Académique Documents

Professionnel Documents

Culture Documents

PR1613 PDF

Transféré par

haerulamriDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PR1613 PDF

Transféré par

haerulamriDroits d'auteur :

Formats disponibles

PR 1613

System Weighing Indicator

Compact Weighing Terminal

global weighing technologies

High accuracy W&M indicators EC

PROFILE

The weight indicators PR 1613 have been

designed for high precision weighing

applications e. g. for platforms, weighbridges, cranes or batching processes.

Operating via:

front panel

control inputs/outputs

remote display/terminal

communication from a supervisory

system (Dust, JBUS/MODBUS, Teleperm,

Profibus-DP)

In case of alpha numerical operation as

for platforms or batching processes it is

recommandable to use the compact

weighing terminal.

Indicator specific features:

- Free programmability of internal PLC

and weighing sequences

conformity certificate 5000 d acc. to

EN 45 50l (corresp. to OIML R 76)

Alibi memory for W&M

Free programmable

Integrated PLC, 6 inputs and

12 outputs

Max. 4 serial interfaces (current

loop, RS 232 or RS 422/485)

Optional:

analogue inputs/putputs

BCD-output

Parallel printer interface

Pulse counter input

PROFIBUS-DP

Various software options for:

Weighbridge applications

Batching applications

Communication protocols

Real time clock and memory

extension

Protection class IP 65 (front)

Use inside EX-areas of Zone 2 (IICT4)

TECHNICAL DATA

Easy connection of barcode reader,

remote displays, printers or PLCs

Load cell supply of 12 V or 20 V

Automatic zero tracking

Multi-range scales possible

(3 ranges)

SW- and HW options later on extendable

Disabling keyboard functions

Analogue test

Customer specific benefits:

Easy and comfortable operating, calibration and configuration

Calibration without weights

(input of load cell identification data)

Operator dialogue in local language

Print layout adjustable

Typical weighbridge, batching and OnBoard Weighing software

available

Housing (PR 1613/00.../01)

Material:

aluminium

Protection class: IP 30

Front panel:

IP 65

Housing (PR 1613/03.../04)

Material:

stainless steel

Protection class: IP 65

Main voltage

PR 1613/00 and PR 1613/03:

110V/220V AC, -15%/+10%, 50/60Hz

PR 1613/01 and PR 1613/04:

24 VAC -15 %/+10 %,

24 VDC -15 %/+20 %

Power consumption

19 W / 25 VA

(PR 1613/00)

18 W / 24 VA

(PR 1613/01)

22.5 W / 30 VA (PR 1613/03)

23 W / 30 VA

(PR 1613/04)

PR 1609/00 Real time clock

runs independently of mains

(for PR 1613/03 standard)

SW Option PR 1613/10

Standard package

for weightbridges

Programming facilities

of the internal PLC and

weighing sequences

or

SW Option PR 1613/20

Standard programm

for batching

Programming facilities

of the internal PLC and

weighing sequences

PR 1613/80

Memory extension

PR 1613/81

Alibi memory

(Weights and Measures)

up to 6 Load Cells

SW Option PR 1613/05

Different communication protocols are

available:

DUST 3964 R

TELEPERM

JBUS/MODBUS

Serial lines

PR 1601/00 TTY

PR 1602/00 RS 232 (V24)

PR 1604/00 RS 422/RS 485

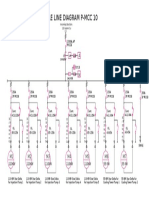

PR 1613 Function Diagram

M.T.B.F.

