Académique Documents

Professionnel Documents

Culture Documents

Equipment and Machinery Department PDF

Transféré par

RaghDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Equipment and Machinery Department PDF

Transféré par

RaghDroits d'auteur :

Formats disponibles

Page 91 of 462

3.0

EQUIPMENT & MACHINERY DEPARTMENT

Introduction

The department of APS that attends to engineering of equipment and

machines is divided in two sections: the first on deals with static

equipment, the second one deals with dynamic machines.

Static Equipment

3.1

Vessels

The design and fabrication of the vessels of different size, shape and

type, required in process plants, represent a complex task that needs,

in an engineering company, the participation of the process engineer,

the project engineer, the mechanical engineer and of course the

manufacturer.

A vessel is mainly constituted by a container holding a fluid (liquid or

gaseous) having pressure greater or lower than the ambient pressure,

with a temperature usually different from the ambient one.

More in detail, the container is constituted by a shell, usually of

cylindrical shape and by the heads which can be of different shapes.

Bending rolls are used to form the cylinder. The shell can be carried out

by bending rolls pieces of different diameter.

The bending rolls are usually fabricated starting from plates which are

calendared, in order to obtain the cylindrical shape, and then

longitudinally welded. Shielded arc welding is maybe the most common

method used in vessel fabrication.

STP-011/13

Acetylene gas welding is common, especially for welding thin plates and

small attachments.

Welding of vessels usually requires the application of several layers of

weld material. It is necessary that great care shall be exercised in

making such multipass welds and it shall be care of the engineering

companys inspectors to ascertain, among the other things, the proper

application of the welding procedures.

Plates for the fabrication of vessels are usually ordered by thickness.

Plates made by a sheared-plate mill are preferred because they are of

better quality ad are available in a greater number of size.

Page 92 of 462

The shell plates are carried out in a wide variety of thickness; lengths

up to 800 inches are produced in the thinner plates. If both the

circumference and length of a shell are greater than 195 inches, it

becomes necessary to employ two or more plates.

Ideally the spherical-shaped pressure vessel should be the more

suitable since it withstands higher pressures for a given metal

thickness, but this solution is very expensive and it is used only in

particular cases (spherical vessels are used in the storage of volatile

liquids and gases, but they are not suitable for the construction of the

usual process vessels). The cylindrical-shaped vessel is the next best

design and it is used most extensively.

STP-011/13

The heads generally have a rounded shape, obtained from plates by

means of forging. The heads for such vessel may be flat, ellipsoidal

(elliptical dished), dished, hemispherical or conical. Examples of such

design are given in the following figure.

Page 93 of 462

The most used curvilinear bottom is the elliptic one with the semi axes

with a 1/2 rate.

All kind of bottoms have a reinforced collar so that the welding to the

shell is displaced compared to the tangent line; the height of the

reinforced collar changes following the used norms. The presence of the

reinforced collar avoid that the welding could be located in a strongly

stressed area.

All pressure vessels require nozzles for the entering and leaving fluids,

for drains, vents and manholes. These nozzles can be fabricated by

means of pipe, pipe couplings, forged steel nozzles, cast steel, fabricated

plates, or other suitable material in accordance with the codes

requirements.

The use of threaded connections is generally avoided.

Cutting of holes into the shell of the vessel for the installation on

nozzles weakens the vessel; therefore reinforcement around the nozzle

has to be provided. Forged steel welding collar of lengths sufficient to

protrude beyond vessel insulation, if any, are mass-produced by the

manufacturers. The lengths of such nozzles have been standardized so

that the vessel designer has, at his availability, various lengths

according to the exigencies.

Welding type nozzles are also available on the market.

STP-011/13

Connections for small drains and vents of one inch size and under are

usually made with pipe couplings.

Page 94 of 462

3.1.1 Vessels Internals

Many process vessels require certain internal elements to effect

modification in the fluids passing through the vessel. They include:

Agitators, to homogenize the fluid

Baffles to deviate the fluids

Distributors to convey the fluids into a certain area of the vessel

Demisters to separate from gas the water little drops

Grids, fixed on support rings, to contain catalyst and inhibitors,

rashig rings and other packing

Bubble trays, used in the distillation towers, including, among

the other accessories, downcomer clamping bars, adjustable

weirs, removable cup and riser assembly

Bubble trays are a typical example of vessel internals which are

purchased by manufacturer specialised in the fabrication of these

items, while the vessel supplier provides the trays supports.

3.1.2 External accessories

External appurtenances are usually required. The main ones, are:

Angles for the support of insulation

Lugs and brackets to support platforms and ladders

Skirt to support vessels and towers

Nameplate in which the main data of the vessels are indicated

STP-011/13

These items are supplied by the vessel manufacturer and welded to the

vessels before shipping.

Page 95 of 462

3.1.3 Calculation Formulas

According to the various codes there are various theoretical formulas

used for the calculation of the thickness of shell and of the heads.

The API ASME formula for the shell is the following:

s =

P Ri / (100 S Z 0,60 P)

+c

Where:

P = design pressure in Kg/cm2

Ri = internal radius in mm

S = allowable working stress in Kg/mm2

Z = efficiency of longitudinal joints

c = corrosion allowance in mm

s = thickness in mm

for the elliptical heads, the formula is:

s =

P Di / (200 S Z 0,20 P) + c

3.1.4 Wind Action

The wind action is calculated as a distributed charge that produces a

flexion to the equipment. This force exercised by the wind is

proportional to the exposed section and to the velocity square.

STP-011/13

Obviously, the wind action changes depending on the vessels

characteristic; more the vessel is high and thin, more dangerous will be

the wind action.

The solicitations are calculated following the construction criteria

considering the equipment as a console table embedded to the base,

and taking into account the combination, and wind concomitance,

vessel weight, radial solicitations and vertical derived from pressures.

Page 96 of 462

3.1.5 Data Sheets

STP-011/13

An example of vessel data sheet is given here below.

STP-011/13

Page 97 of 462

Page 98 of 462

3.2

Heat Exchangers

All the industrial plants require the supply or the removal of heat.

Therefore careful design and application of heat exchanger has to be

given in the plant design.

The design of heat exchangers is seldom job of the process engineer of

the project engineer and of the mechanical specialist: these three people

have to work in strictly connection in order to supply to the exchanger

manufacturer all the technical data, all the specifications, all the

required exigencies to get final equipment in accordance with all

presented requirements.

Many different types of heat exchangers are manufactured.

