Académique Documents

Professionnel Documents

Culture Documents

Pghu Eh Lspds 002004 Rev 0

Transféré par

BhoyPachoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pghu Eh Lspds 002004 Rev 0

Transféré par

BhoyPachoDroits d'auteur :

Formats disponibles

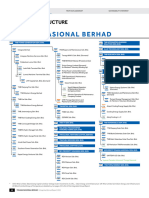

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

SCOPE

1) This Project Design Specification (PDS) contains the Line Class 300 tables that accompany PGPDS 03-01-01. Additional valve information is contained in PG-PDS 03-20-10.

2) This Project Design Specification (PDS) covers the basic requirements for the design of piping

systems for onshore production and processing facilities covered by ASME B31.3.

Esso Highlands Limited

Page 2 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

TABLE OF CONTENTS

1.

REQUIRED REFERENCES.................................................................................... 4

1.1.

1.2.

1.3.

1.4.

1.5.

1.6.

2.

Project Design Specifications ....................................................................... 4

API American Petroleum Institute.............................................................. 4

ASME American Society of Mechanical Engineers ................................... 4

ASTM American Society for Testing and Materials ................................... 5

MSS Manufacturers Standardization Society ............................................ 6

Calculations .................................................................................................. 6

CLASSIFICATION SHEETS................................................................................... 7

2.1.

2.2

2.2

2.3

Class 300: Carbon Steel (Sweet Service) B1E............................................. 7

Class 300: LT Carbon Steel (Sweet Service) B5E ..................................... 18

Class 300: Stainless SteelProcess Piping B11A ...................................... 29

Class 300: Stainless SteelProcess Piping B11A(X).................................. 37

APPENDIX: NOTES TO PIPING LINE CLASS 300 ..................................................... 41

ATTACHMENT: PURPOSE CODE DEFINITIONS...................................................... 42

RECORD OF CHANGE ................................................................................................ 43

Esso Highlands Limited

Page 3 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

1.

Upstream Piping Classification Line Class 300

Mar 2011

REQUIRED REFERENCES

1) This Section lists the Practices, codes, standards, specifications, and publications that shall be

used with this document. Unless otherwise specified herein, use the latest edition.

2) The text of the numbered "Notes" referenced in the classification sheets is found in the Appendix

of PG-PDS 03-01-01. A dagger () is used to identify such notes in this PDS.

1.1.

1.2.

1.3.

Project Design Specifications

PGHU-EH-LSPDS-000101

PG-PDS 03-01-01 Upstream Piping Component Selection and

System Design

PGHU-EH-LSPDS-002010

PG-PDS 03-20-10 Upstream Piping Classifications Valve Indices

and Descriptions

PGHU-EH-LSPDS-001902

PG-PDS 03-19-02 Upstream Piping Fabrication, Erection,

Inspection, Testing, and Cleaning

API American Petroleum Institute

API SPEC 5L

Specification for Line Pipe

API SPEC 6D

Petroleum and Natural Gas Industries Pipeline Transportation

Systems Pipeline Valves

API STD 594

Check Valves: Wafer, Wafer-Lug, and Double-flanged Type

API STD 600

Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas

Industries

API STD 602

Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural Gas Industries

API STD 609

Butterfly Valves: Double-Flanged, Lug-, and Wafer-Type

ASME American Society of Mechanical Engineers

ASME B16.5

Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch

Standard

ASME B16.9

Factory-Made Wrought Buttwelding Fittings

ASME B16.11

Forged Fittings, Socket-Welding and Threaded

ASME B16.20

Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound, and

Jacketed

ASME B16.34

Valves Flanged, Threaded, and Welding End

ASME B16.36

Orifice Flanges

ASME B16.47

Large-Diameter Steel Flanges NPS 26 Through NPS 60 Metric/Inch

Standard

ASME B16.48

Line Blanks

ASME B18.2.1

Square and Hex Bolts and Screws (Inch Series)

ASME B18.2.2

Square and Hex Nuts (Inch Series)

ASME B31.3

Process Piping

Esso Highlands Limited

Page 4 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

1.4.

Upstream Piping Classification Line Class 300

ASME B36.10M

Welded and Seamless Wrought Steel Pipe

ASME B36.19M

Stainless Steel Pipe

Mar 2011

ASTM American Society for Testing and Materials

ASTM A 105/A 105M

Standard Specification for Carbon Steel Forgings for Piping Applications

ASTM A 106/A 106M

Standard Specification for Seamless Carbon Steel Pipe for HighTemperature Service

ASTM A 182/A 182M

Standard Specification for Forged or Rolled Alloy and Stainless Steel

Pipe Flanges, Forged Fittings, and Valves and Parts for HighTemperature Service

ASTM A 193/A 193M

Standard Specification for Alloy-Steel and Stainless Steel Bolting

Materials for High Temperature or High Pressure Service and Other

Special Purpose Applications

ASTM A 194/A 194M

Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High

Pressure or High Temperature Service, or Both

ASTM A 216/A 216M

Standard Specification for Steel Castings, Carbon, Suitable for Fusion

Welding, for High-Temperature Service

ASTM A 234/A 234M

Standard Specification for Piping Fittings of Wrought Carbon Steel and

Alloy Steel for Moderate and High Temperature Service

ASTM A 240/A 240M

Standard Specification for Chromium and Chromium-Nickel Stainless

Steel Plate, Sheet, and Strip for Pressure Vessels and for General

Applications

ASTM A 312/A 312M

Standard Specification for Seamless, Welded, and Heavily Cold Worked

Austenitic Stainless Steel Pipes

ASTM A 320/A 320M

Standard Specification for Alloy-Steel and Stainless Steel Bolting

Materials for Low-Temperature Service

ASTM A 333/A 333M

Standard Specification for Seamless and Welded Steel Pipe for LowTemperature Service

ASTM A 350/A 350M

Standard Specification for Carbon and Low-Alloy Steel Forgings,

Requiring Notch Toughness Testing for Piping Components

ASTM A 351/A 351M

Standard Specification for Castings, Austenitic, for Pressure-Containing

Parts

ASTM A 352/A 352M

Standard Specification for Steel Castings, Ferritic and Martensitic, for

Pressure-Containing Parts, Suitable for Low-Temperature Service

ASTM A 358/A 358M

Standard Specification for Electric-Fusion-Welded Austenitic ChromiumNickel Stainless Steel Pipe for High-Temperature Service and General

Applications

ASTM A 403/A 403M

Standard Specification for Wrought Austenitic Stainless Steel Piping

Fittings

ASTM A 420/A 420M

Standard Specification for Piping Fittings of Wrought Carbon Steel and

Alloy Steel for Low-Temperature Service

ASTM A 516/A 516M

Standard Specification for Pressure Vessel Plates, Carbon Steel, for

Moderate- and Lower-Temperature Service

ASTM A 671

Standard Specification for Electric-Fusion-Welded Steel Pipe for

Atmospheric and Lower Temperatures

Esso Highlands Limited

Page 5 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

1.5.

Mar 2011

MSS Manufacturers Standardization Society

MSS SP-97

1.6.

