Académique Documents

Professionnel Documents

Culture Documents

Zhang 2006

Transféré par

De Capitano DatruCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Zhang 2006

Transféré par

De Capitano DatruDroits d'auteur :

Formats disponibles

Available online at www.xiencedirect.

com

CHEM. R E . CHINESE U. 2006, 2 2 ( 3 ) , 360-363

Indirect Electrochemical Oxidation of 4-Amino-dimethyl-aniline

Hydrochloride *

1. Department

ZHANG Qiang , KANG Bo2 , XU Hong and LIN Hai-bo *

CoUege of Science, Beijing Imtifute of Technology, Beying loooSl, P. R. China ;

2. College of Chemistry, Jilin Universiry , Changchun 130021 , P. R. China

of Chemistry,

Received Dec. IS, 2W5

The indirect electrochemical oxidation of 4-amino-dimethyl-aniline hydrochloride containing Wastewater generated

from vanillin production is presented. Experiments were conducted at a constant current density of 30 mA/cm2 v i a a

TdRu-Ti-Sn ternary oxide coated anode and an undivided reactor. During the various stages of the electrolysis, panunetem such as the v+es of chemical oxygen demand( COD) and total organic carbon( TOC) were determined in

order to evaluate the feasibility of the electrochemical tmatment. The energy consumption and the current efficiency

during the electrolysis were calculated. The present study proves the effectiveness of the electrochemical treatment for

wastewater resulted from vanillin production.

Keywords Electrochemical oxidation; 4-Amino-dimethyl-aniline ; Wastewater treatment ; Vanillin

Article ID 1005-904O( u)o6)-03-360-04

Introduction

4-Amino-dimethyl-aniline hydrochloride is one of

the main components of the wastewater resulted from

vanillin production] which inhibits the normal activity

of the microorganisms of micmbial population, thereby

affecting the biological treatment process of vanillin.

Common treatment processes of wastewater containing

vanillin are complicated[*]. The degradation of 4-amino-dimethyl-aniline is the primary process for the treatment of vanillin.

Electrochemical technology has provided ideal

tools for addressing many environmental problems.

Electrochemical oxidation processes have attracted great

attention because of their versatility that makes the

treatment of liquids, gases and solids possible, their

environmental compatibility, and especially their capability in destructing the toxic and non-biodegradable organic compounds by means of direct or indirect anodic

oxidation. In fact, electrons are the effective substance

in an electrochemical process, which are clean reagents. In recent years, there has been a great demand

for electrochemical methods that have been successfully

applied in the treatment of landfill leachate, tannery

wastes, oil refinery wastewater, textile wastes, etc. [ 3 1 .

In a direct anodic oxidation process, pollutants are

first absorbed on the anode surface and then destroyed

by the anodic electron transferring reaction. In an indirect anodic oxidation process, strong oxidants, such as

hypochlorite , chlorine, ozone and Fenton reagents, are

electrochemically generated. Pollutants are then destroyed in the bulk solution by the oxidation reactions

with the generated oxidants. All of the oxidants are

gentlated in situ and are utilized immediately[41. Chlorides with high concentrations are contained in the

wastewater from vanillin production, 90 there is actual

significance in the study on the degradation of 4-aminodimethyl-aniline hydrochloride via an indirect electrochemical oxidation pmcess.

In this paper are reported COD and TOC removals, the energy consumption, the current efficiency and

the kinetics during the indirect electrochemical oxidation of 4-amino-dimethyl-aniline hydrochloride.

Experimental

1 Equipment

An undivided electrolytic cell( 250 cm3) was assembled to perform the electrochemical oxidation degradation experiments. The anode and cathode were positioned vertically and were parallel to each other. The

anode material was a Ti/Ru-Ti-Sn ternary oxide coated

anode on titanium mesh ( 30 mm x 30 mm x 1.0

Supported by the National Natural Science Foundation of China( No. 20573045).

To whom correspondence should be addressed. E-mail: W 1 0 0 mail. jlu. edu. cn

**

ZHANG Qiang et al.

