Académique Documents

Professionnel Documents

Culture Documents

Motoman HP 20

Transféré par

Esteban Quezada NeriDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Motoman HP 20

Transféré par

Esteban Quezada NeriDroits d'auteur :

Formats disponibles

SOLUTIONS IN MOTION

Motomans HP20 robot

provides a powerful solution

to meet your automation needs

CUTTING DISPENSING HANDLING

MACHINE TENDING PACKAGING MATERIAL REMOVAL

HP20

MULTIPLE ROBOT CONTROL

Payload: 20 kg

MATERIAL HANDLING

Versatile, High-Speed Robot

PACKAGING

n IP65 rated body (optional)

This dynamic, high-speed robot

is compact and requires minimal

installation space. It offers superior

performance in handling, machine

tending, packaging, cutting and

dispensing applications.

The HP20 features a 1,717 mm (67.6")

reach and offers the widest work

envelope in its class. The slim base,

waist, and arm allow the robot to be

placed close to workpiece holding

fixtures to improve part accessibility.

The compact design and built-in

collision avoidance features with

multiple robot control allow up to four

robots to be used together to maximize

productivity while reducing overall

floorspace requirements.

n MotoMax III warranty (standard)

Advanced NX100 Controller

FEATURES & OPTIONS

n Multiple robot control (up to four

robots) simplifies programming

n Widest working envelope in its

class: 1,717 mm (67.6") reach

n Industry-leading 0.06 mm

(0.002") repeatability

n Floor-, wall-, and ceiling-

mounting options

n IP67 rated wrist (standard)

n MotoSim EG simulation

software (optional)

The NX100 high-performance

controller features a Windows CE

programming pendant, fast processing,

easy-to-use INFORM III programming

language, and robust PC architecture.

The NX100 offers unmatched multiple

robot control capability (up to four robots)

to minimize cost of integration and

eliminate risk of robot collisions.

The NX100 includes four security

levels of password protection (user, editor,

maintenance and supervisor) for up to 100

individual users. Password use restricts

access to the production programs and

the controller logs any changes.

The programming pendant features

a color touch-screen display that can

be configured as a custom HMI with

buttons and status indicators.

Dual-channel safety features include

enhanced E-Stop functionality, integrated

speed monitoring, manual brake release

switch, and compliance with both ANSI/

RIA R15.06-1999 and Canadian safety

standards.

The NX100 offers unmatched

connectivity through standard Ethernet

and other network options: DeviceNet,

ControlNet, Profibus-DP and EtherNet/IP.

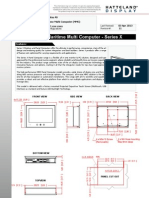

HP20 Robot

All dimensions are metric (mm) and for reference only. Please

request detail drawings for all design/engineering requirements.

0

1417

180

717

R1

150

80

1717 2072

P-Point

Maximum Envelope

795

87.5

140

1485

3063

505

R31

4

180

Tapped holes M6

(Depth: 10mm)

(Pitch: 1.0) (4 holes)

6

45

0

B

559

PCD

View A

4-18 dia 313

375

335

60

335

375

170

250

2-12 dia

C5

260

View B

HP20 SPECIFICATiONS

Structure

Controlled Axes

Payload

Vertical Reach

Horizontal Reach

Repeatability

S-Axis (Turning/Sweep)

Maximum

S-Axis (Wall Mount)

Motion

L-Axis (Lower Arm)

Range

U-Axis (Upper Arm)

R-Axis (Wrist Roll)

B-Axis (Bend/Pitch/Yaw)

T-Axis (Wrist Twist)

S-Axis

L-Axis

Maximum

U-Axis

Speed

R-Axis

B-Axis

T-Axis

Approximate Mass

Brakes

Power Consumption

Allowable

R-Axis

Moment

B-Axis

T-Axis

Allowable

R-Axis

Moment of

B-Axis

Inertia

T-Axis

Air inlet PT3/8

with pipe plug

200

6 dia Depth: 6mm

200

50 dia

25 dia

40

260

0.5

760

P-Point

2

R4

105

Internal user wiring connector type

is JL05-2A20-29PC (with cap)

Mating connector will not be supplied

but complete cables can be purchased

View C

991

Connector for the internal

wiring is JL05-2A20-29SC

(with cap). Mating connector

will not be supplied, but

complete cables can be

purchased.

View D

Air exhaust PT3/8

with pipe plug

NX100 CONTROLLER SPECIFICATiONS*

Vertical jointed-arm type

6

20 kg (44.1 lbs.)

3,063 mm (120.6")

1,717 mm (67.6")

0.06 mm (0.002")

180

30

+155/-110

+255/-165

200

+230/-50

360

170/s

170/s

175/s

355/s

345/s

525/s

280 kg (617.4 lbs.)