35000 hours

Status indicators

->0<- zero display within = 1/4 d

standstill

B

gross weight display

NET

net weight display

T

tare weight display

Dimensions can be set for: g, kg, t,lb

Decimal point can be set

Message display

(only PR1613/03../04)

2 lines with 20 characters

Structure: 5 x 7 Matrix

Control input

Number: 6, opto-isolated

Max. voltage 32 VDC

Input current (high):

5 mA at 12 VDC/11 mA at 24 VDC

Control outputs

Number: 12, opto-isolated output

Max. voltage: 32 VDC

Max. current: 75 mA

6 inputs

OPTIONS

Cable Junction

Box

or

SW Option PR 1613/30

On board weighing

extension

Tilling correction

for truck mounted

weighing systems

Display

Type: vacuum fluorescent display

Elements: 7 - digits (7 segments)

Height: 12.5 mm

Colour: bright green

plus weighing and status symbols

12 Outputs

In/Outputs

Free programmable with

SW-Option PR 1613/10

or PR 1613/20

PR 1603/00 Double interface RS 232 + TTY

PR 1605/00 Parallel printer interface

PR 1606/00 0-10 V, 0-20 mA or

2-10 V, 4-20 mA Analog output

PR 1606/8x Analog / BCD output

(only 1 serial line possible)

PR 1607/00 4 Analoge inputs 0-10 V or 0-20 mA

(only usable with PR 1613/10 or PR 1613/20)

PR 1608/xx 5 Decade BCD - output,

(with PR 1613/10 or PR 1613/20

usable as 24 additional outputs)

PR 1610/00 Pulse counter input

(optional 7 additional inputs available)

PR 1621/00 PROFIBUS-DP

Accuracy

5000 d class III acc. to EN 45 501;

corresponds to OIML R 76

Analog filter

Active Butterworth low pass filter,

40 dB / decade, 2 Hz cut-off frequency

Load cell connection

All strain gauge loadcells;

6- or 4-wire connection

Linearity

<0.007 %

Load cell supply

12 V/20 VDC selectable, short-circuit

proof. External load cell supply is

possible.

Minimum load impedance

(internal supply)

min. 87.5 Ohm

e.g. 6 load cells with 600

or 4 load cells with 350

Temperature effects

Zero:

<0.1 V / K RTI

Span:

<0.006 % / 10 K

ENVIRONMENTAL CONDITIONS

Vibration safety

Acc. to IEC 68-2-6. Test Fc

Static discharge

Acc. to IEC 1000-4-2

Measuring principle

Meas. amplifier: integrating converter,

ratiometric to LC supply

Conversion time 50 ms.

Measuring time: 0.1 s to 2 s, can be set

at intervals of 0.1 s.

Interference on mains and input/output

Acc. to IEC 1000-4-4

Measuring range

Meas. signal: 2.4mV to 36mV

(for 100 % nominal load)

Dead load: 0 33.6 mV

There is no interaction between dead

load and measuring range setting.

Radio noise suppression

Acc. to EN 55 011

Resolution (internal)

0.2 V / div.

(max. 180,000 counts)

Electromagnetic field

Acc. to IEC 1000-4-3

26MHz to 1 GHz

Electrical safety

Acc. to IEC IEC 1010-1

Temperature

W & M operation: -10 C to +40 C

industrial:

-10 C to +55 C

Storage:

-40 C to +70 C

System Weighing Indicator

Compact Weighing Terminal

Typical application

by use of weighbridge

programm PR 1613/10

remote display

e.g. PR 1627

dig outputs

or

PR 1603/00

PR 1613/00.../01

PR 1613/03.../04

RS 232

z.B. PR 1602/00 RS 232

card reader

terminal

e.g. VT 520

printer

e.g. FX 880

STANDARD FUNCTIONS BY USE OF WEIGHBRIDGE SOFTWARE PR 1613/10

record the charge/discharge weight with

saving of the data

editing of: customers tables

vehicles tables

material tables

print of

customers lists

material quantity per customer

create or delete a list of all the vehicles on the site

Typical application by

use of batching software

PR 1613/20

remote display

PR 6130

Interface PR1626/60

Haszardous area

PR1625/60

Interface

IA

IB

safe area

2

TTY

RS 232

card reader

RS 232

supervisory

system

RS 485

printer

e.g. FX 880

STANDARD FUNCTIONS BY USE OF THE BATCHING SOFTWARE PR 1613/20

editing of: material tables

recipe tables

batching process control with alarm signals

print of

batching-reports

production reports

material consumption reports

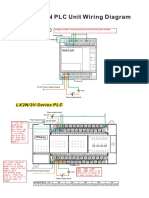

Standard I/O connection (including PR 1613/10)

