Académique Documents

Professionnel Documents

Culture Documents

Ajfn 2 2 47 50

Transféré par

Bismi MaulizaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ajfn 2 2 47 50

Transféré par

Bismi MaulizaDroits d'auteur :

Formats disponibles

AMERICAN JOURNAL OF FOOD AND NUTRITION

Print: ISSN 2157-0167, Online: ISSN 2157-1317, doi:10.5251/ajfn.2012.2.2.47.50

2012, ScienceHu, http://www.scihub.org/AJFN

Furfural production from the epicrap of wild mango (irvingia species)

fruits by acid catalyzed hydrolysis

D. Wankasi1 and E.B Naidoo2

1

Department of Chemical Sciences, Faculty of Science, Niger Delta University, Wilberforce

Island, P.M.B 071, Yenagoa, Bayelsa State, Nigeria.

Email: wankasi@yahoo.com

2

Department of Chemistry, Faculty of Applied and Computer Sciences, Vaal University of

Technology, Private Bag x021, Vanderbijl Park- 1900 South Africa- Andries Potgieter

Boulevard

Email: bobby@vut.ac.za

ABSTRACT

The epicarp of wild mango (irvingia species) fruits were hydrolyzed with 4.5M hydrochloric acid

solution and distilled. The distillates were tested for furfural using volumetric, Uv/visible and IR

spectroscopic methods in addition to other physicochemical parameters. The Uv/visible and IR

scans and the other tests confirm the presence of furfural. The result also show good yield of

furfural.

Keywords: Furfural, production, irvingia species, hydrolysis

INTRODUCTION

Agricultural wastes are abundant, renewable, natural

and rich sources of feedstock for chemicals. These

agricultural by-products are more evenly spread all

over the world in both terrestrial and aquatic

environments. They are readily available in large

quantity for use everywhere.

The importance of furfural and its derivatives has

increased due to its very wide applications and this

has made it imperative for the search for cheap,

renewable and always available feedstock for the

production of furfural.

pawpaw and pineapple peels (Wankasi, etal, 2011)

and Banana and plantain peels (Wankasi and

Yabefa, 2011).

The low yield of furfural from straw and other

materials makes it desirable to extract the aqueous

furfural distillate after acid hydrolysis by a solvent

heavier than water such as chloroform. Sometimes

the distillate is treated with enough sodium hydroxide

so that the mixture is left just faintly acid, and the

furfural separated (Adams and Voorhees 2011).

Furfural can be produced by acid catalyzed

hydrolysis of agricultural by- products containing

hemi-cellulose or pentosan

Some of the applications of furfural and its derivatives

include industrial chemicals and resins, solvent in

petroleum

industry,

medicine,

pesticides,

antiseptics,disinfectors, insecticides, rust removers,

and bio-fuels (De-Jong and Marcotullio 2010)

The possibility of using agricultural by-products for

the production of furfural has been recognized for

many years and over the last 60 years a more

considerable fund of information has been built up.

These include the production of furfural from corncorbs, rice hulls, bagasse (Saad etal, 1978), palm

fruit fibre (Odozi etal, 1985), Garbage (Win, 2005),

raphia hookeri (Wankasi and Tarawou, 2011),

Pentosan is one of the important fibre component of

non-starch polysaccharides called hemi-cellulose.

Hemi-cellulose can be any of several heteropolymers

present in almost all cell walls.

Am. J. Food. Nutr, 2012, 2(2): 47-50

pH of distillate: The pH meter was standardized with

buffer solutions and then 25ml of each sample

distillate was measured into a beaker. The pH values

were read and recorded when the meter readings

were stable.

There are two varieties of the wild mango, i.e

l.Gabonensis with sweet pulp or skin and l.Wombolu

with bitter pulp or skin. They all belong to the family

of irvingiaceae (Harris 1996). Both irvingia species

are found growing wild in the humid lowland Forests

of tropical Africa in Angola, Cameroon, Central

African Republic, Congo, Equitorial Guinea, Gabon,

Zaire, Senegal and Nigeria (Harris 1996).

Furfural estimation in distillate: 25ml of distillate

was measured into a conical flask and 20ml of 0.05M

potassium bromate/bromide (KBrO3/KBr) solution

added and allowed to stand for five minutes. 10ml of

5% (0.05M) potassium iodide (kI) was then added

and the liberated iodine titrated with a standard 0.1M

sodium thiosulphate (Na2SO2. 5H2o) solution. Then

the titre values (volumes of the NaS2O2. 5H2O) were

recorded. A blank experiment was conducted under

the same conditions.