All axes

2.8 kVA

39.2 N m

39.2 N m

19.8 N m

0.9 kg m2

0.9 kg m2

0.25 kg m2

Structure

Dimensions (mm)

Approximate Mass

Cooling System

Ambient

Temperature

Relative Humidity

Primary Power

Requirements

Grounding

Digital I/O

NPN-Standard

PNP-Optional

Position Feedback

Drive Units

Accel/Decel

Program Memory

Pendant Dim. (mm)

Pendant Playback

Buttons

3-phase, 240/480/575 VAC at 50/60 Hz

Grounding resistance: 100 ohms

Separate ground required

Standard I/O: 40 inputs/40 outputs consisting of 16 system

inputs/16 system outputs, 24 user inputs/24 user outputs

Enabled to 1,024 inputs/1,024 outputs

By absolute encoder

Servo packs for AC servo motors

Software servo control

60,000 steps

10,000 ladder instructions

199 (w) x 338 (h) x 60 (d) (7.8" x 13.3" x 2.4")

Teach, Play, Remote, Servo On, Start, Hold, Emergency

Stop, Edit Lock (Play Mode Enabled on Controller)

Concurrent I/O Ladder

Multi Tasking

10,000 Instructions

Up to 8 concurrent jobs

Fieldbus

Ethernet

E-Stop

Safety

DeviceNet Master/Slave, AB RIO, Profibus, Interbus-S,

M-Net, CC Link, EtherNet IP/Slave

10 Base T/100 Base TX

Controlled stop

Dual-channel Emergency Stop Pushbuttons, 3-position Enable

Switch, Manual Brake Release

Meets ANSI/RIA R15.06-1999 and Canadian safety standards

Free-standing, enclosed type

650 (w) x 1,200 (h) x 650 (d) (25.6" x 47.2" x 25.6")

150-250 kg (330.8-551.3 lbs.)

Indirect cooling

During operation: 0 C (32 F) to 45 C (113 F)

During transmit and storage: -10 C (14 F) to +60 C (140 F)

90% max. non-condensing

*See NX100 Controller data sheet (DS-232) for complete specifications

TECHNICAL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

DS-230-d 2007 MOTOMAN INC. FEBRuary 2007

Motoman CORPORATE HEADQUARTERS

805 Liberty Lane, WEST CARROLLTON, OHIO 45449

Tel: 937.847.6200 FAX: 937.847.6277

WEB SITE: www.motoman.com

MOTOMAN IS A REGISTERED TRADEMARK

Windows is a registered trademark of microsoft

ALL other MARKS ARE THE TRADEMARKS AND

REGISTERED TRADEMARKS OF MOTOMAN INC.

Vous aimerez peut-être aussi

- NX100 Robot ControllerDocument2 pagesNX100 Robot ControllerEman GuiruelaPas encore d'évaluation

- Payload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotDocument2 pagesPayload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotRuben AlvaradoPas encore d'évaluation

- MH5S MH5LS DXM100Document2 pagesMH5S MH5LS DXM100Myagmarbayar NerguiPas encore d'évaluation

- XRC ControllerDocument2 pagesXRC ControllersengcyanPas encore d'évaluation

- NXC100 ControllerDocument2 pagesNXC100 ControllermartinimartiiniPas encore d'évaluation

- Motoman-Dx100: Industrial Robot ControllerDocument4 pagesMotoman-Dx100: Industrial Robot ControllerloreyernePas encore d'évaluation

- DENSO Automation Trainer BrochureDocument8 pagesDENSO Automation Trainer BrochureNascostaPas encore d'évaluation

- 3 Bse 044080 G en Compact 800 OverviewDocument12 pages3 Bse 044080 G en Compact 800 OverviewfibirtPas encore d'évaluation

- 1000MII 1000M4II Milling Machine & Machining Center CNC ControllerDocument5 pages1000MII 1000M4II Milling Machine & Machining Center CNC ControllerCNCmakersPas encore d'évaluation

- MH6 MH6SDocument2 pagesMH6 MH6SInlaboPas encore d'évaluation

- Series 0: I - TB CNCDocument6 pagesSeries 0: I - TB CNCGuillermo RamirezPas encore d'évaluation

- Ds Hd08t21mmc XXX XXXXDocument2 pagesDs Hd08t21mmc XXX XXXXbbbru1Pas encore d'évaluation

- Fanuc 0i-MD Standard Features and OptionsDocument9 pagesFanuc 0i-MD Standard Features and OptionsАнѓелковска МаријаPas encore d'évaluation

- Fanuc LR Mate 200ib 200ib 3lDocument4 pagesFanuc LR Mate 200ib 200ib 3lHector Calvillo GtzPas encore d'évaluation

- Eaton AutomationDocument84 pagesEaton AutomationRadu Fabian FishyPas encore d'évaluation