Specials designs can always be devised, which may be advantageous for

a particular application. It is, however, preferable to use standard

design or so-called stocks items wherever possible. Exchange

manufacturers are able to produce certain exchanger types and sizes on

an assembly-line production basis. Any deviation, of consequence, from

these stock designs will require special operations and, therefore,

increases in cost.

3.2.1 Double - Pipe Heat Exchanger

As the name implies, the double-pipe heat exchanger consists of two

concentric pipes. One fluid flows in the internal pipe and the other in

the annulus between the inside and outside pipes.

Such exchangers are most conveniently arranged in the form of

hairpins.

STP-011/13

The usual practical length of these hairpins is about twenty ft. Such

exchangers are very easily made in practically any shop and continue to

prove useful where very small surface requirements exist (approximately

100 sq ft).

Page 99 of 462

3.2.2 Double Pipe Extended Surface Exchanger

One of the advantages of the double pipe exchanger is its low cost.

A desire to benefit from this low cost and at the same time to have the

advantages of larger surfaces prompted the development of the

extended surface tube.

Typical example of this exchanger is shown below.

Transverse fins are employed principally for cross-flow arrangements in

either extended surface tube-and-shell exchangers or in air-cooled

exchangers which are growing more popular in areas where water

scarcity is a problem.

Use of fin tubes is particularly desiderable for gases, viscous liquids, or

steams of small flow rate. Such fluids produce high resistances to heat

flow, which are partially overcome by the larger effective area

introduced by the fins.

STP-011/13

For surface requirements below 1.000 sq ft the use of extended surface

double-pipe exchangers often effects a considerable saving. Particular

consideration should be given to such units for surfaces below 500 sq

ft. The double-pipe sections can be arranged in the rows and connected

in series.

Page 100 of 462

3.2.3 Shell and Tube Heat Exchanger

The most widely employed type of heat exchanger is the so called shell

and tube.

When the exchange surface has to be enlarged for process reasons, the

double-pipe exchangers could require excessive installation area; on the

contrary the shell and tube design, provides an extended heat

exchanger per unit volume of the occupied space.

Even if this type of heat exchanger differs in some details, there are

many standard shell and tube exchangers on the industrial market.

3.2.3.1 Counterflow 1-1 exchangers

A counterflow exchanger type, where one fluid flows in a apposite

direction from the other fluid, provides the most efficient exchanger of

heat.

The so called 1-1 exchanger consists of one shell pass and one tube

pass.

STP-011/13

The 1-1 counterflow exchanger is used when the friction leakages,

tubeside, must be kept to a minimum value and when the requests of

temperature are such that real countercurrent flows have to be

successfully used.

Page 101 of 462

3.2.3.2 Counterflow 1-2 and 2-4 exchangers

The 1-2 exchangers, presents an arrangement of one shell pass and two

or more tube passes.

This type is the most common of all shell and tube exchangers.

STP-011/13

The exchanger 2-4, two shell passes and four tube passes, is based on a

configuration as shown in the figure.

Instead of 2-4 exchangers, we can use 1-2 exchangers connected in

series, so avoiding the installation of the longitudinal baffle, necessary

to separate such two shell passes, the design of which is rather

complex; also the maintenance is facilitated using an exchanger in

series instead of 2-4 exchanger that has to be used in any case for clean

fluids.

Page 102 of 462

Classification and nomenclature of shell and tube exchangers

From the figures of various shell and tube exchangers previously

shown, we can note that the main components of this equipment are:

The shell

The tube bundle

The buffles

The rear read of the shell

The distributors

The exchangers of shell and tube type are of three types:

Floating head

Fixed tubesheet

Tubes, U type

Floating Head

This type of shell and tube heat exchanger is suitable for all the

services. The distributing box consists in a spherical cap bolted to the

tubesheet. The assembly of the cup and of the tubesheet can float since

they are free to move inside the exchanger.

STP-011/13

Floating Head Exchanger

Fixed Tubesheet Exchanger

Page 103 of 462

Fixed Tubesheet

Both tubesheets are welded to the shell.

In case of notable dilation, a dilation joint has to be provided to absorb

it.

U, tubes

This type of exchanger is used when the fluid, tube side, is not fouling,

it is more simple and economic.

U, Tubes

STP-011/13

The TEMA codes individualize the exchangers by means of three letters,

the first points out the distributor, the second one the shell type, the

third one indicates if we have U tubes or floating/fixed head.

AES

Page 104 of 462

A = removable channel and cover

E = one pass shell

S = floating head

BKU

B = bonnet integral cover

K = kettle reboiler

U = U, bundle

BEM

B = bonnet integral cover

E = one pass shell

M = fixed tubesheet head

BFT

B = bonnet integral cover

F = two pass shell

STP-011/13

T = full through float head

Page 105 of 462

3.2.4 Heat Exchanger Design

The thermal calculation to determine the exchange surface is based on

the following equation:

Q = S U Tm

S = Q / U Tm

Where

Q = heat transferred

S = required real surface based in the outside surface area of the tubes

t = indicates temperature difference between the hot fluid and the cold

one

U = global coefficient of heat transfer

Now we will see the calculation of the temperature medium difference

between two fluids with variable temperature.

We suppose that the two fluids are moving in counterflow.

T1

t2

T2

STP-011/13

t1

Page 106 of 462

If we put in the formula Q = S U T

Ta = T1 t2 the resulting surface

S = Q / U T a

should be smaller than the one obtained using Tb = T2 t1; it is clear

that in the first case the exchanger should be under sized, due to the

fact that in each section of the equipment, the temperature difference is

lower than the one used in the surface calculation and therefore the

required performances could not be reached; in the second case, on the

contrary, the exchanger should result oversized, with the increasing of

costs.

So we have to assume a medium value; man can demonstrate that this

medium value is supplied from the logarithmic average of the

temperature difference.