MATERIALS AND METHODS

Sample collection and preparation: Wild mango

(irvingia species) fruits were obtained from

Amassoma Town in Bayelsa State of Nigeria. The

Epicarp were separated from the rest of the fruit. The

o

epicarp were then oven dried at 60 C for 48hours

and ground to 500um mesh sizes.

UV/Visible spectrophotometric scanning of

distillates: A Jenway 6505 single beam scanning

spectrophotometer was used to scan the distillates.

The equipment was set to scan from 200-700nm at a

scan speed of 5mm per minute.

Furfural production by Acid Hydrolysis: 30grams

of the 500um mesh sizes of the epicarp of wild

mango were weighed into a round bottom flask and

refluxed with 500ml of 4.5HCl solution for one hour.

The hydroxylate was cooled and stored in brown

reagent bottles for further experimentation.

IR Spectroscopic scanning of distillates: A drop of

neat sample was placed between two polished flat

sodium chloride plates (cells) which were squeezed

together

and

mounted

in

the

FTIR

SPECTROPHOTOMETER (Model: Spectrum onePerkin Elma) and scanned.

Distillation of hydroxylate: 300ml of the hydroxylate

were put into a round-bottomed flask in distillation

unit set up with a receiver containing chloroform.The

hydroxylate was then distilled so that the distillate

(furfural) passed directly into the layer of chloroform

contained in the receiver. Distillation was continued

until there was no increase in the chloroform layer.

RESULTS AND DISCUSSION

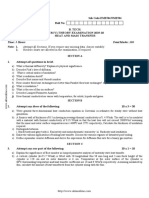

Table 1 gives the density of the distillate as 1.17g/ml

for the irvingia fruit epicarps. This value is within the

1.16g/ml for furfural. This shows that the distillate

was furfural.

Distillation

of

furfural/chloroform

mixture

(chloroform layer): 350ml of furfural/chloroform

mixture were put into a round-bottomed flask in a

distillation unit. The flask was heated with an

electrothermal heating mantle. The chloroform was

o

recovered at 60 C while the furfural remained in the

flask.

Table1; physicochemical properties and percent yield

of distillate

Density of distillate: The empty density bottle was

weighed and recorded. The density bottle was then

filled with the distillate and the weight recorded. The

difference in weight was taken and the density

computed.

TEST

EPICARPS

pH

(o

Boiling point C)

Density (g/ml)

Colour

%yield

IRVINGIA FRUIT

Boiling point determination: 70ml of distillate was

measured into a clean 100ml beaker and a

thermometer with a capillary tube tied together was

inserted. The beaker with its content were then

heated using a hot plate until the first bubble was

observed. The temperature at this point was read and

recorded.

The boiling point as indicated in Table 1 is 160 C.

o

This value is within the 161.7 C for furfural and

further confirms the conversion of the irvingia fruit

epicarps to furfural.

5.82

160

1.17

light brown

33.67

o

48

Am. J. Food. Nutr, 2012, 2(2): 47-50

The pH value of 5.82 for the distillate is acidic. Table

1 also gives a fairly high percent yield of the furfural

to be 33.67.

The carbonyl groups of saturated aldelydes and

ketones give a weak absorption band in the

ultraviolet region between 270-300nm. This band is

shifted to longer wavelengths (300-350nm) when the

carbonyl group is conjugated with a double bond

(Solomon, 1978).

As the degree of conjugation increases, the

absorption will shift to longer wavelength. Generally,

each additional double bond increases or gives rise

to longer wavelength. Each additional conjugated

double bond increases the wavelength of absorption

band for about 300nm (Kamalu and Ogbome 2008).

Figure 2 is the infrared spectrum of irvingia fruit

epicarp distillate. The spectrum shows sharp peaks

-1

between 1640-1710cm

for the distillate which

indicate the presence of aldelyde. This further

confirms the production of furfural from the epicarp of

irvingia fruit by the acid catalyzed hydrolysis.

CONCLUSION

This study revealed a good yield of the furfural from

the epicarp of irvingia fruits, which have been

confirmed by the various tests including the Uv/visible

and infrared spectrophotometric scans. Based on

these findings, epicarps of irvingia fruits are good

sources of renewable raw materials for the

production of furfural. Furfural is a good source of

chemicals and bio-fuels in the future bio-based

economy.

