Académique Documents

Professionnel Documents

Culture Documents

Articulo Jamaica Secado 2009 PDF

Transféré par

Nery Limon OrtizTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Articulo Jamaica Secado 2009 PDF

Transféré par

Nery Limon OrtizDroits d'auteur :

Formats disponibles

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/23663540

Effect of the Temperature on the Spray Drying

of Roselle Extracts (Hibiscus sabdariffa L.)

Article in Plant Foods for Human Nutrition December 2008

Impact Factor: 1.98 DOI: 10.1007/s11130-008-0103-y Source: PubMed

CITATIONS

READS

26

532

4 authors:

Salvador Gonzlez-Palomares

Mirna Estarrn-Espinosa

Consejo Nacional de Ciencia y Tecnologa

Centro de Investigacin y Asistencia en Tec

47 PUBLICATIONS 52 CITATIONS

42 PUBLICATIONS 287 CITATIONS

SEE PROFILE

SEE PROFILE

Juan F. Gomez-Leyva

Isaac Andrade-Gonzlez

Instituto Tecnolgico de Tlajomulco

Instituto Tecnolgico de Tlajomulco

21 PUBLICATIONS 110 CITATIONS

19 PUBLICATIONS 106 CITATIONS

SEE PROFILE

All in-text references underlined in blue are linked to publications on ResearchGate,

letting you access and read them immediately.

SEE PROFILE

Available from: Juan F. Gomez-Leyva

Retrieved on: 27 May 2016

Plant Foods Hum Nutr (2009) 64:6267

DOI 10.1007/s11130-008-0103-y

ORIGINAL PAPER

Effect of the Temperature on the Spray Drying of Roselle

Extracts (Hibiscus sabdariffa L.)

Salvador Gonzalez-Palomares &

Mirna Estarrn-Espinosa &

Juan Florencio Gmez-Leyva & Isaac Andrade-Gonzlez

Published online: 10 December 2008

# Springer Science + Business Media, LLC 2008

Abstract The effect of the drying temperature on the

volatile components and sensory acceptance of the Roselle

(Hibiscus sabdariffa) extract in powder was investigated.

The Roselle extraction was carried out by maceration with

7 L of 30% ethanol (v/v), 560 g of fresh Roselle calyces for

168 h. The Roselle extracts were spray dried at different

temperatures 150, 160, 170, 180, 190, 200 and 210 C,

giving different outlet values about yield and final moisture.

The volatile compounds in Roselle extract and dried

samples were performed using needles of solid phase

microextraction (SPME) and gas chromatography/mass

spectrometry (GC/MS HP-5890). Twenty volatile compounds were identified in the extracts among them

terpenoids, esters, hydrocarbons and aldehydes. Fourteen

volatile compounds were identified in the powder sample,

but only ten were present in the Roselle extract. This

indicates that some compounds were lost and some others

were generated due to a degradation process. An acceptS. Gonzalez-Palomares : J. F. Gmez-Leyva :

I. Andrade-Gonzlez (*)

Graduate and Research Studies Department,

Instituto Tecnolgico de Tlajomulco,

Km. 10 Carr. San Miguel Cuyutln,

CP 45640 Tlajomulco de Ziga, Jal., Mxico

e-mail: isaacag2001@yahoo.com.mx

S. Gonzalez-Palomares

e-mail: chava1142@yahoo.com.mx

J. F. Gmez-Leyva

e-mail: jfgleyva@hotmail.com

M. Estarrn-Espinosa

Centro de Investigacin y Asistencia en Tecnologa

y Diseo del Estado de Jalisco, A.C. Av.,

Normalistas No. 800. Colinas de la Normal,

CP 44270 Guadalajara, Jal., Mxico

e-mail: mestarron@ciatej.net.mx

ability sensory analysis showed that the best powder sample

was the Roselle extract dehydrated using temperature

between 190 C and 200 C (p<0.05). There was not

statistically significant difference in the pH of Roselle

extracts ranging from 3.4 to 3.9. It was concluded that the

spray drying temperature of the Roselle extracts has an

effect on the volatile compounds losses.

Keywords Roselle powder . Sensory analysis . Spray dryer .

