Académique Documents

Professionnel Documents

Culture Documents

Life Cycle

Transféré par

ALIKNFDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Life Cycle

Transféré par

ALIKNFDroits d'auteur :

Formats disponibles

1

Chapter 4.4 (pages 91-101)

Four basic steps

Requirements analysis clarify about what we want

Functional definition identify technical purposes

Physical definition create the solution (output)

Design validation check the solution (output)

These four steps are applied repeatedly in

Needs analysis (chapter 6)

Concept exploration (chapter 7)

Concept definition (chapter 8)

These steps vary in their specifics depending on

the type of system and the phase of its

development

Focus on the input and

output

This is the basic

procedure that needs to

be memorized.

Requirements Analysis

Operational Requirements

Analysis

Understand the operational

requirements

Identify and resolve

problems with the

operational requirements

Conflicts

Incomplete requirements

Obviously

expensive/impossible

Provide feedback to the

users

Request clarifications

Recommend changes

Assemble and organize all input conditions

Identify the whys of all requirements in

terms of operational needs, constraints,

environment or other higher-level objectives

Clarify the requirements of what the system

must do, how well it must do it, and what

constraints it must fit

Correct inadequacies and quantify the

requirements wherever possible

Essence of quantify: make things be more

specific and tangible.

9

Functional Definition

Determine System

requirements

Go to 1st subsystem level

if needed

Determine required

performance

Define top level scope of

system

10

Translate requirements (why) into functions (actions

and tasks) that the system must accomplish (what)

Partition (allocate) requirements into functional

building blocks

Define interactions among functional elements to lay

a basis for their organization into a modular

configuration

Insight: similar to (not the same as) the practice of

Quality Function Deployment (QFD)

The distinctions among objectives, requirements and

functions are tedious.

Objective tends to be at higher level

Requirement tends to be more technical with various

types

Function context of functional build blocks

11

Physical Definition

Define candidate

implementation concepts

(solutions)

Define functions

Assign to candidate

subsystems

Define necessary subsystem

requirements and

performance characteristics

Provide feedback to

Functional Definition

System requirements need

to change?

12

Synthesize a number of alternate system

components representing a variety of design

approaches to implementing the required

functions

Define the most simple practicable interactions

and interfaces among structural sub-divisions

Select a preferred approach by trading off a set

of predefined and prioritized criteria (measures

of effectiveness [MOE]) to obtain the best

balance among performance, risk, cost and

schedule

Elaborate the design to the necessary level of

detail

13

Design Validation

Validate Requirements

Ensure requirements are

consistent and complete

Ensure concepts are

feasible

Provide feedback to Design

Implementation

Correct deficiencies in

candidate concepts

Change system

requirements

Recommend changes to

operational requirements

14

Design models of the system environment

reflecting all significant aspects of the

requirements and constraints

Types of models: logical, mathematical, and physical

Simulate or test and analyze system solution(s)

against environmental models (via scenarios)

Iterate as necessary to revise the system model

or environmental models, or to revise system

requirements if too stringent for a viable solution

until the design and requirements are fully

compatible

Key: check the solution via experimentation on

models

15

16

17

Concept Exploration

Definition of operational requirements

Functional analysis and formulation

Concept Definition

Definition of performance requirements

Functional allocation

Concept Selection and Validation

18

Definition of operational requirements (p. 145)

Mission and purpose of the system

Describe and communicate the end state of the world

Operational requirements analysis (chapter 7.2)

Requirements elicitation

Users and operators (via market survey and interviews)

Subject matter experts

Previous studies and system development efforts

Requirements analysis

Check if the requirements are valid, feasible, vague or

inconsistent

Avoid any redundant requirements

19

Recall the functional building blocks

Functions:

How to identify system functions

Help to interpret the information of operational and performance

requirements with more engineering contents

Help to explore different system concepts

Functional media: signals, data, material and energy

Ask the questions (next slide)

Three function categories: input, transformative and output

Input function: the processes of sensing and inputting

functional media into the system

Output function: the processes of interpreting, display,

synthesizing and output functional media out of the

system

Transformative function: transforming inputs to outputs

20

Are there operational objectives that require sensing

or communications?

If so, this means that signal input, processing, and output

functions must be involved.

Does the system require information to control its

operation?

If so, how are data generated, processed, stored, or

otherwise used?

Does system operation involve structures or

machinery to house, support, or process materials?

If so, what operations contain, support, process, or

manipulate material elements?

Does the system require energy to activate, move,

power, or otherwise provide necessary motion or

heat?

21

High-level system block

22

Definition of performance requirements (p. 145)

How well the system should perform its requirements

and affect its environment

Provide numerical thresholds (should be objective and

quantitative)

System performance characteristics (p. 191)

Define what the system must do, and how well, but not

how the system should do it

Define characteristics in engineering terms that can be

verified by analytical means or experimental tests

If a system possesses the stated characteristics, it will

satisfy the operational requirements

23

Developing functional building blocks (p.

