Académique Documents

Professionnel Documents

Culture Documents

Polyfelt Ts Nonwoven Geotextiles PDF

Transféré par

afrizaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Polyfelt Ts Nonwoven Geotextiles PDF

Transféré par

afrizaDroits d'auteur :

Formats disponibles

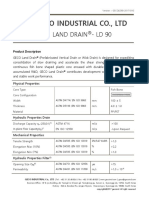

~nttCATE

Polyfele

Properties of Polyfelt TS Nonwoven Geotextiles

Property

Test Standard

Unit

TS 10

TS 20

TS 30

UV Resistance

Tensile strength retention

Puncture strength retention

TS 60

TS 65

TS 70

TS 80

> 70% Strength retention after 3 months outdoor weathering

> 70% Strength retention after 3 months outdoor weathering

ISO 10319

ISO 12236

Chemical Resistance

No influence at pH range 2 13

(ave)

Tensile strength

(MD/CD)

Tensile elongation

Performance energy *

CBR puncture strength

Effective opening size

(090)

Vertical water flow 50mm head

ISO 10319

ISO 10319

Calculated

ISO 12236

ISO 12956

ISO 11058

Horizontal water flow

20 kPa

200 kPa

ISO 12958

ISO 12958

kN/m

%

kN/m

N

mm

lim' Is

(mm/s)

1/m.h

1/m.h

2 kPa

ISO 9864

ISO 9863

g/m'

mm

Nominal mass

Thickness

_.. . ,

TS 50

Continuous filament, nonwoven needle punched

100% polypropylene, UV stabilized

Physical Characteristics

Polymer

Grab strength

Grab elongation

Rod puncture resistance

Apparent opening size

Permittivity

TS 40

(MD/CD)

(MD/CD)

Form of supply

Width

length

Area

Weight of roll

(0,.)

'ASTM

ASTM

ASTM

ASTM

ASTM

D4632

D4632

D4833

D4751

D4491

N

%

N

mm

S'

7.5

75135

2.2

1175

0.13

130

9.5

75/35

2.5

1500

0.12

115

11.5

75/35

3.2

1750

0.10

100

13.5

75135

3.7

2100

0.10

90

15

75/35

4.1

2350

0.10

85

19

80/35

5.5

2900

0.09

2

0.7

4

1.4

7

2.2

9

2.5

105

1.0

125

1.2

155

1.5

180

1.7

72

21.5

80/40

6.5

3300

0.09

65

24

80/40

7.2

3850

0.09

55

28

80/40

8.4

4250

0.08

50

11

2.9

13

3.0

14

3.2

16

3.6

20

4.0

200

1.9

250

2.2

285

2.5

325

2.9

400

3.2

4751420 560/510 690/600 8251720 920/810 1150/10251300/12001500/14001770/1650

75/40 75/40 75140 75/40 75/40 75/40 75/40 75/40 75/40

215

255

310

400

800

550

360

500

650

0.31

0.25

0.21

0.15

0.26

0.24

0.19

0.18

0.18

3.5

3.0

2.7

2.0

1.7

2.5

2.0

1.7

1.7

4

4

300/100 250/100

1200/400 1000/400

136/52 135/60

4

225

900

150

4

200

800

154

4

175

700

150

4

135

540

145

4

125

500

153

4

100

400

140

4

. 90

'360

154

Other forms of supply as well as grades, adjusted to the

requirements of the project. are available on request.

The values given are indicative and correspond to average values obtained in accredited testing laboratories and institutes.

Further details of this application and products can be obtained by contacting your nearest TenCate Technical Support office.

Unauthorized reproduction and distribution prohibited. This document is provided as supporting service only. The information contained in this document is to the best of our knowledge true and correct. No warranty whatsoever

is expressed or implied or given. Engineers wishing to apply this information shall satisfy themselves on the validity of the input data relative to the applicable soil and engineering conditions and doing so assume design liability.

Phones : (021) 6330 150 ( hunting), 6330535

Fax.

: (021) 6330540

: office@geosinindo.co. id

Website : www.geoslnlndo.co.id

<C,

u.

~

CXl

Q.

-6

";'

0

m

m

m'

kg

Polyfelt is a registered trademarkofTenCate.