Upstream Piping Classification Line Class 300

Integrally Reinforced Forged Branch Outlet Fittings Socket Welding,

Threaded, and Buttwelding Ends

Calculations

PGHU-CV-LCCAL000001

Pipe Wall Thickness Calculations

PGHU-CV-LCCAL000002

Blank Thickness Calculations

Esso Highlands Limited

Page 6 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

2.

Upstream Piping Classification Line Class 300

Mar 2011

CLASSIFICATION SHEETS

The text of the numbered "Notes" referenced in the classification sheets is found in the Appendix of

PG-PDS 03-01-01. A dagger () is used to identify such notes in this PDS.

2.1.

Class 300: Carbon Steel (Sweet Service) B1E

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Service

General process, hydrocarbons, glycol, chemicals, produced

water, closed drains, steam

Pipe Material

Carbon steel

Corrosion Allowance

3.00mm

Valve Material

Carbon steel

Valve Trim

13 Cr, except ball valves have 316 SS balls

ASME Pressure Class

300

Design Code

ASME B31.3

PWHT

Not required, except for wall thickness greater than 19 mm (

in.)

Pressure/Temperature Limits

Limits based upon flange ratings, unless noted otherwise

(See Note 6 )

Limits based upon A105 flange

ratings, unless noted otherwise.

(C)

(kPa-g)

(F)

(psig)

29 to +38

5102

20 to +100

740

93

4688

200

680

149

4516

300

655

177

4445

350

645

204

4378

400

635

310

3950

590

573

(*) Reference to PG-PDS 03-01-01,

Appendix E, Note 6, Clause g),

Temperature Range Restrictions for

Elastomers in this Line Class are

indicated below the valve ID No.

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ASTM

Specifications

Ball Valves

NPS 1, Class 800, SW, reduced bore, ASTM A 105/A

API SPEC

316 SS ball/trim, PTFE seats, fire-safe

105M

6D or ASME design

B16.34

NPS 1, Class 800, SW x SE, ditto

Ball Valves

API SPEC

6D

YBAA5

BBAA0(02)

(177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

BBAA0(02)

(177C)*

ASTM A 216/A

216M WCB

Strictly Confidential For Venture Use Only

Notes

2, 3,

6, 7,

9, 11,

21,

28, 30

YBAA7

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 216/A

floating ball, liquid and mixed phase service, 216M WCB

316 SS ball and trim, main seats - RPTFE

seats, other seals Viton, fire-safe design

Esso Highlands Limited

Page 7 of 43

ASTM A 105/A

105M

ID No.

2, 3,

6, 7,

8, 9,

11,

20,

21, 28

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Notes

and mixed phase service, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, fire-safe design

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, DPE x DPE with cavity

bleed valve FBAA9, 316 SS ball and trim,

main seats RPTFE, other seals Viton,

gas service only, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(01)

(177C)*

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 216/A

floating ball, liquid and mixed phase service, 216M WCB

316 SS ball and trim, main seats - RPTFE

seats, other seals HNBR, fire-safe design

BBAA0(12)

(150C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats RPTFE, other seals

HNBR, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(12)

(150C)*

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 216/A

floating ball, liquid and mixed phase service, 216M WCB

316 SS ball and trim , main seats RPTFE,

other seals Viton, with weld overlay, firesafe design

BBAA0(32)

(177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, with weld overlay, fire-safe design

BBAA0(32)

(177C)*

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 216/A

floating ball, liquid and mixed phase service, 216M WCB

316 SS ball and trim, main seats metal

seats, other seals Viton, fire-safe design

BBAA0(02)-(M)

(177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE, 316 SS ball

and trim, main seats metal seats, other

seals Viton, liquid and mixed phase

service, fire-safe design

BBAA0(02)-(M)

(177C)*

Esso Highlands Limited

Page 8 of 43

ASTM A 216/A

216M WCB

ASTM A 216/A

216M WCB

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ID No.

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 216/A

ball, liquid and mixed phase service, 316 SS 216M WCB

ball and trim, main seats RPTFE, other

seals Viton, fire-safe design

BBFA0(02)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion ASTM A 216/A

mounted, SR x DPE seat, liquid and mixed

216M WCB

phase service, 316 SS ball and trim, main

seats RPTFE, other seals Viton, fire-safe

design

BBFA0(02)

(177C)*

NPS 2-24, Class 300, RF, full bore, trunnion

mounted, DPE x DPE seat with cavity bleed

valve FBAA9, 316 SS ball and trim, main

seats RPTFE, other seals Viton, gas

service only, fire-safe design

ASTM A 216/A

216M WCB

BBFA0(01)

(177C)*

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 216/A

ball, liquid and mixed phase service, 316 SS 216M WCB

ball and trim, main seats RPTFE, other

seals Viton, with weld overlay, fire-safe

design

BBFA0(32)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion

mounted, SR x DPE seat, liquid and mixed

phase service, 316 SS ball and trim, main

seats RPTFE, other seals Viton, with

weld overlay, fire-safe design

BBFA0(32)

(177C)*

ASTM A 216/A

216M WCB

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 216/A

ball, liquid and mixed phase service, 316 SS 216M WCB

ball and trim, main seats metal seats,

other seals Viton, with weld overlay, firesafe design

BBFA0(32)-(M)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion ASTM A 216/A

mounted, SR x DPE seat, liquid and mixed

216M WCB

phase service, 316 SS ball and trim, main

seats metal seats, other seals Viton, with

weld overlay, fire-safe design

BBFA0(32)-(M)

(177C)*

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 216/A

ball, liquid and mixed phase service, 316 SS 216M WCB

ball and trim, main seats metal seats,

other seals Viton, fire-safe design

BBFA0(02)-(M)

(177C)*

Esso Highlands Limited

Page 9 of 43

ASTM

Specifications

Strictly Confidential For Venture Use Only

Notes

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ID No.

NPS 8-24, Class 300, RF, full bore, trunnion ASTM A 216/A

mounted, SR x DPE, 316 SS ball and trim,

216M WCB

main seats metal seats, other seals

Viton, liquid and mixed phase service, firesafe design

BBFA0(02)-(M)

(177C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, DPE x DPE seat with

cavity bleed valve FBAA9, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, gas service only, with weld overlay,

fire-safe design

ASTM A 216/A

216M WCB

BBAA0(31)

(177C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

fire-safe design

ASTM A 216/A

216M WCB

BBAA0(21)

(204C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

with weld overlay, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(21)(31)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seals, liquid and mixed phase service, firesafe design

ASTM A 216/A

216M WCB

BBAA0(22)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats - RPTFE, other

seals Lip seals, liquid and mixed phase

service, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(22)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seals, liquid and mixed phase service, with

weld overlay, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(22)(32)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats - RPTFE, other

seals Lip seals, liquid and mixed phase

service, with weld overlay, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(22)(32)

(204C)*

Esso Highlands Limited

Page 10 of 43

ASTM

Specifications

Strictly Confidential For Venture Use Only

Notes

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ID No.