Volatile components

Introduction

Roselle calyx (Hibiscus sabdariffa) is the plant part of

greatest interest because the calyx is utilized in the

processing of fruit preserves, jellies and jams for its rich

content in pectin, ascorbic acid and anthocyanin color [1

3]. Today, the Roselle calyces are utilized as a good source

of natural food colorants by their high natural pigment

content [46]. In addition, Hibiscus sabdariffa anthocyanins have been reported to possess antioxidative, antitumor

and anticarcinogenic activity [79]. Nevertheless, Hibiscus

sabdariffa anthocyanins are unstable during the heat treatments, therefore studies on drying process conditions are

requested in order to achieve the best stability of the final

product [10]. The obtaining of Roselle powder through

spray drying is an important alternative method for the use

of the calyces [1113]. The dehydrated products then can

be added easily to other foods to improve their storage,

transportation and shelf-life. This classifies the spray drying

method as the best alternative to obtain colorants and

natural powder flavoring [1416]. Many studies on Roselle

(Hibiscus sabdariffa) powder have been focused on the

factors that are influencing the reconstitution characteristics

Plant Foods Hum Nutr (2009) 64:6267

or the effects of some additives and processes on characteristics of agglomeration and granulation, in addition of

anthocyanin concentrates and the processing conditions,

and physicochemical characteristics of the powder produced [12]. Although the spray drying is a fast process,

changes on the spray drying temperature can affect the

concentration of volatile compounds which would generate

the loss of some sensorial characteristics [1720]. In spite

of the knowledge that the volatile compounds show low

stability at the spray drying temperatures, only scare studies

have been reported on this issue for volatiles in Roselle [6].

To diminish some degradation effects of compounds and

lost of volatile products is very common to use encapsulation agents [21, 22]. For this reason, the extraction of

volatile substances by micro extraction in a solid phase

(SPME), the quantitative and qualitative analysis by gas

chromatography and mass spectrometry (GC-MS) as well

as sensorial assays are useful tools in the evaluation of the

effect of certain process variables about the quality of the

dehydrated products [2326].

The objective of this work was to evaluate the effect of

the spray drying temperatures on the Roselle extracts

(Hibiscus sabdariffa L.), the retention of the volatile

compounds and the sensorial acceptance of the reconstituted spray dried samples.

Materials and Methods

Roselle Extracts Samples

Fresh Roselle calyces (with 79% humidity) were collected

from an experimental field in Michoacan, Mexico during

October and November 2006. The fresh calyces were

washed for quick dipping over water distilled. After the

calyces were crushed manually and deposited in a closed

container with 7 L of 30% methanol (v/v), all under

constant conditions of static maceration. The content was

left in maceration for 168 h with an occasional shaking to

increase the extraction capacity at room temperature. After,

the macerated extracts were filtered through a 150 m

mesh. A Bchi rotavapor was used to concentrate the

samples and to separate all the ethanol at 40 C. The

characteristics of the roselle extracts were 22% of soluble

solids and pH of 3.4. The roselle extracts were kept under

refrigeration at 4 C. An ATAGO refractometer was used to

determine the percentage of soluble solids. An ORION

potentiometer was used to measure the pH.

Spray Drying

A NIRO spray dryer (with the capacity to evaporate 40 kg

of water per hour) with a wheel rotating atomizer was used

63

for the spray drying process in all the experiments. The

outlet temperature was fixed in 80 C and the atomization

was kept at 37,788g. A flexible plastic tube was inserted

inside one container and connected to a variable flow

peristaltic pump. The flexible outlet tube from the pump

was directly connected to the liquid fed inlet of the

atomizer. Seven different spray drying temperatures were

used; 150, 160, 170, 180, 190, 200 and 210 C. The Roselle

powder samples obtained by spray drying were weighed

and packed in their respective amber-coloured glass flasks

of 100 mL. These were stored in containers with silica for

future analysis.

Determination of Moisture in the Spray Dried

Samples of Roselle

In the samples of spray dried Roselle the percentage of

moisture was measured by the method of the vacuum stove

according to the AOAC-934.06 [27]. Six grams of each

sample were placed in an aluminum dish and introduced in

a vacuum stove with a temperature of 40 C until the

weight remained constant.

Reconstitution of Roselle Powder

The reconstituted samples were carried out by placing a

portion of Roselle powder in 300 mL of distilled water. A

magnetic stirrer was used for mixture homogenization. The

standardization of the mixture was carried out in all the

samples until reaching the same concentration of soluble

solids of the liquid extract (22%) [12]. The reconstituted

samples were stored in amber-colored glass flasks and

refrigerated until their analysis.

