesReportpravincs_007Pas encore d'évaluation

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKPas encore d'évaluation

- Cast in PIM 3Document14 pagesCast in PIM 3Oecoep IteemPas encore d'évaluation

- 1 Input Data: Hilti PROFIS Engineering 3.0.75Document3 pages1 Input Data: Hilti PROFIS Engineering 3.0.75Rosallind daBombPas encore d'évaluation

- Hilti Calc For RC StumpDocument15 pagesHilti Calc For RC StumpSantosoPas encore d'évaluation

- CAL01 Rev 00Document55 pagesCAL01 Rev 00NiemPas encore d'évaluation

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVPas encore d'évaluation

- C1738C1738M-14 Standard Practice For High-Shear Mixing of Hydraulic Cement PastesDocument3 pagesC1738C1738M-14 Standard Practice For High-Shear Mixing of Hydraulic Cement Pastesvikramjain66Pas encore d'évaluation

- RAPT Beam AnalysisDocument16 pagesRAPT Beam Analysisvikramjain66Pas encore d'évaluation

- Railing Design To SS EN 1993Document2 pagesRailing Design To SS EN 1993vikramjain66Pas encore d'évaluation

- C150C150M-15 Standard Specification For Portland Cement PDFDocument9 pagesC150C150M-15 Standard Specification For Portland Cement PDFPrafulla PatilPas encore d'évaluation

- CE5513 Assignment For 2-D Frames - 06082019Document10 pagesCE5513 Assignment For 2-D Frames - 06082019vikramjain66Pas encore d'évaluation

- C10C10M-14 Standard Specification For Natural CementDocument3 pagesC10C10M-14 Standard Specification For Natural Cementjavier perezPas encore d'évaluation

- Design Calculation For L Angle - Eurocode DesignDocument2 pagesDesign Calculation For L Angle - Eurocode Designvikramjain660% (1)

- Spiral Reinforcement 5S & 19SDocument1 pageSpiral Reinforcement 5S & 19Svikramjain66Pas encore d'évaluation

- RSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), MumbaiDocument1 pageRSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), Mumbaivikramjain66Pas encore d'évaluation

- Wind LoadDocument1 pageWind Loadvikramjain66Pas encore d'évaluation

- Anchor Bolt Shock CalculationDocument1 pageAnchor Bolt Shock Calculationvikramjain66Pas encore d'évaluation

- Alternative Proposal of Shifting of Pourstrip of Pour 4 of 4th StyDocument1 pageAlternative Proposal of Shifting of Pourstrip of Pour 4 of 4th Styvikramjain66Pas encore d'évaluation

- Stress Compare - Crane LoadingDocument2 pagesStress Compare - Crane Loadingvikramjain66Pas encore d'évaluation

- Tendon Elongation Calculation - BeamDocument1 pageTendon Elongation Calculation - Beamvikramjain66Pas encore d'évaluation

- Scope of Work - VikramDocument1 pageScope of Work - Vikramvikramjain66Pas encore d'évaluation

- Bda Commer ComplexDocument1 pageBda Commer Complexvikramjain66Pas encore d'évaluation

- RSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), MumbaiDocument1 pageRSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), Mumbaivikramjain66Pas encore d'évaluation

- RSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), MumbaiDocument1 pageRSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), Mumbaivikramjain66Pas encore d'évaluation

- RSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), MumbaiDocument1 pageRSSB - Satsang Hall at F. Plot Nos 276/277/278/289, Tps-Iii 36Th Road Bandra (W), Mumbaivikramjain66Pas encore d'évaluation

- Nicmar Management in 2Document87 pagesNicmar Management in 2Venkatanarasimha KlPas encore d'évaluation

- Quarter 1 Week 4: Electrical Installation and Maintenance (EIM) Grade 10Document21 pagesQuarter 1 Week 4: Electrical Installation and Maintenance (EIM) Grade 10Jhobhel Christopher Galivo50% (2)

- Hilti HIT HY 70 Injection Mortar For MasonryDocument26 pagesHilti HIT HY 70 Injection Mortar For MasonryVenkatesh PadmanabhanPas encore d'évaluation

- 2014 Hilti Hit-Hy 200 With Hit-ZDocument5 pages2014 Hilti Hit-Hy 200 With Hit-ZDifa LiuPas encore d'évaluation