Roxy Mas Business Center Block C4 No.18 - 20

;;;

0CD

Performance energy indicates the ability of the geotextile to absorb construction stress

Performance energy =Y, (energy MD+ energy CO) where

Energy MO = Yz ltensile strength MD x elongation MO)

Energy CD =Yz (tensile strength CD x elongation CD)

Jl. K. H. Hasyim Ashari, Jakarta 10 150

'"

~ TENCATE

materials that make a difference

Vous aimerez peut-être aussi

- Physics 2204: Unit 3: Work, Power and Energy Worksheet 5: Elastic Potential Energy Student NameDocument4 pagesPhysics 2204: Unit 3: Work, Power and Energy Worksheet 5: Elastic Potential Energy Student NameJULIA BINTI AHMAD MoePas encore d'évaluation

- Bar Bending Schedule (Service BLDG)Document20 pagesBar Bending Schedule (Service BLDG)Rania SaiedPas encore d'évaluation

- PCI Data AnalysisDocument20 pagesPCI Data AnalysisJia Yiin100% (1)

- Using Some of Microsoft Office Excel FunDocument79 pagesUsing Some of Microsoft Office Excel FunPal RichardPas encore d'évaluation

- 5 - Vector Calculus PDFDocument87 pages5 - Vector Calculus PDFNgọc NhânPas encore d'évaluation

- BITUMEN SEAL DESIGN CALCULATIONDocument5 pagesBITUMEN SEAL DESIGN CALCULATIONSekson Lapcharoensin100% (1)

- Building Materials Price List for Kota Kinabalu, SabahDocument12 pagesBuilding Materials Price List for Kota Kinabalu, SabahJayson TeePas encore d'évaluation

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduPas encore d'évaluation

- Rock Mass Assessment Using Geological Strength Index (GSI) Along The Ranau-Tambunan Road, Sabah, MalaysiaDocument8 pagesRock Mass Assessment Using Geological Strength Index (GSI) Along The Ranau-Tambunan Road, Sabah, MalaysiaBromocorah BromocorahPas encore d'évaluation

- Wet Retention Ponds: AdvantagesDocument7 pagesWet Retention Ponds: AdvantagesEugene MarcoPas encore d'évaluation

- Specifications of The Application of Class Concrete Paving BlocksDocument10 pagesSpecifications of The Application of Class Concrete Paving BlockshonneyValadasPas encore d'évaluation

- Sika Backing RodDocument2 pagesSika Backing Rodthe pilotPas encore d'évaluation

- Gregory Cajete - Native Science - Natural Laws of Interdependence-Clear Light Books (1999)Document164 pagesGregory Cajete - Native Science - Natural Laws of Interdependence-Clear Light Books (1999)Marcelo Freire100% (1)

- TenCate Polyfelt TS TechnicalData en 502644 Tcm28-36720Document2 pagesTenCate Polyfelt TS TechnicalData en 502644 Tcm28-36720james_frankPas encore d'évaluation

- Syarikat Jurukur MalaysiaDocument6 pagesSyarikat Jurukur MalaysiaPROSURVEY STUDIOPas encore d'évaluation

- Tencate GeotextileDocument12 pagesTencate GeotextileTamilchelvam MurogayahPas encore d'évaluation

- Marshall Test & Extraction & Stripping & Specific GravityDocument19 pagesMarshall Test & Extraction & Stripping & Specific GravityFarhad SkandaryPas encore d'évaluation

- Asphalt Concrete Wearing Course RequirementsDocument29 pagesAsphalt Concrete Wearing Course RequirementsTj TalhaPas encore d'évaluation

- PileDocument5 pagesPileSuman NakarmiPas encore d'évaluation

- Crushed SandDocument5 pagesCrushed Sandshivendra24Pas encore d'évaluation

- MSDS 0008 Concrete Material Safety Data SheetDocument8 pagesMSDS 0008 Concrete Material Safety Data SheetGangsar Lukmanjaya100% (1)

- BRC Wire Mesh SizesDocument1 pageBRC Wire Mesh SizesKamalPas encore d'évaluation

- BQ PmuDocument5 pagesBQ PmuAzamOthman100% (1)

- 5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Document51 pages5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Mohd Muzani MustafaPas encore d'évaluation

- Surge TankDocument1 pageSurge TankALLIFPas encore d'évaluation

- Crack Width Calculation BS 8100 BS 8007Document2 pagesCrack Width Calculation BS 8100 BS 8007Shaniha kkPas encore d'évaluation

- Welded Wire Mesh 50 X 50 X 1 6mm MSDSDocument3 pagesWelded Wire Mesh 50 X 50 X 1 6mm MSDSMounir BoutaghanePas encore d'évaluation

- ASD Specification (Volumn 1 Corrigendum)Document0 pageASD Specification (Volumn 1 Corrigendum)Agnon FungPas encore d'évaluation

- Taking Off SewerageDocument4 pagesTaking Off SewerageMrJanji JohnyPas encore d'évaluation

- CIDB TMO TrainingDocument10 pagesCIDB TMO TrainingA.Halim SamadPas encore d'évaluation

