Académique Documents

Professionnel Documents

Culture Documents

Overview of Pipeline Coatings)

Transféré par

kartalsamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Overview of Pipeline Coatings)

Transféré par

kartalsamDroits d'auteur :

Formats disponibles

The Ins and Outs

of Pipeline

Coatings:

Coatings Used To Protect Oil and Gas Pipelines

oating technology in

the oil and gas industry has come a long

way. The product evolution for protection of

steel pipes has migrated from field-applied asphalt and coal

tar-based materials to the currently used

high-tech, field-applied and plant-applied

coatings. With most coating plants typically located at or near the steel pipe

mill, the economics are good for the

pipeline owners to receive coated pipe of

the highest integrity that is designed to

last for the full projected life of the asset.

The main generic types of pipeline

coatings in use today include coal tar

enamel, polymeric tapes, fusion-bonded

epoxy (FBE), spray-applied liquid coatings, and two- and three-layer polyolefin

coatings. Some coatings are overcoated

with an abrasion-resistant overlay

40

JPCL /

July 2005

PCE

(ARO) designed to protect the main corrosion control coating layer when the

pipe is installed via directional drilling

as is done for road or river crossings.

Field joint or girth weld coatings offer

various technologies to optimize performance with the mainline coating and

provide field-application friendliness.

In addition to the above-mentioned

external coatings, some pipelines are

internally lined with a liquid epoxy or

FBE system to enhance the flow characteristics of the natural gas or oil traveling through the pipeline. Linings are also

used to improve resistance against corrosion and material build-up in oil and

gas production lines.

To overcome negative buoyancy in

offshore applications, wetlands, and

marshland, the use of concrete weight

coatings (CWC) over the corrosion coating is required. Onshore barrier coatings

www.paintsquare.com

By Michael Romano, Tyco Adhesives CPG, with contributions from Matt Dabiri, Williams Companies Inc., and Alan Kehr, 3M

Fig. 1: (opposite page and above) Cold-applied tape and coating process

Courtesy of Tyco Adhesives Corrosion Protection Group

of cement mortar or bendable concrete

are used in rocky terrains, where selective backfill is not used. These coatings

are rare because of cost.

It must be noted that degree and level

of surface preparation as well as dry film

thickness for each corrosion and concrete

coating application including girth weld

coatings typically are specified in standards, customer specifications, and manufacturer recommendations.

This article gives an overview of the

coatings and linings used to protect oil,

gas, and liquid pipelines.

Polymeric Tapes

Cold-applied single or multi-layer tape

systems have been used primarily in the

protection of steel and ductile iron pipes

in the water sector in North America.

However, these coatings are used in other

locations around the world for oil and gas

for new or rehabilitation of pipelines.

These coatings are easy to apply over the

ditch or with portable plants set up near

the pipeline route.

www.paintsquare.com

Systems typically involve the use of

primers designed to meet environmental

regulations for volatile organic compound (VOC) emissions and application

performance requirements. The primer

wets out the surface of the steel and fills

surface irregularities to assist the adhesive layer in bonding without the need

for applied heat. The adhesive layer is

designed with the primer to maximize

adhesion to the prepared and clean steel

substrate. The primer should be dry

before the application of the adhesive

layer so that any residual solvent from

the primer has dissipated.

The adhesive layer is typically a blend

of butyl rubber and synthetic resins in a

tape form. The middle and/or outer

layer, which forms a bond with the adhesive layer, is the mechanical layer and is

made of high-density polyethylene or

polypropylene. The outer layers are resistant to ultraviolet light (UV) for aboveground storage or exposure to sunlight.

The total coating system relies on the

use of tension on the tape to provide a

JPCL /

July 2005

PCE

gasketing effect that provides protection from the ingress of water and oxygen, two essential ingredients for corrosion (Fig. 1). Spiral and longitudinal weld

areas are typically coated with a strip of

adhesive prior to wrapping to assist with

the step-down from the weld beads to

the main pipe surfaces and to prevent a

bridging effect near the weld area. Coldapplied tapes have been used since the

1950s and have seen many performance

advances over the years.

