Académique Documents

Professionnel Documents

Culture Documents

Greensand Casting PDF

Transféré par

Nirmal KushwahaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Greensand Casting PDF

Transféré par

Nirmal KushwahaDroits d'auteur :

Formats disponibles

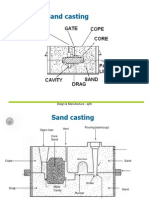

Greensand casting

1 of 10

http://www.foundry101.com/new_page_7.htm

Step-by-Step Sand Casting Instructions

Foundry Sand/Greensand

In commercial foundries the sand is used over and over thousands of times. Between uses, the

sand is rejuvenated by adding water and mulling (mixing and smashing). If you do not let the

sand dry out all the way, you do not have to mull, just add water. Sand grit is determined just

like sandpaper. 150 is very fine and 50 grit is coarse. Fine sand will give good detail, coarse

sand will give a pebbly or rough texture. I

Helpful Hints:

1.Start casting with aluminum (low-melting), then try brass or

bronze. Practice with easy metals.

2.Finish molding before you start your furnace.

If you look at the sand through a microscope there are gaps and spaces like a DO NOT light the furnace then start molding.

sponge. Any moisture that turns to gas during pouring can escape out the

3.Greensand is about 6% moisture. DO NOT let your sand dry

pores (gaps).

out! Keep it covered or in a sealed container when not in use.

Other materials like plaster do not have gaps for the gas to escape. The sand used in

4.DO NOT melt aluminum cans. Can metal is covered in vinyl to

greensand is silica, common/ordinary sand. You can use beach sand, desert sand......it's all

good as long as it is clean and fine. The sand is held together with bentonite, a powdered clay. protect the can from the contents. All other aluminum is good to

Bentonite is also used for wine-making, well drilling, patching dry lake beds, cosmetics,

melt.

farm-feed additive and milkshake thickener. Bentonite is also sold in health food stores for

abdominal problems. You can purchase bentonite locally at well-drillers or well-drilling

5. DO NOT stir molten metal, this adds gas.

suppliers.

Do skim dross off the top right before pouring!

Mold on a clean surface.

Keep your sand in a

sealed container to

retain moisture when

not in use.

Molding tools needed:

Riddle (Sieve/screen), large hole cutter (1/2" copper pipe),

dowels (1/4" and 1/8"), rammer/striker (wood 10"x1.5"x1"),

runner bar pattern, spoon, trowel and parting dust (in the

black sock).

Civil War Plaque

1. Place iron pattern in flask with enough room for gating. In this

mold we use a wood pattern for "runner" and "gate".

Pattern can be made of wood, metal, plastic, plaster or even soft

materials like wax.

Note: Soft materials and wood need to be coated with shellac or other

coating.

2. Dust pattern with parting dust to keep it from sticking.

Parting dust is a hydrophobic material, it repels moisture.

Most powders (baby, talcum) absorb moisture.

18-07-2012 15:44

Greensand casting

2 of 10

http://www.foundry101.com/new_page_7.htm

4. Use paddle side of rammer to tuck edges first.

Hold the flask with your other hand.

3. Use a fine riddle to cover just the pattern, then fill up the flask

with sand, level (flush) with the top. There is no need to riddle all

the sand, just make sure there is no lumps. The riddle fluffs the sand

up so it can be packed properly, the same way a flour sifter works.

5. Use the butt side of rammer east to west (lightly to protect pattern), then

north and south (harder to pack mold tight). Ramming strokes should be 1

inch apart, like you are planting corn. Do not ram twice in the same spot, do

not ram close together.

You can ram too soft, you can't ram too hard.

6. Fill it up with sand to about 2 inches above flask.

Ram really hard the second pass!

18-07-2012 15:44

Greensand casting

3 of 10

http://www.foundry101.com/new_page_7.htm

8. Strike off drag section with rammer, then spread small amount of sand

(handful) out to cushion bottom board.