Output

Function

Output

Function

Input

Function

1

2

3

4

5

6

pass active

minus sign when net display

within zero set range

display dimmed

analogue/load cell/memory error

analogue test active

I

2

3

4

5

6

set zero

set tare

reset tare

start print

switch display to gross

switch display to net

Type numbers

Type

System weighing indicator

in 24 VAC/DC version

Compact weighing terminal

in 24 VAC/DC version

Hardware Options

Current loop TTY

RS 232 (V24)

RS 232 +TTY

RS 422 /485

Parallel printer interface

Analogue output

Analogue / BCD output (open emitter)

Analogue / BCD output (open collector)

Analogue input (4x)

BCD-output (open emitter)

BCD-output (open collector)

Real time clock

Pulse counter

Memory extension

Alibi-memory (W&M)

PROFIBUS-DP

Connecting cable

Relay I/O module

Terminal I/O module

Software Options

Weighbridge-package

On board weighing-package

Communications-package

7

8

9

10

11

12

Type Number

Instrument dimensions

PR 1613/00 and /01

PR 1613/00

PR 1613/01

PR 1613/03

PR 1613/04

PR 1601/00

PR 1602/00

PR 1603/00

PR 1604/00

PR 1605/00

PR 1606/00

PR 1606/80

PR 1606/81

PR 1607/00

PR 1608/00

PR 1608/10

PR 1609/00

PR 1610/00

PR 1613/80

PR 1613/81

PR 1621/00

PR 1623/10

PR 1623/20

PR 1623/30

Rear panel PR 1613/03 and /04

PR 1613/10

PR 1613/30

PR 1613/05

Cable connections PR 1613/03

Rear panel PR 1613/00

Weight net 9.9 kg / shipping 11.2 kg

Weight net 3.6 kg / shipping 4.5 kg

GWT Global Weighing Technologies GmbH

Meiendorfer Strae 205

D-22145 Hamburg, Germany

all dimensions in mm

Autoryzowany przedstawiciel GWT GLOBAL Weighing Technology

P.H.U. WEGA Andrzej Zubka

80-299 Gdansk Osowa

ul. Kasjopei 30A

Dzial handlowy

Tel. (058) 554-52-29

Tel. (+49) 40 679 60-303

Fax. (058) 522-90-05

Fax (+49) 40 679 60-383

e-mail: wega@gd.onet.pl

www.global-weighing.com

http://www.phu-wega.pl

Printed in Germany, 9498 716 13011, 01.2002

tare active

within 1/4 d

standstill

limit 1

limit 2

W&M not fulfilled

Vous aimerez peut-être aussi

- Gefran 2400Document4 pagesGefran 2400Alexandre CamposPas encore d'évaluation

- System Weight Indicators PR 1613/00, .. /04: Operating ManualDocument3 pagesSystem Weight Indicators PR 1613/00, .. /04: Operating ManualPrithwiraj RoyPas encore d'évaluation

- PL2303GT USB To RS232 Serial Bridge Controller With Built-In RS232 TransceiverDocument29 pagesPL2303GT USB To RS232 Serial Bridge Controller With Built-In RS232 TransceiverNabeel MohammedPas encore d'évaluation

- 1234 FBM203Document16 pages1234 FBM203andresg417Pas encore d'évaluation

- Gas Book PLCDocument119 pagesGas Book PLCLucas MeloPas encore d'évaluation

- PAMIO 4enc4a enDocument2 pagesPAMIO 4enc4a enRicardo AlvaradoPas encore d'évaluation

- Disomat Tersus Weighing Terminal: EquipmentDocument4 pagesDisomat Tersus Weighing Terminal: EquipmentN'cho Marius AssiPas encore d'évaluation

- XBT A+connectionsDocument24 pagesXBT A+connectionsMuhammad Akbar Khan100% (1)