No. 3

36 1

mm) "I. A titanium mesh ( TA, , 30 mm x 30 mm x

1 . 0 mm) was used as the cathode. Both of the total effective surface areas of the anode and cathode were all

3.0 cm x 3.0 cm. The distance between the electrodes

was 5.0 mm. The electrolyte solution consisted of

100 mg/L 4-amino-dimethyl-aniline hydrochloride and

0.5 moVL Na, SO, as the sustainable electrolyte at

pH =6.38. The current input was controlled by a stabilized DC power supply.

CE =ACOD F V/(8 I At)

where CE is the current efficiency ( % ) ; ACOD =

COD in,tid - COD fid( gO,/L) ; F is the Faraday constant( 26.8 A * h ) ; V is the volume of electrolyte( L) ;

8 is the amount of oxygen formed by 1 Faraday of electric quantity at 100% yield; I is the current( A ) ; and

At is the time of electrolysis( h ) .

2 Reagents

All the chemicals used were of analytical grade.

1 MtialCharacteristics

All the solutions were prepared from double distilled

water.

3 Procedure

All the experiments were conducted at a current

density of 30 &cm* under galvanostatic conditions at

mom temperature [ (25 0.5 ) T 1. The solution was

constantly stirred at 200 r/min with a magnetic stirrer

in order to maintain the uniformity of the electrolyte solution. The COD ( chemical oxygen demand ) values,

the TOC( total organic carbon) values, the cell voltage

and the coulomb consumption were determined and analyzed at the given electrolysis durations ( 1 . 0 , 2 . 0 ,

3 . 0 , 4.Oand5.O h ) .

4 AdyticalMethods

The chemical oxygen demand( COD) values were

determined with a Model 571 COD analyzer( Shanghai,

P. R. China) which was operated at 150 T for 20

min. The total organic carbon( TOC) values were determined with a Model TOC-VCPH TOC analyzer( Shimadzu Co. , Japan. ) , which was operated via the oxidative combustion infrared method at 680 C with a

sample injection amount of 200 pL, an oxygen flow rate

of 12 m u m i n , and a strip time of 3 min. The pH of

the solution was measured with a Model pHS-25 pH

meter ( Shanghai Hongyi Instrumentation Co. , Ltd. ,

P. R. China).

5 Energetic and Economic Balance of the Employed Electrochemical Oxidation

lation :

Results and Discussion

The initial characteristics of the sample are listed

in Table 1. It is known from literature that the initial

pH does not have a significant effect on the degradation

of organic pollutants by the indirect electrochemical oxidation in a range of 3.0-10.0 at the Ti/Ru-Ti-% anodeL6]. Although indirect electrochemical oxidation of

organic compounds was camed out mainly by the Electrogenerated ehlorine/hypochlorite , the production rate

of chlorine/hypochlorite was not affected by the initial

pH condition. Hence, in the present study, the electrochemical degradation experiment for 4-amino-dimethyl-aniline hydrochloride was conducted without pH

adjustments.

Table 1 The initial characteristics of the sample

COD/( mg L - I

PH

6.38

n>C/( mg * L-I )

143.00

38.04

Treatment Efficiency in Terms of COD with

and without Chloride

The present investigation aimed at examining the

influence of chloride ions on the anodic oxidation of

4-amino-dimethyl-aniline hydrochloride in the wastewater from vanillin production. Hence, the experiment

was carried out by adding 8 . 5 mmoVL chloride as an

oxidant to evaluate the degradation efficiency.

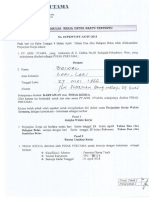

Fig. 1 shows the treatment efficiency in terms of

COD removal after 5 h electrolysis at the Ti/Ru-Ti-Sn

anode, under the condition of a current densitv of 30

1601

1

The energy consumption was determined by the

following equation :

W=I.U-At/(ACOD* V010-~)

where W is the energy consumption of degradation per

kilogram of COD( kW h kg-'COD) ; I is the current( A ) ; U is the cell voltage of electrolysis( V ) ; AZ

is the time of electrolysis( h ) ;A ( COD) = COD ,niud COD ( mg/L) ; and V is the volume of an electrolyte

(L).

