Académique Documents

Professionnel Documents

Culture Documents

Choices in Flying Cutoff Saw Blades - TheFabricator

Transféré par

AndiniPermanaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Choices in Flying Cutoff Saw Blades - TheFabricator

Transféré par

AndiniPermanaDroits d'auteur :

Formats disponibles

Choices in flying cutoff saw blades - TheFabricator.

com

http://www.thefabricator.com/article/tubepipeproduction/choices-in-flyin...

(/)

(http://ad.thefabricator.com/delivery

/ck.php?oaparams=2__bannerid=467__zoneid=1__cb=c5d2470c23__oadest=http%3A%2F%2Fwww.turretpunchpresses.com)

HOME (/) TECHNOLOGIES

INDUSTRY DIRECTORY (HTTP://DIRECTORY.THEFABRICATOR.COM/DIRECTORY/) PUBLICATIONS (/PUBLICATION)

FAB 40 (/FAB40)

SUBSCRIPTIONS (HTTP://WWW.FMA-COMMUNICATIONS.COM/SUBSCRIPTION-CENTER.CFM)

(HTTPS://WWW.FACEBOOK.COM/THEFABRICATOR)

(HTTPS://TWITTER.COM/FABRICATING)

(HTTP://WWW.LINKEDIN.COM/GROUPS?GID=188707

ADVANCED SEARCH (/SEARCH/ADVANCED

Home (/) / Article (/?filter=article) / Tube and Pipe Production (/?filter=article&category=tubepipeproduction) /

SPONSORED CONTENT

Choices in flying cutoff saw blades

hefabricator.com/article/tubepipeproduction/choices-in-flying-cutoff-saw-blades&title=Choices+in+flying+cutoff+saw+blades&

+machines+for+tube+and+pipe+mills.+Drawbacks+include+hazards+%28noise+and+risk+of+breakage%29+and+burrs+they+tend+to+generate.+Tungsten-

re+more+sophisticated+sawing+machines%2C+run+slower+and+safer%2C+cut+cleaner%2C+and+are+less+prone+to+breakage.&img=http:

w-blades-flying-cutoff-saw-blades.jpg)

(https://twitter.com/share)

(http://www.printfriendly.com)

Choices in flying cutoff saw blades

Friction versus carbide

TPJ - THE TUBE & PIPE JOURNAL DECEMBER 2009 (/publication/tpj/issue/357 )

DECEMBER 2, 2009

BY: MIKE RANS (/AUTHOR/MIKE-RANS)

Friction saws are the conventional cutoff machines for tube and pipe mills. Drawbacks include

hazards (noise and risk of breakage) and burrs they tend to generate. Tungsten-carbide-tipped

(TCT) blades, which require more sophisticated sawing machines, run slower and safer, cut cleaner,

and are less prone to breakage.

PWTV: Aluminum Welding Principl

(/video/pwtv-aluminum-weldingprinciples-part1)

Todd Bridigum, welding instructor at Minneapolis

Community and Technical College and author of,

to Weld, provides an overview of the various prin

behind welding aluminum successfully.

Watch Welding Videos by PWTV (/pwtv)

Watch Tube & Pipe Videos by TPJ TV (/tpjtv

Tube and pipe producers are a demanding breed. They

have to be. With line costs up to $15,000 per hour,

unexpected downtime can destroy the bottom line.

Keeping the line up and running is critical, and in tube

and pipe production shops everywhere, one important

concern is the cutoff area.

Until recently tube producers relied on friction and

high-speed steel (HSS) saw blades for circular sawing

cutoff lines. Friction blades serve a purpose in the tube

and pipe industry, and some companies continue to use

them for existing and new installations. They are low-cost

items that operate at high speeds and do not require a lot

of sawing knowledge to use.

(http://image.thefabricator.com/a/choices-in-flying-cutoffsaw-blades-flying-cutoff-saw-blades.jpg)

That said, friction saws do have disadvantages. Safety

is one concern. Friction blades are large in diameter, and

depending on the rotational speed, the linear velocity at the tips of the teeth can exceed 180 feet per second (FPS).

Breakage at such a speed can cause severe damage to the machine and its surroundings. Also, they tend to generate

quite a bit of noise and heat (see Figure 1). In many cases, extra precautions, such as sound attenuation cabinets and

protective shields, must be in place to conform to OSHA regulations. The service life of friction blades can be inconsistent,

and therefore can cause unexpected line stops and tool changes.

