Académique Documents

Professionnel Documents

Culture Documents

Is 1121 3 1974

Transféré par

Venugopalan ManaladikalamDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Is 1121 3 1974

Transféré par

Venugopalan ManaladikalamDroits d'auteur :

Formats disponibles

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 1121-3 (1974): Methods of Test for Determination of

Strength Properties of Natural Building Stones, Part III:

Tensile Strength [CED 6: Stones]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS 1121 (Part 3) : 2012

Hkkjrh; ekud

kfrd fuekZ.k iRFkjksa osQ lkeF;Z xq.kksa dks

Kkr djuk ijh{k.k ifr;k

Hkkx 3 ruu lkeF;Z

( nwljk iqujh{k.k )

Indian Standard

DETERMINATION OF STRENGTH PROPERTIES OF

NATURAL BUILDING STONES METHODS OF TEST

PART 3 TENSILE STRENGTH

( Second Revision )

ICS 91.100.15

BIS 2012

B U R EAU O F I N D IAN S TAN DAR D S

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 2012

Price Group 2

Stones Sectional Committee, CED 6

FOREWORD

This Indian Standard (Part 3) (Second Revision) was adopted by the Bureau of Indian Standards, after the

draft finalized by the Stones Sectional Committee had been approved by the Civil Engineering Division

Council.

Building stones are available in large quantity in various parts of the country and to choose and utilize them

for their satisfactory performance, it is necessary to know the various strength properties determined according

to standard procedure. This standard has, therefore, been formulated to cover the standard method for

determining the strength properties of various stones. This standard covering compressive, transverse and

shear strength properties was published in 1957 and was subsequently revised in 1974 where property of

tensile strength was also added as the same was also important for assessing the suitability of stone; the

revision was issued in four parts. Other parts are:

Part 1

Part 2

Compressive strength

Transverse strength

Part 4

Shear strength

This standard is brought out to incorporate the experience gained based on the use of the standard since its

last revision. The major modifications incorporated in this revision are as follows:

a) SI units have been used,

b) Size of the samples has been specified as stones of adequate size in place of the requirement of at

least 25 kg specified earlier,

c) Surface finishing requirement of specimen has been modified by making reference to IS 9179 : 1979

Method for preparation of rock specimen for laboratory testing,

d) Vacuum saturation in water has been specified for conditioning of the test specimens in place of

normal immersion,

e) Rate of loading has been modified in line with IS 10082 : 1981 Method for the determination of tensile

strength by indirect tests on rock specimens,

f) The word rift has been replaced with plane of anisotropy, and

g) The minimum number of test specimen has been revised from three to five for test for each of the set

of conditions.

In reporting the results of a test or analysis made in accordance with this standard, if the final value, observed

or calculated, is to be rounded off, it shall be done in accordance with IS 2 : 1960 Rules for rounding off

numerical values (revised).

IS 1121 (Part 3) : 2012

Indian Standard

DETERMINATION OF STRENGTH PROPERTIES OF

NATURAL BUILDING STONES METHODS OF TEST

PART 3 TENSILE STRENGTH

( Second Revision )

1 SCOPE

Separate samples for each class of stone that would

be considered for use in construction as indicated

by visual inspection shall be selected.

This standard (Part 3) lays down the procedure for

determination of split tensile strength of natural

building stones used for constructional purposes.

3.3 When perceptible variations occur in the quality

of rock, as many samples as are necessary for

determining the range in properties shall be selected.

2 REFERENCE

The standard listed below contains provision which

through reference in this text, constitutes provision

of this standard. At the time of publication, the edition

indicated was valid. All standards are subject to

revision and parties to agreements based on this

standard are encouraged to investigate the

possibility of applying the most recent editions of

the standard indicated below:

4 TEST SPECIMENS AND CONDITIONING

4.1 Test specimens shall be made from samples

selected in accordance with 3 and shall be in the

form of cylinders. They shall be drilled from the

samples. The diameter of the test specimen shall be

not less than 50 mm and the ratio of diameter to

height shall be 1:2.

IS No.

Title

IS 9179 : 1979 Method for preparation of rock

specimen for laboratory testing

4.2 The specimen shall be prepared in accordance

with IS 9179.

