Académique Documents

Professionnel Documents

Culture Documents

Resumen Sifones

Transféré par

Richard EleraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Resumen Sifones

Transféré par

Richard EleraDroits d'auteur :

Formats disponibles

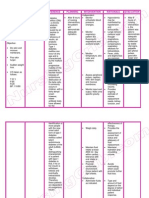

INDEX

1 introduction

2 structural components of a SIPHON

a tube

b. transitions

c. gates

d. breath builds

e surplus channel

f security features

3 design of SIPHONS

a speed limit in pipeline

b. head losses

c. seal hydraulic

d. design steps

1.

2 introduction

-Siphons, or inverted siphons, are used to

transport water through a natural

depression, under a road, or surround

channel

-Some traps have rectangular cross

sections

-Siphons can have a straight side

alignment, or they may have changes in

direction

-The siphon must be buried in general

with a minimum of approximately 1 m of

cover.

-Open channels (bridge - channel) can be

alternative but they can be expensive and

unsightly.

-The traps are very dangerous therefore

provides a grating at the entrance to

avoid the accidental entry of people and

objects.

-Sediments are a serious problem

because they settle at the point of the

siphon.

-Cleaning can only be in large siphons but

is impossible in small traps, also means

interruption of the service.

3 structural components of a SIPHON

a tube

-The majority of traps are constructed of

concrete premoulded and can go up to

200 feet.

-Previously but prestressed concrete

pipes used the experience to

demonstrated that the wire may corrode

in just 15-18 alos of service.

-The traps can also be built with plastic or

steel pipe, including less common

possibilities even wood.

b. transitions

-The transisiones are structures of

inlet and outlet of the siphon.

-Are necessary to prevent erosion

on the inlet and outlet of the

siphon and maintain immersing the

pipe.

-The transisicones the same design

for inlet and outlet can be taken in

small traps to save costs. But in

large siphons is neseario design

separately.

c. gates

-Valves can be installed: to the check of a

siphon to control the water level

upstream. At the exit of a siphon to

control the immersion waters above.

-The operation of a door at the entrance

of a siphon can ensure hydraulic

tightness.

d. structures of BREATHING

-A "blow-off" structure is an output valve

in the top of the pipe at a point low on the

siphon

-Smaller traps often do not have a

structure of expulsion

-These structures are used to help drain

the siphon in the event of emergency,

routine maintenance, and to remove

sediments from the pipe.

e surplus channel

-An evacuator (spout side) was

sometimes built in the channel just

upstream of an entry from trap to divert

the flow of the channel in the case of

obstruction of the siphon or other

emergency situation.

-In addition, the entrance to a siphon

should always be trash racks and / or

screens to prevent rocks and other debris

from entering the tube.

f safety features

-In operation, traps may seem harmless,

especially in a Grand canal, but can be

deadly

-Just upstream from the entrance of the

trap can be used as follows:

-Posters with warnings

-Rungs of the ladder on the banks of the

canals

-Steps on the banks of the canals

-Cable with fleet across the surface of the

water

-Network security with cables and chains

-Grilles or trash racks

4 design of SIPHONS

Siphons design has many similarities

with the design of sewers; However,

unlike the sewers project:

-Traps are usually designed for the flow

of the pipe complete

-Traps are usually designed to minimize

head loss

-Siphons carry water down, then back up

USBR trap designs are usually for 50

years assumed useful life

a speed limit in the pipe

-In accordance with the USBR, speeds in

the pipes must be between 3.5 and 10 fps

-The latest designs of the Bureau have

been called especially for the speed of 8

fps.

-Long siphons can cost less with a size

slightly more small tube.

b. loss of load

-Total load loss is the sum of: input,

output, pipe, and minor losses

- Most of the loss of a siphon is

pipe friction.

-Output losses are typically about

twice the loss of input.

c. hydraulic seal

-"Hydraulic seal" is the minimum

requirement of upstream head, relative to

the top edge of the siphon tube, to avoid

air drag at that location.

-Hydraulic seal recommended by the

USBR is equal 5hv, where hv is the

difference in the heads of speed in the

open of upstream channel and pipeline

(when full flow) a1.