Volatile Analysis of Roselle Extracts by SPME-GC-MS

The extraction of volatile compounds from the matrix of the

Roselle extracts was carried out by solid-phase microextraction (SPME). Twenty milliliters of Roselle extract

were placed in a 40 mL amber headspace vial. The vial was

fitted with a PTFE-faced silicone septum and put in a

thermostatted bath. A fiber coated with 50/30 mm of

divinylbenzene/carboxen on polydimethylsiloxane (DVB/

Carboxen/PDMS, Supelco, Bellefonte, PA) exposed for

30 min at 60 C in the headspace of the vial was then

immediately inserted into the injection port of the gas

chromatograph for 5 min at 240 C [28]. A HewlettPackard 5890 Series II gas chromatograph with flame

ionization detector (FID) coupled to 5972 MSD quadrupole

mass spectrometer was used. The HP5890 chromatograph

was equipped with HP-1 (50 m0.2 mm ID0.33 m film

thickness) a capillary column. Operating conditions for GC/

MS were: the oven temperature was programmed at 40 C

64

Plant Foods Hum Nutr (2009) 64:6267

for 5 min then ramped at 5 C/min to 240 C, helium with a

flow rate of 0.8 mL/min, injector port and detector temperatures were 220 and 260 C. All the samples were run at

least in triplicates. Volatile compounds were identified by

comparison of their retention indices tentatively only by

mass spectra library Wiley 275L. Quantitation was based in

area percent corresponding to the identified components in

the Total Ion Chromatogram (TIC).

Sensorial Analysis

All the powder samples were reconstituted at 12% of soluble

solids and slightly sweetened with sugar. The control was the

original extract. All the reconstituted samples were evaluated

for sensorial acceptability by pairing a preference test. The

panel participating in the acceptance evaluation included 50

volunteers (50% females 1845 years), who were students

and staff members of the Technological Institute of the West

Mexico, Jalisco Campus. These panelists were randomly

selected based on availability, interest and regular consumption of Roselle drinks.

The reconstituted samples were chilled at 5 C for 24 h

prior to sensory evaluation. Each panelist received the

reconstituted sample in a random order, and a glass of water

for rinsing and crackers for consumption between samples

were supplied. Each panelist was served with 10 mL of

chilled reconstituted samples and control in 30 mL clear

plastic containers, which were randomly coded. In this

paired preference test, panelists were asked to make a

forced choice between the drinks [2, 4, 29]. This test was

used as a measurement of relative preference of one Roselle

drink over another.

Statistical Analysis

An Analysis of Variance (ANOVA) using the Statistical

Analysis System Software (SAS) and Duncan test at

(p>0.05), was performed with the data obtained from GCMS. Also, analysis of significant minimum difference

(DMS) was made, among the Roselle powders to determine

differences based on the pick area of each volatile

component. The peak areas identified by GC-MS were

used as variables. The paired preference data were analyzed

by binomial distribution [23].

Results & Discussion

Spray Drying of Roselle Extracts

The processing conditions for all the spray drying experiments

were kept at the outlet temperature (80 C) and the atomizer

rate (26,000 rpm). In all experiments, Roselle powder showed

a noticeable tendency to stick to internal stainless steel surfaces

of the drying chamber especially at higher inlet temperature

because this temperature increase the feed flow rate [12]. This

is probably due to the nature of the soluble solids. The

adherence of powder to walls of the drying chamber is a

commonly recognized effect in spray drying of solutions

containing sugars and solids easy to agglomerate [30].

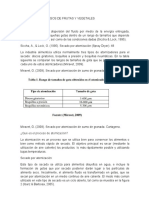

The weight, moisture and pH of seven Roselle powder

samples obtained by spray drying at different temperature

are shown in Table 1. It is observed that the pH of the

powder does not change with different temperature treatment;

the name of current Roselle variety and the cited one should be

mentioned [1, 12].

Volatile Compounds Identified in the Roselle Extract

by SPME and GC-MS

In the Roselle extract, 20 volatile compounds were

identified. In general, there were terpene components,

esters, aldehydes and phenolic derivatives. However, only

the terpene compounds were similar to another works [6].