LMTD = T a - T b / ln (Ta : T b)

Example:

T a = 60 C,

T b = 25 C

LMTD = 60 -25 /ln (60 : 25) = 39,98 C

This formula is valid only for the cases that the fluids are moving in

equi flow and counter flow, in a double pipe exchanger; in a shell and

tube exchanger the conditions are different in fact while a fluid passes

in the shell only one time, the second fluid passes in the tubes at least

two times. The problem is solved making use of a corrective coefficient

Ft that depends from two factors:

R = T1- T2 / t2 t1

STP-011/13

P = t2 t1/T2 - t1

Page 107 of 462

Where

t1 = temperature at the tubes inlet

t2 = temperature at the tubes outlet

T1 = temperature at shell inlet

T2 = temperature at shell outlet

The LMTD correction factors given by specific diagrams:

STP-011/13

The design global coefficient of heat transfer based on outside surface

area, U, is given by the formula:

U = 1/S:hiSi + rfi S:Si + St:SmK + rfo + 1:ho

Page 108 of 462

Where

S = outside surface area of tube

hi = inside coefficient

Si = inside surface area of tube

rfi = inside fouling factor

t = thickness of tube

Sm = surfaces average between S and Si

K = conductivity of tube

rfo = outside fouling factor

ho = outside film coefficient

Apart the calculation programs, the global coefficient of heat transfer

can be given, in the first approximation from the following figures:

Hydrocarbon liq. Hydrocarbon liq.

150-500 Kcal/hm2 C

Hydrocarbon liq. Water.

250-500 Kcal/hm2 C

Water Water

500-1000 Kcal/hm2 C

Hydrocarbon vap. Hydrocarbon vap.

100-200 Kcal/hm2 C

Hydrocarbon vap. Water

200-350 Kcal/hm2 C

Gas Gas

200 300 Kcal/hm2 C

STP-011/13

Without change of state

Condenser

NH3 Vap. water

500 -600 Kcal/hm2 C

Hydrocarbon vap. Hydrocarbon liq.

250 -350 Kcal/hm2 C

Hydrocarbon vap. Water

350 -600 Kcal/hm2 C

Gas Water

400 -500 Kcal/hm2 C

Page 109 of 462

Dynamic Machines

3.3

Pumps

All the industrial plants, would be inoperative were it not for the pumps

which maintain the steady fluids flow trough the plant operation and

activities.

Very different types and sizes of pumps are installed in an industrial

plant, depending by the requirements (head and flowrate) of the process

fluids they will treat.

An unfit, or quite wrong, selection of the pumps could cause serious

problems during the plant operation.

Therefore the process engineer, the project engineer and the mechanical

engineer, the specialist of the rotating machine, have to strictly

cooperate in order to supply to the pump manufacturer all the data, all

the information, all the specifications, which allow them the selection of

the size and type, among the ones of their standard production, which

most nearly fits the service in question. It is also very important that,

before placing the order, the manufacturers recommendations are

properly considered.

STP-011/13

Basing a first classification of the pumps on the physical principles

their working is based on, we can consider:

Centrifugal pumps;

Volumetric pumps, that includes reciprocating and screw pumps.

Page 110 of 462

3.3.1 Centrifugal Pumps

The centrifugal pumps are the most employed because of their

adaptability to operative conditions as well as for their relative

constructive simplicity and for the lack of pulsations in the flux.

Deferring from the others, the centrifugal pumps can be employed both

for big and very big flow rates.

From a service point of view, centrifugal pumps can be divided in:

Process Pumps

These pumps handle process liquids of Refinery: as hydrocarbons,

chemical compounds, solutions of compounds. The process pumps have

to be usually designed in accordance with API 610 codes; these are

particularly strict codes that impose hard construction with relevant

increasing of the costs.

General Service Pumps

These pumps are employed and designed for services which do not

require the special alloys and mechanical design features needed by

high temperature or corrosive conditions.

They treat mainly water of different type as drinking waters, river

waters, dirty waters and demineralised waters.

STP-011/13

Chemical Pumps

These pumps treat the process fluids of chemical end petrochemical

plants; pumps in this category are constructed of corrosion resistant

materials, such as alloy steels, rubber-lined steel, but even plastic and

glass.

Page 111 of 462

3.3.2 Characteristics of a Centrifugal Pump

A centrifugal pump working is based on increased static fluid pressure.

This action is based on the Bernoulli's principle.

The rotation of the pump impeller (produced by an electric motor or

turbine) provides kinetic energy to the fluid as it is drawn in, from the

impeller eye (centre) to the periphery, being forced outward the impeller

vanes.

As the fluid exits the impeller with increased speed, it passes through a

volute or a diffuser: these are two possible arrangements in the design

of the centrifugal pumps.

In both arrangements, the flow passes through an increasing area that

slows it causing the conversion of kinetic energy in potential pressure

energy.

This conversion results in an increased pressure of the fluid

downstream the pump.

It is important to fix that the centrifugal pump supplies a head to the

fluid, and not a pressure. This head, measured in meters of water

column, does not depend by the fluid; the final pressure depends by the

specific gravity of the treated fluid and they are connected by the

following:

p =

Where:

p is the differential pressure between suction and

discharge;

is the specific gravity;

H

is the Head.

STP-011/13

The effective energy the pump gives to the fluid depends by the flowrate,

the head and the specific gravity of the fluid:

Ph = Q g

This is the Hydraulic Power.

Page 112 of 462

The power needed by the pump to supply the hydraulic power to the

fluid is the Pump Shaft Power: it takes into account all the losses due to

friction, leakages an warming up of the fluid, resumed in the efficiency

[] of the pump. It can be obtained dividing the hydraulic power by the

efficiency:

Psp = (Q g) /

This power term is used to choose the nominal power of the driver; it

shall be higher than the Psp.

A safety increase is adopted, according to API requirements (+10%,

+15% or +25%, depending by the value of required power).

E.g.: if

[Q]=mc/h; head expressed as p (= H) in kPa, and to

obtain the power in kW, the formula is:

Psp =

Q p 1,0197

27 1,36 100

Differently, if [Q]=mc/s and [H]=m, with []=kg/mc the power in kW

shall be:

Psp =

Q H

101,97

STP-011/13

The head a centrifugal pump can supply to the fluid is higher as the

impeller diameter increases. On the same pump, the impeller can have

a diameter variable between a minimum and a maximum value.

Due to high head requirements, that would lead to increase too much

the diameter of the impeller (and consequently the exit speed of the

fluid, with less efficiency), it is preferred to use two or more impellers

(and volutes/diffusers): these are the so-called multistages centrifugal

pumps. The head enhancement is equally divided between the stages

that treat the same flowrate, in series.

Page 113 of 462

For high flowrates requirements, or when the flowrate vary greatly, 2 or

more pumps can be arranged for parallel operation. The flowrate is

equally divided between the pumps, each of them gives the same head

to the treated part of fluid.

NPHS of a pump

The acronym NPSH means net positive suction head, but apart from

the definition that let always engineering students perplexed, we try

now to catch the essence.

