Académique Documents

Professionnel Documents

Culture Documents

4800-w0 Fabrication and Installation of Set On Concrete Pipeline Weights

Transféré par

LorenaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4800-w0 Fabrication and Installation of Set On Concrete Pipeline Weights

Transféré par

LorenaDroits d'auteur :

Formats disponibles

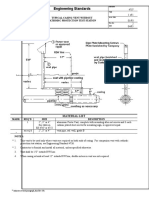

Engineering Standards

Standard

4800

Page

1 of 4

FABRICATION AND INSTALLATION OF

SET-ON CONCRETE PIPELINE WEIGHTS

Issue Date

02/94

Rev. No.

Date

1.

SCOPE

This standard covers requirements for the supply and installation of set-on weights on steel pipe to achieve the

negative buoyancy required for laying pipe in marshes or through river bottoms.

2.

3.

GENERAL

2.1

The concrete density shall be as specified by Design Engineer or as specified in Design Drawings or other

documents. Set-on weight design and spacing are based on the specified concrete density and density of

buoyant medium. The set-on weights shall produce a negative buoyancy of 10 lbs per lineal foot or as

3.

specified in other contract documents. Concrete densities normally range from 140 to 190 lbs/ft

2.2

All materials and procedures shall conform to the specifications set forth by the American Concrete

Institute (ACI) and the American Society for Testing and Materials (ASTM), latest revision, as applicable,

and be acceptable to Company's Representative.

MATERIALS

3.1

Concrete

3.1.1

The minimum compressive strength of the concrete shall be 3000 psi at 28 days. High early

strength concrete shall have a minimum compressive strength of 3000 psi at 7 days.

3.1.2

All concrete materials shall be furnished by the Contractor and shall consist of Portland

Cement, sand and aggregate, water, and if necessary to achieve the specific gravity specified,

crushed magnetite ore (ilmenite, hematite, etc.).

3.1.3

Cement shall conform to ASTM C 150, Type I or III; shall be stored in a manner that will

protect it from the elements; and shall be rejected and removed from the site if it has

hardened, partially set or become lumpy.

3.1.4

Sand and aggregate shall conform to ASTM C 33; shall be well graded from fine to coarse;

and shall be clean and free from injurious amounts of salt, alkali, deleterious substances or

organic impurities.

3.1.5

Magnetite ore, if required, shall be free of clay and injurious amounts of alkali, deleterious

substances and organic impurities that may affect the strength of concrete and shall conform to

ASTM C 29. Magnetite ore shall be crushed to the following screen analysis:

100% passing 1/4" mesh screen

30-75% passing #16 mesh screen

10-40% passing #50 mesh screen

0-25% passing #100 mesh screen

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4800

Page

2 of 4

FABRICATION AND INSTALLATION OF

SET-ON CONCRETE PIPELINE WEIGHTS

Issue Date

02/94

Rev. No.

Date

3.1.6

3.2

4.

Water shall be potable and free from oil, acid, alkali, scale, organic matter or large quantities

of sulfates.

Reinforcing Steel

3.2.1

Reinforcing bars shall be intermediate grade, deformed, new billet steel in conformance with

ASTM A 615. All reinforcing bars shall be Grade 60.

3.2.2

Welded steel wire fabric for concrete reinforcement shall conform with ASTM A 185.

3.2.3

Alternate combinations of mesh pattern, size, wire gauge and manufacturing specification are

allowed to accommodate a specific concrete application process, provided equivalent

reinforcement will be obtained.

TESTING

4.1

4.2

Concrete Strength

4.1.1

Representative samples of each new batch of concrete mix and samples of cured concrete shall

be furnished not less than four days of age to a reputable laboratory for tests.

4.1.2

The tests shall include a 7-day and a 28-day compressive test as well as a bulk density test.

The test specimen shall be tested according to ASTM C 31.

4.1.3

Tests shall be conducted until the control of the equipment and the mixture of materials are

satisfactory to meet the above specifications. Tests shall be conducted throughout the concrete

placement operations to assure adequate quality control of the concrete.

4.1.4

Company's Representative shall be furnished a copy of the results of each test required by this

section, prior to weights being installed.

4.1.5

A previously tested mix may be used if done according to the above requirements and meets

the requirements of this standard.

4.1.6

Contractor shall bear all costs in connection with testing.

Weights

Contractor shall furnish the necessary scales to accurately weigh the set-on weights. At the beginning of

operations each day, the scales shall be checked by weighing a set-on weight of known weight.