Advances in blade geometry and coating technology have made tungsten carbide-tipped (TCT) circular saws a viable

option. TCT blades typically are smaller in diameter and run at lower peripheral speeds than friction blades. Blade

breakage is less an issue, and if a crash does occur, flying debris is a smaller hazard. Also, TCT blades run quietly. Sound

attenuation cabinets are not necessary.

Because TCT saws draw a chip at the workpiece, material removal is clean, precise, and repeatable throughout the cut

(see Figure 2).

The most important advantage of TCT circular saws in tube production is durability. Depending on the tube size and

workpiece material grade, a TCT blade can last up to four shifts.

1 of 5

All Videos (/?filter=video)

(http://ad.thefabricator.com/delivery

/ck.php?oaparams=2__bannerid=51__zone

%3A%2F%2Fwww.kukarobotics.com%2Fusa%2Fen%2Fsolutions%

RELATED CONTENT

Producing quality ASTM A249 an

ASME SA 249 pressure tubes

(/article/tubepipeproduction

/producing-quality-astm-a249and-asme-sa-249-pressure-tube

Maintaining and troubleshooting

welders: A common-sense appro

for vacuum tube and solid-state

machines (/article

/tubepipeproduction/maintaining

and-troubleshooting-hf-welders-

23/02/2016 17:33

Choices in flying cutoff saw blades - TheFabricator.com

http://www.thefabricator.com/article/tubepipeproduction/choices-in-flyin...

Switching to TCT blades isn't as simple as installing new blades on an existing saw. TCT blades require a more

sophisticated equipment setup than

friction blades do. Five tips can help you get started in planning the switch.

1. A TCT blade runs at a lower peripheral speed and higher chip loads, so you should plan to reduce the cutting

speed. A good target is 12.5 to 25 FPS.

2. To get the best results, you need precise feed control. An optimal cut relies on a variable-speed system that

allows you to use a slow feed rate as the blade enters the tube, a fast feed rate for making the cut, and a slow

feed rate as the blade exits the tube. The feed system should provide accurate and backlash-free movement.

3. The reduction gear between the drive motor and saw blade should be free of play and preferably have

pretensioned gear engagement.

4. The operator interface should indicate the motor's current consumption (measured in amps).

5. You should be able to fine-tune the motion so that the carriage speed matches the line speed.

Manipulating the Variables

The ability to manipulate the blade speed and feed rate is critical to both line speed and blade life. The speed doesn't refer

to revolutions per minute (RPM), but the peripheral speed of the blade, which is measured in feet per second or meters per

minute. The peripheral speed = RPM x pi x blade diameter.

The feed rate is measured in inches per tooth or millimeters per tooth. Most of the technical work associated with tuning a

flying cutoff setup deals with manipulating these variables to optimize every application.

During the testing process, it is a good idea to start with the manufacturer's suggested blade speed and feed rate and tune

the saw by changing the feed rate. The key is to make changes that affect the chip load by a maximum of 0.001 in. Note

that the blade's speed, the number of teeth, and material feed rate, and the chip load are related to each other by the

following formulas:

a-common-sense-approachfor-vacuum-tube-and-solid-statemachines)

Using flowformed titanium alloy

seamless tubes in production

(/article/tubepipeproduction/usin

flowformed-titanium-alloy-seamle

tubes-in-production)

Tooling, the key for mill productio

(/article/tubepipeproduction/tooli

the-key-for-mill-production)

Increasing tube mill welding spe

Examining technology for tube

producers (/article

/tubepipeproduction/increasingtube-mill-welding-speed-examini

technology-for-tube-producers

More Tube and Pipe Production Articles (/?filter=a

category=tubepipeproduction)

Upcoming Industry Events

The FABRICATORs Leadership Summit

FMA Annual Meeting (/event/the-fabricators-leadership-summit-at-fma-annual-meeting

February 24-26, 2016

FABTECH Canada 2016 (/event/fabtechcanada-2016)

RPM = Feed rate / (Number of Teeth x Chip load)

March 22-24, 2016

Feed rate = RPM x (Number of Teeth x Chip load)

Wire & Tube Dsseldorf 2016 (/event/wire-t

sseldorf-2016)

Chip load = Feed rate / (RPM x Number of Teeth)

(http://image.thefabricator.com

The last formula is useful for demonstrating appropriate

changes for optimizing the sawing process. A slight

increase in the feed rate or decrease in the blade speed

results in a chip load change of approximately 0.001:

Initial Setting: Chip load = 15 FPM / (25 RPM x 60 teeth)

= 0.01

New Setting 1: Chip load = 16.5 FPM / (25 RPM x 60

teeth) = 0.011

International Manufacturing Technology S

(IMTS) (/event/international-manufacturingtechnology-show-imts-)

/a/choices-in-flying-cutoff-saw-blades-friction-sawing-resultsburrs.jpg)

Figure 1 Friction sawing usually generates heat that softens the

workpiece, resulting in a burr which must be removed before

shipping the product.