Hot-applied tape systems consist of a

fused multi-layer coating system made

up of a thermally activated primer layer,

a thermoplastic elastomer adhesive layer,

and a thermoplastic outer layer. The

primer is a solvated thermoplastic elastomer that chemically bonds to the adhesive layer. This primer contains additives

designed to directly improve the anti-corrosion properties of the system. The

adhesive layer is a butyl compound that

fuses to the outer polyethylene layer. The

outer layer is typically a high-density

polyethylene (PE). The approach is to

form an integrated system that bonds to

the pipe and resists mechanical damage.

The process is one that involves the

application of heat to achieve the desired

performance (Fig. 2). In their current

form, these systems have been in use

since the late 1980s.

Heat-Shrinkable Tape Coatings

Heat shrinkable corrosion prevention

coatings in tape form have been used

since the 1980s for buried and offshore

pipelines operating at temperatures up to

120 C (250 F). These products consist of

a thick, radiation crosslinked polyethylene-based backing coated with a high

shear strength, thermoplastic, hot-melt

adhesive.

When the coating is applied to a pre41

Fig. 2: (above and right) Hot-applied tape and coating process

Courtesy of Tyco Adhesives CPG

heated pipe, the thermoplastic adhesive

melts and flows. The preheated temperature is critical in ensuring that the adhesive wets out the steel and bonds to its

surface. The manufacturers instructions

will give the recommended minimum

temperature. The crosslinked polyethylene backing is heated from the outside

by propane torches and shrinks onto the

heated pipe surface so that the adhesive

bonds to the substrate.

Once the product has cooled, the high

shear strength adhesive is anchored to

the pipe and can be handled and buried.

The tape is typically supplied in a twolayer form as rolls of various widths.

The products are installed by professional pipe coaters in their factories or

may be applied nearer the pipeline construction site using portable coating

equipment (Fig 3).

Fusion-Bonded Epoxy (FBE)

Fusion-bonded epoxy coatings are 100%

solids, thermosetting materials in powder form that bond to the steel surface as

a result of a heat-generated chemical

reaction. Formulations consist of epoxy

resins, hardeners, pigments, flow control

additives, and stabilizers to provide ease

of application and performance.

The pipe must be preheated to remove

moisture, and it must be shot and grit

blasted to attain a clean surface with

proper anchor pattern profile and to

improve the adhesion properties. It is

important to observe the powder manufacturers pipe preheat temperature.

Heating the pipe to be coated is typically

done with induction or gas burners to

temperatures in the range of 215 to 245

C (420 to 475 F).

Electrostatic guns are used to apply

the epoxy powder. The epoxy powder

melts on contact with the heated steel

pipe, then flows, gels, and cures to form

the tough coating required to protect the

steel pipe from corrosion (Fig. 4). These

systems became commercially available

in 1960.

Dual-layer systems involve the use of

a second layer of FBE that overcoats the

first layerthe corrosion coating. The

second layer has select characteristics to

impart unique properties for special

applications and service conditions, such

as mechanical protection for directional

drilling. The second layer, or topcoat, is

applied directly after the first layer on

the coating line while there is still functionality in the primary layer to give a

chemical bond at the interface in a continuous application.

Liquid epoxy coatings are also used

Fig. 4: Fusion-bonded Epoxy (FBE) application

Photo courtesy of 3M

Fig. 3: Holiday detection of heat shrink tape coating. Courtesy of Tyco Adhesives CPG

42

JPCL /

July 2005

PCE

www.paintsquare.com

Fig. 5: Two-layer polyolefin coating system

Courtesy of Durabond

over FBE to protect the pipeline against

abrasion during directional drilling and

thrust bore installations.

Two-Layer Polyolefin Coatings

Extrusion of plastic coatings that include

an adhesive or sealant to form the inner

layer and provide the bonding and corrosion protection dates back to the late

1950s when pipelines were first coated

in the controlled environment of a coating plant. Two-layer coating systems

Fig. 6: Three-layer coating system application

come in various types with butyl-based

adhesives or asphalt-based mastics as

their primary coat and with a sideextruded or crosshead-extruded polyolefin layer (Fig. 5). Typically, high-density polyethylene is used as the outer

layer, but polypropylene has also been

used.