The NPHS of a pump practically is the resistance that pump offer to the

fluid flux; it is an intrinsic pump characteristic that only the

manufacturer can knows. This is the requested NPSH.

A more rigorous definition can be given only once we have described the

cavitation phenomena.

At the impeller inlet, the fluid is accelerated, consequently it undergoes

through a local pressure decrease: if the pressure goes under the

vapour pressure value (proper of the fluid and varying with temperature

only) the fluid starts flashing. Passing trough the impeller vanes, the

pressure rises up and the bubbles previously generated in the fluid

suddenly collapse, causing a mechanical pit on the impeller surface. If

this working condition for the pump goes on, in not too much time the

impeller of the pump will definitively break down. This phenomenon is

well known as Cavitation.

NPSH Required can be defined as the minimum fluid pressure required

at the pump suction so to avoid any risk of cavitation.

This is an intrinsic characteristic, proper of considered pump: it cannot

be calculated, but only obtained as information from the pump

manufacturer.

Different is the NPSH available.

STP-011/13

The NPSH available is a characteristic depending by the hydraulic plant

and completely independent by the pump itself. It can be calculated as

the difference between the liquid pressure at inlet flange of the pump

(Hs) and the vapour pressure of the liquid at operative temperature (Pv).

Page 114 of 462

e.g.:

Hs = Hb + H1 Hd

Hb is the hydrostatic pressure at

the top of liquid level;

H1 is the static head, measured

from the centerline of the pump

suction to the top of the liquid level:

if the level is below the centerline of

the pump it will be a negative

number.

Hd is the pressure drop in the

piping,

fittings

and

valves,

measured from the pipe inlet, to the

pump inlet flange.

NPSHa = [Hb - (H1 + Hd)] Pv = Hs

- Pv

To assure a correct operating for the centrifugal pump it is necessary

that:

STP-011/13

NPSHa > NPSHr

Page 115 of 462

Example for calculation.

Normally, an available NPSH 0, 5 m bigger than the one requested is

accepted.

The ESSO accepts also 0,3 m if the NPSH test, performed at

manufacturer workshop, has been attended by the client.

Example: water pumping from an atmospheric tank located at a lower

level than the pump one.

Example:

atmospheric pressure in loco = 9, 78 m

suction ground water level = 4 m

load loss between suction and foot valve = 0, 75 m

vapour pressure, at reference temperature = 0, 0143 m

The pump manufacturer requests NPSH equal to 3 ,5 m.

We shall therefore have:

NPHS available = 9,78 (4 + 0,75 + 0,0143) 5 m

STP-011/13

Being NPHS requested equal to 3, 5 we should not be afraid of

cavitation phenomena.

Page 116 of 462

3.3.3 Specific Speed and Suction Specific Speed

Pump Specific Speed (ns) is a dimensionless numeric value which

roughly defines the pump geometry and the shape of the pump

characteristics. It is calculated basing on the flowrate, head and

rotating speed values measured at the best efficiency point with the

maximum possible diameter impeller for given pump:

nS = n (Q)1/2 / ()3/4

As the specific speed increases, the ratio of the impeller outlet diameter

to the inlet of the eye diameter decreases. This ration becomes 1.0 for

an axial flow pump. Radial flow impellers develop head through

centrifugal force, and are characterized by low flow and high head

designs. Pump of higher specific speeds develop head partly by

centrifugal force and partly by axial force. A higher specific speed

indicates a pump design with head generation more by axial forces and

less by centrifugal forces. An axial flow or propeller pump with a specific

speed of 10,000 or greater generates its head exclusively through axial

forces. Axial flow impellers are high flow and low head designs.

STP-011/13

Specific speed (ns) identifies the approximate acceptable ratio of the

impeller eye diameter (D1) to the impeller maximum diameter (D2) in

designing an impeller:

ns = 500 to 5000

D1/D2 > 1.5

radial flow pump

ns = 5000 to 10000

D1/D2 < 1.5

mixed flow pump

ns = 10000 to 15000

D1/D2 = 1

axial flow pump

Page 117 of 462

These are the reference values when ns is calculated using US system of

measure:

n = rpm; H = ft; Q = gpm.

If SI (n = rpm; H = m; Q = m3/s) is used, result ns can be converted in

US system multiplying by 51.64.

Remark:

For double-suction pumps the Q value used in ns calculation shall be

the total flowrate divided by 2. In analogy, for multistage pumps the H

value shall be the total Head supplied divided by the number of the

pump stages.

Suction Specific Speed (nss) may be used to determine what pump

geometry - radial, mixed flow or axial - to use for maximum efficiency

and prevent cavitation.

Suction Specific Speed is commonly used as a basis for estimating the

safe operating range of a pump.

Suction Specific Speed is dimensionless and are expressed as:

nss = n (Q)1/2 / (NPSHa)3/4

where:

nss = Suction Specific Speed;

n = rpm;

STP-011/13

Q = flowrate capacity (m3/h, l/s, m3/min, US gpm, British gpm) at

Best Efficiency Point BEP;

NPSHa = available Net Positive Suction Head (m, ft).

As a rule of thumb the Specific Suction Speed should be below 8500 if

calculated with US measure system (165 if calculated with SI) to avoid

cavitation.

Page 118 of 462

As for Specific Speed, the conversion factor for the suction specific

speed is 51,64.

3.3.4 Selection of Centrifugal Pump

Task of process engineer, or project engineer or mechanical specialist,

belonging to an Engineering Company, is the one to select, and

subsequently to verify, a proper pump which satisfies the requirements

of the process and of the mechanical data sheet; the design and the

construction of the pump is task of one of the many manufacturer

Firms, operating on the market.

A centrifugal pump which operates, at a certain speed, provides for a

certain flow rate with a certain head.

STP-011/13

These parameters are linked each to other: their functional relationship

is graphically represented by the characteristic curve given by the pump

manufacturer, drawn on a coordinate axis system, where you can find

the flowrate on the X axis (abscissa) and the head on the Y axis

(ordinate). On the same coordinate system we can draw the curve

representing the resistant characteristic of the hydraulic circuit,

typically a parabolic shaped curve (remember that the hydraulic

resistance of the circuit has a quadratic relationship with the flowrate).

The pump regulates itself so to work at the equilibrium condition, that

is the intersection point between these two curves (the working point [P]

of the centrifugal pump).