7. Use rammer again North to South, then East to West pattern. Planting

corn. Hard, to pack the sand very tight. Hold the flask with your hand.

10. Holding bottom board and flask together, flip it over.

9. Place bottom board on top of your mold.

18-07-2012 15:44

Greensand casting

4 of 10

http://www.foundry101.com/new_page_7.htm

12. Use your spoon and smooth the edges of the pattern and any

rough areas.

11.Remove the cope and pattern board.

Repeat steps 3-8.

Ramming the cope full of sand, the same way we

did the drag (bottom).

13. Replace cope and apply parting dust. WAIT! Make sure hinges

and latches are on the SAME side! This cope needs to be flipped

the other way.

18-07-2012 15:44

Greensand casting

5 of 10

http://www.foundry101.com/new_page_7.htm

14. Strike off cope level with the rammer/striker. Use your trowel to smooth. 15. Take cope off and set it aside.

16. Form sprue hole with copper pipe, place hand against

opposite side to prevent excess breakage.

Make sprue hole at one end and the pop-up in the

middle somewhere. Do not make the pop-up at the

end.

17. Form pop-up with 1/4" dowel, place hand against

opposite side.

18.When molten flows into the mold, erosion eats away at

sharp edges. Round sharp or rough areas with your finger.

Do not rub with your finger, push gently.

The mold is delicate and fragile, be very careful.

18-07-2012 15:44

Greensand casting

6 of 10

19. For areas you can't reach with finger, use the dowel to

smooth inside holes. Clean pop-up hole also!

21. Clean rough areas around sprue and pop-up with your

finger and dowel.

23. Remove wood gate pattern.

http://www.foundry101.com/new_page_7.htm

20. Carve pouring cup into the sprue hole on the top of the

mold. Like a small cup. Slick what you can with the spoon.

22. Tap runner pattern to loosen, then remove.

24. Tap pattern lightly to loosen.

18-07-2012 15:44

Greensand casting

7 of 10

http://www.foundry101.com/new_page_7.htm

26. Smooth any rough or sharp edges where molten metal

will flow. Where the runner meets the gate and where the

gate meets the pattern.

Your finger is the most useful molding tool.

25. Put a screw partially into the pattern for a handle.

Remove pattern.

Lightly touch rough areas to smooth with your finger, do

not rub with your finger, just touch.

The sand mold is very delicate and fragile,

touch as little as possible with surgical skill.

28. Replace cope (top section).

27. Is your sand too wet? Torch the casting area

for about a minute, this will dry out excess moisture.

This small mold was torched less than a minute, sand

will blacken.

18-07-2012 15:44

Greensand casting

8 of 10

Most molds have the flask remain on the mold. If this mold

were to be poured with brass or bronze, we would leave the

flask on the mold. And clamp it!

http://www.foundry101.com/new_page_7.htm

29. A "snap flask" has hinges and clasps, allowing it to be

removed after molding. This mold is going to be poured

with aluminum.

30. Fill crucible with metal, place the crucible in the furnace

and light.

Light furnace by releasing gas and dropping a wooden

match into the furnace in front of burner (blue area), AT THE

SAME TIME! There should be no flame inside the metal burner

31.

tube, only in the refractory area.

Is the furnace running properly?

Look.......inside the burner for flame.

Listen.....to the sound. A high pitched gurgling or a

Replace lid. Turn gas all the way

up. Feed metal into the exhaust hole.

misfiring engine sound indicates flame in the burner tube.

A steady roaring sound indicates proper burning, like a

jet! If your furnace is not operating correctly, relight and

release the propane faster with more pressure. Releasing the

gas too slowly will allow it to go in the burner tube.

18-07-2012 15:44

Greensand casting

9 of 10

http://www.foundry101.com/new_page_7.htm

32. Feed metal into the exhaust hole as fast as it will take it

until the crucible is full.

Do not operate furnace with lid plug in.

33. After the last piece of aluminum has turned molten

(liquid), let the furnace run 3 more minutes to reach

pouring temperature. With brass, 5 minutes.