- PIDcontrollers2007 VDocument5 pagesPIDcontrollers2007 VPardeep KhosaPas encore d'évaluation

- F8650X eDocument4 pagesF8650X escribdkhatnPas encore d'évaluation

- EnDat 21 - 22Document7 pagesEnDat 21 - 22Arshiya TabassumPas encore d'évaluation

- Programmable Signal Isolator: Universal Input, 5 Outputs, Integral LCD DisplayDocument7 pagesProgrammable Signal Isolator: Universal Input, 5 Outputs, Integral LCD DisplayKalaivani MurugesanPas encore d'évaluation

- Manual Transmitter M200 Easy e 52121501 Sept09Document76 pagesManual Transmitter M200 Easy e 52121501 Sept09prancesiPas encore d'évaluation

- PT650M Weighing Display Controller (English Version)Document9 pagesPT650M Weighing Display Controller (English Version)Osa Nilefun0% (1)

- Manual Pl7 3Document416 pagesManual Pl7 3soltero_triste7710100% (1)

- 8600 Frequency Inverters En.12Document126 pages8600 Frequency Inverters En.12Syed Hassan TariqPas encore d'évaluation

- SCD-FBM218 HART Communication Redundant Output Interdace Module PDFDocument12 pagesSCD-FBM218 HART Communication Redundant Output Interdace Module PDFIVANPas encore d'évaluation

- Catalog NS K - 2000Document6 pagesCatalog NS K - 2000rasim_m1146Pas encore d'évaluation

- Hitachi PLC Function Code TableDocument2 pagesHitachi PLC Function Code Tablegreggg123Pas encore d'évaluation

- Wecon Hmi Pi3070i-NDocument1 pageWecon Hmi Pi3070i-NMiguel LunaPas encore d'évaluation

- OI CablesDocument6 pagesOI CablesvassetoPas encore d'évaluation

- Gorenje Tiki TGRDocument32 pagesGorenje Tiki TGRmiroslavPas encore d'évaluation

- VCB 2C Vector - GBDocument117 pagesVCB 2C Vector - GBppeanut70100% (1)

- Man FL10Document54 pagesMan FL10BiljanaKovacevic100% (1)

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionD'EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionPas encore d'évaluation

- Ecler DPA600 - DPA1000 - DPA1400 - DPA2000 Stereo AmplifierDocument139 pagesEcler DPA600 - DPA1000 - DPA1400 - DPA2000 Stereo AmplifierJUAN CARLOS TARMA CASTILLOPas encore d'évaluation

- 6.2.2.3.81 Schneider Electric Invensys Foxboro FBM201 Datasheet 2017324111432Document14 pages6.2.2.3.81 Schneider Electric Invensys Foxboro FBM201 Datasheet 2017324111432Eddie Gomez VillalobosPas encore d'évaluation

- Power Factor Controllers: ERN 11005 / ERN 11007 Advanced Key Features: ERN 11206 / ERN 11214 Smart Key FeaturesDocument3 pagesPower Factor Controllers: ERN 11005 / ERN 11007 Advanced Key Features: ERN 11206 / ERN 11214 Smart Key FeaturesSaeed AhmedPas encore d'évaluation

- Rechner s10 268 553 01 Heidenhain ManualDocument752 pagesRechner s10 268 553 01 Heidenhain ManualDaniel SchuchPas encore d'évaluation

- Hitachi H SeriesDocument3 pagesHitachi H SeriesIsaac SantosPas encore d'évaluation

- Profibus Manual EnglishDocument87 pagesProfibus Manual Englishpecirepi0% (1)

- StrataFlash 28F640J3Document37 pagesStrataFlash 28F640J3Alexandre Anderson AlvesPas encore d'évaluation

- Model 5190-C Temperature/Humidity Probe User's ManualDocument8 pagesModel 5190-C Temperature/Humidity Probe User's ManualNguyễn Văn TrungPas encore d'évaluation