4.3 Five test specimens shall be used for conducting

the test in each of the conditions mentioned in 4.3.1

and 4.3.2.

3 SELECTION OF SAMPLES

3.1 The sample shall be selected to represent a true

average of the type or grade of stone under

consideration.

4.3.1 The test specimens shall be saturated by

vacuum saturation by immersing in water maintained

at 20 C to 30 C in an evacuation vessel under a

vacuum of about 50 mm of Hg to 100 mm of Hg.

Specimens shall be initially immersed continuously

for about 4 h to 5 h in vacuum and then its mass is

measured at an interval of 1 h (sample being replaced

back in evacuation vessel after weighing) till constant

mass. Constant mass is considered to have been

achieved when two consecutive hourly measurement

of mass do not vary by more than 0.1 percent of the

saturated mass. Vacuum may be created by a suitable

air suction pump.

3.2 The sample shall be selected from the quarried

stone or taken from the natural rock, as described

in 3.2.1 and 3.2.2 and shall be of adequate size to

permit the preparation of the requisite number of test

specimens.

3.2.1 Stones from Ledges or Quarries

The ledge or quarry face of the stone shall be

inspected to determine any variation in different

strata. Differences in colour, texture and structure

shall be observed. Separate samples of stone of

adequate size of the unweathered specimens shall

be obtained from all strata that appear to vary in

colour, texture and structure. Specimens that have

been damaged by blasting, driving wedges, heating,

etc, shall not be included in the sample.

4.3.2 The test specimens shall also be tested in a

dry condition and shall be dried in an oven at 70

5 C for 48 h and cooled in a desiccator to room

temperature (20 C to 30 C) to constant mass.

Constant mass is considered to have been achieved

when two consecutive hourly measurement of mass

do not vary by more than 0.1 percent.

3.2.2 Field Stone and Boulders

A detailed inspection of the stone and boulders over

the area shall be made where the supply is to be

obtained. The different kinds of stones and their

conditions at various quarry sites shall be recorded.

5 APPARATUS

A testing machine of sufficient capacity for the tests

and capable of applying load at the specified rate

1

IS 1121 (Part 3) : 2012

shall be used. The machine shall be equipped with

two steel bearing plates not less than 10 mm thick

with hardened faces. One of the plates (preferably

the one that normally bears on the upper surface of

the test specimens) shall be fitted with a ball seating

in the form of a portion of a sphere, the centre of

which coincides with the central point of the face of

the plate. The other compression plate shall be plain

rigid bearing block. The bearing faces of both plates

shall be of width greater than 25 mm and the length

at least equal to the length of the test specimen. The

bearing surface of the plates when new, shall not

depart from a plane by more than 0.012 5 mm at any

point. The movable portion of spherically seated

compression plate shall be held on the spherical seat,

but the design shall be such that it is possible to

rotate the bearing face freely and tilt it through small

angles in any direction.

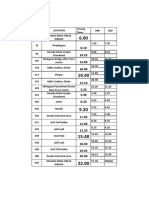

7.1 The split tensile strength of the specimen shall

be calculated as follows:

S=

2W

dL

where

S

W

d

L

=

=

=

=

split tensile strength in N/mm 2,

applied load in N at which specimen splits,

diameter of specimen in mm, and

length of specimen in mm.

7.2 The average of all the five results separately for

each condition shall be taken as the split tensile

strength of the sample.

7.3 The average of the five results in each condition

separately (see 4.3) shall be taken for purposes of

reporting the tensile strength of the sample provided

the individual variation is not more than 15 percent

of the average. Otherwise repeat tests shall be made.

6 PROCEDURE

6.1 Each test specimen to be tested is sandwiched in

between two steel plates of width 25 mm, thickness

10 mm and length equal to the length of test specimen

(see Fig. 1). The load shall be applied without shock

and increased continuously at a uniform rate of

200 N/s until the specimen splits and no greater load

is sustained. The maximum load applied to the

specimen shall be recorded in Newton with one

percent accuracy.

7.4 The split tensile strength of the sample shall be

expressed in N/mm2.

7.5 Identification of the sample, date when the

sample was taken and type of the stone shall be

reported.

7.6 The size and shape of test specimen used in the

tests shall be indicated.

7 EVALUATION AND REPORT OF TEST

RESULTS

All dimensions in millimetres.