These compounds were limonene, linalool and alphaTerpineol. This has two significant reasons: first, the variety

of the Roselle is different; this indicates that each variety

can have different compositions. The second is that the

isolation method of volatile compounds used in this work

did not require boiling temperatures, only required an

appropriate material of the fiber (DVB/Carboxen/PDMS)

and a temperature of 60 C. This implies that the

degradation problem in the samples of powder Roselle

extracts were not gendered by the SPME analysis method.

Volatile Compounds of the Roselle Powder

The Roselle powder was rehydrated to the same soluble

solid concentration than the liquid extract to determine the

volatile compounds. In these samples 14 volatile com-

Table 1 Weight (grams), moisture percentage and pH of the Roselle powder dried at different temperatures

Treatment

Spray drying temperature (C)

T1

150

T2

160

T3

170

T4

180

T5

190

T6

200

T7

210

Weight (g)

Humidity (%)

pH

73

5.0

3.48

74

4.0

3.48

74

4.0

3.44

78

4.0

3.44

80

3.0

3.44

75

3.0

3.48

74

3.1

3.48

Plant Foods Hum Nutr (2009) 64:6267

65

pounds were identified. Ten of the 14 compounds identified

are the same as the ones identified in the liquid extract,

although there was a decrease in their concentration. Four

different compounds were also generated, derived of the

degradation of sugar and fatty acids that were present in the

liquid Roselle extract [6]. In Table 2 the compounds of

the Roselle powder are shown and the chromatograms are

illustrated in Fig. 1.

The compounds generated by chemical degradation of

the samples during the spray drying were the furfural, cislinalool oxide, furanic linalool oxide Z and E, and the

eugenol. It was observed that the concentration of the

furfural increased because the drying temperature propitiated its formation by degradation of sugars. The cis-linalool

oxide and the furanic linalool oxide Z and E were the product

of the chemical degradation of the fatty acids. The eugenol

is a compound resulting from degradation of the phenolic

compounds as a consequence of the spray drying temperature of the Roselle samples. This also was reported in drying

Roselle calyces [6]. In Fig. 2 is shown the upward behavior

of the furfural, cis-linalool oxide, furanic linalool oxide Z

and E and eugenol compounds due to the obtained the

changes by the spray drying temperature.

Duncans test (p<0.05) determined that exist significant

difference among the seven treatments realized to obtain

Roselle powder at different spray drying temperatures.

The Duncans test was based on the percentage area of the

volatile compounds. Only the compounds the alphaterpinolene, ethyl hexadecanoate, and decanal compounds

were present in all experiments without significant

difference, as shown in Table 2. According to the analysis

of the least significant difference (LSD) carried out among

the Roselle powder samples, the Roselle extract dehydrated

at 190 C presented the biggest concentration of volatile

compounds and the least concentrations of degraded

compounds that the other samples obtained from different

spray drying temperatures, as shown in Table 2. This result

proved the hypothesis that the drying temperature had an

effect on the retention of volatiles compounds. In addition,

it is important to acknowledge that significant differences

exist among the compounds identified in the liquid extract

as the compounds identified in the Roselle powder. This

Table 2 Volatiles identified in the Roselle powder

Spray drying temperature (C)

Area (%)