During application, the adhesive is

heated to obtain the optimal flow characteristics to provide a uniform coating

on the pipe surface. The adhesive is then

immediately overcoated with a polyolefin to the specified thickness.

Three-Layer Polyolefin Coatings

Three-layer polyolefin coatings have

been in use since the 1980s. Multi-layer

coating systems consist of an FBE or liquid epoxy primer and copolymer adhesive intermediate or tie layer topcoated

with a polyolefin.

Pipelines coated with this system have

high electrical resistance. Polyethylene is

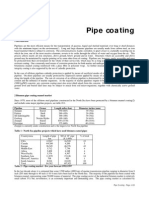

Table 1: Types of Field Joint Coatings

Type of Field Joint Coating

Hot-Applied Bituminous Tapes

Cold-Applied Polymeric Tapes

Petrolatum Tapes

Wax Tapes

Heat-Shrinkable Sleeves

Fusion-Bonded Epoxies

Liquid Epoxies

Liquid Polyurethanes

Flame-Sprayed Polyolefins

Hot-Applied Coal Tar Enamels

44

Description

Polymer-backed, bituminous-based adhesive tapes. May consist of a bonding primer with a single

or multiple layers of a fusible bituminous tape that is hot applied.

Polymer-based adhesive tapes, which may consist of a primer with single or multiple layers of a

polymeric tape

Non-woven synthetic fabric tapes fully impregnated with a natural petrolatum-based compound

A blend of microcrystalline wax-saturated synthetic fabric in the form of tapes

Cross-linked polyolefin backings coated with a mastic or hot melt type adhesive

Available as there-layer systems with liquid epoxy as the first layer.

One-part, heat-curable thermosetting powder epoxy coating

Two-part, ambient temperature-cured, 100% solids (no VOCs) thermosetting liquid epoxy coatings

with an epoxy resin and a curing agent as the two parts

Two-part, 100% solids, liquid coatings with polyisocyanate and polyol as the two components

Multi-layer systems that use a flame-sprayed thermoplastic topcoat over a thermosetting resin,

typically epoxy

Consist of primer, coal tar enamel, glass fiber innerwrap, coated glass fiber, or other outerwrap with

comparable performance and optional final wrap of kraft paper

JPCL /

July 2005

PCE

www.paintsquare.com

typically the topcoat, but polypropylene

is used for higher service temperatures

and where better mechanical properties

are required for handling. The tie layer or

adhesive layer is typically a copolymer or

terpolymer adhesive that is grafted and

compatible with the outer layer of polyethylene or polypropylene.

The FBE layer is applied by electrostatic

spray. Induction or gas heating brings the

pipe to the required surface temperatures

for the proper application of the powder.

The adhesive layer is then applied by side

extrusion or spray followed by the polyolefin outer layer (Fig. 6).

Coal Tar Enamel and Asphalt Coatings

Coal tar coatings have been used for more

than 80 years and dominated the pipeline

coatings market for the early years. They

were also one of the first pipeline coatings

to be successfully applied in a plant. Coal

tar coatings were very popular until the

1970s and are still used for corrosion protection onshore as well as under concrete

weight coated (CWC) pipe offshore.

Coal tar enamel (CTE) is a polymerbased coating produced from the plasticization of coal tar pitch, coal, and distillates. Inert fillers are added to give the

desired properties of the system. The coal

tar pitch, which forms the basis for the

enamel, consists of poly-nuclear aromatic

hydrocarbons and heterocyclic compounds. Over the years, this coating has

been used in conjunction with a primer, a

fiber glass, or mineral felt reinforcement,

and an outer wrap. The introduction of

glass fiber inner wraps and the application of outer wraps onto the coating surface improved the mechanical strength of

the system and provided extra protection

against soil stresses and impact damage

during handling and installation.