207)

Identification of functional media

Identification of functional elements (p. 47)

Relation of performance requirements to element

attributes

Configuration of functional elements

Analysis of integration of all external interactions

Functional block diagramming tools (p. 209)

A representation tool for better communication

E.g., functional block diagram, IDEF, etc

24

Source: pages 181-182, 209-210

Step 1: identify the necessary inputs

Signals: user commands

Data: none

Material: fresh coffee grinds, filter, and water

Energy: electricity

Forces: mechanical support

Signals: status (on or off, coffee done or not)

Data: none

Materials: brewed coffee, used filter, used coffee grinds

Energy: heat

Forces: none

Step 2: identify the outputs

25

Remark: the functions confine what to look at

for the system

How do we transform fresh coffee grinds, a filter, water,

and an on/off command into brewed coffee, a used

filter, used coffee grinds and a status?

Input functions: accept user command, receive

coffee materials, distribute electricity, distribute

weight

Transformative functions: heat water, mix hot

water with coffee grinds, filter out coffee grinds,

warm brewed coffee

Output functions: provide status, facilitate

removal of materials, dissipate heat

26

Accept water

Accept Coffee Grounds

Accept filter

Accept power setting

Display power setting

Produce heat

Make coffee

Keep coffee warm

27

Accept water

Input water

Store water

Accept Coffee Grounds

Convert electricity to heat

Accept filter

Input filter

Remove filter

Accept user input

Turn electricity on/off

Display power setting

Sense power usage

Illuminate power indicator

Make coffee

Transport water from storage

Heat water

Filter water through ground

coffee

Send coffee to coffee storage

Input coffee grounds

Remove coffee grounds

Accept power setting

Produce heat

Keep coffee warm

Store coffee

Transfer heat to coffee to

keep warm

Remove coffee

28

29

Source: chapter 8.4

Allocation of functions to physical components of

the system (p. 212)

It can be viewed as concept formulation

Decision on functions decision on physical

components affect the following two issues

System measures: ultimate performance, cost, etc

Who will develop the system (supplier selection)

Modularity issue (pages 212-213)

Multiple functions single physical component or a

single function multiple sub-systems

Ideal: one-to-one mapping modular structure

30

Predecessor system as a baseline

Technological advances

Focus on the deficient components or sub-systems

Minimize the modifications

System upgrade: same function improved component

Possibility of a radical departure from the existing

system

Be aware of the risks such as deliverable of new

technology, cost and time

Original concepts: relatively rare

Output

Functional block diagram (or FFBD)

Pictorial or other physical description produced for

providing a more realistic view of the system candidate

31

Source: chapter 8.5-8.6

Trade-off analysis

Assessment of goodness degrees

Achieve the balance among different goodness

measures

Goodness measures

Operational performance and compatibility

Program cost and schedule

Risk in achieving each of the above

32

Design margins

Program risks

Selection strategy: guidelines for trade-off

Referred to the amount that a given system parameter

can deviate from its nominal value without producing

unacceptable behavior of the system as a whole

Similar concept: robustness

Probability of failure + criticality of failure

Conserve analytical effort, use a staged approach to the

selection process, in which only the most likely winners

are subjected to the full system evaluation

Retain the visibility of the complete evaluation profile of

each concept (rather than combining the measures into

one merit)

33

Car 1

Fuel efficiency = 10 km/L (Goodness score = 7)

Cost = $10,000 (Goodness score = 8)

Total score = 15

Car 2

Fuel efficiency = 12 km/L (Goodness score = 9)

Cost = $12,000 (Goodness score = 7)

Total score = 16

If we just look at the total scores, we may

lose the overall picture.

34

Critical experiments

Obtain sufficient data to understand thoroughly the

behavior of the system element

Stress the proposed design feature to its extreme

limits to ensure that it is not just marginally

satisfactory

At the conceptual stage, validation can be a

piece of arguments with some evidence

(based on existing systems)