September 12 - 17, 2016

FABTECH 2016 (/event/fabtech-2016)

November 16-18, 2016

More Industry Events (/?filter=

RELATED BUYER'S GUIDES

New Setting 2: Chip load = 15 FPM / (23 RPM x 60 teeth) = 0.0109

Decrease the chip load for harder, heavier materials; increase the chip load for lighter, softer materials. The sound of the

sawing process is a good guide. Tune to the point where you hear a smooth, consistent sound.

Using TCT blades requires more than a few formulas. TCT sawing is an advanced process that requires a specialized line

technician. If you plan to run TCT, make sure you have access to a technician who understands the dynamics of process

control, including proper chip load, peripheral speed, and feed control. The right person should be able to help you make

improvements, establish parameters, and adapt those parameters for difficult jobs.

2 of 5

April 4-8, 2016

Tube Mill Entry/Exit Equipment Buyers' Guide

(/guide/tube-mill-entry-exit-equipment)

Tube & Pipe Supplier Directory (/guide/tube

pipe-supplier-directory)

Tube & Pipe Mill Machine Buyers' Guide

/tube-pipe-mill-machine)

Tube & Pipe Buyers' Guide (/guide/tubepipe-guide)

Tube & Pipe Bending Machine Buyers' Guide

(/guide/tube-pipe-bending-machine)

Flaw Detection & Measurement Equipment B

Guide (/guide/flaw-detection-measurement

More Buyer's Guides

(http://image.thefabricator.com/a/choices-in-flying-cutoff-saw-blades-tct-blade-

clean-cut.jpg)

Figure 2 Tubes cut by a TCT blade exhibit a clean cut. In most cases, the workpieces do not require deburring.

(http://ad.thefabricator.com/delivery

/ck.php?oaparams=2__bannerid=34__zone

23/02/2016 17:33

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

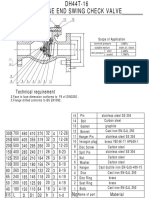

- Flanged End Swing Check Valves DIN3202 F6Document2 pagesFlanged End Swing Check Valves DIN3202 F6AndiniPermanaPas encore d'évaluation

- Abd El Rahman Et - AlDocument11 pagesAbd El Rahman Et - AlAndiniPermanaPas encore d'évaluation

- Common Etchants PDFDocument2 pagesCommon Etchants PDFAndiniPermanaPas encore d'évaluation

- FM Approvals Certification MarksDocument3 pagesFM Approvals Certification MarksAndiniPermanaPas encore d'évaluation

- Permit To Work PolicyDocument5 pagesPermit To Work PolicyAndiniPermanaPas encore d'évaluation

- Effect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillDocument6 pagesEffect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillAndiniPermanaPas encore d'évaluation

- Tabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXDocument1 pageTabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: Vidar SupremeDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: Vidar SupremeAndiniPermanaPas encore d'évaluation

- CCT Vanadis 60Document1 pageCCT Vanadis 60AndiniPermanaPas encore d'évaluation

- CCT Vanadis 60 PDFDocument1 pageCCT Vanadis 60 PDFAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: ElmaxDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: ElmaxAndiniPermanaPas encore d'évaluation

- Hari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000Document2 pagesHari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000AndiniPermanaPas encore d'évaluation

- CCT Vanadis 23Document1 pageCCT Vanadis 23AndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 4Document1 pageUddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 4AndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: ToughtemDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: ToughtemAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: GraneDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: GraneAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: Impax SupremeDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: Impax SupremeAndiniPermanaPas encore d'évaluation

- CCT Orvar Supreme PDFDocument1 pageCCT Orvar Supreme PDFAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: Orvar SupremeDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: Orvar SupremeAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: CompaxDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: CompaxAndiniPermanaPas encore d'évaluation

- CCT Chipper VikingDocument1 pageCCT Chipper VikingAndiniPermanaPas encore d'évaluation

- Uddeholm C Si MN CR Mo V W Ni Co P S: DievarDocument1 pageUddeholm C Si MN CR Mo V W Ni Co P S: DievarAndiniPermanaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- U4E TransformersGuide 201711 FinalDocument103 pagesU4E TransformersGuide 201711 FinalMateo A. Cortés100% (1)