T150

150 C

Volatile compounds retained in the powder

Terpenoids

p-Cymene

0.10 ab

Limonene

1.70 ab

Alpha-Terpinolene

0.10 a

Linalool

0.10 b

Esters

Ethyl hexadecanoate

1.70 a

Ethyl linoleate

0.53 b

Ethyl linoleolate

0.10 c

Aldehydes

Benzaldehyde

0.07 c

Decanal

0.18 a

Divers

4-Ethylguaiacol

0.06 b

Volatile compounds generated by chemical degradation

Sugar derivatives

Furfural

0.30 d

Phenolic derivatives

Eugenol

0.09 c

Fatty acid derivatives

cis-Linalool oxide

0.76 b

Furanic linalool oxide Z and E

0.20 c

T160

160 C

T170

170 C

T180

180 C

T190

190 C

T200

200 C

T210

210 C

0.14

1.60

0.09

0.09

0.12

1.80

0.04

0.05

0.13

1.50

0.06

0.06

0.20

4.00

0.07

0.33

0.12

1.00

0.10

0.25

0.07

0.05

0.08

0.10

ab

ab

a

b

ab

ab

a

b

ab

ab

a

b

a

a

a

a

ab

b

a

ab

b

b

a

b

1.70 a

0.50 b

0.13 c

1.72 a

0.47 b

0.13 c

1.68 a

0.71 ab

0.19 b

1.69 a

0.87 a

0.28 a

1.68 a

0.83 a

0.11 c

1.67 a

0.45 b

0.10 c

0.09 c

0.16 a

0.35 b

0.17 a

0.31 b

0.18 a

0.55 a

0.18 a

0.40 ab

0.16 a

0.05 c

0.16 a

0.06 b

0.07 b

0.07 b

0.13 a

0.06 b

0.02 c

2.51 c

2.69 c

3.80 b

4.00 ab

4.28 a

4.44 a

0.10 c

0.10 c

0.15 b

0.20 b

0.35 a

0.30 a

0.87 b

0.29 b

0.85 b

0.35 b

1.00 ab

0.40 b

1.07 ab

0.51 ab

1.55 a

0.69 a

1.40 a

0.50 ab

Different letters mean statistically significant difference using Duncan (p<0.05). Multiple range tests with base in their retention

66

Plant Foods Hum Nutr (2009) 64:6267

Fig. 1 Chromatogram of

volatile constituents in Roselle

powder dried at 190 C. The

time is in minutes

indicates that it is difficult to obtain a powder exactly

similar to the liquid extract of Roselle.

Sensorial Analysis

According to the sensorial analysis, more than 76% of the

panelists showed that preference for the sample T190 than

corresponded to 190 C drying outlet temperature, although

the liquid extract has 92% of preference in the same

conditions (T0). In comparison to the other treatments

(different temperatures), this had the lowest percentage of

5

preference: T150=16%, T160=40%, T170=52%, T180=

52%, T200=12%, and T210=12%. Figure 3 shows the

percentage over the flavor preference among all the samples

analyzed, where the highest acceptability was for the liquid

extract followed by the T190 sample with statistically

significant differences (p<0.05).

Therefore, it is clear than there is significant difference

on acceptance among the Roselle powders and the original

liquid extract according to the preference tests. The major

components detected by chromatographic analysis played

an important role.

Conclusions

4.5

The inlet air temperature of 190 C used in the spray the

drying of Roselle extract resulted in the best powder in

terms of composition regarding the other treatments, since

it contained the highest concentration of ten volatile com-

Area (%)

3.5

3

2.5

2

100

1.5

90

0.5

0

150

160

170

180

190

200

210

Spray Drying Inlet Temperature (C)

Furfural

Cis-linalool oxide

Furanic linalool oxide Z

and E

Eugenol

Fig. 2 Effect of spray drying temperature on the concentration of

degradation compounds present in Roselle powder

Acceptance (%)

80

70

60

50

40

30

20

10

0

T0

T150

T160

T170

T180

T190

T200

T210

Treatments at different temperatures (C)

Fig. 3 Results of the paired preference tests of the Roselle

reconstituted powder. T0 is Roselle liquid original extract

Plant Foods Hum Nutr (2009) 64:6267

pounds also showed in the original liquid extract, and the

peak area of the degraded compounds is smaller than other

samples treated at higher temperature. This result was

rehearsed for panelists in the preference test, choosing the

T190 sample as the best after the original extract, with an

acceptability of 76%. This work suggests that the inlet air

temperature of spray drying has a significant effect on the

volatile compounds concentration of the Roselle liquid

extract and therefore in its acceptance.

Acknowledgement We thank their support in this investigation to

the ITA-JAL, DGETA, CoSNET and CIATEJ.

References

1. Mouning P, Badrie N (2006) Roselle/sorrel (Hibiscus sabdariffa

L.) wines with varying calyx puree and total soluble solids:

sensory acceptance, quantitative descriptive and physicochemical

analysis. J Foodserv 17:102110 doi:10.1111/j.1745-4506.2006.