The feedback from validation can lead to

some development iterations for refining and

improving the system models

35

Customer

Surveys & Feedback, Marketing Data

Related Designs

Specs & Drawings for previous versions

Similar designs of competitors

Analysis Methods

Handbooks, Textbooks, Monographs, Technical

Reports, Specialized computer programs

Materials

Performance in past designs, Properties

Manufacturing

Capability of Processes, Capacity analysis

Manufacturing sources, Assembly methods

Cost

Cost history, Current material & manufacturing

costs

Standard Components

Availability & Quality of vendors, Size & Technical

Data

Technical standards

ISO, ASTM, Company specific

Governmental

Regulations

Performance-based, Safety requirements

Life Cycle issues

Maintenance/service feedback,

Reliability/quality/warranty data

36

Libraries

Dictionaries, engineering handbooks, texts, periodicals

Internet

A massive depository of information

Government

Technical reports, databases, agency-based search

engines, laws & regulations

Engineering

professional

societies & trade

associations

Technical journals & news magazines, Technical

conference proceedings, Codes & standards

Intellectual property

Patents, Copyrights, Trademarks

Personal activities

Buildup of knowledge, Contacts with colleagues, Personal

network, contacts with suppliers & vendors, Attendance f

conferences, Visits of other companies

Customers

Direct involvement, Surveys, Feedback from warranty

payments

37

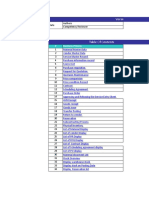

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Civ324 HW1Document1 pageCiv324 HW1ALIKNFPas encore d'évaluation

- CH 12 Shear Strength NewDocument72 pagesCH 12 Shear Strength NewALIKNFPas encore d'évaluation

- Civ324 HW3Document1 pageCiv324 HW3ALIKNFPas encore d'évaluation

- CH 7 PermeabilityDocument30 pagesCH 7 PermeabilityALIKNFPas encore d'évaluation

- Civ324 HW2Document1 pageCiv324 HW2ALIKNFPas encore d'évaluation

- CH 11 Compressiblity NewDocument72 pagesCH 11 Compressiblity NewALIKNFPas encore d'évaluation

- CH 5 Phase RelationsDocument26 pagesCH 5 Phase RelationsALIKNFPas encore d'évaluation

- Ch-10-Stresses in A Soil MassDocument62 pagesCh-10-Stresses in A Soil MassALIKNFPas encore d'évaluation

- CIV324 - Geotechnical EngineeringDocument5 pagesCIV324 - Geotechnical EngineeringALIKNFPas encore d'évaluation

- Soil Comp ActionDocument74 pagesSoil Comp ActionEng Ayman ShalabyPas encore d'évaluation

- CH 9 Insitu StressesDocument33 pagesCH 9 Insitu StressesALIKNFPas encore d'évaluation

- CH 8 SeepageDocument30 pagesCH 8 SeepageALIKNFPas encore d'évaluation

- Consistency Limits 1Document41 pagesConsistency Limits 1ipog_2k1Pas encore d'évaluation

- Assignment 4 6331 PDFDocument10 pagesAssignment 4 6331 PDFALIKNFPas encore d'évaluation

- CH 4 ClassificationDocument25 pagesCH 4 ClassificationALIKNFPas encore d'évaluation

- CH 1 FormationDocument31 pagesCH 1 FormationALIKNFPas encore d'évaluation

- The Progress Report - Indu - 6331 PDFDocument2 pagesThe Progress Report - Indu - 6331 PDFALIKNFPas encore d'évaluation

- Solucionario Análisis Estructural Kassimali PDFDocument723 pagesSolucionario Análisis Estructural Kassimali PDFangelams100% (1)

- CH 2 MineralogyDocument36 pagesCH 2 MineralogyALIKNFPas encore d'évaluation

- FinalExamSol 12 10 PDFDocument5 pagesFinalExamSol 12 10 PDFALIKNFPas encore d'évaluation

- In6331outl 2017W PDFDocument2 pagesIn6331outl 2017W PDFALIKNFPas encore d'évaluation

- Fig. 1 The Process Yield HistogramDocument10 pagesFig. 1 The Process Yield HistogramALIKNFPas encore d'évaluation

- CH 2 B Grain Size AnalysisDocument16 pagesCH 2 B Grain Size AnalysisALIKNFPas encore d'évaluation

- Assignment 8 6331 PDFDocument11 pagesAssignment 8 6331 PDFALIKNFPas encore d'évaluation

- Assignment 7 6331 PDFDocument11 pagesAssignment 7 6331 PDFALIKNFPas encore d'évaluation

- Lec - 1 - Indu 6331Document40 pagesLec - 1 - Indu 6331ALIKNFPas encore d'évaluation

- Assignment 6 6331 PDFDocument5 pagesAssignment 6 6331 PDFALIKNFPas encore d'évaluation

- Assignment 1 6331Document4 pagesAssignment 1 6331ALIKNFPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- (REDEX) - Scrum MasterDocument3 pages(REDEX) - Scrum MasterAly Pasha MohamedPas encore d'évaluation

- 1609608518cyber SecurityBDocument337 pages1609608518cyber SecurityBJuan HoyosPas encore d'évaluation

- Csaf CVRF v1.2 cs01Document101 pagesCsaf CVRF v1.2 cs01EstebanPas encore d'évaluation