- 5 Phase Stepper Motor Catalog - PF SeriesDocument5 pages5 Phase Stepper Motor Catalog - PF SeriesTran Tien DatPas encore d'évaluation

- Alonex Special Amp Industrial Electronic Equipment PDFDocument342 pagesAlonex Special Amp Industrial Electronic Equipment PDFthanh vanPas encore d'évaluation

- Olicorp: Maintenance and Support Guide For Pwr24 and PWRSDL Version Beta 1.3 - May 13, 2009 Comments Are WelcomeDocument35 pagesOlicorp: Maintenance and Support Guide For Pwr24 and PWRSDL Version Beta 1.3 - May 13, 2009 Comments Are WelcomerishatPas encore d'évaluation

- Click PLC CommunicationDocument40 pagesClick PLC Communicationobinnabenedict100% (1)

- 1 General Information: Model Number Short Description Servo DrivesDocument14 pages1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- PocketPAD Buffer ManualDocument68 pagesPocketPAD Buffer ManualAravind_Vijaya_2158Pas encore d'évaluation

- Equalis L B006 Bro GB Rev1Document2 pagesEqualis L B006 Bro GB Rev1Armel Brissy100% (1)

- Foxboro IDP50Document32 pagesFoxboro IDP50dennisheadley50% (2)

- Service ManualDocument40 pagesService ManualBruno KosPas encore d'évaluation

- 5419 - ETN 40 Eng Rev1Document1 page5419 - ETN 40 Eng Rev1hormiganegra431Pas encore d'évaluation

- 05-670 Microx User Manual V233P PDFDocument33 pages05-670 Microx User Manual V233P PDFYoucef KherroubiPas encore d'évaluation

- Schmidt Haensch - Sugar Colorimeter Coloromat 100Document55 pagesSchmidt Haensch - Sugar Colorimeter Coloromat 100Do PhungPas encore d'évaluation

- Manuel Profibus Aertronic Aerzener G2 V107Document15 pagesManuel Profibus Aertronic Aerzener G2 V107Diana ConsstantinPas encore d'évaluation

- 1SAP130300R0271 Pm573 Ethac500 Prog Logic Contr 512kbDocument3 pages1SAP130300R0271 Pm573 Ethac500 Prog Logic Contr 512kbErick Romucho SánchezPas encore d'évaluation

- ATC-277MM User's ManualDocument0 pageATC-277MM User's ManualMaitry ShahPas encore d'évaluation

- Manual - 9j - CS2G-10 - 00018MC300-500Document34 pagesManual - 9j - CS2G-10 - 00018MC300-500vuong buiPas encore d'évaluation

- PGQS e 2Document104 pagesPGQS e 2selavilizationPas encore d'évaluation

- Siemens LR560 HART Man 7ML19985KB01 PDFDocument157 pagesSiemens LR560 HART Man 7ML19985KB01 PDFcesarPas encore d'évaluation

- 2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Document6 pages2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Ravi Kant GuptaPas encore d'évaluation

- PanelView Component SpecificationsDocument12 pagesPanelView Component SpecificationsmateusT850Pas encore d'évaluation

- Revisions HistoryDocument25 pagesRevisions Historyabdel taibPas encore d'évaluation

- VT 400Document2 pagesVT 400darscribdPas encore d'évaluation

- 85XX (Scanner)Document4 pages85XX (Scanner)maheshPas encore d'évaluation

- 85XX (Scanner) 1Document4 pages85XX (Scanner) 1someshwar12345Pas encore d'évaluation

- Masibus 85XX - R2 - 0110 - ScannerDocument4 pagesMasibus 85XX - R2 - 0110 - ScannerKvj Srinivasa RaoPas encore d'évaluation

- E6000 InstructionManual v27Document42 pagesE6000 InstructionManual v27rommel76Pas encore d'évaluation

- Pr1613adf PDFDocument2 pagesPr1613adf PDFhaerulamriPas encore d'évaluation

- Demolis Pipe REPORT - Rev1 PDFDocument11 pagesDemolis Pipe REPORT - Rev1 PDFhaerulamriPas encore d'évaluation