FIG. 1 GENERAL ARRANGEMENT FOR TESTING TENSILE STRENGTH OF BUILDING STONE

2

IS 1121 (Part 3) : 2012

ANNEX A

(Foreword)

COMMITTEE COMPOSITION

Stones Sectional Committee, CED 6

Organization

Representative(s)

In personal capacity (C-3/3188, Vasant Kunj, New Delhi)

DR A. K. D HAWAN (Chairman)

A.P. Engineering Research Laboratories, Hyderabad

DIRECTOR

J OINT D IRECTOR (Alternate)

Associated Stones Industries (Kotah) Limited, Mumbai

SHRI S. C. A GARWAL

Builders Association of India, Mumbai

SHRI LAL CHAND RALHAN

SHRI RAM A VTAR (Alternate)

Building Materials and Technology Promotion Council, New Delhi

DR SHAILESH KUMAR AGRAWAL

SHRI J. K. P RASAD (Alternate)

Central Building Research Institute (CSIR), Roorkee

DR (S MT) R AJNI LAKHANI

DR ACHAL K UMAR M ITTAL (Alternate)

Central Public Works Department, New Delhi

CHIEF ARCHITECT (NDR)

SENIOR ARCHITECT- IV (Alternate)

Central Road Research Institute (CSIR), New Delhi

HEAD (PAVEMENT EVALUATION D IVISION)

SHRI K. S ITARAMANANJEYULU (Alternate)

Central Soil and Materials Research Station, New Delhi

SHRI MURARI RATNAM

SHRI H ASAN ABDULLAH (Alternate)

Centre for Development of Stones, Jaipur

SHRI KULVEER S INGH

Directorate General Border Roads, New Delhi

SHRI B. S. P ANDEY

Directorate of Geology & Mining, Lucknow

REPRESENTATIVE

Directorate of Mines and Geology, Udaipur

S HRI O. P. J AIN

SHRI N. S. B OHRA (Alternate)

Gem Granites, Chennai

SHRI SHIV SHANKAR

SHRI RAJIV B AHADUR (Alternate)

Geological Survey of India, Kolkata

S HRI G. S. M URTHY

DR G. M. R AO (Alternate)

Gujarat Engineering Research Institute, Vadodara

S HRI L. V. ASHARA

SHRI S. H. M AKWANA (Alternate)

Indian Bureau of Mines, Nagpur

REPRESENTATIVE

Indian Institute of Technology, Chennai

DR MANU S ANTHANAM

PROF M. S. M ATHEWS (Alternate)

Military Engineer Services, Engineer-in-Chief'ss Branch,

Army Headquarters, New Delhi

M S MALA M OHAN

S HRI J AGDEV THAKUR (Alternate)

National Council for Cement and Building Materials, Ballabgarh

DR V. P. CHATTERJEE

SHRI N. K. SHARMA (Alternate)

Public Works Department, Government of National Capital

Territory of Delhi, Delhi

CHIEF ENGINEER (BPZ B-1)

SHRI A JAY G UPTA (Alternate)

Public Works Department, Government of Rajasthan, Jaipur

SHRI CHIRANJI LAL

SHRI G. C. P ANWR (Alternate)

Public Works Department, Government of Tamil Nadu, Chennai

SUPERINTENDING ENGINEER

EXECUTIVE ENGINEER (G ENERAL) (Alternate)

School of Planning and Architecture, New Delhi

P ROF S. K. K HANNA

SHRI S HUVOJIT S ARKAR (Alternate)

Shriram Institute of Industrial Research, Delhi

DR LAXMI RAWAT

SHRI R. K. SINGH (Alternate)

IS 1121 (Part 3) : 2012

Organization

Representative(s)

Stone Technology Centre, Jaipur

SHRI K. V IKRAM

S HRI V IKRANT V. RASTOGI (Alternate)

Stone Technology Foundation, Jaipur

SHRI JAYESH V. RASTOGI

Svil Mines Ltd, Floriana Group, New Delhi

SHRI SANJAY J AIN

S HRI M ANMOHAN G ARG (Alternate)

Tamilnadu Minerals Limited, Chennai

SHRI K. SUMANTH BABU

S HRI S. VISWANATHAN (Alternate)