- TS (SDP-1) MSWD Skill ExperimentsDocument18 pagesTS (SDP-1) MSWD Skill ExperimentshavebexPas encore d'évaluation

- DC v2016.12-SP3 Lab Setup Checks: 1. UNIX% CP - R Lab5 Test - Lab5 CD Test - Lab5 DC - Shell - TopoDocument3 pagesDC v2016.12-SP3 Lab Setup Checks: 1. UNIX% CP - R Lab5 Test - Lab5 CD Test - Lab5 DC - Shell - TopomanojkumarPas encore d'évaluation

- SAP Blog - Setting Up Business Partner S4 HANADocument23 pagesSAP Blog - Setting Up Business Partner S4 HANAlovely lovely100% (1)

- Goals DBIs KKKDocument42 pagesGoals DBIs KKKRajanikant Tagarrati VenkataPas encore d'évaluation

- Crash ReportDocument2 pagesCrash ReportLidia GheraliuPas encore d'évaluation

- Exemple de Dissertation Sur Le CapitalismeDocument8 pagesExemple de Dissertation Sur Le CapitalismeCollegePaperHelpFargo100% (1)

- E-Assignment: German-Malaysian InstituteDocument8 pagesE-Assignment: German-Malaysian InstituteYeshi UchihaPas encore d'évaluation

- Real-Time Data Exchange (RTDE) GuideDocument16 pagesReal-Time Data Exchange (RTDE) Guide徐海东Pas encore d'évaluation

- KPI LTE FormulaDocument5 pagesKPI LTE FormulaArielPas encore d'évaluation

- AIS Chapter 1-3Document24 pagesAIS Chapter 1-3Crissa SamsamanPas encore d'évaluation

- Tree Data Structures: S. SudarshanDocument28 pagesTree Data Structures: S. SudarshanVikas NagarePas encore d'évaluation

- Name: Evelyn Daniela Rojas Crucerira Code:36151055 Date: 15/04/2019Document3 pagesName: Evelyn Daniela Rojas Crucerira Code:36151055 Date: 15/04/2019EvelynRojasPas encore d'évaluation

- Internet of Things Xia YangDocument3 pagesInternet of Things Xia YangPrashant PathakPas encore d'évaluation

- Module9 Backup RecoveryDocument12 pagesModule9 Backup RecoverySandip ChatterjeePas encore d'évaluation

- Communication ProtocolsDocument9 pagesCommunication ProtocolsKarthik N SPas encore d'évaluation

- CCNA 1 v7 Modules 4 - 7 - Ethernet Concepts Exam AnswersDocument27 pagesCCNA 1 v7 Modules 4 - 7 - Ethernet Concepts Exam AnswersBagus Fajariyanto 21.01.4647Pas encore d'évaluation

- Ubisoft Graduate Program PDFDocument8 pagesUbisoft Graduate Program PDFThomas HarrisonPas encore d'évaluation

- BN68-15687F-01 - Leaflet-Remote - Y23 QLED QD CU8 LS03 - TK SQ - L05 - 230609.0Document2 pagesBN68-15687F-01 - Leaflet-Remote - Y23 QLED QD CU8 LS03 - TK SQ - L05 - 230609.0batuhanoyalPas encore d'évaluation

- CHS Periodical Test Grade 8Document3 pagesCHS Periodical Test Grade 8Romel A. De Guia100% (1)

- Semester 2 Final Exam - Oracle AcademyDocument23 pagesSemester 2 Final Exam - Oracle AcademyAri Yanto100% (1)

- WeldQ Test Centre Examiner Manual v1.3Document63 pagesWeldQ Test Centre Examiner Manual v1.3mammad EhsaniPas encore d'évaluation

- Speed Control of Three Phase Induction Motor Using PLC Under Open and Closed Loop ConditionDocument6 pagesSpeed Control of Three Phase Induction Motor Using PLC Under Open and Closed Loop ConditionTana AzeezPas encore d'évaluation

- C Program On Electricity-Billing-SystemDocument19 pagesC Program On Electricity-Billing-SystemAnand GoudPas encore d'évaluation

- Addressing Mode General Meaning: RegisterDocument27 pagesAddressing Mode General Meaning: RegisterkPas encore d'évaluation

- Sharp Install Assistant Tool Operation ManualDocument12 pagesSharp Install Assistant Tool Operation ManualPanait Daniel IonutPas encore d'évaluation

- Sri Venkateswara College of Engineering Course Delivery Plan - Lab Page 1 ofDocument3 pagesSri Venkateswara College of Engineering Course Delivery Plan - Lab Page 1 ofxperiaashPas encore d'évaluation

- Fiori MM Test ScriptsDocument125 pagesFiori MM Test Scriptsabhi_ray22Pas encore d'évaluation