The CTE system is made up of four

main components: primer, coal tar enamel,

glass fiber inner wrap, and glass fiber

outer wrap. When selecting the enamel

and outer wrap grades, end users must

consider the performance requirements,

www.paintsquare.com

based on factors such as service temperPolyurethanes are used in the oil and

atures, local ground conditions, and

gas coating sector as a rehabilitation

ambient conditions.

mainline coating or as an abrasion-resisCTE is easily repaired with fieldtant overlay for directional drills. They

applied coal tar enamel, coal tar epoxy,

are applied easily in the field or the

or tape coatings. CTE coatings have

plant and are designed to provide excelvery good electrical insulating properlent performance. Epoxies and

ties and low water permeation properpolyurethanes can be spray-applied,

ties that resist bacterial attack and the

although the details of application differ

solvent action of petroleum oils.

between the two types.

CTE is heated to approximately 240

C (465 F) and poured over a rotating

Field Joint Coatings

section of pipe surface that has been

Many field joint coatings are available

prepared and primed in accordance

to complete the coating of a pipeline

with the manufacturers recommenda(Table 1). In planning a pipeline coating

tions. A fiber

glass inner wrap,

which becomes

saturated with liquefied enamel, is

immediately

pulled over the

coating. A second

fiber glass or mineral felt outer

wrap, already

impregnated with

coal tar, is applied

Fig. 7: Spray-applied epoxy coatings. Courtesy of Tyco Adhesives CPG

over the first

wrap. A second layer of CTE is then

system, it is critical to pay attention to

applied. Liquid CTE will spread through

the field-applied joint protection coatthe wrap. The coating is then finished

ing; otherwise, the joint can become the

with one coat of white wash or a single

pipelines weakest link. Field joint coatwrap of Kraft paper to prevent ultravioings are installed under construction

let (UV) degradation of the enamel durconditions anywhere in the world, so

ing storage in direct sunlight.

they must be field friendly to the application environment or easy to install

Spray-Applied Liquid Coatings

correctly. Field joint coatings can make

These liquid products are usually twoor break the integrity of the total

component materials, consisting of an

pipeline coating solution (Figs. 8 and 9).

A and a B part. Typical sprayKey considerations for a successful

applied coatings are a high-build epoxy,

field joint coating scenario would

a polyurethane, or a combination of

include project planning, coating selec both. Epoxy coatings are two-part,

tion and prequalification, surface

ambient temperature-cured, 100%

preparation, applicator training and

solids (no VOCs), thermosetting matericertification, equipment selection,

als with a base resin and curing agent

inspection, and storage and handling.

(Fig. 7). Polyurethanes are also two-part,

Table 2 lists some of the available field

100% solids coatings but with a polyisojoint coatings used with various maincyanate curing agent and a polyol.

line coatings.

JPCL /

July 2005

PCE

45

Fig. 9: Liquid epoxy hand applied onto FBE mainline coating

Courtesy of Tyco Adhesives CPG

Fig. 8: Cold tape applied to three-layer mainline coating

Courtesy of Tyco Adhesives

Internal Diameter (ID) Coatings

Flow efficiency or corrosion coatings

typically consist of an epoxy liquid that

has a sufficient thickness to coat the

anchor pattern of the inside of the blasted steel pipe (Fig. 10). These coatings are

used worldwide for high-pressure gas

transmission pipelines to reduce the

friction and enhance the gas flow, hence

increasing the efficiency of gas delivery

with less compressor horsepower. This

thin coating also provides some degree

of corrosion protection, and it helps

accelerate the drying of the pipeline

after hydrostatic testing, pigging, and

cleaning. The main standards governing

the qualification of these coatings are

API RP 5L2 and ISO 15741.

The components are pumped to a

mixing block on the spray machine,

where the A and B components are

mixed in the correct ratio. The mixed

material then travels to a single or multiple airless spray tip arrangement to be

applied onto the ID of the pipe. Lance

coating is very common and involves a

long boom that travels through the

pipes center spraying the liquid epoxy

as it travels. Material delivery pressures

can reach 2,0003,000 psi.