The Indian Institute of Architects, Mumbai

SHRI D IVYA K USH

S HRI A JAY P URI (Alternate)

BIS Directorate General

SHRI A. K. S AINI , Scientist F & Head (Civ Engg)

[Representing Director General (Ex-officio)]

Member Secretaries

SHRI SANJAY P ANT

Scientist E & Director (Civ Engg), BIS

SHRI S. ARUN K UMAR

Scientist C (Civ Engg), BIS

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious

development of the activities of standardization, marking and quality certification of goods and attending to

connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form without

the prior permission in writing of BIS. This does not preclude the free use, in course of implementing the standard,

of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be

addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

BIS Catalogue and Standards: Monthly Additions.

This Indian Standard has been developed from Doc No.: CED 6 (7720).

Amendments Issued Since Publication

______________________________________________________________________________________

Amendment No.

Date of Issue

Text Affected

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones: 2323 0131, 2323 3375, 2323 9402

Website: www.bis.org.in

Regional Offices:

Telephones

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

7617

{ 2323

2323 3841

Eastern

: 1/14, C.I.T. Scheme VII M, V.I.P. Road, Kankurgachi

KOLKATA 700054

Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

8499, 2337 8561

{2337

2337 8626, 2337 9120

3843

{ 260

260 9285

1216, 2254 1442

{2254

2254 2519, 2254 2315

2832 9295, 2832 7858

{2832

7891, 2832 7892

Branches : AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. DEHRADUN.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW.

NAGPUR. PARWANOO. PATNA. PUNE. RAJKOT. THIRUVANATHAPURAM. VISAKHAPATNAM.

Published by BIS, New Delhi

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Journey To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileDocument14 pagesJourney To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileSungwon Kang100% (2)

- Manage a micro business with BSB30315Document3 pagesManage a micro business with BSB30315Theo A W JacksonPas encore d'évaluation

- Bike Fit Measurement Instructions ManualDocument10 pagesBike Fit Measurement Instructions ManualVenugopalan ManaladikalamPas encore d'évaluation

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (1)

- Electrical SyllabusDocument1 pageElectrical SyllabusUmesh GuptaPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Central Cooperative Leaflet (Products)Document2 pagesCentral Cooperative Leaflet (Products)Venugopalan ManaladikalamPas encore d'évaluation

- Curriculum-Bicycle and Tricycle RepairDocument36 pagesCurriculum-Bicycle and Tricycle RepairVenugopalan ManaladikalamPas encore d'évaluation

- 73 2013 PDFDocument8 pages73 2013 PDFSoundar PachiappanPas encore d'évaluation

- Kerala Tourism To Tap Culinary Skills of Women To Enliven Stay of Visitors20190711110741 1Document2 pagesKerala Tourism To Tap Culinary Skills of Women To Enliven Stay of Visitors20190711110741 1Venugopalan ManaladikalamPas encore d'évaluation

- Notice Violence Against Women DWCDODocument2 pagesNotice Violence Against Women DWCDOVenugopalan ManaladikalamPas encore d'évaluation

- FORT PEDALLERS O Cial Jersey: at 6.45 AmDocument1 pageFORT PEDALLERS O Cial Jersey: at 6.45 AmVenugopalan ManaladikalamPas encore d'évaluation

- Electrical SyllabusDocument1 pageElectrical SyllabusUmesh GuptaPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument6 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- RH StudyGuide V2Document32 pagesRH StudyGuide V2NamraPas encore d'évaluation

- You and Your Bike Details For Sizing CalculationsDocument3 pagesYou and Your Bike Details For Sizing CalculationsVenugopalan ManaladikalamPas encore d'évaluation

- Is 229 1993 PDFDocument15 pagesIs 229 1993 PDFVenugopalan ManaladikalamPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Is 11000 1 3 1993Document11 pagesIs 11000 1 3 1993Venugopalan ManaladikalamPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Is 11000 2 1 2008Document17 pagesIs 11000 2 1 2008Venugopalan ManaladikalamPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- Is 11000 1 3 1993Document11 pagesIs 11000 1 3 1993Venugopalan ManaladikalamPas encore d'évaluation

- BS 5486-13Document24 pagesBS 5486-13Venugopalan Manaladikalam0% (1)