Adjustments of the scales shall be made if necessary. Final acceptance of the weights to be in accordance

with section 8.0 of this standard.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4800

Page

3 of 4

FABRICATION AND INSTALLATION OF

SET-ON CONCRETE PIPELINE WEIGHTS

Issue Date

02/94

Rev. No.

Date

5.

APPLICATION

5.1

Concrete

The set-on weights shall be free of burrs or irregularities on the inside that could damage coating or pipe.

5.2

Reinforcement

For the form and pour method, the reinforcing steel shall be tied in place using wires, concrete and metal

supporters, spacer bars and chairs to maintain reinforcement in proper position during concrete

application. Spacers or chairs shall be sized and positioned to allow 3" concrete cover over reinforcement.

6.

CURING

6.1

7.

Concrete surface shall be kept from dehydrating using one of the following methods:

6.1.1

The concrete shall be sprayed with a pigmented membrane sealant conforming to ASTM C

309.

6.1.2

The concrete shall be continuously kept moist for at least seven (7) days when Type I cement

has been used or three (3) days when Type III cement has been used.

6.1.3

The concrete shall be wrapped in impervious sheet materials while curing. Application shall

concur with Concrete Construction Handbook guidelines or per contractor's approved

procedure.

6.2

Before further handling, the concrete should be allowed to cure for a minimum of seven (7) days when

Type I cement has been used or three (3) days when Type III cement has been used.

6.3

No concrete shall be applied while the ambient temperature is 40 F and falling. If during the curing

period the temperature falls below 40F, the concrete shall be protected in accordance with the standard

practices recommended by the American Concrete Institute and to the satisfaction of Company's

Representative.

REPAIRS TO WEIGHTS

Weights may be repaired per the following guidelines. Company Representative shall be responsible to accept or

reject any repaired weights.

7.1

Spalling

7.1.1

A loss of concrete of more than 25% of the total concrete thickness or sufficient loss to cause

the reinforcing steel to be visible shall be repaired.

7.1.2

A area of spalling less than one square foot, where the remaining concrete is sound, will be

acceptable without repairs.

7.1.3

If an area of spalling is more than one, but less than two square feet, the concrete remaining in

place over that area shall be removed as necessary to expose the reinforcing steel throughout

the damaged area. Edges of the spoiled area shall be undercut to provide a key lock for the

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4800

Page

4 of 4

FABRICATION AND INSTALLATION OF

SET-ON CONCRETE PIPELINE WEIGHTS

Issue Date

02/94

Rev. No.

Date

repair material. The set-on weights having damaged area more than two square feet will be

rejected.

7.1.4

7.2

8.0

9.0

Repaired set-on weight shall be carefully stored and allowed to moist cure a minimum of 36

hours before further handling.

Cracking

7.2.1

Concrete cracks shall be repaired where they are over 1/16" wide or extend over 12"

irrespective of width.

7.2.2

Repair shall be made by chiseling material from the crack to a width not exceeding one (1)

inch and filling with cement mortar. The repairs shall be allowed to remain undisturbed for a

period not less than 24 hours.

REJECTION OF WEIGHTS

8.1

Any failure to meet the requirements of this standard shall be cause for rejection.

8.2

Weights damaged in handling or storage that is excessive and beyond repair shall be cause for rejection.

8.3

Improper placement of reinforcing steel shall be cause for rejection.

8.4

Set-on weights that weigh less than the weight specified shall be rejected, unless the average weight of the

set-on weight is maintained by compensating for each set-on weight location that is underweight by

placing a compensatory extra weight on the surrounding set-on weight locations. On all pipe sizes, the

weight of the set-on weight must be within 5% below and 7-1/2% above the specified weight.

INSTALLATION OF WEIGHTS

When set-on weights are to be used, the following sequential actions will be implemented unless the Company's

Representative specifically approves otherwise.

9.1

The ditch will be de-watered to a level where the upper half of the pipe is above water elevation. The

pipe may have been previously placed in the ditch and submerged to grade by filling with water.

9.2

Rockshield will be placed on pipe at the locations specified for weights to be installed. The rockshield

will extend 12" longitudinally beyond the end of weight and 12" beyond the vertical tangent on the sides.

9.3

The weight will be carefully installed achieving full contact with the rockshield through the top 180 of

the pipe.

9.4

The ditch will be backfilled with suitable material after the weights have been successfully installed.