Table 2: Typical Field Joint Solutions versus Mainline Coatings

Mainline Coating

Fusion Bonded Epoxy (FBE)

Two-Layer Polyethylene (PE)

Three-Layer Polethylene

Three-Layer Polypropylene (PP)

Polymeric Tapes

Coal Tar Enamel/Asphalt

46

Typical Field Joint Coating

FBE,

100% solids liquid, epoxy, epoxy-urethane,

Heat-shrink sleeves (HSS)

Cold-and hot-applied tapes

Mastic coated two-layer HSS

Cold-and hot-applied tapes

Three-layer HSS with epoxy primer and hot melt adhesive

Multi-layer flame spray with PE

Three-layer HSS with epoxy primer and hot melt adhesive

Multi-layer flame spray with PP

FBE, Spray-applied adhesive, coextruded PP tape

Cold-and hot-applied tapes

Mastic coated HSS

Hot applied molten coal tar enamel and asphalt coatings

Heat shrinkable sleeves with asphalt based mastic adhesive

JPCL /

July 2005

PCE

Internal coatings, besides those mentioned above, have played an important

role in corrosion control and resistance

against scale formation in oil and gas

production and paraffin build up in oil

production. Typical systems include

100% solids liquid epoxies and FBE. The

FBE systems may use a phenolic primer

for the adhesion to the metal substrate,

while the FBE topcoat provides the barrier against the corrosive environment.

Concrete Weight

and Barrier Coatings

Concrete weight coatings (CWC) on

pipes ensure that the pipes laid offshore,

in wetlands and marshland, have a negative buoyancy. (Negative buoyancy is a

positive downward force created by the

weight of the concrete coating to prevent the pipe from floating [Fig. 11]).

Iron ore in the concrete increases the

density, which lowers the required

thickness to provide the negative buoyancy. To prepare the surface for the concrete weight coating the main corrosion

coating surface must be prepared, so

that the concrete weight coating is

applied properly.

When laying pipe offshore, the

anchoring of the concrete is very important because the longitudinal forces are

high when the concrete pipe coating is

held in the tensioner of the lay-barge.

www.paintsquare.com

yard until the concrete has fully cured

(generally 37 days,

although cure time

depends on the relative humidity).

Once out on the

lay-barge the pipe is

welded and field

joint-coated before

Fig. 12: Polyurethane infill on the field joint

the infill is applied

enters water from laybarge

(Fig. 12). The infill

Courtesy of CCSI, A Bayou Company

will build up the

thickness of the field

try today. Probably one of the most sigjoint

coating

to

that

nificant is the choice to drill deeper

Fig. 10: Liquid epoxy used for flow efficiency (inside pipe)

of the CWC.

wells. Pipelines in turn will be operating

This helps avoid slippage of the concrete Polyurethane foam infill is typically used

at higher temperatures and pressures

over the corrosion coating.

at the joint areas. The foam is poured

and this will drive future coating develThere are four types of application

into a plastic or steel mould that is locatopments. This will require coatings with

methods for CWC pipe: a wrap (comed around the field joint.

good hot and wet performance that can

pression), impingement, a combination

Onshore concrete or cement mortaroperate at higher temperatures.

of wrap and impingement, and forming.

coated pipelines add a degree of mechanWith new pipeline integrity regulaWith the wrap method, the concrete

tions recently introduced

mixture is fed onto a belt, and the belt

and more anticipated,

wraps and compresses the concrete

pipeline coatings will undermixture around the pipe. At the same

go rigorous inspection, which

time, a steel wire mesh is placed within

will lead to the development

the concrete matrix to add reinforceof even more field friendly

ment to the system. Polyethylene tape is

solutions with high perforwrapped around the concrete to hold it

mance.

in place and assist in the curing process.

To ensure success in develThe impingement method involves

oping new coating technolospraying concrete at high speed onto the

gies, suppliers, applicators,

rotating pipe.

contractors, specifiers, and

When the wrap method and the

asset owners will have to

Fig. 11: Concrete weight coating plant using the wrap method

impingement method are combined, the

work together.