- CNC STANDARD FEATURES AND OPTIONSDocument7 pagesCNC STANDARD FEATURES AND OPTIONSTamil SelvanPas encore d'évaluation

- FS100 ControllerDocument2 pagesFS100 ControllermartinimartiiniPas encore d'évaluation

- TouchscreenDocument2 pagesTouchscreenRanadurjoy GhoshPas encore d'évaluation

- Fanuc ARC Mate 100ibe 120ibeDocument4 pagesFanuc ARC Mate 100ibe 120ibeAzimatronics SA de CV100% (1)

- 009-1137-00 HST-SMRTD Savant Smart Host Tech SpecDocument6 pages009-1137-00 HST-SMRTD Savant Smart Host Tech Specferna2420Pas encore d'évaluation

- 928TEII Turning Machine CNC SystemDocument0 page928TEII Turning Machine CNC SystemCNCmakersPas encore d'évaluation

- Aurotek Motion Control CardDocument1 pageAurotek Motion Control CardjuliangoalPas encore d'évaluation

- A1000 DriveDocument15 pagesA1000 DriveNguyen Danh HuyPas encore d'évaluation

- User Guide: Read This ManualDocument112 pagesUser Guide: Read This Manualjulie.garrel94Pas encore d'évaluation

- Operator Control and Monitoring - Simple and Cost-Effective ... Perfect For The SIMATIC S7-200Document3 pagesOperator Control and Monitoring - Simple and Cost-Effective ... Perfect For The SIMATIC S7-200Robney FiuzaPas encore d'évaluation

- ControlDocument5 pagesControlamerquipPas encore d'évaluation

- GP2500T - TFT Color: Pro-Face Graphic Operator InterfacesDocument2 pagesGP2500T - TFT Color: Pro-Face Graphic Operator Interfacesthanh_cdt01Pas encore d'évaluation

- DisplayDocument2 pagesDisplaybbbru1Pas encore d'évaluation

- Ea7 Cmore HmiDocument16 pagesEa7 Cmore HmiJesus GarciaPas encore d'évaluation

- HIO TouchScreenDocument4 pagesHIO TouchScreenMaitry ShahPas encore d'évaluation

- 14 - HPL2010-EN. AutomatizaciónDocument126 pages14 - HPL2010-EN. AutomatizaciónCesar PomposoPas encore d'évaluation

- SSF2000Document2 pagesSSF2000sujinssridaPas encore d'évaluation

- FS30i-BPlus(E)-01Document16 pagesFS30i-BPlus(E)-01ngoccuongckPas encore d'évaluation

- AX 20controller NRSDocument2 pagesAX 20controller NRSTuan Bu Dich nguyenPas encore d'évaluation

- XTREMOSERIESDocument2 pagesXTREMOSERIESFarmer JoePas encore d'évaluation

- Exor eTOP06 SpecsheetDocument3 pagesExor eTOP06 SpecsheetElectromatePas encore d'évaluation

- System R-J3 Controller: Basic DescriptionDocument2 pagesSystem R-J3 Controller: Basic Descriptionvanwyksc1Pas encore d'évaluation

- Leica ScanStation C10 DS enDocument2 pagesLeica ScanStation C10 DS enBogdan CîrlugeaPas encore d'évaluation

- TP170X Product BriefDocument3 pagesTP170X Product Briefkamran79Pas encore d'évaluation

- InteliDrive Mobile: A Highly Flexible Mobile Electronic ControllerDocument2 pagesInteliDrive Mobile: A Highly Flexible Mobile Electronic ControllerdeeparunPas encore d'évaluation

- UTS Digital Signage SpecDocument5 pagesUTS Digital Signage SpecMohammed JifarPas encore d'évaluation

- Aurotek Motion Control CardDocument1 pageAurotek Motion Control CardjuliangoalPas encore d'évaluation

- Electronic CircuitsDocument91 pagesElectronic Circuitsvinay Shastry100% (6)

- RV-2A 3AJ BrochureDocument6 pagesRV-2A 3AJ BrochurePHONG279Pas encore d'évaluation

- AGP3000 eDocument25 pagesAGP3000 eElena MaxmiucPas encore d'évaluation

- Heidenhain MANUALplus620Document48 pagesHeidenhain MANUALplus620Muhammed ShahidPas encore d'évaluation

- System Control Keyboard: Technical SpecificationsDocument1 pageSystem Control Keyboard: Technical Specificationsnk1969Pas encore d'évaluation

- Catalogo Controlador CD 600Document8 pagesCatalogo Controlador CD 600robertocarlosroa100% (1)

- iQA Series: Portable Passive Intermodulation AnalyzerDocument2 pagesiQA Series: Portable Passive Intermodulation AnalyzerRafat AdawiPas encore d'évaluation