DO NOT overheat aluminum. DO NOT overheat steel

crucibles.

Aluminum pouring temp is 1325 to 1400F.

35.Pour in the winter or summer.

Place a brick or two on each mold to prevent leaking!

34. Turn off furnace, remove lid, scoop off dross (slag) that is

floating on top. Remove dross with a slotted steel spoon, a

cheap kitchen one will do.

Remove crucible.

Pronounced: crew-sybil

18-07-2012 15:44

Greensand casting

10 of 10

http://www.foundry101.com/new_page_7.htm

36. Pour extra metal into a steel muffin pan to make ingots.

When using a brand new pan, pre-heat in the furnace exhaust

before using. Pre-heating will burn off any teflon coating and 37. Allow mold to cool for at least 5 minutes.

keep the ingots from sticking.

38. Shake-out mold into sand container.

39. Cut off gating system. Grind flashing. Buff flat

surfaces with compound and cloth wheel.

Sprinkle about 2 cups of water on the crunchy parts of

sand. Cover your sand, do not let it dry out.

For more molding tips read through

our project pages and foundry facts.

Home

Beautiful mask made using a ceramic pattern.

Visit a ceramic store for inexpensive patterns to use for

casting.

Copyright 2011-Lost & Foundry of Spokane!

18-07-2012 15:44

Vous aimerez peut-être aussi

- Making CruciblesDocument3 pagesMaking Cruciblesborakas2011Pas encore d'évaluation

- Advanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingD'EverandAdvanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingShigeyuki SomiyaPas encore d'évaluation

- Metals: Thermal and Mechanical DataD'EverandMetals: Thermal and Mechanical DataSimonne AllardPas encore d'évaluation

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationD'EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationPas encore d'évaluation

- Chemistryofpaint00churuoft PDFDocument438 pagesChemistryofpaint00churuoft PDFraluca_ibPas encore d'évaluation

- Calculation of Thermal Expansion Coefficient of Glasses 1976 Journal of Non Crystalline SolidsDocument9 pagesCalculation of Thermal Expansion Coefficient of Glasses 1976 Journal of Non Crystalline SolidsGarlapati Srinivasa RaoPas encore d'évaluation

- Making A BurnerDocument13 pagesMaking A BurnerangelPas encore d'évaluation

- Everyday Electronics 1974 01Document5 pagesEveryday Electronics 1974 01marcosscarato0% (1)

- Metalcastingprocess 110925103638 Phpapp02 PDFDocument51 pagesMetalcastingprocess 110925103638 Phpapp02 PDFramesh tPas encore d'évaluation

- Homemade Refractories: "2 Bucks" FurnaceDocument6 pagesHomemade Refractories: "2 Bucks" FurnaceFIREREALM66Pas encore d'évaluation

- Simple HHO Boosters Improve Fuel EfficiencyDocument29 pagesSimple HHO Boosters Improve Fuel EfficiencyLudovicPas encore d'évaluation

- Introduction To Electrical Theory and DC Circuits: James Doane, PHD, PeDocument33 pagesIntroduction To Electrical Theory and DC Circuits: James Doane, PHD, PeMatty WrobelPas encore d'évaluation

- Fe Co ElectroformingDocument8 pagesFe Co ElectroformingIsman KhaziPas encore d'évaluation

- Vertial Axis Wind Turbine From 30 of Scrap MateriaDocument7 pagesVertial Axis Wind Turbine From 30 of Scrap MateriaMarius DanilaPas encore d'évaluation

- Charcoal by Gary GilmoreDocument10 pagesCharcoal by Gary GilmoreMarky MaypoPas encore d'évaluation

- Project One.2: Materials, Production + ProcessesDocument13 pagesProject One.2: Materials, Production + ProcessesYellkGnPas encore d'évaluation

- Guide To Hand SolderingDocument1 pageGuide To Hand SolderingNICComp100% (1)

- Foundry Work For The Amateur 1975Document116 pagesFoundry Work For The Amateur 1975Rob Furnald100% (3)