REFERENCES

Examination of the resulting spectra as shown in

figure 1 revealed broad absorption band in the region

between 350-500nm for the irvingia fruit epicarp

distillate. This significant absorption band indicate the

presence of conjugated unsaturated bonds. This also

further confirms the presence of furfural as the broad

band may be due to the conjugation in the furfural.

Adams R and Voorhees-checked by Clarke H. T. and

Taylor E,R (2011); Organic synthesis, coll. Vol 1 pp.49

and 280 (copyright).

De- Jong W and Marcotullio G. (2010); Overview of

Biorefineries based on co- production of furfural,

Existing Concepts and Novel Developments.

International Journal of Chemical Reactor Engineering,

Vol 8, Article A69.

Carbonyl groups of aldehydes and ketones give rise

to very strong c=o stretching bands in the 1665-1

1780cm region of the infraned spectrum. The exact

location of the peak depends on the structure of the

aldehyde or ketone. For example RCHO (1729-1

-1

1740cm ) Ar -CHO (1695-1715cm ), -C=C-CHO

-1

(1680-1690cm ) the CHO group of aldehydes also

-1

gives two weak bands in the 2700-2775cm and

-1

2820-2900cm regions of the infrared spectrum

(Solomon, 1978).

Harris D.J (1996). A Revision of the Irvingiacea in Africa.

Bulletin du Jurdin. Batanique National de Belgique. 65

(1-2); 55-64

Kamalu O.I.C and Ogbome P. (2008); Extraction and

Characterisation of Tiger Nut Oil J. chem. Soc. Nigeria,

vol. 33, No 1, pp 79-87.

49

Am. J. Food. Nutr, 2012, 2(2): 47-50

Odozi T.O, Akaranta O. Ogban I. U. (1985). Development

of Wood Varnishes from Palm Fruit Fibre Hydroxylate

(Eliesis Gelineesis) and Red Onion skin (Allium cepa)

Tannin Extract. JOCCA: 94-97

Wankasi D and Yabafa J. A (2011), Furfral Production from

the Peels of Ripe Banana (musa sapientum L) by Acid

catalyzed

Hydrolysis.

Electronic

Journal

of

Environmental Agricultural and Food Chemistry

(EJEAChe) 10(5) 2011 (2199-2205)

Saad S.M; Naser A.M; EL-Zi M, Abel-Moged (1978); 2Furfuraldehyde (furfural) from Local By-products and

its Utilization in the Field of Surface Coatings. JOCCA

61: 41-48

Wankasi, D and Tarawou T (2011). Furfural Production

from Epicarp and Mesocarp of Raphia Hookeri Fruit by

Acid catalyzed Hydrolysis. International Journal of

Chemistry Vol. 21 No 2, 141-145

Solomon T.W.G. (1978). Organic Chemistry. John Whiley

and Sons-New York. Chichelar Barisbane. Toronto.

Wankasi D; Tarawou J.T and Yabefa A.J (2011). Furfural

production from the peels of Ripe pawpaw (carica

papaya) and pineapple (ananas comosus) fruits by

Acid catalyzed Hydrolysis. American Journal of Food

and Nutrition. 1(3): 136-140.

Win T.D (2005); Furfural from Garbage. AUJT. 8(4); 185190

50

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Rights of An Accused Under Custodial InvestigationDocument17 pagesRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- Dawn of The DhammaDocument65 pagesDawn of The Dhammaarkaprava paulPas encore d'évaluation

- 06 Renr5908 08 01 All PDFDocument108 pages06 Renr5908 08 01 All PDFFrancisco Ospino Arrieta100% (2)

- Play Tennis Manual PDFDocument52 pagesPlay Tennis Manual PDFAnonymous GJuRvp9A5T100% (2)

- The Goldfish and Its Culture. Mulertt PDFDocument190 pagesThe Goldfish and Its Culture. Mulertt PDFjr2010peruPas encore d'évaluation

- Transformational and Charismatic Leadership: The Road Ahead 10th Anniversary EditionDocument32 pagesTransformational and Charismatic Leadership: The Road Ahead 10th Anniversary Editionfisaac333085Pas encore d'évaluation

- Active and Inactive Volcano LPDocument2 pagesActive and Inactive Volcano LPhorace hernandez100% (5)