- IRC5Document2 pagesIRC5Luis Miguel ZapataPas encore d'évaluation

- Ds Hd13t21std XXX FXXXDocument2 pagesDs Hd13t21std XXX FXXXbbbru1Pas encore d'évaluation

- Impinj Speedway Revolution BrochureDocument4 pagesImpinj Speedway Revolution BrochureHugh Haskell-ThomasPas encore d'évaluation

- Series 0+-MODEL F Plus: Easier To Use The World Standard CNC From FANUCDocument16 pagesSeries 0+-MODEL F Plus: Easier To Use The World Standard CNC From FANUCWazabi MooPas encore d'évaluation

- Microprocessor Architectures and Systems: RISC, CISC and DSPD'EverandMicroprocessor Architectures and Systems: RISC, CISC and DSPÉvaluation : 4 sur 5 étoiles4/5 (1)

- Computer Organization and Design: The Hardware / Software InterfaceD'EverandComputer Organization and Design: The Hardware / Software InterfaceÉvaluation : 4 sur 5 étoiles4/5 (12)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0D'EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Évaluation : 5 sur 5 étoiles5/5 (1)

- Post Marketing SurveillanceDocument19 pagesPost Marketing SurveillanceRamanjeet SinghPas encore d'évaluation

- Steps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersDocument5 pagesSteps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersruhelanikPas encore d'évaluation

- Expressive Matter Vendor FaqDocument14 pagesExpressive Matter Vendor FaqRobert LedermanPas encore d'évaluation

- 'K Is Mentally Ill' The Anatomy of A Factual AccountDocument32 pages'K Is Mentally Ill' The Anatomy of A Factual AccountDiego TorresPas encore d'évaluation

- (Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingDocument17 pages(Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingKatherine Natalia Pino Arredondo100% (1)

- Single-Phase Induction Generators PDFDocument11 pagesSingle-Phase Induction Generators PDFalokinxx100% (1)

- 10 Slides For A Perfect Startup Pitch DeckDocument6 pages10 Slides For A Perfect Startup Pitch DeckZakky AzhariPas encore d'évaluation

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDocument61 pagesBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriPas encore d'évaluation

- 2019-10 Best Practices For Ovirt Backup and Recovery PDFDocument33 pages2019-10 Best Practices For Ovirt Backup and Recovery PDFAntonius SonyPas encore d'évaluation

- Emerson Park Master Plan 2015 DraftDocument93 pagesEmerson Park Master Plan 2015 DraftRyan DeffenbaughPas encore d'évaluation

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Document14 pagesDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiPas encore d'évaluation

- The Product Development and Commercialization ProcDocument2 pagesThe Product Development and Commercialization ProcAlexandra LicaPas encore d'évaluation

- Digital Communication Quantization OverviewDocument5 pagesDigital Communication Quantization OverviewNiharika KorukondaPas encore d'évaluation

- BoQ East Park Apartment Buaran For ContractorDocument36 pagesBoQ East Park Apartment Buaran For ContractorDhiangga JauharyPas encore d'évaluation

- Amul ReportDocument48 pagesAmul ReportUjwal JaiswalPas encore d'évaluation

- Key ssl101 Academic Skills For University Success ssl101cDocument196 pagesKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnPas encore d'évaluation

- Introduction To OpmDocument30 pagesIntroduction To OpmNaeem Ul HassanPas encore d'évaluation

- ExpDocument425 pagesExpVinay KamatPas encore d'évaluation

- Waves and Thermodynamics, PDFDocument464 pagesWaves and Thermodynamics, PDFamitPas encore d'évaluation

- Oblicon SampleDocument1 pageOblicon SamplelazylawatudentPas encore d'évaluation

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Document16 pagesTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Yanmar America publication listing for engine parts, service, and operation manualsDocument602 pagesYanmar America publication listing for engine parts, service, and operation manualsEnrique Murgia50% (2)

- Application D2 WS2023Document11 pagesApplication D2 WS2023María Camila AlvaradoPas encore d'évaluation

- Deep Groove Ball Bearings PDFDocument11 pagesDeep Groove Ball Bearings PDFArpit VermaPas encore d'évaluation

- SYNOPSIS - Impact of GST On Small Traders!Document21 pagesSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaPas encore d'évaluation

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocument12 pagesGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTOROPas encore d'évaluation

- Scharlau Chemie: Material Safety Data Sheet - MsdsDocument4 pagesScharlau Chemie: Material Safety Data Sheet - MsdsTapioriusPas encore d'évaluation

- MSDS FluorouracilDocument3 pagesMSDS FluorouracilRita NascimentoPas encore d'évaluation

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoPas encore d'évaluation

- Material Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008Document6 pagesMaterial Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008suckrindjink100% (1)