- Metal Sand Casting ProcessDocument22 pagesMetal Sand Casting ProcessCharo Mel Tablo100% (1)

- Glass On Metal Online - Past Articles - Hydraulic Die FormingDocument13 pagesGlass On Metal Online - Past Articles - Hydraulic Die FormingSotiris AslanopoulosPas encore d'évaluation

- Vortex Tube ManufacturingDocument3 pagesVortex Tube ManufacturingSameer JainPas encore d'évaluation

- Cyanide Copper Plating Reinvents ItselfDocument5 pagesCyanide Copper Plating Reinvents ItselfServet TimurPas encore d'évaluation

- The Pocket FoundryDocument6 pagesThe Pocket FoundryNatalie WyattPas encore d'évaluation

- Frosty T Burner Build: All The Ratios Are Derived From The Pipe IameterDocument4 pagesFrosty T Burner Build: All The Ratios Are Derived From The Pipe IameterKain402Pas encore d'évaluation

- Design Sand Casting Class IDocument23 pagesDesign Sand Casting Class Iiamajith123Pas encore d'évaluation

- A Review of Free-Piston Engine History and Applications.Document16 pagesA Review of Free-Piston Engine History and Applications.Thulasi RamPas encore d'évaluation

- Coil Winder Rev 3-19-11Document17 pagesCoil Winder Rev 3-19-11dougforbes000Pas encore d'évaluation

- Shaft Drive Vs Chain DriveDocument3 pagesShaft Drive Vs Chain DriveSubroto MukerjiPas encore d'évaluation

- Glass Blowing EquipmentDocument7 pagesGlass Blowing EquipmentJustine VivasPas encore d'évaluation

- Microwave TubesDocument58 pagesMicrowave TubesDhyey DesaiPas encore d'évaluation

- Scientific GlassblowingDocument13 pagesScientific GlassblowingFacundo BaróPas encore d'évaluation

- Hive-Bodies 20110323Document9 pagesHive-Bodies 20110323khaldoonPas encore d'évaluation

- Lost Wax Casting PDFDocument78 pagesLost Wax Casting PDFMiki PetricPas encore d'évaluation

- Starlite PDFDocument35 pagesStarlite PDFPuturrú De FuáPas encore d'évaluation

- Design Calculations For No-Head, Low-Head Waterwheels... by RuDocument2 pagesDesign Calculations For No-Head, Low-Head Waterwheels... by RuSPYDERSKILL100% (1)

- Reduce Fuel Costs Up To 28% With Fuel EnergizerDocument26 pagesReduce Fuel Costs Up To 28% With Fuel EnergizerAmal JithPas encore d'évaluation

- Nikola Tesla-Colorado Springs Notes-1899-1900Document431 pagesNikola Tesla-Colorado Springs Notes-1899-1900Anonymous a7S1qyXPas encore d'évaluation

- Stirling Engine ProjectDocument16 pagesStirling Engine ProjectAya DiabPas encore d'évaluation

- The Making of The Källe-GasifierDocument15 pagesThe Making of The Källe-GasifierMarky Maypo100% (1)

- Woodfirefreemium PDFDocument13 pagesWoodfirefreemium PDFlembusuro1Pas encore d'évaluation

- Cutting and Drilling Compound TableDocument4 pagesCutting and Drilling Compound TablemountaineerjpPas encore d'évaluation

- Build A Simple Marx GeneratorDocument19 pagesBuild A Simple Marx GeneratorMS schPas encore d'évaluation

- FluxDocument9 pagesFluxking59Pas encore d'évaluation

- 2Document2 pages2Aman SodhiPas encore d'évaluation

- Saltpeter - Instructions For The Manufacture of Saltpetre by Joseph Leconte 1862Document13 pagesSaltpeter - Instructions For The Manufacture of Saltpetre by Joseph Leconte 1862Fernando de AssisPas encore d'évaluation