00028.x

2. Pouget MP, Vennat B, Pourrat A (1990) Identification of

anthocyanins of Hibiscus sabdariffa. Food Technol 23:101102

3. DHeureux C, Badrie N (2004) Consumer acceptance and

physicochemical quality of processed red sorrel/roselle (Hibiscus

sabdariffa L.) sauces from enzymatic extracted calyces. Food

Serv Technol 4:141148 doi:10.1111/j.1471-5740.2004.00100.x

4. Esselen WB, Sammy GM (1975) Applications for roselle as red

color food colorant. Food Prod Develop 9:3740

5. Jirovetz L, Jger W, Remberg G, Espinosa-Gonzlez J, Mora R,

Woidich A, Nikiforov A (1992) Analysis of the volatiles in the

seed oil of Hibiscus sabdariffa (Malvaceae) by means of GC-MS

and GC-FTIR. J Agric Food Chem 40:11861187 doi:10.1021/

jf00019a021

6. Chen SH, Huang TC, Ho CT, Tsai PJ (1998) Extraction, analysis,

and study on the volatiles in roselle tea. J Agric Food Chem

46:11011105 doi:10.1021/jf970720y

7. Carvajal O, Waliszewski SM, Barradas DM, Orta Z, Hayward

PM, Nolasco C, Angulo O, Sanchez R, Infanzon RM, Trujillo

PRL (2005) The consumption of Hibiscus sabdariffa dried calyx

ethanolic extract reduced lipid profile in rats. Plant Foods Hum

Nutr 60:153159 doi:10.1007/s11130-005-9023-x

8. Akindahunsi AA, Olaleye MT (2003) Toxicological investigation

of aqueous-methanolic extract of the calyces of Hibiscus

sabdariffa L. J Ethnopharmacol 89:161164 doi:10.1016/S03788741(03)00276-9

9. Tsai P, McIntosh J, Pearce P, Camden B, Jordan B (2004)

Anthocyanin and antioxidant capacity in roselle (Hibiscus

sabdariffa L.) extract. Food Res Int 35:351356 doi:10.1016/

S0963-9969(01)00129-6

10. Chen HH, Tsai PJ, Chen SH, Su YM, Chung Ch, Huang TCh

(2005) Grey relational analysis of dried roselle (Hibiscus sabdariffa

L.). J Food Process Preserv 29:228245

11. Rosenberg M, Talmon Y, Kopelman IJ (1988) The microstructure

of spray-dried microcapsules. Food Microstruct 7:1523

67

12. Al-Kahtani AA, Hassan BH (1990) Spray drying of roselle

(Hibiscus sabdariffa) extract. J Food Sci 55:10731078 doi:10.1111/

j.1365-2621.1990.tb01601.x

13. Andrade I, Flores H (2004) Optimization of spray drying of roselle

extracts (Hibiscus sabdariffa L.). Drying Proceedings of the 14th

International Drying Symposium. Sao Paulo, Brazil. A: 597604

14. Brenner J (1983) The essence of spray-dried flavors. Perf Flav

40:886888

15. Huang L, Passos ML, Kumar K, Mujumdar AS (2004) A threedimensional simulation of a spray dryer with a rotary atomizer.

Drying. Proceedings of the 14th International Drying Symposium.

Sao Paulo, Brazil. A: 319325

16. Re M, Messias LS, Schettini H (2004) The influence of the liquid

properties and the atomizing conditions on the physical characteristics of the spray-dried ferrous sulfate microparticles. Drying.

Proceedings of the 14th International Drying Symposium. Sao

Paulo, Brazil. B: 11741181

17. King CJ, Kieckbush TG, Greenwald CG (1984) Food quality

factors in spray drying. Adv Dry 3:322327

18. King CJ (1990) Spray drying food liquids and the retention of

volatiles. Chem Eng Prog 54:3339

19. Futura T (2000) Estimating retention of emulsified flavor in a

single droplet during drying. Dry Technol 2(3):11251130

20. Scarpellino R, Soukup RJ (1993) Key flavors from heat reactions

of food ingredients. In: Acree TE, Teranishi R (eds) Flavour

science. Sensible principles and techniques. American Chemical

Society, Washington, DC

21. Beristain CI, Vernon-Carter EJ (1995) Studies on the interaction

of arabic (Acacia senegal) and mesquite (Prosopis juliflora) gum as

emulsion stabilizing agent. Dry Technol 13:455461 doi:10.1080/

07373939508916965

22. R M (1998) Microencapsulation by spray drying. Dry Technol

16:11951236 doi:10.1080/07373939808917460

23. Pedrero FDL, Pangborn RM (1989) Evaluacin sensorial de los

alimentosMtodos analticos. Alhambra mexicana S.A. de C.V.,

Mxico, D. F.