- Pipe CulvertDocument12 pagesPipe CulvertSumit HackPas encore d'évaluation

- Steel Fabric PropertiesDocument2 pagesSteel Fabric PropertiesDennis Tan100% (1)

- SCIB RC Square PilesDocument6 pagesSCIB RC Square PilesSevet Gnow DrachirPas encore d'évaluation

- Solcourse - Polythene DPM DatasheetDocument2 pagesSolcourse - Polythene DPM DatasheetkibzeamPas encore d'évaluation

- Civil Engineering Works Measurement (CEWMDocument2 pagesCivil Engineering Works Measurement (CEWMFairus IthninPas encore d'évaluation

- Guidance Note On The Design of Thrust BlocksDocument1 pageGuidance Note On The Design of Thrust BlocksLi Tsz ChunPas encore d'évaluation

- Asean Standards (Brunei) - ElectricalDocument5 pagesAsean Standards (Brunei) - ElectricalsulaimanPas encore d'évaluation

- Is-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteDocument23 pagesIs-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteSachin PawarPas encore d'évaluation

- PWD Schedule of Rates for Civil Works 10th EditionDocument87 pagesPWD Schedule of Rates for Civil Works 10th EditionQamrul HasanPas encore d'évaluation

- IWK - Recommended PEDocument1 pageIWK - Recommended PECalvin KewPas encore d'évaluation

- Pipe Jacking - Herren PDFDocument2 pagesPipe Jacking - Herren PDFnurPas encore d'évaluation

- Bar Bending Schedule OF Box CulvertDocument1 pageBar Bending Schedule OF Box CulvertMaladi MustamilPas encore d'évaluation

- TDC 6 388Document3 pagesTDC 6 388sonnu151Pas encore d'évaluation

- Karnataka PWD SR 11-12Document446 pagesKarnataka PWD SR 11-12NITESH SINGHPas encore d'évaluation

- Service Chiler Trane RTHC 200TR ProjectDocument4 pagesService Chiler Trane RTHC 200TR Projectoki100% (1)

- Signature of Owner: Borang PDC 2Document8 pagesSignature of Owner: Borang PDC 2Mageswary KunalanPas encore d'évaluation

- Cebex 100 Non-Shrink Grout AdmixtureDocument19 pagesCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- Mesh Fabric BS4483 1998Document1 pageMesh Fabric BS4483 1998eotp1Pas encore d'évaluation

- Typical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sDocument6 pagesTypical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sJennifer PearsonPas encore d'évaluation

- Quantity and Cost Estimate Combined Infrastructure ServicesDocument4 pagesQuantity and Cost Estimate Combined Infrastructure ServicesThai NguyenPas encore d'évaluation

- Cost Estimation BundDocument26 pagesCost Estimation BundAnonymous UUw70xirbl100% (1)

- JKR-Mackintosh Probe ChartDocument1 pageJKR-Mackintosh Probe ChartNurmuliana Abdul WahabPas encore d'évaluation

- BMP 2014 - SelangorDocument7 pagesBMP 2014 - SelangorHyrul Nizam HamediPas encore d'évaluation

- Mutu Beton Standar EropaDocument1 pageMutu Beton Standar EropaDedy RachayuPas encore d'évaluation

- Mastertop 100 PDFDocument2 pagesMastertop 100 PDFMohiuddin MuhinPas encore d'évaluation

- Material Cutting List'sDocument40 pagesMaterial Cutting List'sdopakPas encore d'évaluation

- REKAPITULASI PERHITUNGAN PENYESUAIAN HARGA (ESKALASIDocument33 pagesREKAPITULASI PERHITUNGAN PENYESUAIAN HARGA (ESKALASIAndy YuliantoPas encore d'évaluation

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoPas encore d'évaluation

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuPas encore d'évaluation

- Geco Industrial Co., LTD: Land Drain - LD 90Document2 pagesGeco Industrial Co., LTD: Land Drain - LD 90Gisella Mariel RubilarPas encore d'évaluation

- GEOTESS PP HT TC-Fisa Tehnica Generala (En) 100-400 GRDocument1 pageGEOTESS PP HT TC-Fisa Tehnica Generala (En) 100-400 GRdutucojPas encore d'évaluation

- HVZ adhesive anchor installation and design guideDocument13 pagesHVZ adhesive anchor installation and design guideMihnea-Bogdan NicolaescuPas encore d'évaluation

- Macgrid Asia BiDocument2 pagesMacgrid Asia Bisundra0Pas encore d'évaluation

- PreviewpdfDocument41 pagesPreviewpdfJulio Cesar Tapia ReyesPas encore d'évaluation

- Magnetic Flux Indicators Product Data Sheet EnglishDocument1 pageMagnetic Flux Indicators Product Data Sheet EnglishRob WillestonePas encore d'évaluation