- Making Plastic From Potato StarchDocument4 pagesMaking Plastic From Potato StarchManinderjeet SinghPas encore d'évaluation

- How To Successfully Bend Tubing, by TONY BINGELISDocument4 pagesHow To Successfully Bend Tubing, by TONY BINGELISlhoffman3Pas encore d'évaluation

- How To Make A Broom: BroomcornDocument4 pagesHow To Make A Broom: BroomcornSTEM JordanPas encore d'évaluation

- Vortex Tube Analysis CFD InsightsDocument15 pagesVortex Tube Analysis CFD InsightsPravinSharmaPas encore d'évaluation

- Building High Performance EnginesDocument17 pagesBuilding High Performance Engineslone_anarchistPas encore d'évaluation

- Koltec Vapouriser RevisionDocument9 pagesKoltec Vapouriser RevisionZoli BorbelyPas encore d'évaluation

- Lost Crafts: "Preserving The Crafts and Trades of Yesterday..... "Document4 pagesLost Crafts: "Preserving The Crafts and Trades of Yesterday..... "glvl88100% (1)

- High power rocket motor basics simplifiedDocument5 pagesHigh power rocket motor basics simplifiedpamos1111Pas encore d'évaluation

- Water Wheel TurbineDocument138 pagesWater Wheel TurbineFaridhul IkhsanPas encore d'évaluation

- Glazed and Confused: Exposing The Mysteries of Glazed Architectural Terra CottaDocument208 pagesGlazed and Confused: Exposing The Mysteries of Glazed Architectural Terra Cottacarly143100% (2)

- Chess Salt and Pepper MillsDocument23 pagesChess Salt and Pepper MillsMaxmore KarumamupiyoPas encore d'évaluation

- Cones and Buller RingsDocument6 pagesCones and Buller RingsTravis WoodPas encore d'évaluation

- Metal Clay For Jewelry Makers BLADDocument2 pagesMetal Clay For Jewelry Makers BLADInterweave0% (4)

- MCJM F12 BLAD WebDocument2 pagesMCJM F12 BLAD WebInterweavePas encore d'évaluation

- Engineering Drawing M.B Shah B.C. RanaDocument485 pagesEngineering Drawing M.B Shah B.C. RanaHardiansyah Hamzah DawiPas encore d'évaluation

- Gyroscope: Presented By: Akshay Agrawal Bits Edu CampusDocument52 pagesGyroscope: Presented By: Akshay Agrawal Bits Edu CampusNirmal KushwahaPas encore d'évaluation

- Gujarat Technological University: Semester - I/II Subject Name: Basic Mechanical EngineeringDocument3 pagesGujarat Technological University: Semester - I/II Subject Name: Basic Mechanical EngineeringNirmal KushwahaPas encore d'évaluation

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Nirmal KushwahaPas encore d'évaluation

- 01 - 1animated Engine 1217511160861915 9Document27 pages01 - 1animated Engine 1217511160861915 9Nirmal KushwahaPas encore d'évaluation

- Vibration Analysis of A Simply Supported Beam With Multiple Breathing Cracks - 2014 - Procedia Engineering PDFDocument8 pagesVibration Analysis of A Simply Supported Beam With Multiple Breathing Cracks - 2014 - Procedia Engineering PDFalkhiatPas encore d'évaluation

- Vibration Analysis of Simple Rotor With Transverse CrackDocument8 pagesVibration Analysis of Simple Rotor With Transverse CrackNirmal KushwahaPas encore d'évaluation

- Nonlinear Dynamics Model of Transversal Cracked Rotor System and Its Matlab ImplementationDocument5 pagesNonlinear Dynamics Model of Transversal Cracked Rotor System and Its Matlab ImplementationNirmal KushwahaPas encore d'évaluation

- Ijet 25318 PDFDocument3 pagesIjet 25318 PDFNirmal KushwahaPas encore d'évaluation

- RRB Cen 03-2018Document63 pagesRRB Cen 03-2018NDTVPas encore d'évaluation

- Ijet 25318 PDFDocument3 pagesIjet 25318 PDFNirmal KushwahaPas encore d'évaluation