- Iso 3874 1997Document87 pagesIso 3874 1997ferruxo69Pas encore d'évaluation

- BRM Time 600Document1 pageBRM Time 600Venugopalan ManaladikalamPas encore d'évaluation

- Nutrition and Cycling PerformanceDocument20 pagesNutrition and Cycling PerformanceVenugopalan ManaladikalamPas encore d'évaluation

- Rear View Mirror Specification for L Category VehiclesDocument18 pagesRear View Mirror Specification for L Category VehiclesVenugopalan ManaladikalamPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationVenugopalan ManaladikalamPas encore d'évaluation

- Arai in Ais 117 2011 PDFDocument9 pagesArai in Ais 117 2011 PDFMarco CruzPas encore d'évaluation

- PremiumpaymentReceipt 10663358Document1 pagePremiumpaymentReceipt 10663358Kartheek ChandraPas encore d'évaluation

- Lambika YogaDocument2 pagesLambika Yogavsyamkumar100% (3)

- The Four Principles of SustainabilityDocument4 pagesThe Four Principles of SustainabilityNeals QuennevillePas encore d'évaluation

- Release emotions with simple questionsDocument10 pagesRelease emotions with simple questionsDubravko ThorPas encore d'évaluation

- Captive Screws - Cap Head: Hex. SocketDocument5 pagesCaptive Screws - Cap Head: Hex. SocketvikeshmPas encore d'évaluation

- 2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409Document16 pages2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409AnisahPas encore d'évaluation

- 68rfe IntroductionDocument71 pages68rfe IntroductionThePokeOne83% (6)

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhPas encore d'évaluation

- PPPoE Packet Format - HCNADocument6 pagesPPPoE Packet Format - HCNARobert Sanchez OchochoquePas encore d'évaluation

- Henderson PresentationDocument17 pagesHenderson Presentationapi-577539297Pas encore d'évaluation

- Messier 88Document3 pagesMessier 88Matheus RochaPas encore d'évaluation

- Implementing a JITD system to reduce bullwhip effect and inventory costsDocument7 pagesImplementing a JITD system to reduce bullwhip effect and inventory costsRaman GuptaPas encore d'évaluation

- Xbox Accessories en ZH Ja Ko - CN Si TW HK JP KoDocument64 pagesXbox Accessories en ZH Ja Ko - CN Si TW HK JP KoM RyuPas encore d'évaluation

- Ti 1000 0200 - enDocument2 pagesTi 1000 0200 - enJamil AhmedPas encore d'évaluation

- Cbydp Draft SK BaracbacDocument13 pagesCbydp Draft SK BaracbacLikey PromisePas encore d'évaluation

- Hazop Recommendation Checked by FlowserveDocument2 pagesHazop Recommendation Checked by FlowserveKareem RasmyPas encore d'évaluation

- ExportDocument18 pagesExportDolon MukherjeePas encore d'évaluation

- Vijay Solvex PROJECT "Retention Strategy"Document110 pagesVijay Solvex PROJECT "Retention Strategy"Jayesh SinghPas encore d'évaluation

- Theravada BuddhismDocument21 pagesTheravada BuddhismClarence John G. BelzaPas encore d'évaluation

- GDcorrespondencecourselessons 165Document8 pagesGDcorrespondencecourselessons 165olly rathbonePas encore d'évaluation

- 3.5 Lonaphala S A3.99 PiyaDocument9 pages3.5 Lonaphala S A3.99 PiyaPiya_TanPas encore d'évaluation

- No-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Document20 pagesNo-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Chelsea Green PublishingPas encore d'évaluation

- Latihan Soal Recount Text HotsDocument3 pagesLatihan Soal Recount Text HotsDevinta ArdyPas encore d'évaluation

- Pure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchDocument27 pagesPure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchhelenPas encore d'évaluation

- Application of Carbon-Polymer Based Composite Electrodes For Microbial Fuel CellsDocument26 pagesApplication of Carbon-Polymer Based Composite Electrodes For Microbial Fuel Cellsavinash jPas encore d'évaluation

- Lesson Plan 160205 Jelly Snake PracticalDocument7 pagesLesson Plan 160205 Jelly Snake Practicalapi-309206763Pas encore d'évaluation

- Linked ListDocument83 pagesLinked Listshahida18Pas encore d'évaluation