Page 119 of 462

If a decrease of the hydraulic resistance downstream the pump

happens, related curve tends to be less slanting and the working point

(intersection) moves along the curve towards the growing flowrates

direction (point P1), viceversa, in case of hydraulic resistance increasing

happens, the working point moves towards decreasing flowrates

direction (point P2).

The indicated point P3, is the operating point at shut-off condition: zero

flow for closed discharge valve.

Its important to fix that on a same pumps several impellers with

different diameters can be mounted: the manufacturer shall choose the

diameter so that the working point shall be as near as possible to the

maximum reachable efficiency (BEP: Best Efficiency Point).

STP-011/13

The graph can be completed with the indication of efficiency and

absorbed power curves:

You can see that for centrifugal pumps the absorbed power curve is

continuously rising with growing flowrates: this means that we have the

minimum absorbed power at shut-off and the maximum at the end of

the curve.

Due to process requirements, there are two possible scenarios:

Page 120 of 462

pump starting with the discharge valve closed: in this case at the

start up the pump absorbs the power measured at shut-off: less

than power absorbed at the working point;

pump starting with the discharge valve open: in this case at the

start up the pump absorbs the maximum power, since the

starting point is at the end of the characteristic curve.

This means that the electric motor chosen as driver shall have a

nominal power not only major than absorbed power at working point,

but major than absorbed power at the end of the curve: otherwise driver

shall not be enough powerful to assure the start up of the pump.

3.3.5 Centrifugal Pump Characteristic Curve.

STP-011/13

Typical characteristic curves for a centrifugal pump: the design impeller

has 407,5 mm diameter, intermediate between the minimum (369,6

mm) and the maximum (425,5 mm) diameter available for the

considered pump.

Page 121 of 462

Mixed flow centrifugal pumps and axial flow or propeller pumps have

considerably different characteristics as shown in figures below.

The head curve for a mixed flow pump is steeper than for a radial flow

pump. The shut-off head is usually 150% to 200% of the design head,

the brake horsepower remains fairly constant over the flow range.

STP-011/13

For a typical axial flow pump, the head and brake horsepower both

increase drastically near shutoff as shown below

Page 122 of 462

The distinction between the above three classes is not absolute, and

there are many pumps with characteristics falling somewhere between

the three.

3.3.6 Centrifugal Pumps: Classification

STP-011/13

In following table are indicated the most important types of centrifugal

pumps, usually installed in a refinery plant and described in the

International reference most used standard (API Std. 610):

STP-011/13

Page 123 of 462

Page 124 of 462

Hereafter, you will find the schematic representation of the various

types of pumps described in the table.

OVERHUNG:

OH1 type

Foot-mounted single stage overhung

OH3 type

STP-011/13

Vertical in/line single Stage overhung (Flexible

coupling)

OH2 type

Centerline-mounted single stage overhung

OH4 type

Vertical in/line single stage overhung

(Rigid coupling)

OH5 type

OH6 type

Vertical in/line single stage overhung

High speed integral gear-driven

single stage overhung

Page 125 of 462

BETWEEN BEARINGS:

BB1 type

BB2 type

Axially split one/two-stage between bearings

Radially split one/two-stage between bearings

BB3 type

BB4 type

Axially split multistage

Single casing radially split multistage Between

bearings

Between bearings

BB5 type

STP-011/13

Double casing radially split multistage Between bearings (Barrel Pumps)

Page 126 of 462

VERTICAL:

VS1 type

VS2 type

Wet pit, vertically suspended, single-casing

diffuser with discharge through the column

Wet pit, vertically suspended, single-casing volute

with discharge through the column

VS3 type

VS4 type

STP-011/13

Wet pit, vertically suspended, single-casing axial Vertically suspended, single-casing volute line-shaft

flow with discharge through the column

driven with separate discharge

VS5 type

VS6 type

Page 127 of 462

Vertically suspended cantilever sump pumps

Double casing diffuser vertically suspended

VS7 type

Double casing volute vertically suspended

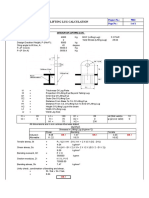

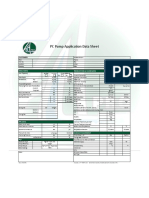

3.3.7 Example of a Mechanical Data Sheet of a Centrifugal Pump

STP-011/13

Here below is given an example of a centrifugal pump data sheet.

STP-011/13

Page 128 of 462

STP-011/13

Page 129 of 462

STP-011/13

Page 130 of 462

STP-011/13

Page 131 of 462

Page 132 of 462

3.3.8 Positive Displacement Pumps (Volumetric Pumps)

Positive displacement pumps working principle is based on the transfer

of finite volumes of fluid from the suction side to the discharge side of

the pump.

The flowrate is proportional to the pump speed (as for dynamic pumps),

while the head does not depend by the flowrate and by the pump speed,

but is highly variable, depending by the pressure in the hydraulic

circuit downstream the pump.

A Positive Displacement Pump, unlike a Centrifugal Pump, will produce

the same flow at a given rotation speed, no matter what the discharge

pressure is: as consequence it cannot be operated against a closed

discharge valve and, unlike centrifugal pumps, it does not have a shutoff referred head.

If a Positive Displacement Pump is allowed to operate against a closed

valve, placed somewhere in the circuit downstream the pump, it will

continue to produce flow which will increase the pressure in the

discharge line as long as the power of the pump driver is enough to

guarantee the pump working. This leads to the real risk of damage for

the part of circuit downstream the pump and there installed equipment,

or for the pump itself, or both.

As consequence, a relief valve shall always be installed on the discharge

side of a positive displacement pump, so to prevent such dangers.

STP-011/13

Following is a representation of typical characteristic curves for positive

displacement

Page 133 of 462

pumps.

Slippage

H

[m]

Real

Ideal

resistant characteristic

curve

rated working point

characteristic curve

Q rated

Q [mc/h]

You can see that over a certain head, the characteristic curve has a

deviation form the ideal vertical curve. This is due to the fact that, as

the discharge pressure increases for the higher resistance of external

circuit, some amount of liquid will leak from the discharge of the pump

back to the pump suction, reducing the effective flow rate of the

pump.

The rate at which liquid leaks from the pump discharge to its suction is

called slippage, and of course it implies a dramatic decrease of pump

efficiency.

STP-011/13

The positive displacement pumps can be divided in two main classes

reciprocating

rotary

Page 134 of 462

Typical application of positive displacement design are in the following

types of pump:

rotary lobe pump;

progressing cavity pump (spiral pump);

gear pump;

piston pump;

diaphragm pump;

screw pump;

vane pump;

peristaltic.