- Shaktivell M.letchumanan Dd160012 ReportDocument56 pagesShaktivell M.letchumanan Dd160012 ReportShaktivell LetchumananPas encore d'évaluation

- Design and Frabrication of Pneumatic Bore Well Child Rescue SystemDocument7 pagesDesign and Frabrication of Pneumatic Bore Well Child Rescue SystemAnonymous kw8Yrp0R5rPas encore d'évaluation

- Engineroom Manual2Document13 pagesEngineroom Manual2Sarm1s100% (1)

- Development of Oil-Pump For Lubrication of Turbocharger in Wankel Rotary EngineDocument3 pagesDevelopment of Oil-Pump For Lubrication of Turbocharger in Wankel Rotary EnginefullkulePas encore d'évaluation

- FAA AircraftDocument252 pagesFAA AircraftRolando Rumiche HernándezPas encore d'évaluation

- HYCHEM Catalogue BookDocument32 pagesHYCHEM Catalogue Bookengage4u2020Pas encore d'évaluation

- AS9100 in Plain EnglishDocument30 pagesAS9100 in Plain EnglishhimanshunepalPas encore d'évaluation

- Megaworld CanopyDocument6 pagesMegaworld CanopyNanam ZaerPas encore d'évaluation

- Mumbai Port Trust: Civil Engineering DepartmentDocument96 pagesMumbai Port Trust: Civil Engineering Departmentsuji91Pas encore d'évaluation

- PdsDocument3 pagesPdsEnrico SaviraPas encore d'évaluation

- NZS 3104 - Specification For Concrete ConstructionDocument43 pagesNZS 3104 - Specification For Concrete ConstructionRihab AbukhdairPas encore d'évaluation

- Jurnal QFDDocument25 pagesJurnal QFDsuryaniPas encore d'évaluation

- Ladder Risk AssessmentDocument3 pagesLadder Risk Assessmentvasanth pugazhendhiPas encore d'évaluation

- T-4.196.224 Road MarkingDocument4 pagesT-4.196.224 Road MarkingYuvaraj PonrajPas encore d'évaluation

- Laporan Teknikal Latihan IndustriDocument55 pagesLaporan Teknikal Latihan IndustriFarah Alzahari100% (1)

- "Agricultural Equipment Repair & Motor Repair'': A Powerpoint Presentation OnDocument17 pages"Agricultural Equipment Repair & Motor Repair'': A Powerpoint Presentation OnAniruddha MPas encore d'évaluation

- Enhanced Supplier Performance Measurement Severity Incident Per Billion (S-Ipb) How To Access S-Ipb Summary in SPMDocument54 pagesEnhanced Supplier Performance Measurement Severity Incident Per Billion (S-Ipb) How To Access S-Ipb Summary in SPMJuan Carlos Horowich CastroPas encore d'évaluation

- Chapter 4: Trends in Information Systems Development: System TheoryDocument19 pagesChapter 4: Trends in Information Systems Development: System TheoryMina twicePas encore d'évaluation

- MasterCAM For SolidWorks PDFDocument62 pagesMasterCAM For SolidWorks PDFrafaeldctPas encore d'évaluation

- Cerrejón Achieves World-Class Coal Mining With End-To-End Gemcom Minex SolutionDocument3 pagesCerrejón Achieves World-Class Coal Mining With End-To-End Gemcom Minex SolutionJorge Eliecer Acevedo SilvaPas encore d'évaluation

- ROG Crosshair VIII Series Memory QVL 20200211Document8 pagesROG Crosshair VIII Series Memory QVL 20200211Arif YuliantoPas encore d'évaluation

- CHAITANYA KAMBOJ - ProductDocument2 pagesCHAITANYA KAMBOJ - Productchaitanya kambojPas encore d'évaluation

- Materi Dasar Pengenalan Kapal-PrintoutDocument28 pagesMateri Dasar Pengenalan Kapal-Printoutdian.yudistiro8435100% (1)

- CraneDocument24 pagesCraneagungPas encore d'évaluation

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressDocument6 pagesPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LePas encore d'évaluation

- CND Course OutlineDocument26 pagesCND Course OutlinesigmaPas encore d'évaluation

- 2011 Penn West Seal 11377Document42 pages2011 Penn West Seal 11377GKeddy85Pas encore d'évaluation

- WEF Technology and Innovation The Next Economic Growth Engine PDFDocument33 pagesWEF Technology and Innovation The Next Economic Growth Engine PDFPiroch RudolfPas encore d'évaluation

- Turbocharger CatalogDocument16 pagesTurbocharger CatalogAdi PoianaPas encore d'évaluation