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - metal seats, other seals Lip seals,

liquid and mixed phase service, with weld

overlay, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(22)(32)-(M)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 216/A

216M WCB

BBAA0(22)(32)-(M)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - metal seats, other seals Lip seals,

liquid and mixed phase service, fire-safe

design

ASTM A 216/A

216M WCB

BBAA0(22)-(M)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 216/A

216M WCB

BBAA0(22)-(M)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

fire-safe design

ASTM A 216/A

216M WCB

BBFA0(21)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

with weld overlay, fire-safe design

ASTM A 216/A

216M WCB

BBFA0(21)(31)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

ASTM A 216/A

trunnion mounted, DPE x DPE seat with

216M WCB

cavity bleed valve FBAA9, gas service only,

316 SS ball and trim, main seats - RPTFE

seats, other seals Viton, with weld overlay,

fire-safe design

BBFA0(31)

(177C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats -

BBFA0(22)

(204C)*

Esso Highlands Limited

Page 11 of 43

ASTM

Specifications

ASTM A 216/A

216M WCB

Strictly Confidential For Venture Use Only

Notes

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Notes

RPTFE seats, other seals Lip seals, liquid

and mixed phase service, fire-safe design

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats RPTFE seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 216/A

216M WCB

BBFA0(22)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats RPTFE seats, other seals Lip seals, liquid

and mixed phase service, with weld overlay,

fire-safe design

ASTM A 216/A

216M WCB

BBFA0(22)(32)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats RPTFE seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 216/A

216M WCB

BBFA0(22)(32)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats Metal seats, other seals Lip seals, liquid

and mixed phase service, with weld overlay,

fire-safe design

ASTM A 216/A

216M WCB

BBFA0(22)(32)-(M)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats Metal seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 216/A

216M WCB

BBFA0(22)(32)-(M)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats Metal seats, other seals Lip seals, liquid

and mixed phase service, fire-safe design

ASTM A 216/A

216M WCB

BBFA0(22)-(M)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats Metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 216/A

216M WCB

BBFA0(22)-(M)

(204C)*

Esso Highlands Limited

Page 12 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ASTM

Specifications

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 216/A

floating ball, liquid and mixed phase service, 216M WCB

316 SS ball and trim, main seats - Metal

seats, other seals Viton, with weld overlay,

fire-safe design

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats - Metal seats, other seals

Viton, with weld overlay, fire-safe design

Ball Valves

NPS 6 36, Class 300, RF, reduced bore,

(optional for ASTM A 105/A 105M ENP-plated ball/seat

clean

pockets and body-stem seal area, nylon

service only) seats, other seals-Viton fire-safe design

API SPEC

6D

NPS 636, Class 300, RF, full bore, ditto

Check

Valves

API STD

602

Check

Valves

API STD

594

Check

Valves

API SPEC

6D

BBAA0(32)-(M)

(177C)*

ASTM A 105/A

105M or

ASTM A 216/A

216M WCB

BBAA0(P)

(177C)*

ASTM A 105/A

105M or

ASTM A 216/A

216M WCB

NPS 1, Class 800, SW, BC, API trim 8 ASTM A 105/A

(13 Cr), swing-type, integral HF seat

105M

BBFA0(P)

(177C)*

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 105/A

105M

BCAA0

NPS 1, Class 800, SW, BC, API trim

8 (13 Cr), piston-type, integral HF seat

ASTM A 105/A

105M

YCNA5

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 105/A

105M

BCNA0

NPS 3 10, Class 300, RF, retainerless

dual plates, through-drilled solid lugs,

integral metal seat, Inconel springs, CS

plates and 316 SS pins

ASTM A 216/A

216M WCB

BCYA0

NPS 12 24, Class 300, RF, retainerless

ASTM A 216/A

dual plates, double-flanged, integral metal

216M WCB

seat, Inconel springs, CS plates and 316 SS

pins

BCYA0

NPS 2 24, Class 300, RF, BC, swing-type

(piggable), 13 Cr Trim, HF seat

BCFA0

ASTM A 216/A

216M WCB

Strictly Confidential For Venture Use Only

Notes

BBAA0(32)-(M)

(177C)*

ASTM A 216/A

216M WCB

Esso Highlands Limited

Page 13 of 43

ID No.

YCAA5

2, 3,

6, 7,

8, 11,

17,

20,

21, 28

25, 27

23,

24, 25

8, 25,

26

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Check

Valves

API STD

600

Globe

Valves

API STD

602

Description

ASTM

Specifications

ID No.

Notes

NPS 2, Class 300, RF, BC, swing-type (non- ASTM A 216/A

piggable), Trim 8, integral HF seat

216M WCB

BCAA0

25,

26, 29

NPS 1, Class 800, SW, BB, OS&Y,

ASTM A 105/A

T-Body, API trim 8 (13 Cr), graphitic packing 105M

YTAA5

28

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 105/A

105M

NPS 2 12, Class 300, RF, BB, OS&Y, TASTM A 216/A

Body, API trim 8 (13 Cr), graphitic packing

216M WCB

BTAA0

BTAA0

3, 28,

29

NPS 10, Class 300, RF, through-drilled lugs, ASTM A 216/A

CS disc, 316 SS seal ring, CS body,

216M WCB

graphitic packing

BFAA0

2, 3,

7, 8,

11, 28

NPS 12-24, Class 300, RF, double-flanged,

CS disc, 316 SS seal ring, CS body,

graphitic packing

ASTM A 216/A

216M WCB

BFAA0

NPS 1, Class 800, SW, BB, OS&Y,

API trim 8 (13 Cr), standard port, graphitic

packing

ASTM A 105/A

105M

YGAA5

NPS -1, Class 800, SW x SE, BB, OS&Y, ASTM A 105/A

API trim 8 (13 Cr), standard port, graphitic

105M

packing

YGAA7

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 105/A

105M

NPS 2 4, Class 300, RF, BB, OS&Y, solid ASTM A 216/A

wedge, integral flange, API trim 8 (13 Cr),

216M WCB

standard port, graphitic packing

BGAA0

NPS 6-24, Class 300, RF, BB, OS&Y,

flexible wedge with cavity relief, integral

flange, API trim 8 (13 Cr), standard port,

graphitic packing

ASTM A 216/A

216M WCB

BGAA0

Gate Valves

API SPEC

6D

NPS 2 24, Class 300, RF, BB, OS&Y,

ASTM A 216/A

Through-conduit slab gate, floating HF seats 216M WCB

BGFA0

Instrument

Connection

Valves

NPS 2, applies to the first-block valve

(or double-block valve where required). See

Note 4 for additional requirements and

information.