Internal gear pump

STP-011/13

Gear pump

Diaphragm pump sectional drawing

Lobe pump

Page 135 of 462

3.4

Compressors

The compressors are another very important category of machinery,

always present in an oil refinery; they are operating machines directed

to increase the pressure of gases and they are very similar to pumps:

the main and evident difference is that pumps treat liquids, while

compressors treat gases.

As for the pumps, different types of compressors are produced,

depending by the physical principles their working is based on. A first

basic classification is between:

Dynamic compressors (centrifugal and axial);

Volumetric or positive displacement compressors (reciprocating

and rotary).

Since the specific volume of a gas varies greatly with its pressure and

temperature, always the flow rate is indicated by 3 terms:

Volumetric flow rate at operating temperature;

Weight flow rate, not depending by pressure and temperature

variations;

Volumetric flow rate @ normal conditions (atmospheric pressure

and 0 C temperature).

The specific volume is linked to gas conditions (pressure and

temperature) by the following:

STP-011/13

Vsp =

Z R T

105 P

Page 136 of 462

Where: Z is the compressibility index of the gas; R is the gas constant

(=8314/gas molecular weight).

When compressed, a gas naturally increases its temperature, the final

temperature (T2) can be calculated by the formula:

n 1

2

T2 = T1

P1

Where:

temperatures are expressed in Kelvin degrees;

P2/P1 = is the compression ratio (P1 and P2 are respectively the

suction and discharge pressures);

n 1 k 1

=

p ; k is the specific heats ratio

n

k

p is the polytropic efficiency of the compression.

c

X p ;

cv

The polytrophic efficiency is unitary when the compression can be

considered as adiabatic (e.g. reciprocating compressors), otherwise, for

polytropic compression the efficiency is less than 1 (e.g. in dynamic

compressors).

Since we have a superior limit for the discharge temperature, due to

commercial design requirements, the gas temperature at the end of

compression is a very important reference value the manufacturer has

to consider during the design phase of the equipment, so to fix the

number of compression stages.

The single stage compression ratio can be calculated as nth root (for n

stages) of the total.

STP-011/13

[e.g. if = 6, and we have n = 3 stages, then 1 = 2 = 3 =

6 1,817 ].

Between two consecutive stages, the gas shall be cooled down by an

inter-stage cooler. In case the cooling would cause the production of

some condensate, it shall be necessary to separate it by a separator,

installed downstream the cooler.

Page 137 of 462

3.4.1 Dynamic Compressor: Centrifugal and Axial

As for the centrifugal pumps, the working of centrifugal compressors is

based on the Bernoulli principle: the rotation of an impeller provides

kinetic energy to the gas, and this energy is then converted into

pressure static energy in the volute.

Axial flow compressors produce a continuous flow of compressed gas,

and have the benefits of high efficiencies and large mass flow capacity,

particularly in relation to their cross-section.

However they require several rows of aerofoils to achieve large pressure

rises, making them complex and expensive. The motion of the blades

relatively to the fluid adds velocity or pressure or both to the fluid as it

passes through the rotor.

The fluid velocity is increased through the rotor, and the stator converts

kinetic energy to pressure energy.

Some diffusion also occurs in the rotor in most practical designs.

The increase in velocity of the fluid is primarily in the tangential

direction (swirl): the stator removes this angular momentum.

Axial compressor can manage larger flowrate than centrifugal

compressors, but in comparison they develop very lower head.

Typical working range in terms of flowrate (volumetric, inlet) is between

40.000 mc/h and 1 million mc/h; in terms of head, between 10 and

800 bar (as discharge pressure).

High compression ratio is available for axial compressors working as

part of a gas turbine gas generator, for other aims, typically for refinery

services; this requirement is preferable to be obtained by centrifugal

compressors that reach same performances with smaller machine.

Both centrifugal and axial compressors are subject to a physical limit

regarding the working, well known as surge phenomena: it imposes an

inferior limit to the flowrate the equipment can manage safely.

STP-011/13

As consequence, 0-100% regulation is available only by an intercooled

partial recirculation of gas flowrate that of course involves a drastic

downfall for the global efficiency of the machinery.

Page 138 of 462

Typical characteristic curves for centrifugal compressor:

CHARACTERISTIC CURVES FOR VARIOUS SPEEDS

WORKING POINT

SURGE

LIMIT

RISING

SPEED

The characteristic operating curve is fixed for a given

compressor at constant speed. Variation of the suction

pressure or system conditions will change the

differential pressure developed by the machine.

The differential pressure will increase for any condition

which causes increase suction inlet gas density.

The characteristic curve moves up due to any of

following gas characteristic variations:

1.increased suction pressure;

2.increased molecular weight;

3.lower inlet temperature;

RISING

SPEED

4.lower compressibility factor;

5.lower k [cp/cv] value.

Some process cannot fix gas composition and system

conditions exactly and it is important to recognized the

possible implications of changes in the suction

conditions on the compressor performance, so to verify

the compressor is well sized for the different possible

working conditions.

mc/h

STP-011/13

EFFICIENCY CURVES FOR VARIOUS SPEEDS

Page 139 of 462

Before examining it, we want to consider more deeply the surge

phenomena: it is primed from a lessening of flowrate, due to compressor

incorrect operating, or unstable process conditions (typical example is

the restriction at the compressor inlet or discharge).

The lower inlet volume flow rate makes the pressure head decrease as

consequence of turbulent dissipation of the velocity head of the gas

leaving the impeller.

As flow is further reduced, the pressure developed, by the compressor

tends to be lower than the pressure in the outer discharge line: this

leads to a momentary flow reversal which reduces the discharge line

pressure, and as it becomes less then the developed the flow takes

again the proper direction, with rising discharge pressure, up to a

certain point that cause a new start of the phenomena, that becomes a

repeating cycle, unless proper correction action is taken.

SURGE REGION

OPERATING

REGION

DELTA P

A

D

STP-011/13

VOLUME FLOW RATE

Pressuring, surging is an unstable working condition, with rapid flow

and discharge pressure pulsation, which produces high frequency

reversal in axial thrust of the compressor shaft, varying its intensity

from an audible rattle to a violent shock.

To avoid any risk of surging, it is important the rated working point of

the compressor is enough remote form the surge line.

Page 140 of 462

Several things can be done to prevent surge in centrifugal or axial

compressors during working:

Reducing the resistance of the outlet stream (reducing the

compression ratio);

Increasing the flow through the compressor.