Courtesy of The Bayou Companies

first half of the pipe is coated with the

wrap method and is immediately folical protection to the pipeline coating as

lowed by the impingement method for

it is being handled during the construcBased in Houston, TX, Mike

the remainder of the specified thickness.

tion process, especially in rocky terrains,

Romano is responsible for

The forming method consists of

or where selective backfill is too expenmanaging Tyco Adhesives

installing sheet metal forms around the

sive. Concrete barrier coatings are availNorth American business,

pipe with reinforcement wires situated

able that can be bent in the field.

developing global business

within. A spacer holds the wires within

Concrete has also been used as an insulaopportunities, and growing

the center space of the form. CWC is

tion for casing pipe and for other

the companys relationships with engineering

then poured through the opening at the

pipeline-related applications.

firms. He has more than 16 years of experitop of the form. Once the pipe has been

ence with corrosion protection and pipelines.

concrete weight coated, CWC is then

Closing Thoughts

He can be reached at Tyco Adhesives CPG

allowed to fully cure. The pipe has limits

There are several significant trends factel: 832-526-2696; or email:

on how high it can be stacked in the

ing the oil and gas pipeline coating indusromanom@tycoadhesives.com.

www.paintsquare.com

JPCL /

July 2005

PCE

47

Vous aimerez peut-être aussi

- Overview of Pipeline Coatings) PDFDocument7 pagesOverview of Pipeline Coatings) PDFTamer Hesham AhmedPas encore d'évaluation

- Non-Metallic Piping SpecsDocument2 pagesNon-Metallic Piping SpecssoumenhazraPas encore d'évaluation

- Cathodic ProtectionDocument52 pagesCathodic Protectionredback666100% (2)

- 3LPE Coating SpecificationDocument21 pages3LPE Coating SpecificationHướng PhạmPas encore d'évaluation

- Inspection Thermal Spray WebinarDocument29 pagesInspection Thermal Spray WebinarShriya Soni100% (1)

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Pipeline Coating ProcessDocument34 pagesPipeline Coating Processzenisler100% (2)

- Chevron Specification for Fusion Bonded Epoxy Pipeline CoatingDocument15 pagesChevron Specification for Fusion Bonded Epoxy Pipeline CoatingChozha RajanPas encore d'évaluation

- SSPC SP 7 Brush OffDocument6 pagesSSPC SP 7 Brush OffPipeMelgarejoLopezPas encore d'évaluation

- The Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral BucklingDocument13 pagesThe Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral Bucklingmaz234Pas encore d'évaluation

- PDF MC NorskDocument56 pagesPDF MC NorskIsaac EliasPas encore d'évaluation

- Fusion Bonded Epoxy Coatings for PipelinesDocument23 pagesFusion Bonded Epoxy Coatings for PipelinesIshani Gupta75% (4)

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724Pas encore d'évaluation

- A - Pipe CoatingDocument25 pagesA - Pipe Coatingpaivensolidsnake100% (1)

- SP-2217 Rev 1.1 March 2017 Specification of Internal FBE and Liquid Coating SystemsDocument43 pagesSP-2217 Rev 1.1 March 2017 Specification of Internal FBE and Liquid Coating SystemsAllan LindoPas encore d'évaluation

- Case Study-Corrosion ProtectionDocument25 pagesCase Study-Corrosion ProtectionAjeng Fadillah100% (1)

- HSS80 Heat Shrink Sleeve: Features & BenefitsDocument2 pagesHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- Benefits of Reinforced Thermoplastic Pipe (RTP) For Oil and Gas PipelinesDocument4 pagesBenefits of Reinforced Thermoplastic Pipe (RTP) For Oil and Gas PipelinesMFPas encore d'évaluation

- Field CoatingDocument26 pagesField Coatingsohn2342100% (1)

- Repair Procedure For High Temperature Boiler PipingDocument14 pagesRepair Procedure For High Temperature Boiler PipingEzhil Vendhan PalanisamyPas encore d'évaluation

- 56r 08Document21 pages56r 08manojsingh4allPas encore d'évaluation

- A Complete Guide of Epoxy Coatings For Industrial and Marine ApplicationsDocument8 pagesA Complete Guide of Epoxy Coatings For Industrial and Marine ApplicationsCông NguyễnPas encore d'évaluation