- ArrestorDocument3 pagesArrestorhaerulamriPas encore d'évaluation

- Sharp Is A Pioneer in Photovoltaics Sharp Solar Modules Have Set Standards For Over 50 YearsDocument2 pagesSharp Is A Pioneer in Photovoltaics Sharp Solar Modules Have Set Standards For Over 50 YearshaerulamriPas encore d'évaluation

- LX 310Document2 pagesLX 310Anastasia NoormaPas encore d'évaluation

- PR1613 PDFDocument4 pagesPR1613 PDFhaerulamri100% (1)

- Grease Trolley PDFDocument4 pagesGrease Trolley PDFhaerulamriPas encore d'évaluation

- BRO Combics - Pro e PDFDocument8 pagesBRO Combics - Pro e PDFhaerulamriPas encore d'évaluation

- Electronic Weighbridge PDFDocument2 pagesElectronic Weighbridge PDFhaerulamriPas encore d'évaluation

- Grease Trolley PDFDocument4 pagesGrease Trolley PDFhaerulamriPas encore d'évaluation

- I Beth09gb - e Tdmas4000tec PDFDocument12 pagesI Beth09gb - e Tdmas4000tec PDFhaerulamriPas encore d'évaluation

- Lifter Storage PDFDocument5 pagesLifter Storage PDFhaerulamriPas encore d'évaluation

- Katalog PeralatanDocument438 pagesKatalog PeralatanSurya Kazu MaruPas encore d'évaluation

- List Tabel Berat Besi PDFDocument18 pagesList Tabel Berat Besi PDFhaerulamri100% (1)

- WTP BoqDocument26 pagesWTP Boqkajale_shrikant2325Pas encore d'évaluation

- Rail Scraper PDFDocument1 pageRail Scraper PDFhaerulamriPas encore d'évaluation

- List Flowmeter Yang Akan Di Kalibrasi PDFDocument1 pageList Flowmeter Yang Akan Di Kalibrasi PDFhaerulamriPas encore d'évaluation

- Single Line Drawing MCC 10 PDFDocument1 pageSingle Line Drawing MCC 10 PDFhaerulamriPas encore d'évaluation

- Schematic Line Diagram Cable Power PDFDocument1 pageSchematic Line Diagram Cable Power PDFhaerulamriPas encore d'évaluation

- GAMBAR SURVEY LAY OUT PULLING KABEL AREA INJEKSI Rev 1 PDFDocument1 pageGAMBAR SURVEY LAY OUT PULLING KABEL AREA INJEKSI Rev 1 PDFhaerulamriPas encore d'évaluation

- WTP BoqDocument26 pagesWTP Boqkajale_shrikant2325Pas encore d'évaluation

- Lifter Parking Stand Cut List PDFDocument1 pageLifter Parking Stand Cut List PDFhaerulamriPas encore d'évaluation

- Electrical Bill of QuantitiesDocument32 pagesElectrical Bill of QuantitiesAbdul RawoofPas encore d'évaluation

- cONTACTOR MITSUBISHI PDFDocument89 pagescONTACTOR MITSUBISHI PDFhaerulamriPas encore d'évaluation

- Drawing Lifter Storage PDFDocument6 pagesDrawing Lifter Storage PDFhaerulamriPas encore d'évaluation

- E4C-UD Digital Ultrasonic Sensor Brochure PDFDocument8 pagesE4C-UD Digital Ultrasonic Sensor Brochure PDFhaerulamriPas encore d'évaluation

- Rajesh Scientific Industries: Instruction ManualDocument12 pagesRajesh Scientific Industries: Instruction ManualrajeshPas encore d'évaluation

- VAR Catalogue UkDocument72 pagesVAR Catalogue Ukgeisbrian1Pas encore d'évaluation

- Set No: 1: Electrical Machines - IiiDocument8 pagesSet No: 1: Electrical Machines - IiiViswa ChaitanyaPas encore d'évaluation

- Anna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperDocument5 pagesAnna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperMuruga AnanthPas encore d'évaluation