Globe

Valves

API STD

600

Butterfly

Valves

API STD

609

Gate Valves

API STD

602

Gate Valves

API STD

600

Esso Highlands Limited

Page 14 of 43

Strictly Confidential For Venture Use Only

BGAA0

22, 28

3, 22,

28, 29

3, 8,

22,

28, 29

4

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Instrument

Double

Isolation

Valves

(Monoblok)

Manufacturers

standard

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a bleed,

standard bore, DN 20 body, CS body, firesafe design

ASTM A 105/A

105M

BSAA10

NPS 2, Class 300, 2 RF x FNPT, single

body with two obturators and a bleed,

standard bore, DN 20 body, CS body, firesafe design

ASTM A 105/A

105M

BSAA10(04)

NPS 2, Class 300, RF, single body with two

obturators and a bleed, standard bore, DN

50 body, CS body, Metal Seats, fire-safe

design

ASTM A 105/A

105M

BSAA0(M)

NPS 2, Class 300, 2 RF x FNPT, single

body with two obturators and a bleed,

standard bore, DN 20 body, CS body, metal

seats, fire-safe design

ASTM A 105/A

105M

BSAA10(04)(M)

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a bleed,

standard bore, DN 20 body, CS body, metal

seats, fire-safe design

ASTM A 105/A

105M

BSAA10(M)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a bleed,

standard bore, DN 20 body, CS body, firesafe design

ASTM A 105/A

105M

BSAA10(06)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a bleed,

standard bore, DN 20 body, CS body, metal

seats, fire-safe design

ASTM A 105/A

105M

BSAA10(06)(M)

Notes

2, 3,

4, 30

See the Appendix of PG-PDS 03-01-01 for text of numbered Notes.

Esso Highlands Limited

Page 15 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Component/

Standard

Description

ASTM Specifications

Notes

Bolting

Stud bolts

ASME B18.2.1 and

ASME B18.2.2

Heavy, semi-finished, hex nuts

Flanges

NPS 1, Class 300, RF, SW

ASME B16.5

NPS 2 24, Class 300, RF, WN, bore to

match pipe

ASTM A 193/A 193M B7,

80

ASTM A 194/A 194M 2H

ASTM A 105/A 105M

86

Orifice Flanges

ASME B16.36

NPS 224, Class 300, RF, WN, bore to

match pipe

ASTM A 105/A 105M

86

Gaskets

ASME B16.20

Class 300, spiral wound, CS centering

ring, 304 SS windings, flexible graphite

filler, inner ring for all sizes

Fittings

ASME B16.11

NPS 1, SW, Sch. 160 and lighter

Class 3000, Sch. XXS and heavierClass

6000

ASTM A 105/A 105M

53, 54,

62, 86

Fittings

ASME B16.9

NPS 2 16, SMLS, BW, same thickness as ASTM A 234/A 234M

pipe

WPB

55, 56

Branch Outlet:

MSS SP-97

60

NPS 18-24, BW, WELDED

ASTM A420/A420M WPL6

NPS 1, sockolet, SW outlet, Class

3000 for Sch. 160 and lighter, Class 6000

for Sch. XXS

ASTM A 105/A 105M

53, 62,

86

ASTM A 106/A 106M B

51, 52,

53, 54,

63

NPS 2 6, weldolet, BW outlet to match

branch wall

Pipe

ASME B36.10M

NPS 16, seamless, thickness (see

below)

NPS 18 24, EFW, Class 22, Normalized, ASTM A671 CC65-S2

(Impact tested for -29C (-20F) service,

for pipe Thk > 31.8mm)

Spectacle Blind /

Paddle Blank /

Spacers

ASME B16.48

NPS 1-24, RF, Class 300 Impact test for 29C service for Thk > 31.8mm

ASTM A516 Gr. 65,

Normalized (Refer Table 4

PG-PDS 03-01-01 for the

type)

See the Appendix of PG-PDS 03-01-01 for text of numbered Notes.

Esso Highlands Limited

Page 16 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Carbon Steel (Sweet Service) B1E Classification Sheet

Corrosion Allowance (C.A.)

(see Appendix Note 87)

E

C.A. = 3.0 mm (0.12 in.)

NPS

Sch.

XXS

160

36

80

8 24

40

Class 300Carbon Steel (Sweet Service) B1E Classification Sheet

Branch Table

B

24 BWT

20

BRT BWT

18

BRT BRT BWT

16

RB BRT BRT BWT

14

RB

RB BRT BRT BWT

12

RB

RB

RB BRT BRT BWT

10

RB

RB

RB

RB BRT BRT BWT

RB

RB

RB

RB

WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

RB BRT BRT BWT

1 SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL BRT SWT

N

P

S

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SWT

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SRT SWT

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SRT SRT SWT

24

20

18

16

14

12

10

HEADER SIZESNPS

Legend:

SOL = Socket Weld O-let Fitting

SRT

SWT = Socket Weld Tee

WOL = Buttweld O-let Fitting

BRT = Buttweld Reducing Tee

BWT = Buttweld Tee

Esso Highlands Limited

Page 17 of 43

= Socket Weld Reducing Tee

Strictly Confidential For Venture Use Only

RB = Reinforced Branch

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

2.2

Upstream Piping Classification Line Class 300

Mar 2011

Class 300: LT Carbon Steel (Sweet Service) B5E

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Service

General process, hydrocarbons, glycol

Pipe Material

Impact-tested carbon steel (for low temperature service)

Corrosion Allowance

3.00mm

Valve Material

Carbon steel

Valve Trim

13 Cr, except ball valves have 316 SS balls (See note above)

ASME Pressure Class

300

Design Code

ASME B31.3

PWHT

Yes, except for conditions specified elsewhere in project

specifications

Pressure/Temperature Limits

Limits based upon flange ratings, unless noted otherwise

(See Note 6 )

Limits based upon A352 LCB flange

ratings, unless noted otherwise.

(C)

(kPa-g)

(F)

(psig)

46 to +38

4791

50 to +100

695

93

4550

200

660

149

4412

300

640

177

4324

350

627

204

4240

400

615

310

3812

590

553

(*) Reference to PG-PDS 03-01-01,

Appendix E, Note 6, Clause g),

Temperature Range Restrictions for

Elastomers in this Line Class are

indicated below the valve ID No.

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

Ball Valves

NPS 1, Class 800, SW, reduced bore,

API SPEC

316 SS ball/trim, PTFE seats, fire-safe

6D or ASME design

B16.34

NPS 1, Class 800, SW x SE, ditto

Ball Valves

API SPEC

6D

ID No.

ASTM A 350/A

350M LF2 Class

1

YBAB5

ASTM A 350/A

350M LF2 Class

1

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 352/A

floating ball, liquid and mixed phase service, 352M LCB

316 SS ball and trim, main seats - RPTFE

seats, other seals Viton, fire-safe design

YBAB7

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(02)

(177C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, DPE x DPE with cavity

ASTM A 352/A

352M LCB

BBAB0(01)

(177C)*

Esso Highlands Limited

Page 18 of 43

ASTM

Specifications

Strictly Confidential For Venture Use Only

BBAB0(02)

(177C)*

Notes

2, 3,

5, 6,

7, 9,

11,

21,

28, 30

2, 3,

5, 6,

7, 8, 9

11,

20,

21, 28

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Notes

bleed valve FBAB9, 316 SS ball and trim,

main seats RPTFE, other seals Viton,

gas service only, fire-safe design

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 352/A

ball, liquid and mixed phase service, 316 SS 352M LCB

ball and trim, main seats - RPTFE seats,

other seals HNBR, fire-safe design

BBFB0(12)