- Baileys Plant Hire Price-ListDocument8 pagesBaileys Plant Hire Price-ListWashington Anjichi Okang'aPas encore d'évaluation

- Stayer CatalogueDocument112 pagesStayer CataloguePercival BugnosenPas encore d'évaluation

- Atlas Copco Blasthole Drills Dm45-SeriesDocument4 pagesAtlas Copco Blasthole Drills Dm45-SeriesfelipePas encore d'évaluation

- 2014 Metabo Katalog GB LRDocument291 pages2014 Metabo Katalog GB LRTh Nattapong100% (1)

- Milwaukee 18v Hammer-Drill ManualDocument11 pagesMilwaukee 18v Hammer-Drill ManualTodd WagnerPas encore d'évaluation

- DEWALT Onsite Offers Q4 2014 Hi Res PDF - CompressedDocument12 pagesDEWALT Onsite Offers Q4 2014 Hi Res PDF - CompressedRiverland Welding and Tool SuppliesPas encore d'évaluation

- Telescopic Gate Install Metal Frame For TimberDocument13 pagesTelescopic Gate Install Metal Frame For TimberZobbadPas encore d'évaluation

- 16 Catalog Krisbow9 Power ToolDocument14 pages16 Catalog Krisbow9 Power ToolEnrique da Matta100% (1)

- Bti Katalog Drilling Sawing Grinding CuttingDocument120 pagesBti Katalog Drilling Sawing Grinding CuttingCitac_1Pas encore d'évaluation

- CE 3220 11 Drilling Rock and Earth PDFDocument67 pagesCE 3220 11 Drilling Rock and Earth PDFMohamedRaahimPas encore d'évaluation

- FRD Product LineDocument8 pagesFRD Product Linegiapy0000Pas encore d'évaluation

- Drill and BitsDocument6 pagesDrill and BitsEduardo Antonio Duran SepulvedaPas encore d'évaluation

- Power Tools CatalogueDocument92 pagesPower Tools CatalogueKurniawanPas encore d'évaluation

- DRILLTECH Handbook PDF PDFDocument64 pagesDRILLTECH Handbook PDF PDFSebastian100% (5)

- 1 Input Data: Profis Anchor 2.7.1Document6 pages1 Input Data: Profis Anchor 2.7.1Shafeeq KTPas encore d'évaluation

- Bosch Power Tools Product Catalogue 2012-2013 In-EnDocument144 pagesBosch Power Tools Product Catalogue 2012-2013 In-EnPankaj Kumar KushwahaPas encore d'évaluation

- Bosch Power Tools Product Catalogue Full 2012-2013 MY-EnDocument131 pagesBosch Power Tools Product Catalogue Full 2012-2013 MY-EnSérgio SantosPas encore d'évaluation

- Bosch20182019 Catalog - Masonryconcretedrilling PDFDocument40 pagesBosch20182019 Catalog - Masonryconcretedrilling PDFSahithi KatakamPas encore d'évaluation

- GMC Catalogo 2012Document27 pagesGMC Catalogo 2012patroleitorPas encore d'évaluation

- Grouting TAMDocument42 pagesGrouting TAMPinoyini100% (2)

- Einhell Catalog 2012Document92 pagesEinhell Catalog 2012iuliavedislavPas encore d'évaluation

- Tools On Demand List - 01232015 PDFDocument4 pagesTools On Demand List - 01232015 PDFdpatelPas encore d'évaluation

- Competence in Tunnelling: Underground ConstructionDocument20 pagesCompetence in Tunnelling: Underground ConstructionechavarriPas encore d'évaluation

- Types of BoringsDocument13 pagesTypes of BoringspandiyanPas encore d'évaluation

- Machinery Hire Rates - LIST B 2015 Kota KinabaluDocument24 pagesMachinery Hire Rates - LIST B 2015 Kota KinabaluAbdul Aziz Julkarnain ZulkifliPas encore d'évaluation

- E BrochureDocument53 pagesE BrochureKurniawanPas encore d'évaluation

- Blasthole Reference Book - tcm892-1923757Document248 pagesBlasthole Reference Book - tcm892-1923757Paul Gossen80% (5)