- Certificate of Training: Nirmal Kumar KushwahaDocument1 pageCertificate of Training: Nirmal Kumar KushwahaNirmal KushwahaPas encore d'évaluation

- JSM - Volume 11 - Issue 1 - Pages 181-200 PDFDocument20 pagesJSM - Volume 11 - Issue 1 - Pages 181-200 PDFNirmal KushwahaPas encore d'évaluation

- View PDFDocument267 pagesView PDFNirmal KushwahaPas encore d'évaluation

- Vibration of cracked shafts in bending analyzedDocument11 pagesVibration of cracked shafts in bending analyzedNirmal KushwahaPas encore d'évaluation

- (1990) On The Dynamis of Cracked Rotors, A Literature SurveyDocument5 pages(1990) On The Dynamis of Cracked Rotors, A Literature SurveyJoel Morales PerezPas encore d'évaluation

- Haruh I Ko AsadaDocument9 pagesHaruh I Ko AsadaNirmal KushwahaPas encore d'évaluation

- A New Method To Approximate The Field of Movements of 1-DOF Linkages With Lower-PairsDocument12 pagesA New Method To Approximate The Field of Movements of 1-DOF Linkages With Lower-PairsNirmal KushwahaPas encore d'évaluation

- Kinematics, Statics, and Dynamics of 2-d ManipulatorsDocument36 pagesKinematics, Statics, and Dynamics of 2-d ManipulatorsNirmal KushwahaPas encore d'évaluation

- Force/torque relationship for flexible link manipulatorsDocument5 pagesForce/torque relationship for flexible link manipulatorsNirmal KushwahaPas encore d'évaluation

- Tom SolutionDocument14 pagesTom SolutionNirmal KushwahaPas encore d'évaluation

- A New Method To Approximate The Field of Movements of 1-DOF Linkages With Lower-PairsDocument12 pagesA New Method To Approximate The Field of Movements of 1-DOF Linkages With Lower-PairsNirmal KushwahaPas encore d'évaluation

- 4emily Tai, Master of Science, 2007Document129 pages4emily Tai, Master of Science, 2007Nirmal KushwahaPas encore d'évaluation

- 3s.ramasamy and M.R.arshadDocument6 pages3s.ramasamy and M.R.arshadNirmal KushwahaPas encore d'évaluation

- 3s.ramasamy and M.R.arshadDocument6 pages3s.ramasamy and M.R.arshadNirmal KushwahaPas encore d'évaluation

- School of Electrical and Electronic Engineering Nanyang Technological University, Singapore 639798 Ehyguan@ntu - Edu.sgDocument4 pagesSchool of Electrical and Electronic Engineering Nanyang Technological University, Singapore 639798 Ehyguan@ntu - Edu.sgNirmal KushwahaPas encore d'évaluation

- 1naoki Fukaya and Shigeki ToyamaDocument6 pages1naoki Fukaya and Shigeki ToyamaNirmal KushwahaPas encore d'évaluation

- 35 Design of Shoe BrakesDocument10 pages35 Design of Shoe BrakesPRASAD326100% (1)

- 1naoki Fukaya and Shigeki ToyamaDocument6 pages1naoki Fukaya and Shigeki ToyamaNirmal KushwahaPas encore d'évaluation

- Project Report Power Hacksaw by Beam IngineDocument6 pagesProject Report Power Hacksaw by Beam IngineAtiq shahPas encore d'évaluation

- Iso 15348-2002Document26 pagesIso 15348-2002Alexyz33Pas encore d'évaluation

- Ams 2400Document11 pagesAms 2400SURYAS63Pas encore d'évaluation

- College Accounting Chapters 1-30-15th Edition Price Test BankDocument35 pagesCollege Accounting Chapters 1-30-15th Edition Price Test Bankdeemsterazotineaj9ta100% (22)