Both solutions have as consequence that the working point goes away

from the surge limit, reaching a safety operating point.

Compressor Regulation

The operation of the compressor to meet or establish the desired point

on the head-capacity system curve requires a control which can be

variable speed or constant speed type.

Variable speed control

It is the most efficient method of controlling the capacity of a

compressor.

Constant speed control

STP-011/13

This system includes:

a. Inlet throttling: This is very common and simple way to vary the

capacity when using constant speed driver. The gas density at

the inlet of compressor is reduced by throttling action but this

does not alter the system after the discharge. There is an energy

loss during this operation but much less than the loss with the

throttling on discharge side of the machine. The pumping

capacity in terms of weight of flow is reduced in proportion to the

density decrease whereas the volume pumped capacity remains

the same (generally a butterfly valve is used for this service).

Page 141 of 462

b. For large machines the control is made by adjusting the

orientation of the inlet distributor.

Inlet throttling with variable inlet guide vane.

This device is the most efficiency control for constant speed

compressor.

The vanes provide inlet gas throttling and the pre-rotation of inlet

gas with the consequence of a lower surge limit.

c. Discharge throttling

The absorbed power remains constant for this type of operation.

STP-011/13

For dynamic compressors, we can define the following operating limits:

Minimum Operating Speed - the minimum speed for acceptable

operation, below this value the compressor may be controlled to

stop or go into an "Idle" condition.

Maximum Allowable Speed - the maximum operating speed for

the compressor. Beyond this value stresses may rise above

prescribed limits and rotor vibrations may increase rapidly. At

speeds above this level the equipment will likely become very

dangerous and shall be controlled to slower speeds.

Stonewall or Choke - occurs under one of following events.

Typically for high speed equipment, as flow increases, the velocity

of the gas/fluid can approach the gas/fluid's sonic speed

somewhere within the compressor stage. This location may occur

at the impeller inlet "throat" or at the vaned diffuser inlet "throat".

In most cases, it is generally not detrimental to the compressor,

but has impact on equipment efficiency. For low speed

equipment, as flows increase, losses increase too, such that the

pressure ratio drops to 1:1.

Different construction arrangements are available and used in

compressors manufacture, varying with the required characteristics (in

terms of flowrate and compression ratio) and with the gas handled.

Growing up the compression ratio, the number of stages becomes

higher, with the obvious need of interstage cooling features, and

involves different arrangements for the compressor casing (axial split for

low discharge pressure, radial split with higher values, and barrel

configuration for the highest required discharge pressures).

Page 142 of 462

The applicable operative range for centrifugal compressor is very wide:

the rated power can reach extremely high values (up to around 100

MW), and the type of driver changes, as well.

For power up to around 20 MW an electric motor still can be used (with

inverter for speed regulation and start-up), for higher values, using of

steam turbine or gas turbine as driver is preferable.

In case of electric motor drivers, it is important to consider not only the

absorbed power at rated working point, but the starting torque needed

at compressor start-up.

3.4.2 Reciprocating Compressor

Reciprocating Compressors

In the reciprocating compressors, the gas compression is consequent to

the volume decrease due to the motion of the piston inside the cylinder.

STP-011/13

The reciprocating compressor is mainly constituted of following

components:

The crankshaft inside a frame: it receives rotating motion by an

external driver;

The flywheel, placed between the driver and the crankshaft end,

that regularizes the rotating motion;

The connecting rod, that converts the shaft rotating motion in

alternative motion;

The crosshead that connects the connecting rod to the piston rod;

Distant piece, that houses the crosshead and the sliding piston

rod;

The piston, that moves inside the Cylinder of the compressor and

together with it realizes the variable volume for the gas;

The inlet and outlet valves;

Unloaders and clearance pockets (with fixed or variable volume),

are special valves that control the percent of full load carried by

the compressor at a given rotational speed of the driver.

Pulsation dampers (on suction and discharge), that mitigate the

gas pressure pulsation consequent to the fact that the

reciprocating compressor operates discrete volumes of gas.

Page 143 of 462

In a reciprocating compressor the number of cylinders is variable,

depending on the flowrates and compression ratio requirements.

The position of the cylinders can be variously arranged: vertically, in V

angle and horizontally.

Main characteristics of the reciprocating compressor is that it is a slow

speed equipment: an important data to be considered with attention is

the average piston linear speed.

Theoretically there is no superior limit to the pressure these type of

compressor can assure, and for this reason they are typically used for

extremely high pressure requirements, obtained with multistage (and

multi-cylinder), intercooled, design.

Valves

Clearance pocket

Cylinder

Distant piece

STP-011/13

Piston Rod

Piston

STP-011/13

Page 144 of 462

Page 145 of 462

3.5

Heater and Furnaces

3.5.1 General

The primary function of a fired heater is to supply all heat required by

the process stream to raise its temperature as need for the distillation,

operation, catalytic reaction, etc.

A fired heater utilizes gaseous or liquid fuels often produced as a byproduct.

Size and type of heaters vary considerably, depending upon the duty

and required service.

3.5.2 Types

There are different types of heaters: cylindrical, single or double box

with horizontal or vertical coils.

The most simple and common type is the vertical cylindrical (see fig. 1

here below), commonly used up to 40 MMkcal/h of duty.

The main parts of the furnace are:

Radiation section

This section is a vertical cylinder made by a steel plate shell, internally

lined by castable refractory. Inside this cylinder the coils are vertical,

located close to the refractory wall all around the internal perimeter.

The floor is made by steel plates, refractory lined, and supports for the

burners.

STP-011/13

The heat generated in the radiant tubes is mainly produced by direct

radiation from the heating flame.

Page 146 of 462

Convection section

This section is located on the top of the radiant and the heat is

exchanged by convection between the flue gas flowing to the stack and

the horizontal tube bundle.

The first two or three rows face directly the radiant top and the burner

flames, so may be considered as an extension of the radiant coil. This

part is called the shock zone and it is always made by bare tubes.

All the other rows of convective usually finned or studded, to increase

the heat flow.

Stack

The stack collects and discharges flue gases. It is made by steel plates

internally lined by castable refractory.

STP-011/13

A damper is installed to control the draft through the stack.

Page 147 of 462

STP-011/13

Figure 1. vertical heater with radiant section

Page 148 of 462

STP-011/13

Data and information to be supplied to the Manufacturer, to get

relevant offer, are:

Physical and the chemical properties of charge and product as:

density or API gravity, viscosity (at several temperatures), inlet

and outlet molecular weight of vapours, coking characteristics of

charge.