24. Zhang ZM, Zeng DD, Li GK (2008) Study of the violatile

composition of tomato during storage by a combination sampling

method coupled with gas chromatography/mass spectrometry. J

Sci Food Agric 88:116124

25. Acree TE (1993) Bioassay in flavor research. In: Acree TE,

Teranishi R (eds) Flavor science: sensible principles and techniques. American Chemical Society, Washington, DC, pp 122

26. Spanier AM, Miller JA (1993) Roles of proteins and peptides in

meat flavor. In: Food flavor and safety. Molecular analysis and

design. ACS Symp. Series 528, Washington, DC

27. AOAC (1996) Official methods of analysis, 18th edn. Association

of Official Analytical Chemists, USA

28. Ortiz MA, Dorantes L, Galndez J, Guzmn RI (2003) Effect of

different extraction methods on fatty acids, volatile compounds,

and physical and chemical properties of avocado (Persea

americana Mill.) oil. J Agric Food Chem 51:22162221

doi:10.1021/jf0207934

29. Shahidi F, Rubin L, Souza L (1986) Meat flavor volatiles: a

review of the composition, techniques of analysis and sensory

evaluation. Food Sci Nutr 24:141243

30. Brennan JG, Herrera J, Jowitt R (1971) A study of some factors

affecting the spray drying of concentrated orange juice, on a

laboratory scale. J Food Technol 6:295

Vous aimerez peut-être aussi

- DISOLUCIONES (Autoguardado)Document20 pagesDISOLUCIONES (Autoguardado)Nery Limon OrtizPas encore d'évaluation

- CalculosDocument13 pagesCalculosNery Limon OrtizPas encore d'évaluation

- Presin de VaporDocument51 pagesPresin de VaporNery Limon OrtizPas encore d'évaluation

- Ejercicios de DiagnosticosDocument4 pagesEjercicios de DiagnosticosNery Limon OrtizPas encore d'évaluation

- Hechos y Fenomenos GeograficosDocument11 pagesHechos y Fenomenos GeograficosNery Limon OrtizPas encore d'évaluation

- Factor de Conversion de Unidades PDFDocument2 pagesFactor de Conversion de Unidades PDFNery Limon OrtizPas encore d'évaluation

- Temas Selectos de Química I Primer ParcialDocument1 pageTemas Selectos de Química I Primer ParcialNery Limon Ortiz0% (1)

- Actividad Integradora 4 WordDocument7 pagesActividad Integradora 4 WordNery Limon OrtizPas encore d'évaluation

- Yersinia EnterocoliticaDocument12 pagesYersinia EnterocoliticaNery Limon OrtizPas encore d'évaluation

- Ejercicios de MinitadDocument31 pagesEjercicios de MinitadNery Limon OrtizPas encore d'évaluation

- PRACTICA INDIVIDUAL Mercados Del Carbono Nery Noemi Limon OrtizDocument7 pagesPRACTICA INDIVIDUAL Mercados Del Carbono Nery Noemi Limon OrtizNery Limon OrtizPas encore d'évaluation

- Pérez, 2013 Tesis VeronicaDocument158 pagesPérez, 2013 Tesis VeronicaNery Limon OrtizPas encore d'évaluation

- DPI-Diseño de Plantas Leche en Polvo FINALDocument100 pagesDPI-Diseño de Plantas Leche en Polvo FINALEdu CondePas encore d'évaluation

- Microencapsulación Practica 3Document8 pagesMicroencapsulación Practica 3Juan SalasPas encore d'évaluation

- La Seleccionn de La TecnologíaDocument10 pagesLa Seleccionn de La TecnologíaFranklin MadrizPas encore d'évaluation

- Laboratorio de SecadoDocument9 pagesLaboratorio de SecadoAngelo PacahualaPas encore d'évaluation

- Practica 5 - Secado en SprayDocument18 pagesPractica 5 - Secado en SpraymquinterosPas encore d'évaluation

- Leche en PolvoDocument2 pagesLeche en PolvoDaniela GalvezPas encore d'évaluation

- 3ra Guía SecadoDocument2 pages3ra Guía SecadoJackeline Condori sanchezPas encore d'évaluation