(150C)*

NPS 8-24, Class 300, RF, full bore, trunnion

mounted, SR x DPE seat, liquid and mixed

phase service, 316 SS ball and trim, main

seats RPTFE, other seals HNBR, firesafe design

ASTM A 352/A

352M LCB

BBFB0(12)

(150C)*

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 352/A

floating ball, liquid and mixed phase service, 352M LCB

316 SS ball and trim , main seats RPTFE,

other seals Viton, with weld overlay, firesafe design

BBAB0(32)

(177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, with weld overlay, fire-safe design

BBAB0(32)

(177C)*

NPS 2-8, Class 300, RF, reduced bore,

ASTM A 352/A

floating ball, liquid and mixed phase service, 352M LCB

316 SS ball and trim, main seats metal

seats, other seals Viton, fire-safe design

BBAB0(02)-(M)

(177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE, 316 SS ball

and trim, main seats metal seats, other

seals Viton, liquid and mixed phase

service, fire-safe design

BBAB0(02)-(M)

(177C)*

ASTM A 352/A

352M LCB

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 352/A

ball, liquid and mixed phase service, 316 SS 352M LCB

ball and trim, main seats RPTFE, other

seals Viton, fire-safe design

BBFB0(02)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion

mounted, SR x DPE seat, liquid and mixed

BBFB0(02)

(177C)*

Esso Highlands Limited

Page 19 of 43

ASTM A 352/A

352M LCB

ASTM A 352/A

352M LCB

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Notes

phase service, 316 SS ball and trim, main

seats RPTFE, other seals Viton, fire-safe

design

NPS 2-24, Class 300, RF, full bore, trunnion

mounted, DPE x DPE seat with cavity bleed

valve FBAB9, 316 SS ball and trim, main

seats RPTFE, other seals Viton, gas

service only, fire-safe design

ASTM A 352/A

352M LCB

BBFB0(01)

(177C)*

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 352/A

ball, liquid and mixed phase service, 316 SS 352M LCB

ball and trim, main seats RPTFE, other

seals Viton, with weld overlay, fire-safe

design

BBFB0(32)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion

mounted, SR x DPE seat, liquid and mixed

phase service, 316 SS ball and trim, main

seats RPTFE, other seals Viton, with

weld overlay, fire-safe design

BBFB0(32)

(177C)*

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 352/A

ball, liquid and mixed phase service, 316 SS 352M LCB

ball and trim, main seats metal seats,

other seals Viton, with weld overlay, firesafe design

BBFB0(32)-(M)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion ASTM A 352/A

mounted, SR x DPE seat, liquid and mixed

352M LCB

phase service, 316 SS ball and trim, main

seats metal seats, other seals Viton, with

weld overlay, fire-safe design

BBFB0(32)-(M)

(177C)*

NPS 2-6, Class 300, RF, full bore, floating

ASTM A 352/A

ball, liquid and mixed phase service, 316 SS 352M LCB

ball and trim, main seats metal seats,

other seals Viton, fire-safe design

BBFB0(02)-(M)

(177C)*

NPS 8-24, Class 300, RF, full bore, trunnion ASTM A 352/A

mounted, SR x DPE, 316 SS ball and trim,

352M LCB

main seats metal seats, other seals

Viton, liquid and mixed phase service, firesafe design

BBFB0(02)-(M)

(177C)*

Esso Highlands Limited

Page 20 of 43

ASTM A 352/A

352M LCB

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ID No.

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, DPE x DPE seat with

cavity bleed valve FBAB9, 316 SS ball and

trim, main seats RPTFE, other seals

Viton, gas service only, with weld overlay,

fire-safe design

ASTM A 352/A

352M LCB

BBAB0(31)

(177C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

fire-safe design

ASTM A 352/A

352M LCB

BBAB0(21)

(204C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

with weld overlay, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(21)(31)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seals, liquid and mixed phase service, firesafe design

ASTM A 352/A

352M LCB

BBAB0(22)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats - RPTFE, other

seals Lip seals, liquid and mixed phase

service, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(22)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seals, liquid and mixed phase service, with

weld overlay, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(22)(32)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats - RPTFE, other

seals Lip seals, liquid and mixed phase

service, with weld overlay, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(22)(32)

(204C)*

ASTM A 352/A

352M LCB

BBAB0(22)(32)-(M)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - metal seats, other seals Lip seals,

liquid and mixed phase service, with weld

Esso Highlands Limited

Page 21 of 43

ASTM

Specifications

Strictly Confidential For Venture Use Only

Notes

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

Notes

overlay, fire-safe design

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 352/A

352M LCB

BBAB0(22)(32)-(M)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - metal seats, other seals Lip seals,

liquid and mixed phase service, fire-safe

design

ASTM A 352/A

352M LCB

BBAB0(22)-(M)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 352/A

352M LCB

BBAB0(22)-(M)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

fire-safe design

ASTM A 352/A

352M LCB

BBFB0(21)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip seal,

with weld overlay, fire-safe design

ASTM A 352/A

352M LCB

BBFB0(21)(31)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

ASTM A 352/A

trunnion mounted, DPE x DPE seat with

352M LCB

cavity bleed valve FBAB9, gas service only,

316 SS ball and trim, main seats - RPTFE

seats, other seals Viton, with weld overlay,

fire-safe design

BBFB0(31)

(177C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats RPTFE seats, other seals Lip seals, liquid

and mixed phase service, fire-safe design

BBFB0(22)

(204C)*

Esso Highlands Limited

Page 22 of 43

ASTM A 352/A

352M LCB

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ID No.

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats RPTFE seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 352/A

352M LCB

BBFB0(22)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats RPTFE seats, other seals Lip seals, liquid

and mixed phase service, with weld overlay,

fire-safe design

ASTM A 352/A

352M LCB

BBFB0(22)(32)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats RPTFE seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 352/A

352M LCB

BBFB0(22)(32)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats Metal seats, other seals Lip seals, liquid

and mixed phase service, with weld overlay,

fire-safe design

ASTM A 352/A

352M LCB

BBFB0(22)(32)-(M)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats Metal seats,

other seals Lip seals, liquid and mixed

phase service, with weld overlay, fire-safe

design

ASTM A 352/A

352M LCB

BBFB0(22)(32)-(M)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats Metal seats, other seals Lip seals, liquid

and mixed phase service, fire-safe design

ASTM A 352/A

352M LCB

BBFB0(22)-(M)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats Metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 352/A

352M LCB

BBFB0(22)-(M)

(204C)*

Esso Highlands Limited

Page 23 of 43

ASTM

Specifications

Strictly Confidential For Venture Use Only

Notes

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ASTM

Specifications

Ball Valves

(optional for

clean

service only)

API SPEC

6D

NPS 6 36, Class 300, RF, reduced bore,

ASTM A 350/A 350M LF2 Class 1 ENPplated ball/seat pockets and body-stem seal

area, nylon seats, other seals-Viton fire-safe

design

ASTM A 350/A

350M LF2 Class

1 or

ASTM A 352/A

352M LCB

BBAB0(P)