- Design Methodology For Wheel Corner Module Topology Based On Position and Orientation Characteristics PDFDocument19 pagesDesign Methodology For Wheel Corner Module Topology Based On Position and Orientation Characteristics PDFdreamtheater666Pas encore d'évaluation

- Invertec 135S, 150S & 170SDocument7 pagesInvertec 135S, 150S & 170SDiegoPas encore d'évaluation

- Project Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LPL-06 5 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Document5 pagesProject Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LPL-06 5 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Fatholla SalehiPas encore d'évaluation

- Preventive Maintenance Checklist - KR150Document7 pagesPreventive Maintenance Checklist - KR150Juan c sanchezPas encore d'évaluation

- Ricoh GG 2017Document3 318 pagesRicoh GG 2017Acevedo OrlandoPas encore d'évaluation

- Plumbing Tools: Professor: Arch. Flynn B. Arana, Uap, RMPDocument12 pagesPlumbing Tools: Professor: Arch. Flynn B. Arana, Uap, RMPMherliePas encore d'évaluation

- 6000PLUSensor-Range Issue 1 PDFDocument2 pages6000PLUSensor-Range Issue 1 PDFjfs.santos3570Pas encore d'évaluation

- Tribhuvan University Institute of EngineeringDocument36 pagesTribhuvan University Institute of Engineeringatheb12345Pas encore d'évaluation

- WECON LX3V Product Wiring DiagramDocument2 pagesWECON LX3V Product Wiring DiagramMilind Bhavsar100% (1)

- Hirose df57 Connettore BatteriaDocument9 pagesHirose df57 Connettore BatteriaRaffaele FasuloPas encore d'évaluation

- 8107 Decap279 Office Automation ToolsDocument272 pages8107 Decap279 Office Automation ToolsNihanth MunnaPas encore d'évaluation

- ES.2.14.0035 LV Cage Induction MotorsDocument54 pagesES.2.14.0035 LV Cage Induction MotorsAhmed FayedPas encore d'évaluation

- Travel Systems - 7Document59 pagesTravel Systems - 7اياد القباطيPas encore d'évaluation

- Computer Architecture Measuring PerformanceDocument33 pagesComputer Architecture Measuring PerformanceazhiPas encore d'évaluation

- Standard MaterialDocument29 pagesStandard MaterialTiar Rahman100% (1)

- RS1117Document10 pagesRS1117asismamenPas encore d'évaluation

- RT 5100Document76 pagesRT 5100Hobi's WaifuPas encore d'évaluation

- 22m Boom - Circuit + Bom-Vr-0628 (1) - 1Document7 pages22m Boom - Circuit + Bom-Vr-0628 (1) - 1MuthuPas encore d'évaluation

- Service FORMS FOR GENERATORSDocument78 pagesService FORMS FOR GENERATORSJose MoralesPas encore d'évaluation

- Microguard 414 Troubleshooting Manual PDFDocument84 pagesMicroguard 414 Troubleshooting Manual PDFDaniel Castillo PeñaPas encore d'évaluation

- Engineering Utilities 1 CE 354: Group-CentinoDocument16 pagesEngineering Utilities 1 CE 354: Group-CentinoAnnie TheExplorerPas encore d'évaluation

- CCTV QuotDocument2 pagesCCTV QuotkollidrPas encore d'évaluation

- I) Absolute or Fully Decoding and II) Linear Select or Partial Decoding PDFDocument5 pagesI) Absolute or Fully Decoding and II) Linear Select or Partial Decoding PDFBaisakh Sweet100% (1)

- Computer Architecture 計算機結構: ScoreboardDocument36 pagesComputer Architecture 計算機結構: Scoreboardlloyd24390_874347375Pas encore d'évaluation

- Receiving and Inspection: Installation, Operation and Maintenance ManualDocument16 pagesReceiving and Inspection: Installation, Operation and Maintenance ManualIvy LeePas encore d'évaluation

- AeromechDocument31 pagesAeromechMohd Kamaruddin LiauPas encore d'évaluation