- Pipeline Coatings Nov 2013Document46 pagesPipeline Coatings Nov 2013vincent.w.stone6724100% (3)

- Advancement in Internal Field Joint Coating SystemsDocument5 pagesAdvancement in Internal Field Joint Coating SystemsKnight rider100% (1)

- Steel Erection ITPDocument26 pagesSteel Erection ITPIksan Adityo MulyoPas encore d'évaluation

- ICorr Insulation InspectorDocument31 pagesICorr Insulation Inspector22238.spoPas encore d'évaluation

- ISO-21809-1-2018 - IncompletaDocument15 pagesISO-21809-1-2018 - IncompletaBruno SantosPas encore d'évaluation

- Coating Test With The ISOTEST Holiday Detector PDFDocument6 pagesCoating Test With The ISOTEST Holiday Detector PDFÖzgür TuştaşPas encore d'évaluation

- UG Pipe CoatingDocument8 pagesUG Pipe CoatingcenthilkrPas encore d'évaluation

- Pull-Off Adhesion Testing ExplainedDocument5 pagesPull-Off Adhesion Testing Explainedzavisa2Pas encore d'évaluation

- Duplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasDocument40 pagesDuplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasXiaohua Chen100% (1)

- Engineering Design Verification InspectionsDocument20 pagesEngineering Design Verification InspectionsixoteePas encore d'évaluation

- Chemrite - 540Document2 pagesChemrite - 540ghazanfarPas encore d'évaluation

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruPas encore d'évaluation

- FBE Coating PDFDocument12 pagesFBE Coating PDFthadikkaran100% (1)

- Insulating Flange Kits DatasheetDocument4 pagesInsulating Flange Kits DatasheetAndry RimanovPas encore d'évaluation

- BS en 12068.1999Document33 pagesBS en 12068.1999yy20100% (1)

- 12.11 Design Guidelines For Stifflegs and Box CulvertsDocument6 pages12.11 Design Guidelines For Stifflegs and Box CulvertsDave ThompsonPas encore d'évaluation

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23Pas encore d'évaluation

- Chevron Pre-Inspection ChecklistDocument2 pagesChevron Pre-Inspection ChecklistosersPas encore d'évaluation

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaPas encore d'évaluation

- 07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementDocument8 pages07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementSamuel JohnPas encore d'évaluation

- 3LPE Coating Spec.Document28 pages3LPE Coating Spec.9320008521100% (1)

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainPas encore d'évaluation

- As 4822-2008 External Field Joint Coatings For Steel PipelinesDocument8 pagesAs 4822-2008 External Field Joint Coatings For Steel PipelinesSAI Global - APAC0% (1)

- 3LPP Three Layer Polypropylene CoatingDocument3 pages3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarPas encore d'évaluation

- Coating Selection Recommendations in <40 CharactersDocument16 pagesCoating Selection Recommendations in <40 Charactersstdshop100% (2)

- Piping Guide Pipe WorkDocument8 pagesPiping Guide Pipe WorkSiddiq RahimPas encore d'évaluation

- 15-1915-08e3-Hempaline Defend 630 (Cure 72)Document28 pages15-1915-08e3-Hempaline Defend 630 (Cure 72)ashishpearlPas encore d'évaluation

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- MSDS Primer S1301-M Parte ADocument2 pagesMSDS Primer S1301-M Parte AMichael Betetta AbadPas encore d'évaluation

- BGAS-CSWIP Site Coatings Inspector TrainingDocument3 pagesBGAS-CSWIP Site Coatings Inspector Trainingdang21720140% (2)

- ANSI-B16.47 Ser B Blind and Welding Neck FlangesDocument7 pagesANSI-B16.47 Ser B Blind and Welding Neck FlangesRicelles Silveira MartinsPas encore d'évaluation

- Osmotic Blisters in Coatings and Adhesives - Metal FinishingDocument2 pagesOsmotic Blisters in Coatings and Adhesives - Metal FinishingMaulana Mufti MuhammadPas encore d'évaluation