(177C)*

ASTM A 350/A

350M LF2 Class

1 or

ASTM A 352/A

352M LCB

NPS 1, Class 800, SW, BC, API trim 8 ASTM A 350/A

(13 Cr), swing-type, integral HF seat

350M LF2 Class

1

BBFB0(P)

(177C)*

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 350/A

350M LF2 Class

1

BCAB0

NPS 1, Class 800, SW, BC, API trim

8 (13 Cr), piston-type, integral HF seat

ASTM A 350/A

350M LF2 Class

1

YCNB5

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 350/A

350M LF2 Class

1

BCNB0

NPS 3 10, Class 300, RF, retainerless

dual plates, through-drilled solid lugs,

integral metal seat, Inconel springs, CS

plates and 316 SS pins

ASTM A 352/A

352M LCB

BCYB0

NPS 12 24, Class 300, RF, retainerless

ASTM A 352/A

dual plates, double-flanged, integral metal

352M LCB

seat, Inconel springs, CS plates and 316 SS

pins

BCYB0

Check

Valves API

SPEC 6D

NPS 2 24, Class 300, RF, BC, swing-type

(piggable), 13 Cr Trim, HF seat

ASTM A 352/A

352M LCB

BCFB0

5, 8,

25, 26

Check

Valves API

STD 600

NPS 2, Class 300, RF, BC, swing-type (non- ASTM A 352/A

piggable), Trim 8, integral HF seat

352M LCB

BCAB0

5, 8,

25,

26, 29

NPS 6 36, Class 300, RF, full bore, ditto

Check

Valves API

STD 602

Check

Valves API

STD 594

Esso Highlands Limited

Page 24 of 43

Strictly Confidential For Venture Use Only

ID No.

YCAB5

Notes

2, 3,

5, 6,

7, 8,

11,

17,

20,

21, 28

5, 25,

27

5, 8,

23,

24, 25

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Globe

Valves

API STD

602

Globe

Valves

API STD

600

Butterfly

Valves

API STD

609

Gate Valves

API STD

602

Gate Valves

API STD

600

Description

ID No.

Notes

NPS 1, Class 800, SW, BB, OS&Y,

ASTM A 350/A

T-Body, API trim 8 (13 Cr), graphitic packing 350M LF2 Class

1

YTAB5

NPS 1 2, Class 300, RF, integral flgs, ditto ASTM A 350/A

350M LF2 Class

1

BTAB0

NPS 2 8, Class 300, RF, BB, OS&Y, TBody, API trim 8 (13 Cr), graphitic packing

BTAB0

3, 5,

28, 29

NPS 10, Class 300, RF, through-drilled lugs, ASTM A 352/A

CS disc, 316 SS seal ring, LTCS body,

352M LCB

graphitic packing

BFAB0

2, 3,

5, 7,

8, 11,

28

NPS 12-24, Class 300, RF, double-flanged,

CS disc, 316 SS seal ring, LTCS body,

graphitic packing

ASTM A 352/A

352M LCB

BFAB0

NPS 1, Class 800, SW, BB, OS&Y,

solid wedge, API trim 8 (13 Cr), standard

port, graphitic packing

ASTM A 350/A

350M LF2 Class

1

YGAB5

NPS 1 2, Class 300, RF flgs, ditto

ASTM A 350/A

350M LF2 Class

1

BGAB0

NPS -1, Class 800, SW x SE, BB, OS&Y, ASTM A 350/A

solid wedge, API trim 8 (13 Cr), standard

350M LF2 Class

port, graphitic packing

1

YGAB7

NPS 2 4, Class 300, RF, BB, OS&Y, solid

wedge, integral flange, API trim 8 (13 Cr),

standard port, graphitic packing

ASTM A 352/A

352M LCB

BGAB0

NPS 6-24, Class 300, RF, BB, OS&Y,

flexible wedge with cavity relief, integral

flange, API trim 8 (13 Cr), standard port,

graphitic packing

ASTM A 352/A

352M LCB

BGAB0

Instrument

Connection

Valves

NPS 2, applies to the first-block valve

(or double-block valve where required). See

Note 4 for additional requirements and

information.

Instrument

Double

Isolation

Valves

(Monoblok)

Manufacturers

standard

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

fire-safe design

Esso Highlands Limited

Page 25 of 43

ASTM

Specifications

ASTM A 350/A

350M LF2 Class

1

5, 28

3, 5,

22, 28

3, 5,

8, 22,

28, 29

ASTM A 350/A

350M LF2 Class

1

Strictly Confidential For Venture Use Only

BSAB10

2, 3,

4, 5,

30

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Valves

Description

ASTM

Specifications

ID No.

NPS 2, Class 300, 2 RF x FNPT, single

body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

fire-safe design

ASTM A 350/A

350M LF2 Class

1

BSAB10(04)

NPS 2, Class 300, RF, single body with two

obturators and a bleed, standard bore, DN

50 body, LTCS body, Metal Seats, fire-safe

design

ASTM A 350/A

350M LF2 Class

1

BSAB0(M)

NPS 2, Class 300, 2 RF x FNPT, single

body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

metal seats, fire-safe design

ASTM A 350/A

350M LF2 Class

1

BSAB10(04)(M)

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

metal seats, fire-safe design

ASTM A 350/A

350M LF2 Class

1

BSAB10(M)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

fire-safe design

ASTM A 350/A

350M LF2 Class

1

BSAB10(06)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a bleed,

standard bore, DN 20 body, LTCS body,

metal seats, fire-safe design

ASTM A 350/A

350M LF2 Class

1

BSAB10(06)(M)

Notes

See the Appendix of PG-PDS 03-01-01 for text of numbered Notes.

Esso Highlands Limited

Page 26 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Component/

Standard

Bolting

ASME B18.2.1

and ASME

B18.2.2

Flanges

ASME B16.5

Description

ASTM Specifications

Stud bolts

ASTM A 320/A 320M L7

Heavy, semi-finished, hex nuts

ASTM A 194/A 194M 4L

NPS 1, Class 300, RF, SW

ASTM A 350/A 350M LF2

Class 1

Notes

80

NPS 2 24, Class 300, RF, WN, bore to

match pipe

Orifice Flanges

ASME B16.36

NPS 2 24, Class 300, RF, WN, bore to

match pipe

Gaskets

ASME B16.20

Class 300, spiral wound, CS centering

ring, 304SS windings, flexible graphite

filler, inner ring for all sizes

Fittings

ASME B16.11

NPS 1, SW, Sch. 160 and lighter

Class 3000

Sch. XXS and heavierClass 6000

ASTM A 350/A 350M LF2

Class 1

53, 54,

62

Fittings

ASME B16.9

NPS 2 16 , BW, SMLS, same thickness

as pipe

ASTM A 420/A 420M

WPL6

55, 56

ASTM A 350/A 350M LF2

Class 1

53, 62

NPS 16, seamless, thickness (see

below)

ASTM A 333/A 333M Gr.