- Mechatronics MaterialDocument86 pagesMechatronics MaterialKota Tarun ReddyPas encore d'évaluation

- Ijcre 2010 8 1 2174Document27 pagesIjcre 2010 8 1 2174Bismi MaulizaPas encore d'évaluation

- Hemicellulose Biorefinery For Furfural Production Energy Requirement Analysis and MinimizationDocument6 pagesHemicellulose Biorefinery For Furfural Production Energy Requirement Analysis and MinimizationBismi MaulizaPas encore d'évaluation

- Herrick JAE Aridmanage 2006Document17 pagesHerrick JAE Aridmanage 2006Bismi MaulizaPas encore d'évaluation

- Iipee ) Ibed (ZCL: DencanDocument10 pagesIipee ) Ibed (ZCL: DencanBismi MaulizaPas encore d'évaluation

- HP Solar Food Dryer ArticleDocument11 pagesHP Solar Food Dryer ArticleBismi MaulizaPas encore d'évaluation

- Quick-Guide M1M 20Document2 pagesQuick-Guide M1M 20KhaledPas encore d'évaluation

- Difference Between Dada and SurrealismDocument5 pagesDifference Between Dada and SurrealismPro FukaiPas encore d'évaluation

- Quiz Application in Visual BasicDocument20 pagesQuiz Application in Visual BasicShivangi SahaPas encore d'évaluation

- Design and Fabrication of Light Electric VehicleDocument14 pagesDesign and Fabrication of Light Electric VehicleAshish NegiPas encore d'évaluation

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Document2 pagesBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaPas encore d'évaluation

- Concordance C Index - 2 PDFDocument8 pagesConcordance C Index - 2 PDFnuriyesanPas encore d'évaluation

- Paula Moraga (Author) - Geospatial Health Data-Modeling and Visualization With R-InLA and Shiny-Chapman and Hall - CRC (2019)Document295 pagesPaula Moraga (Author) - Geospatial Health Data-Modeling and Visualization With R-InLA and Shiny-Chapman and Hall - CRC (2019)M Khahfi ZuhandaPas encore d'évaluation

- Myplan Assessment Skills Profiler Report Summary AnalysisDocument5 pagesMyplan Assessment Skills Profiler Report Summary Analysisapi-338283524Pas encore d'évaluation

- Algorithm Design TechniquesDocument24 pagesAlgorithm Design TechniquespermasaPas encore d'évaluation

- Paper 19 AugustDocument552 pagesPaper 19 AugustUma Sankar Pradhan100% (1)

- Colombo Port City Causing Unimaginable Environmental HarmDocument6 pagesColombo Port City Causing Unimaginable Environmental HarmThavam RatnaPas encore d'évaluation

- Secondary Scheme of Work Form 2Document163 pagesSecondary Scheme of Work Form 2Fariha RismanPas encore d'évaluation

- Pre-Qin Philosophers and ThinkersDocument22 pagesPre-Qin Philosophers and ThinkersHelder JorgePas encore d'évaluation

- Defining Who Is A Volunteer ConceptualDocument21 pagesDefining Who Is A Volunteer ConceptualYosep Trisaputro WahyuPas encore d'évaluation

- Ap Reg W# 5-Scaffold For Transfer TemplateDocument2 pagesAp Reg W# 5-Scaffold For Transfer TemplateJunafel Boiser Garcia100% (2)

- 67 9268Document34 pages67 9268Salvador ReyesPas encore d'évaluation

- January 2014 QP - Paper 1 Edexcel (B) Maths IGCSEDocument24 pagesJanuary 2014 QP - Paper 1 Edexcel (B) Maths IGCSEStevenstrange001 CattyPas encore d'évaluation

- Erp FinalDocument33 pagesErp FinaltenetchatPas encore d'évaluation

- Robe Draft Geotechnical Report - Edited by k2nDocument43 pagesRobe Draft Geotechnical Report - Edited by k2nASAMNEW GULILATPas encore d'évaluation

- HRIRDocument23 pagesHRIRPhuong HoPas encore d'évaluation

- Declaration of Absence of Conflict of InterestDocument1 pageDeclaration of Absence of Conflict of InterestJvhelcoronacondat CondatPas encore d'évaluation

- Maxdb Backup RecoveryDocument44 pagesMaxdb Backup Recoveryft1ft1Pas encore d'évaluation