The current efficiency during the electrochemical

oxidation can be obtained by means of the following re-

40 60

2

3

4

Electrolysis time/ h

COD removal during the electrochemical treatment of the sample without ( a ) and with 8.5

mmd/L chloride( b ) .

CHEM. RES. CHINESE U.

362

mA/cm2 with or without the addition of chloride. The

COD values without( trace a ) and with chloride( trace

b ) decrease from the initial value of 143.00 to 113.00

and 37.00 mg/L at the end of electrolysis, respectively. However, the degradation efficiency in terms of

COD removal is notably high in the case with chloride.

The COD removal rate is 74. 13% under the condition

with chloride, while it is only 22. 38% under the condition without chloride. This result maybe caused by

increasingly oxidizing 4-amino-dimethyl-aniline hydrochloride in the presence of a high chloride concentration, because under constant current electrolysis, chloride with a high concentration may produce an adequate

amount of hypochlorite or chlorine, which favors the

fast indirect oxidation.

3 The Formation of Stable Compounds

The following conditions ( initial pH = 6. 38, a

chloride concentration of 8. 5 mmoVL, and a current

density of 30 rnA/cm2 ) were maintained during 5 h

continuous electrolysis at the Ti/Ru-Ti-% anode. Total

organic carbon( TOC) analysis can be used to quantify

all the weight fractions of total petroleum hydrocarbons

(THP) and can be performed quickly and easily on

site. The determination of TOC values is a gross measure of all forms of organic carbon including petroleum

hydrocarbons and natural matter"].

Trace b in Fig. 2 shows the relatively efficient mineralization of 4-amino-dimethyl-aniline hydrochloride

up to 5 h. The TOC value reduces fmm an initial value

of 38.04 mg/L to 22. 80 mg/L at the end of the electrolysis. The TOC removal rate is 40.06% , which is

less than the COD removal. The evolution of strongly

oxidized species during this indirect electrochemical

degradation is reflected by the concomitant decrease of

the COD/TOC ratio from 3 . 7 6 to 1.61 ( trace a ) ,

which indicates that stable compounds were formed.

However, such stable compounds will be degraded with

the elongation of the electrolysis time according to the

160 1

40

20

0

Fig.2

v-

3

Electrolysis time/h

2

-Y

4

The values d the ratio d COD to Toc(0)

rutd TOC(Q)vs. the time of iadirect electrochemical oxidation.

VOl. 22

declination of COD and TOC values.

These observations suggest the following sequence

for the process:

cI,/oc1-

Organic compounds -Intermediate

products + CO,

+ H,O

(F-t)

C1,/OcI -

-CO,

stable

+ H,O

Because of the presence of chloride, active chloro

species ( C1,/OC1- ) are generated first in the indirect

oxidation process :

2C1 - - - L I Z+ 2e

(1)

C1, +H,O-+HOCl+H' +C1(2)

HOCI-H + + OC1(3)

The organic compounds( pollutants) are then destroyed in the bulk solution by the active chloro species

and further degrade to other organic intermediate products.

4 The Kinetics of Reaction

In an indirect electrochemical oxidation process,

the COD removal rate is proportional to the total concentration of the organic compounds( pollutants) and to

the concentration of chlorine or hypochlorite because

the indirect oxidation is mediated by chlorine or hypochlorite. Therefore, the kinetics for COD .removal is

- d[ COD]/dt= k[ COD] [ C12]

(4)

where [COD] is the concentration of the organic compound( mg/L) ; t is the time of reaction( s ) ; k is the

rate constant( L * mol-' * s - ' ) ; and [ Cl,] is the concentration of chloride( mg/L).

Electrochemical treatment involves the application

of an electrical current to the effluent, to convert chloride to chlorine and hypochlorite. Chlorine and hypochlorite can oxidize the organic compounds and then

can be reduced to a chloride. The process is repeated

in a catalytic fashion. Therefore, the concentration of

chlorine or hypochlorite during the electrolysis is assumed to be a constant and so eq. ( 4 ) can be written

as a pseudo first-order kinetic equation :

- d[ COD]/dt = - k'[ COD]

(5)

where [COD] is the concentration of the organic compounds( mg/L) ; t is the time of reaction( s) ; and k' is

the rate constant ( s - ' ) .