6

51, 52,

53, 54,

63

NPS18-24, EFW, Class 22, normalized

(impact tested for46C (50F) service,

for pipe Thk > 14.3mm)

ASTM A 671 CC65-S2

ASTM A 350/A 350M LF2

Class 1

60

NPS 18-24, BW, Welded

Branch Outlet

Fittings (O-lets)

MSS SP-97

NPS 1, branch outlet fitting, SW

outlet, Class 3000 for Sch. 160 and

lighter, Class 6000 for Sch. XXS

NPS 2 6, branch outlet fitting, BW outlet

to match branch wall

Pipe

ASME B36.10M

Spectacle Blind /

NPS 1-24, RF, Class 300, Impact test for

ASTM A516 Gr. 65,

Paddle Blank /

-46C service for Thk > 14.3mm

Normalized (Refer Table

Spacer

4 PG-PDS 03-01-01 for

ASME B16.48

the type)

See the Appendix of PG-PDS 03-01-01 for text of numbered Notes.

Esso Highlands Limited

Page 27 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Corrosion Allowance (C.A.)

(see Appendix Note 87)

E

C.A. = 3.0 mm (0.12 in.)

NPS

Sch.

XXS

160

36

80

8 24

40

Class 300 LT Carbon Steel (Sweet Service) B5E Classification Sheet

Branch Table

B

24 BWT

20

BRT BWT

18

BRT BRT BWT

16

RB BRT BRT BWT

14

RB

RB BRT BRT BWT

12

RB

RB

RB BRT BRT BWT

10

RB

RB

RB

RB BRT BRT BWT

RB

RB

RB

RB

WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

WOL WOL WOL WOL WOL WOL WOL WOL WOL BRT BRT BWT

RB BRT BRT BWT

1 SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL BRT SWT

N

P

S

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SWT

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SRT SWT

SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SOL SRT SRT SRT SWT

24

20

18

16

14

12

10

HEADER SIZESNPS

Legend:

BWT = Buttweld Tee

BRT

SOL = Socket Weld O-let Fitting

SWT = Socket Weld Tee

SRT = Socket Weld Reducing Tee

WOL = Buttweld O-let Fitting

RB

= Buttweld Reducing Tee

= Reinforced Branch

Esso Highlands Limited

Page 28 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

2.2

Upstream Piping Classification Line Class 300

Mar 2011

Class 300: Stainless SteelProcess Piping B11A

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Service

Corrosive hydrocarbons, chemicals, glycol, produced water,

amines

Pipe Material

316L stainless steel

Corrosion Allowance

0mm

Valve Material

316L stainless steel (flanged), 316L stainless (SW, BW)

Valve Material

316 or 316L stainless steel for flanged valves

Valve Trim

316 stainless steel

ASME Pressure Class

300

Design Code

ASME B31.3

PWHT

No

Pressure/Temperature Limits

Limits based upon flange ratings, unless noted otherwise

(See Notes 6 & 33 )

Limits based upon 316L flange

ratings, unless noted otherwise.

(*) Reference to PG-PDS 03-01-01,

Appendix E, Note 6, Clause g),

Temperature Range Restrictions for

Elastomers in this Line Class are

indicated below the valve ID No.

For blow-down scenario (short term

condition), elastomer Viton and

HNBR are suitable to -70C.

(C)

(kPa-g)

(F)

(psig)

101 to 38

4136

150 to +100

600

93

3516

200

510

149

3137

300

455

177

3013

350

437

204

2895

400

420

270

2688

518

390

310

2586

590

375

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Ball Valves

API SPEC

6D or

ASME

B16.34

Ball Valves

API SPEC

6D

Description

ASTM

Specifications

Notes

ID No.

NPS 1, Class 800, SW, reduced

bore, 316 SS ball/trim, reinforced PTFE

seats, fire-safe design

ASTM A 182/A

182M F316L

YBAK5

NPS 1, Class 800, SW x SE, ditto

ASTM A 182/A

182M F316L

YBAK7

NPS 1 1, Class 300, RF, ditto

ASTM A 182/A

182M F316

BBAJ0

NPS 28, Class 300, RF, reduced bore,

floating ball, liquid and mixed phase

service, 316 SS ball and trim, main seats RPTFE , other seals Viton, fire-safe

design

ASTM A 351/A

351M CF8M

BBAJ0(02)

(-50C to 177C)*

Esso Highlands Limited

Page 29 of 43

Strictly Confidential For Venture Use Only

2, 3, 6,

7, 9,

11, 21,

29, 30,

33, 58

2, 3, 6,

7, 8, 9,

11, 20,

21, 28,

33, 58

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Description

ASTM

Specifications

Notes

ID No.

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats - RPTFE, other seals

Viton, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(02)

(-50C to 177C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, DPE x DPE with cavity

bleed valve FBAK9, 316 SS ball and trim,

main seats - RPTFE, other seals Viton,

gas service only, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(01)

(-50C to 177C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, liquid and mixed phase

service, 316 SS ball and trim, main seats metal seats, other seals Viton, fire-safe

design

ASTM A 351/A

351M CF8M

BBAJ0(02)-(M)

(-50C to 177C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats - metal seats, other seals

Viton, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(02)-(M)

(-50C to 177C)*

NPS 26, Class 300, RF, full bore, floating

ball, liquid and mixed phase service, 316

SS ball and trim, main seats - RPTFE,

other seals Viton, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(02)

(-50C to 177C)*

NPS 8-24, Class 300, RF, full bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats - RPTFE, other seals

Viton, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(02)

(-50C to 177C)*

NPS 2-24, Class 300, RF, full bore,

trunnion mounted, DPE x DPE seat with

cavity bleed valve FBAK9, 316 SS ball

and trim, main seats - RPTFE, other seals

Viton, gas service only, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(01)

(-50C to 177C)*

NPS 28, Class 300, RF, reduced bore,

floating ball, liquid and mixed phase

service, 316 SS ball and trim, main seats RPTFE , other seals HNBR, fire-safe

design

ASTM A 351/A

351M CF8M

BBAJ0(12)

(-50C to 150C)*

Esso Highlands Limited

Page 30 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Description

ASTM

Specifications

Notes

ID No.

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x DPE seat, liquid

and mixed phase service, 316 SS ball and

trim, main seats - RPTFE, other seals

HNBR, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(12)

(-50C to 150C)*

NPS 2-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seal, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(21)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seals, liquid and mixed phase service, firesafe design

ASTM A 351/A

351M CF8M

BBAJ0(22)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats - RPTFE, other

seals Lip seals, liquid and mixed phase

service, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(22)

(204C)*

NPS 2-8, Class 300, RF, reduced bore,

floating ball, 316 SS ball and trim, main

seats - metal seats, other seals Lip

seals, liquid and mixed phase service, firesafe design

ASTM A 351/A

351M CF8M

BBAJ0(22)-(M)

(204C)*

NPS 10-24, Class 300, RF, reduced bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 351/A

351M CF8M

BBAJ0(22)-(M)

(204C)*

NPS 2-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, gas

service only, 316 SS ball and trim, main

seats - RPTFE seats, other seals Lip

seal, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(21)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats RPTFE seats, other seals Lip seals,

ASTM A 351/A

351M CF8M

BBFJ0(22)