- Spray DryerDocument106 pagesSpray DryerElvis Saavedra PoncePas encore d'évaluation

- Reciclado de Aguas Residuales en Fabricacion de Ceramicas Baldosas PDFDocument6 pagesReciclado de Aguas Residuales en Fabricacion de Ceramicas Baldosas PDFsheyla salazar terrazasPas encore d'évaluation

- Informe-Final GVA Cosmética DefDocument36 pagesInforme-Final GVA Cosmética DefANGIE TATIANA RUIZ LADINOPas encore d'évaluation

- en EsDocument4 pagesen EsFernanda AltamiranoPas encore d'évaluation

- Folleto Spray SecaderoDocument2 pagesFolleto Spray SecaderoFlor Ruiz DiazPas encore d'évaluation

- Transición VítreaDocument6 pagesTransición VítreaHannia GomezPas encore d'évaluation

- El Proceso de Secado Es El Método Más Antiguo en La Conservación de AlimentosDocument4 pagesEl Proceso de Secado Es El Método Más Antiguo en La Conservación de Alimentosjose david perezPas encore d'évaluation

- Tecnologías Aplicadas en La Leche y LácteosDocument4 pagesTecnologías Aplicadas en La Leche y LácteosFátima FigueroaPas encore d'évaluation

- 1 s2.0 S0023643822006296 MainDocument9 pages1 s2.0 S0023643822006296 MainLUIS ANGEL LLANOS ACUÑAPas encore d'évaluation

- Secado Por Aire CalienteDocument9 pagesSecado Por Aire CalienteValentina AzueroPas encore d'évaluation

- Guía para El Desarrollo Del Componente Práctico - Unidad 1, 2 y 3 - Fase 5 - Desarrollo Del Componente PrácticoDocument20 pagesGuía para El Desarrollo Del Componente Práctico - Unidad 1, 2 y 3 - Fase 5 - Desarrollo Del Componente PrácticoYeraldinePas encore d'évaluation

- Proceso de Secado SprayDocument5 pagesProceso de Secado SprayVicky Olivero MengoPas encore d'évaluation

- Atomizador ATM Documentación TecnicaDocument20 pagesAtomizador ATM Documentación TecnicaRobert Hernandez MatheusPas encore d'évaluation

- Guía para El Desarrollo Del Componente Práctico y Rúbrica de Evaluación - Unidad 1, 2 y 3 - Fase 5 - Desarrollo Del Componente PrácticoDocument20 pagesGuía para El Desarrollo Del Componente Práctico y Rúbrica de Evaluación - Unidad 1, 2 y 3 - Fase 5 - Desarrollo Del Componente PrácticoEl MayaPas encore d'évaluation

- AGUADO - Diseño de Equipamiento para Procesos Combinados de MicroencapsulaciónDocument71 pagesAGUADO - Diseño de Equipamiento para Procesos Combinados de MicroencapsulaciónAdán Razo TapiaPas encore d'évaluation

- Elaboracion de Las Formas Farmaceuticas Solidas en La Industria Farmaceutica y Posibles Errores en Su FabricaciónDocument33 pagesElaboracion de Las Formas Farmaceuticas Solidas en La Industria Farmaceutica y Posibles Errores en Su Fabricaciónacpomier-esPas encore d'évaluation

- Secador SprayDocument15 pagesSecador SprayShirley Bautista DiazPas encore d'évaluation

- 4 EsDocument43 pages4 EsJuan Sebastian MontoyaPas encore d'évaluation

- Estudio Parcial 2Document23 pagesEstudio Parcial 2WENDY LAURA GALINDO RIVERAPas encore d'évaluation

- Atomizacion de Jugos de Frutas y VegetalesDocument11 pagesAtomizacion de Jugos de Frutas y VegetalesNérida HUARHUA QUISPEPas encore d'évaluation

- Ficha Spray Dryer Adl Series YamatoDocument4 pagesFicha Spray Dryer Adl Series YamatoKarol Hdz.BPas encore d'évaluation

- T5 Metodos de Concentración de Alimentos Por Concentración G-A PomarrosaDocument19 pagesT5 Metodos de Concentración de Alimentos Por Concentración G-A PomarrosaCamila LópezPas encore d'évaluation

- Segunda ParteDocument47 pagesSegunda ParteElvis Wiliams Villavicencio VillarrealPas encore d'évaluation