'The logarithmic plots of the COD concentration

show the plot of the rate expression:

In[COD],/[COD],,=

-k't

or

In c,/co = - k ' t

(6)

where [ COD], or c, is the COD value at time t

( mg/L) ; [ COD 3, or co is the initial COD value

(mg/L) ; t is the time of reaction( s) ; and k' is the

rate constant ( s - ' ) .

ZHANG Qiang et al.

No. 3

363

Table 2 displays the rate constant ( k' ) and the

corresponding y2 values for COD removal.

Table 2 Summary of the electrochemical treatment d the initial sample

Charge paseed

'

( Ah * kg - COD)

5.09 10'

Initial COD/

'

Final COD/

( mg * L - ) ( mg L - )

143

37

Kinetica

Rate constant k'( a - I )

2.93x10-~

Conclusion

The study shows that the proposed indirect electrochemical oxidation process of 4-amino-dimethyl-aniline hydrochloride-containing wastewater generated

from vanillin production is effective. At a constant current density of 30 mA/cm2 via the Ti/Ru-Ti-% ternary

oxide coated anode and an undivided reactor, the electrolysis has been carried out for 5 h , the COD and TOC

removal rates are 74. 13% and 40.06% , respectively,

and the COD/TOC ratio decreases from 3.76 to 1.61,

which indicates the stable compounds have been

formed, but such stable compounds will be degraded

with the elongation of electrolysis time according to the

declination of COD and TOC values. Hence, it is feasible for wastewater from vanillin production to be trea-

Current elhiency

7'

(%

0.9778

27.40

Cell voltage/V

3.41

Energy consumption/

(kWh kg-' COD)

122.60

ted by electrochemical methods.

References

*1

Liu Xis, Li Quan-gen, 1. Xu&u N

d Uni. , Narurd ScKm

Edition, 1999, 17(4), 37

[ 2 1 He Ming-Lei, Zhang Xin-Sheng, Chen Yin-Sheng, Fine Chemical, 2002, 19(12), 694

[ 3 3 JanaPen L. J. J . , Koene L . , Chem Eng. J . , Zooz, 85, 137

[ 4 1 Chiang Li-Choung. Chang Juu-en. Wen Ten-Chin, Wat. Ru. ,

1995, 29(2), 671

[ 5 1 Jin Xiang-jun , Lin Hai-bo, Chemise and A d h i o n , 2003, 3 ,

12

[ 6 1 Li Xiao-ping. Lin Hai-bo, Wu Yan, d d. , J. Jilin Uni. , Science Edirion, #)(H, 43(3), 358

Schreier C. G. , Walker W. J. , Bums J. R. , Chcmos&re,

1999, 39, 503

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Roof Walling Installation Entire ManualDocument70 pagesRoof Walling Installation Entire ManualclmtharmPas encore d'évaluation

- Ashford Gauge Manual PDFDocument20 pagesAshford Gauge Manual PDFJoe_Merchant100% (1)

- 16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)Document15 pages16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)krainajackaPas encore d'évaluation

- Erosion Rate CalculationDocument3 pagesErosion Rate CalculationAnkiq MaqapagalPas encore d'évaluation

- Robusta Cupping ProtocolsDocument9 pagesRobusta Cupping Protocolswienda100% (1)

- 'Natural' Traditions - Constructing Tropical Architecture in Transnational Malaysia and SingaporeDocument70 pages'Natural' Traditions - Constructing Tropical Architecture in Transnational Malaysia and SingaporeKurt ZepedaPas encore d'évaluation

- 5 Carbon Brush Technical Guide Mersen - 07Document40 pages5 Carbon Brush Technical Guide Mersen - 07Dhanraj PatilPas encore d'évaluation

- ZAINAL PKWT - CompressedDocument5 pagesZAINAL PKWT - CompressedDe Capitano DatruPas encore d'évaluation

- Jawaban UTSDocument7 pagesJawaban UTSDe Capitano DatruPas encore d'évaluation

- Greg Burton 1Document7 pagesGreg Burton 1De Capitano DatruPas encore d'évaluation