* Indicates revised paragraph, this Rev. No.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaPas encore d'évaluation

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDocument2 pages4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- 4776 Subsea Pipeline CrossingDocument4 pages4776 Subsea Pipeline CrossingLorenaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 4780-w8 Selection and Design of Branch Connections and ReinforcementDocument8 pages4780-w8 Selection and Design of Branch Connections and ReinforcementLorenaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 4737-w2 Typical Casing Vent Without Junction Box AssemblyDocument1 page4737-w2 Typical Casing Vent Without Junction Box AssemblyLorenaPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsDocument2 pages4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsLorenaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaPas encore d'évaluation

- Fendolite Proofing PDFDocument4 pagesFendolite Proofing PDFShaji MathewPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 01 Flyash Brick1Document142 pages01 Flyash Brick1Jigar M. Upadhyay100% (2)

- Scada Pro - 1 - Example - Concrete - EN PDFDocument105 pagesScada Pro - 1 - Example - Concrete - EN PDFrelu59Pas encore d'évaluation

- Pavement Design Good Ref.Document68 pagesPavement Design Good Ref.ภาคใต้โพสต์ southernpost100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Irussor Sor 24 12 2019 PDFDocument128 pagesIrussor Sor 24 12 2019 PDFPARTH DOSHI0% (1)

- Schedule Excavation r1Document1 pageSchedule Excavation r1Yosses Sang NahkodaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- HA 2022 B1 Structural 2148-2609Document462 pagesHA 2022 B1 Structural 2148-2609ha hePas encore d'évaluation

- Point Load Test 2Document12 pagesPoint Load Test 2Rajitha ShehanPas encore d'évaluation

- Asphaltic Concrete Mix DesignDocument70 pagesAsphaltic Concrete Mix DesignKumaran Balakrishnan100% (5)

- Astm C1436-13Document2 pagesAstm C1436-13adolfo camayoPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 3 Fibres and Matrices: 3.2.1 PropertiesDocument10 pages3 Fibres and Matrices: 3.2.1 PropertiesMiljan TrivicPas encore d'évaluation

- Roof DeckDocument62 pagesRoof DeckAtul Kumar Engineer100% (1)

- Main Roads Technical Standard: MRTS70 ConcreteDocument36 pagesMain Roads Technical Standard: MRTS70 ConcreteelcivilengPas encore d'évaluation

- View Tower ReportDocument33 pagesView Tower ReportSalin Shrestha100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Post TensioningDocument118 pagesPost TensioningMay Fadrigore100% (1)

- Cast-In-Place Concrete For Pharaonic Obelisk at Al Tahrir SquareDocument19 pagesCast-In-Place Concrete For Pharaonic Obelisk at Al Tahrir SquareEng Hammam El MissiryPas encore d'évaluation

- Qa - QC ManualDocument84 pagesQa - QC Manualiasonmar100% (2)

- Water Proofing SpecificationDocument7 pagesWater Proofing SpecificationjeevanPas encore d'évaluation

- Precast FactoryDocument25 pagesPrecast Factoryamirsh78Pas encore d'évaluation

- 1032 1561 1 PBDocument9 pages1032 1561 1 PBJHON WILMAR CARDENAS PULIDOPas encore d'évaluation

- Building Specification of First Second and Third Class BuildingDocument12 pagesBuilding Specification of First Second and Third Class Buildingahmedmushtaq041100% (2)

- Final Concrete Mix Design ManualDocument30 pagesFinal Concrete Mix Design ManualAyodele Oluwaseyi Dina100% (2)

- DM Fillerboard - HuntonDocument65 pagesDM Fillerboard - HuntonFahis V MPas encore d'évaluation

- Civil Engineering MCQ'S: Ans. (A)Document4 pagesCivil Engineering MCQ'S: Ans. (A)Nishikanta MondalPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Concrete Mix RatioDocument6 pagesConcrete Mix RatioTamunotonye EmmanuelPas encore d'évaluation

- DR Satyanarayana HILDocument4 pagesDR Satyanarayana HILvaratharajank100% (1)

- JMF FC 25 Fence PanelDocument7 pagesJMF FC 25 Fence PanelDrajat StemonescaPas encore d'évaluation

- Document Control ProcedureDocument14 pagesDocument Control ProcedureVasilijePas encore d'évaluation

- Sika Anchorfix®-1: Product Data SheetDocument5 pagesSika Anchorfix®-1: Product Data SheetdherymuammarnazriPas encore d'évaluation

- Blastrac Catalogue 2018 ENG LR2Document122 pagesBlastrac Catalogue 2018 ENG LR2elfigossPas encore d'évaluation

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesD'EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesPas encore d'évaluation