Operating conditions as: charge flow rate, inlet and outlet

pressure and temperature, maximum allowable pressure drop,

furnace duty (Kcal/h adsorbed).

Fuel: analysis of gas, heat content, viscosity (oil) density,

temperature.

Desired efficiency.

Vous aimerez peut-être aussi

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghPas encore d'évaluation

- Specs For Aluminum Geodesic Batten Domes 2012Document5 pagesSpecs For Aluminum Geodesic Batten Domes 2012RaghPas encore d'évaluation

- Heinkel Flyer Classifying Centrifuge v630 BK TiocentDocument2 pagesHeinkel Flyer Classifying Centrifuge v630 BK TiocentRaghPas encore d'évaluation

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghPas encore d'évaluation

- Hi-T Pigalert IOM ManualDocument14 pagesHi-T Pigalert IOM ManualRaghPas encore d'évaluation

- Hi-T Pigalert LiteratureDocument2 pagesHi-T Pigalert LiteratureRaghPas encore d'évaluation

- Centrifugal Pumps - Part 1Document156 pagesCentrifugal Pumps - Part 1Ragh100% (2)

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghPas encore d'évaluation

- SlabDocument25 pagesSlabRaghPas encore d'évaluation

- G-Slab 2way SiemensDocument20 pagesG-Slab 2way SiemensRaghPas encore d'évaluation

- Nozzle & FlangeDocument14 pagesNozzle & FlangeRaghPas encore d'évaluation

- Pipeline Lowering CalculationDocument5 pagesPipeline Lowering CalculationRagh88% (16)

- Oil & Gas HandbookDocument170 pagesOil & Gas HandbookRagh100% (10)

- Kpgi Process Presentation: Introduction To Oil and Gas With Special Mention of 9 Well Platform ProjectDocument21 pagesKpgi Process Presentation: Introduction To Oil and Gas With Special Mention of 9 Well Platform ProjectRaghPas encore d'évaluation

- Typical Systems Depiction For PIDsDocument38 pagesTypical Systems Depiction For PIDsRaghPas encore d'évaluation

- Piping PhilosophyDocument15 pagesPiping PhilosophyRagh100% (1)

- Types of Flow Measurements AND Their ApplicationsDocument44 pagesTypes of Flow Measurements AND Their ApplicationsRaghPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Membrane TypeDocument46 pagesMembrane TypeDeniPas encore d'évaluation

- AD II Unit I & II 2 Marks Q&ADocument6 pagesAD II Unit I & II 2 Marks Q&AthandialPas encore d'évaluation

- Air Products - Air Separation Plants PosterDocument1 pageAir Products - Air Separation Plants PosterVictor PomboPas encore d'évaluation

- PRO PCP Data SheetDocument1 pagePRO PCP Data SheetJude RodriguesPas encore d'évaluation

- ENT-1253 Engineering Properties of MatterDocument24 pagesENT-1253 Engineering Properties of MatterAchintha NayanajithPas encore d'évaluation

- API MPMS List PDFDocument5 pagesAPI MPMS List PDFhtutswePas encore d'évaluation

- Gas CalculationsDocument3 pagesGas CalculationsaizatPas encore d'évaluation

- Ethylene Recovery Through Dephlegmator TechnologyDocument9 pagesEthylene Recovery Through Dephlegmator TechnologyMohamed Abushrida100% (1)

- Densities Liquid-Acetone-Water Solutions Up To Their Normal Boiling PointsDocument4 pagesDensities Liquid-Acetone-Water Solutions Up To Their Normal Boiling PointsEric RodriguezPas encore d'évaluation

- Fluid Mechanics - BuoyancyDocument6 pagesFluid Mechanics - BuoyancyAbduljalil AlabidiPas encore d'évaluation

- Student Handout - Advanced Gas Tanker Training PDFDocument136 pagesStudent Handout - Advanced Gas Tanker Training PDFPrassanna Venkatesh100% (2)

- Experiment 6 (Formal Report)Document9 pagesExperiment 6 (Formal Report)Thea IbarraPas encore d'évaluation

- Advance Semiconductor DevicesDocument1 pageAdvance Semiconductor DevicesMuhammad Atiq Ur Rehman 22-FET/PHDEE/S19Pas encore d'évaluation

- GasDocument26 pagesGasJoshua PhillippsPas encore d'évaluation

- HWK 5Document1 pageHWK 5Kelly SmithPas encore d'évaluation

- Presentation of Internship ProjectDocument34 pagesPresentation of Internship ProjectReinaldo Ongky Billy AnandoPas encore d'évaluation

- Leonid SurguchevDocument12 pagesLeonid SurguchevkglorstadPas encore d'évaluation

- Advanced Solid State Physics by Philip Phillips PPDocument2 pagesAdvanced Solid State Physics by Philip Phillips PPSubhadip PalPas encore d'évaluation

- FORMATEMANUAL A5 Crystallization TemperatureDocument20 pagesFORMATEMANUAL A5 Crystallization TemperaturejcPas encore d'évaluation

- Chemistry s4 Notes - Unit 3Document9 pagesChemistry s4 Notes - Unit 3UDAHEMUKA DenisePas encore d'évaluation

- Etd4264 PDFDocument163 pagesEtd4264 PDFrahma rahmaPas encore d'évaluation

- Experiment 2 - ColloidsDocument15 pagesExperiment 2 - ColloidsRodelyn CantorPas encore d'évaluation

- AHRI Standard 700 2017Document29 pagesAHRI Standard 700 2017enricoPas encore d'évaluation

- Calculation StandardDocument3 pagesCalculation Standardxjaf01Pas encore d'évaluation

- Propelyne ChartDocument2 pagesPropelyne ChartKurt BuehringPas encore d'évaluation

- CHEM1 Q2 M2-Lewis-StructuresDocument32 pagesCHEM1 Q2 M2-Lewis-StructuresMark TerradoPas encore d'évaluation

- Oerlikon Rogers LEAKDocument19 pagesOerlikon Rogers LEAKLorena Jimenez100% (1)

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTAPas encore d'évaluation

- RAC (7th&8th) Dec2016 PDFDocument3 pagesRAC (7th&8th) Dec2016 PDFMuDas IrPas encore d'évaluation

- Q2M3Document22 pagesQ2M3Sophia Jhayne AquinoPas encore d'évaluation