- FCE ACADEMY ASSESSMENT UNIT 2 - Google FormsDocument9 pagesFCE ACADEMY ASSESSMENT UNIT 2 - Google FormsPATRICIO MALESPas encore d'évaluation

- Chapter 3 - Conservation of EnergyDocument79 pagesChapter 3 - Conservation of EnergyBananaliksPas encore d'évaluation

- TNPSC Group 2 Complete Syllabus: TNPSC Group 2 Previous Questions: TNPSC Group 2 Model QuestionsDocument7 pagesTNPSC Group 2 Complete Syllabus: TNPSC Group 2 Previous Questions: TNPSC Group 2 Model QuestionsanbuPas encore d'évaluation

- NCERT Solutions For Class 7 Maths Chapter 4Document18 pagesNCERT Solutions For Class 7 Maths Chapter 4kusuma kadirimangalamPas encore d'évaluation

- Control Systems Prof. C. S. Shankar Ram Department of Engineering Design Indian Institute of Technology, Madras Lecture - 40 Root Locus 4 Part-2Document7 pagesControl Systems Prof. C. S. Shankar Ram Department of Engineering Design Indian Institute of Technology, Madras Lecture - 40 Root Locus 4 Part-2HgPas encore d'évaluation

- Thermal Properties & Temperature 6 QPDocument9 pagesThermal Properties & Temperature 6 QPJeffrey PiggottPas encore d'évaluation

- Hegelian Theory Thesis Antithesis SynthesisDocument6 pagesHegelian Theory Thesis Antithesis Synthesismichelelataseattle100% (2)

- Nano TribologyDocument96 pagesNano TribologyMinh Tâm PhạmPas encore d'évaluation

- PH600 CH 10 Problems PDFDocument5 pagesPH600 CH 10 Problems PDFMike GaoPas encore d'évaluation

- Einstein's Rank-2 Tensor Compression of Maxwell's Equations Does Not Turn Them Into Rank-2 Spacetime CurvatureDocument3 pagesEinstein's Rank-2 Tensor Compression of Maxwell's Equations Does Not Turn Them Into Rank-2 Spacetime CurvatureNige Cook100% (1)

- Orifice and Jet Flow AppDocument40 pagesOrifice and Jet Flow AppMayuresh ChavanPas encore d'évaluation

- Direct & Inverted PendulumDocument2 pagesDirect & Inverted PendulumAnonymous kxOcSmhcPas encore d'évaluation

- Seismic Design of Spherical Liquid Storage Tanks (COMPDYN 2011Document19 pagesSeismic Design of Spherical Liquid Storage Tanks (COMPDYN 2011paaryPas encore d'évaluation

- The Introduction of Self-Registering Meteorological Instruments by George Forrest BrowneDocument20 pagesThe Introduction of Self-Registering Meteorological Instruments by George Forrest BrownesigjoatrumbzPas encore d'évaluation

- Week2-Mechanical PropertiesDocument34 pagesWeek2-Mechanical PropertiesMuhammad AzeemPas encore d'évaluation

- AC510U/AC520U: High Performance Turning Grade For Heat Resistant AlloyDocument4 pagesAC510U/AC520U: High Performance Turning Grade For Heat Resistant AlloyFabianoKovalechenPas encore d'évaluation

- Health Assessment of Structures PaperDocument4 pagesHealth Assessment of Structures PaperNirmal ModyPas encore d'évaluation

- 45 Days Long Virtual Internship On Oil & Gas Industrial PracticesDocument10 pages45 Days Long Virtual Internship On Oil & Gas Industrial PracticesKaran LunaPas encore d'évaluation

- 1-2-1 EN Frese COMBIFLOW 6-WayDocument10 pages1-2-1 EN Frese COMBIFLOW 6-WayAliKarimliPas encore d'évaluation

- ICFBN'23 Brochure MatterDocument10 pagesICFBN'23 Brochure MatterDANIEL DASPas encore d'évaluation

- Perry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyDocument20 pagesPerry Johnson Laboratory Accreditation, Inc.: Calibration Scopes of Accreditation PolicyEnrique AntonioPas encore d'évaluation

- Electromagnetic Theory, Photons, and Light: OpticsDocument29 pagesElectromagnetic Theory, Photons, and Light: OpticsLatifaKhumairaPas encore d'évaluation

- CFD FDP Online Five-Day ScheduleDocument1 pageCFD FDP Online Five-Day ScheduleSujit MishraPas encore d'évaluation

- Plasticity Notes For MTechs GRIET & JNTUHDocument24 pagesPlasticity Notes For MTechs GRIET & JNTUHvempadareddyPas encore d'évaluation