- Types of NC SystemsDocument2 pagesTypes of NC SystemsKrishna MohanPas encore d'évaluation

- Inspection Trends Magazine - May 2023Document28 pagesInspection Trends Magazine - May 2023dantegimenezPas encore d'évaluation

- Catalogo Mercosul Espanhol CompactadoDocument32 pagesCatalogo Mercosul Espanhol CompactadorafaelpuaPas encore d'évaluation

- JDS WHT 25801Document1 pageJDS WHT 25801archit singhPas encore d'évaluation

- Formwork Materials Estimation GuideDocument48 pagesFormwork Materials Estimation GuidedencioPas encore d'évaluation

- Finance 1, Philippine MoneyDocument46 pagesFinance 1, Philippine MoneyAbegail Uyaco-Salvador92% (12)

- SPCR - CabawanDocument12 pagesSPCR - CabawanReycia Vic QuintanaPas encore d'évaluation

- Industrial Fasteners, Nuts & BoltsDocument79 pagesIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyPas encore d'évaluation

- Topic 9.3Document10 pagesTopic 9.3Yahya ShukurovPas encore d'évaluation

- Hardness Test ResultsDocument7 pagesHardness Test ResultsAmyHuiPas encore d'évaluation

- Vetta: Vertical Form Fill and Seal MachineDocument14 pagesVetta: Vertical Form Fill and Seal MachineAhmad عfiaPas encore d'évaluation

- Chemical ProcessDocument60 pagesChemical ProcessThung LingPas encore d'évaluation

- MaxxShot & MaxxShot Plus Extend Die LifeDocument4 pagesMaxxShot & MaxxShot Plus Extend Die LifeDhinesh DftPas encore d'évaluation

- CNC Machining DrawingDocument41 pagesCNC Machining DrawingGokulPas encore d'évaluation

- Scientific Background:: Warren TrussDocument2 pagesScientific Background:: Warren TrussMohamed Nour eldenPas encore d'évaluation

- This Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionDocument13 pagesThis Product Masterspec Section Modifies The Original Masterspec Text and Does Not Include The Full Content of The Original Masterspec SectionEltonPas encore d'évaluation

- TUERCA UNION - UNY - UNF - and - UNL - UnionsDocument3 pagesTUERCA UNION - UNY - UNF - and - UNL - UnionsJesús Cortés SosaPas encore d'évaluation

- Bahir Dar University: Submitted To: Submission DateDocument24 pagesBahir Dar University: Submitted To: Submission DateTeshale TumlchaPas encore d'évaluation

- Self Drilling Screws PDFDocument12 pagesSelf Drilling Screws PDFJanice FernandezPas encore d'évaluation

- Architectural RAILING SYSTEMS Catalogue 2018 Edition 2 Vol 3Document32 pagesArchitectural RAILING SYSTEMS Catalogue 2018 Edition 2 Vol 3Ñýì Ñýì ÑâìñgPas encore d'évaluation

- Esxp 4 MainDocument9 pagesEsxp 4 Mainutsho dasPas encore d'évaluation

- Trinidad, Brittny Lourde Bspe-4C Types of CorrosionDocument3 pagesTrinidad, Brittny Lourde Bspe-4C Types of CorrosionBrittny LourdePas encore d'évaluation

- Zinc/ammonium Formate: A New Facile System For The Rapid and Selective Reduction of Oximes To AminesDocument3 pagesZinc/ammonium Formate: A New Facile System For The Rapid and Selective Reduction of Oximes To AminesUltrachemis ChemisPas encore d'évaluation

- Zinc-Coated Steel Strand For Messenger Support of Figure 8 CableDocument3 pagesZinc-Coated Steel Strand For Messenger Support of Figure 8 CableSha ZhaPas encore d'évaluation

- Sandwich Corrosion Test: Standard Test Method ForDocument4 pagesSandwich Corrosion Test: Standard Test Method ForMahdi abanPas encore d'évaluation

- Piping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Document3 pagesPiping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Lucian GrigorasPas encore d'évaluation