(204C)*

Esso Highlands Limited

Page 31 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Description

ASTM

Specifications

Notes

ID No.

liquid and mixed phase service, fire-safe

design

Check

Valves

API STD

602

Check

Valves

API STD

594

Check

Valves

API SPEC

6D

Check

Valves

ASME

B16.34

Globe

Valves

API STD

602

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats RPTFE seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(22)

(204C)*

NPS 2-6, Class 300, RF, Full bore, floating

ball, 316 SS ball and trim, main seats metal seats, other seals Lip seals, liquid

and mixed phase service, fire-safe design

ASTM A 351/A

351M CF8M

BBFJ0(22)-(M)

(204C)*

NPS 8-24, Class 300, RF, Full bore,

trunnion mounted, SR x SR seat, 316 SS

ball and trim, main seats metal seats,

other seals Lip seals, liquid and mixed

phase service, fire-safe design

NPS 1, Class 800, SW, BC, API trim

12 (316 SS), swing-type, integral HF seat

ASTM A 351/A

351M CF8M

BBFJ0(22)-(M)

(204C)*

ASTM A 182/A

182M F316L

YCAK5

NPS 1, Class 800, SW, BC, API

trim 12 (316 SS), piston-type, integral HF

seat

ASTM A 182/A

182M F316L

YCNK5

NPS 3 10, Class 300, RF, retainerless

dual plates, through-drilled solid lugs,

integral metal seat, Inconel springs, 316

SS plates and pins

ASTM A 351/A

351M CF8M

BCYJ0

NPS 12 24, Class 300, RF, retainerless

dual plates, double-flanged, integral metal

seat, Inconel springs, 316 SS plates and

pins

NPS 2 24, Class 300, RF, BC, swingtype (piggable), 316 SS trim, HF seat

ASTM A 351/A

351M CF8M

BCYJ0

ASTM A 351/A

351M CF8M

BCFJ0

NPS 2, Class 300, RF, BC, swing-type

(non-piggable), API trim 12 (316 SS),

integral HF seat

ASTM A 351/A

351M CF8M

NPS 1, Class 800, SW, BB, OS&Y,

T-Body, API trim 12 (316 SS), graphitic

packing

NPS 1 2, Class 300, RF, integral flgs,

ditto

Esso Highlands Limited

Page 32 of 43

25, 27,

58

23, 24,

25, 58

8, 25,

26, 58

BCAJ0

25, 26,

29, 58

ASTM A 182/A

182M F316L

YTAK5

33, 58

ASTM A 182/A

182M F316

BTAJ0

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Globe

Valves

ASME

B16.34

Butterfly

Valves

API STD

609

Gate

Valves

API STD

602

Gate

Valves

ASME

B16.34

Description

ASTM

Specifications

Notes

ID No.

NPS 2 8, Class 300, RF, BB, OS&Y, TBody, API trim 12 (316 SS), graphitic

packing

ASTM A 351/A

351M CF8M

BTAJ0

3, 28,

29, 33,

58

NPS 10, Class 300, RF, through-drilled

lugs, 316 SS disc, 316 SS seal ring, 316

SS body, graphitic packing

ASTM A 351/A

351M CF8M

BFAJ0

2, 3, 7,

8, 11,

28, 33,

58

NPS 12-24, Class 300, RF, doubleflanged, 316 SS disc, 316 SS seal ring,

316 SS body, graphitic packing

ASTM A 351/A

351M CF8M

BFAJ0

NPS 1, Class 800, SW, BB, OS&Y,

solid wedge, API trim 12 (316 SS),

standard port, graphitic packing

ASTM A 182/A

182M F316L

YGAK5

NPS -1, Class 800, SW x SE, BB,

OS&Y, solid wedge, API trim 12 (316 SS),

standard port, graphitic packing, integral

flange

ASTM A 182/A

182M F316L

YGAK7

NPS 1 2, Class 300, RF, integral flgs,

ditto

ASTM A 182/A

182M F316

BGAJ0

NPS 2 4, Class 300, RF, BB, OS&Y,

solid wedge, integral flange, API trim 12

(316 SS), standard port, graphitic packing

ASTM A 351/A

351M CF8M

BGAJ0

NPS 6-24, Class 300, RF, BB, OS&Y,

flexible wedge with cavity relief, integral

flange, API trim 12 (316 SS), standard

port, graphitic packing

ASTM A 351/A

351M CF8M

BGAJ0

Instrument

Connection

Valves

NPS 2, applies to the first-block valve

(or double-block valve where required).

See Note 4 for additional requirements

and information.

Instrument

Double

Isolation

Valves

(Monoblok)

Manufacturers

standard

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a

bleed, standard bore, DN 20 body, 316 SS

body, fire-safe design

ASTM A 182/A

182M F316

BSAJ10

NPS 2, Class 300, 2 RF x FNPT,

single body with two obturators and a

bleed, standard bore, DN 20 body, 316 SS

body, fire-safe design

ASTM A 182/A

182M F316

BSAJ10(04)

NPS 2, Class 300, RF, single body with

ASTM A 182/A

BSAJ0(M)

Esso Highlands Limited

Page 33 of 43

3, 22,

28, 33,

58

3, 8,

22, 28,

29, 33,

58

Strictly Confidential For Venture Use Only

2, 3, 4,

30

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Valves

Description

ASTM

Specifications

Notes

ID No.

two obturators and a bleed, standard bore,

DN 50 body, SS316 body, Metal Seats,

fire-safe design

182M F316

NPS 2, Class 300, 2 RF x FNPT,

single body with two obturators and a

bleed, standard bore, DN 20 body, SS316

body, metal seats, fire-safe design

ASTM A 182/A

182M F316

BSAJ10(04)-(M)

NPS 2, Class 300, 2 RF x 1 i-Flange,

single body with two obturators and a

bleed, standard bore, DN 20 body, SS316

body, metal seats, fire-safe design

ASTM A 182/A

182M F316

BSAJ10(M)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a

bleed, standard bore, DN 20 body, SS

body, fire-safe design

ASTM A 182/A

182M F316L

BSAK10(06)

NPS 3/4, Class 300, PE x FNPT,

single body with two obturators and a

bleed, standard bore, DN 20 body, SS

body, metal seats, fire-safe design

ASTM A 182/A

182M F316L

BSAK10(06)-(M)

See the Appendix of PG-PDS 03-01-01 for text of numbered Notes.

Esso Highlands Limited

Page 34 of 43

Strictly Confidential For Venture Use Only

PGHU-EH-LSPDS-002004

Rev 0

PG-PDS 03-20-04

Upstream Piping Classification Line Class 300

Mar 2011

Class 300 Stainless SteelProcess Piping B11A Classification Sheet

Component/

Standard

Description

Bolting

ASME B18.2.1

and ASME

B18.2.2

Stud bolts

Flanges

ASME B16.5

NPS 1 1, Class 300, RF, SW

Heavy, semi-finished, hex nuts

ASTM Specifications

Notes

ASTM A 320/A 320M Gr.

L7

ASTM A194/A194M Gr.

4L

80

ASTM A 182/A 182M

F316L

89

57