- Standard Specification FOR Pipeline Internal CoatingDocument2 pagesStandard Specification FOR Pipeline Internal CoatingRanjan KumarPas encore d'évaluation

- Adhesion Characteristics of Protective Coatings for Nuclear Power PlantsDocument8 pagesAdhesion Characteristics of Protective Coatings for Nuclear Power PlantsHaidarHussaini100% (1)

- 0604-14-01 Report - International Paint Coating System-May 12 2014 PDFDocument88 pages0604-14-01 Report - International Paint Coating System-May 12 2014 PDFMBastawy100% (1)

- Marathon XHBDocument4 pagesMarathon XHBeskim00Pas encore d'évaluation

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27Pas encore d'évaluation

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocument6 pagesCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnPas encore d'évaluation

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947Pas encore d'évaluation

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- Asset Integrity Management A Complete Guide - 2020 EditionD'EverandAsset Integrity Management A Complete Guide - 2020 EditionPas encore d'évaluation

- Ins and Outs of Pipeline Coatings Used To Protect Oil PipelinesDocument7 pagesIns and Outs of Pipeline Coatings Used To Protect Oil PipelinesBigBaby JulianPas encore d'évaluation

- CDE Prequalification - 2023Document103 pagesCDE Prequalification - 2023sameer ahmadPas encore d'évaluation

- 1.03 - High-Rise Buildings PDFDocument19 pages1.03 - High-Rise Buildings PDFNicolas De NadaiPas encore d'évaluation

- P 615 SN 4147526Document52 pagesP 615 SN 4147526Dan Alin MirceaPas encore d'évaluation

- Introduction To Cold FormingDocument54 pagesIntroduction To Cold FormingRestu SihotangPas encore d'évaluation

- Ecoply Bracing - EP1 Specification (Apr-09)Document1 pageEcoply Bracing - EP1 Specification (Apr-09)郭骥Pas encore d'évaluation

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 pageStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilPas encore d'évaluation

- 3 - Precast Frame Analysis - Connections DesignDocument35 pages3 - Precast Frame Analysis - Connections DesignFatima rafiqPas encore d'évaluation

- Scully U31766uDocument2 pagesScully U31766unumonvePas encore d'évaluation

- International: Convention CentreDocument53 pagesInternational: Convention CentreBatool Al-kharabshehPas encore d'évaluation

- 1 20 PDFDocument1 page1 20 PDFRushil ShahPas encore d'évaluation

- SC20 Sample Cooler PDFDocument2 pagesSC20 Sample Cooler PDFjdanastasPas encore d'évaluation

- LONG TERM CONSTRUCTION REVENUEDocument5 pagesLONG TERM CONSTRUCTION REVENUERoxell CaibogPas encore d'évaluation

- Master Architects - International StyleDocument13 pagesMaster Architects - International StylesakshiPas encore d'évaluation

- BS 4550-0 1978 - General IntroductionDocument8 pagesBS 4550-0 1978 - General IntroductionAhmed BabikirPas encore d'évaluation

- Presentasi Ahu DXDocument17 pagesPresentasi Ahu DXpt.esasurya arcapadaPas encore d'évaluation

- 000 - Proj Description - ISSUE - SHEETDocument3 pages000 - Proj Description - ISSUE - SHEETbra9tee9tiniPas encore d'évaluation

- Ground Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDocument1 pageGround Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDhairyaPas encore d'évaluation

- Liebherr Fridge ManualDocument18 pagesLiebherr Fridge ManualJames RavensdalePas encore d'évaluation

- HVAC - Heating, Ventilation and Air - ConditioningDocument31 pagesHVAC - Heating, Ventilation and Air - ConditioningAtiq MoghulPas encore d'évaluation

- Identifying Compressor Mechanical FailuresDocument13 pagesIdentifying Compressor Mechanical FailuresDesiderio BourdetPas encore d'évaluation

- Iwaki Diafragma 1.25 inDocument4 pagesIwaki Diafragma 1.25 inRaul ArizagaPas encore d'évaluation

- Introduction To TOS-I: Theory of Structure - IDocument54 pagesIntroduction To TOS-I: Theory of Structure - Iaditya20530% (1)