- 00463516626Document5 pages00463516626De Capitano DatruPas encore d'évaluation

- Fluid Phase Equilibria: Hu-Sheng Hu, Yu-Long Wu, Ming-De YangDocument10 pagesFluid Phase Equilibria: Hu-Sheng Hu, Yu-Long Wu, Ming-De YangDe Capitano DatruPas encore d'évaluation

- 14 27 1 SMDocument5 pages14 27 1 SMDe Capitano DatruPas encore d'évaluation

- Solid-State Oxidation of Aniline Hydrochloride With Various OxidantsDocument8 pagesSolid-State Oxidation of Aniline Hydrochloride With Various OxidantsDe Capitano DatruPas encore d'évaluation

- Executive Summery SuthaliyaDocument3 pagesExecutive Summery SuthaliyaAkash JainPas encore d'évaluation

- Nalapattu Conservation Paper New - Doc1Document10 pagesNalapattu Conservation Paper New - Doc1Narasimha MurthyPas encore d'évaluation

- Water Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35Document28 pagesWater Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35jeromeduytschePas encore d'évaluation

- Sds Msds 000039 Mobil Dte Oil Light 1991 NocoDocument11 pagesSds Msds 000039 Mobil Dte Oil Light 1991 NocoeadriesPas encore d'évaluation

- Dredging QuestionsDocument13 pagesDredging QuestionsPaulo Edrian Dela PenaPas encore d'évaluation

- Model LFN36-M1 Specification SheetDocument2 pagesModel LFN36-M1 Specification SheetWattsPas encore d'évaluation

- Slurry Pumps Parastaltic PumpsDocument9 pagesSlurry Pumps Parastaltic Pumpsmtl40Pas encore d'évaluation

- Water Resources: - Use and Over-Utilization of Surface and Ground Water - Floods, Drought, Conflicts Over WaterDocument48 pagesWater Resources: - Use and Over-Utilization of Surface and Ground Water - Floods, Drought, Conflicts Over Waterprasad_bathePas encore d'évaluation

- En VisciDocument25 pagesEn VisciRosPapPas encore d'évaluation

- Ground Water Information Booklet of Kozhikode District, Kerala StateDocument29 pagesGround Water Information Booklet of Kozhikode District, Kerala StateNeena VarghesePas encore d'évaluation

- Hand Pump Maintenance 1977 PDFDocument40 pagesHand Pump Maintenance 1977 PDFmvqfernandesPas encore d'évaluation

- Md. Abdul KhalequeDocument358 pagesMd. Abdul KhalequeRidwanPas encore d'évaluation

- Solar ThermalDocument31 pagesSolar ThermalatulsemiloPas encore d'évaluation

- Tugas Alkohol 1 (3 Kelompok)Document39 pagesTugas Alkohol 1 (3 Kelompok)Galuh Eka WulandariPas encore d'évaluation

- Methodology For Capliary Cut-OffDocument5 pagesMethodology For Capliary Cut-OffMarees KumarPas encore d'évaluation

- Brackish WaterDocument20 pagesBrackish WaterMarie PeneyraPas encore d'évaluation

- Using of Artificial Neural Network For Modeling of Oily Wastewater in Reverse Osmosis ProcessDocument5 pagesUsing of Artificial Neural Network For Modeling of Oily Wastewater in Reverse Osmosis ProcessIJARP PublicationsPas encore d'évaluation

- Personal Eco-Footprint Calculator ProcedureDocument4 pagesPersonal Eco-Footprint Calculator ProcedureNCTDREAM 07Pas encore d'évaluation

- 05-Water Quality Standards PDFDocument38 pages05-Water Quality Standards PDFSubuk T. Rathod0% (1)

- # 5. Moving Toward Water Sensitive CityDocument52 pages# 5. Moving Toward Water Sensitive CityYonaminos Taye WassiePas encore d'évaluation

- Recycling of WaterDocument5 pagesRecycling of WatershaniaPas encore d'évaluation

- Soil Improvement by Vacuum Preloading For A Power Plant Project in VietnamDocument10 pagesSoil Improvement by Vacuum Preloading For A Power Plant Project in VietnamZaky PrawiraPas encore d'évaluation

- Help the EnvironmentDocument1 pageHelp the EnvironmentSimona FourtakPas encore d'évaluation