-For a more conservative value of

hydraulic seal, use 1.5hpipe, when hpipe

is the speed all the way-trap pipe.

d. steps of design

-Determine the path that the siphon will

continue

-Determine the diameter of the tubing

required in accordance with the approval

of the management of the design and the

speed limit

-Determine the types of transition

structures right at the entrance and exit,

or custom for the installation in particular

design transitions

-Design siphon according to the existing

land disposal and the proposal (or

existing) elevations of the channel in the

input and output

-Determine the requirements of the line

pressure in accordance with the head (the

lowest point) during operation

-Determine the head loss total in design

spending trap

-If the pressure drop is too high, choose a

larger tube or different

material; Alternatively, consider adjusting

the elevations of the channel at the

entrance and exit

Download

link: http://ocw.usu.edu/Biological_and_Ir

rigation_Engineering/Irrigation___Convey

ance_Control_Systems/6300__LectureNo

tes.pdf

SOURCE:

Publication by the University of the State

of Utah, United States.

http://ocw.usu.edu/Biological_and_Irrigati

on_Engineering/Irrigation___Conveyance

_Control_Systems/Lecture_Notes.htm

Vous aimerez peut-être aussi

- Loza Aligerada Primer Nivel Loza Aligerada Segundo Nivel: ESC. 1/50 ESC. 1/50Document1 pageLoza Aligerada Primer Nivel Loza Aligerada Segundo Nivel: ESC. 1/50 ESC. 1/50Richard EleraPas encore d'évaluation

- E 2 (Estructuracion)Document1 pageE 2 (Estructuracion)Richard EleraPas encore d'évaluation

- Primer Nivel Segundo Nivel: ESC. 1/50 ESC. 1/50Document1 pagePrimer Nivel Segundo Nivel: ESC. 1/50 ESC. 1/50Richard EleraPas encore d'évaluation

- Produced by An Autodesk Educational Product: Planta Tercer NivelDocument1 pageProduced by An Autodesk Educational Product: Planta Tercer NivelRichard EleraPas encore d'évaluation

- Produced by An Autodesk Educational Product: VP - 10 (0.25m X 0.45m)Document1 pageProduced by An Autodesk Educational Product: VP - 10 (0.25m X 0.45m)Richard EleraPas encore d'évaluation

- Produced by An Autodesk Educational Product: VP - 10 (0.25m X 0.45m)Document1 pageProduced by An Autodesk Educational Product: VP - 10 (0.25m X 0.45m)Richard EleraPas encore d'évaluation

- Produced by An Autodesk Educational Product: Primer NivelDocument1 pageProduced by An Autodesk Educational Product: Primer NivelRichard EleraPas encore d'évaluation

- Produced by An Autodesk Educational Product: Planta Segundo NivelDocument1 pageProduced by An Autodesk Educational Product: Planta Segundo NivelRichard EleraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Compact Switch: Series 96201, 96211, 96221Document2 pagesCompact Switch: Series 96201, 96211, 96221Sales DIGIHU100% (1)

- WB-Mech 120 Ch05 ModalDocument16 pagesWB-Mech 120 Ch05 ModalhebiyongPas encore d'évaluation

- Final Report of BBSMDocument37 pagesFinal Report of BBSMraazoo1967% (9)

- Sponsor and Principal Investigator: Responsibilities of The SponsorDocument10 pagesSponsor and Principal Investigator: Responsibilities of The SponsorNoriPas encore d'évaluation

- Part-II Poem Article and Report For College Magazine-2015-16 Dr.M.Q. KhanDocument4 pagesPart-II Poem Article and Report For College Magazine-2015-16 Dr.M.Q. KhanTechi Son taraPas encore d'évaluation

- Assignment Brief - Starting A Business and Fundamental of MarketingDocument7 pagesAssignment Brief - Starting A Business and Fundamental of Marketingmd rahimPas encore d'évaluation

- BLDG Permit Form (Back To Back)Document2 pagesBLDG Permit Form (Back To Back)ar desPas encore d'évaluation

- Science9 Q3 SLM1Document15 pagesScience9 Q3 SLM1Zandra Musni Delos ReyesPas encore d'évaluation

- Siemens 6SL31622AA000AA0 CatalogDocument20 pagesSiemens 6SL31622AA000AA0 CatalogIrfan NurdiansyahPas encore d'évaluation

- Solution Manual For C How To Program 8th Edition Paul J Deitel Harvey DeitelDocument34 pagesSolution Manual For C How To Program 8th Edition Paul J Deitel Harvey Deiteldryas.czech0gkl100% (47)

- Defining The Market Research Problem & Developing An ApproachDocument77 pagesDefining The Market Research Problem & Developing An ApproachSakshi Bhati I H21O41Pas encore d'évaluation

- Gulfpub Wo 201805Document81 pagesGulfpub Wo 201805Patricia.PPas encore d'évaluation

- Causal Relationships WorksheetDocument2 pagesCausal Relationships Worksheetledmabaya23Pas encore d'évaluation

- D2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsDocument46 pagesD2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsMarcelo Gonçalves100% (1)

- Joy BoosterDocument2 pagesJoy BoosterAlexsandro TorezinPas encore d'évaluation

- Apc 10kva Ups ManualDocument36 pagesApc 10kva Ups Manualraj rajPas encore d'évaluation

- Think Feel DoDocument3 pagesThink Feel DoHardik MehtaPas encore d'évaluation

- Power Systems (K-Wiki - CH 4 - Stability)Document32 pagesPower Systems (K-Wiki - CH 4 - Stability)Priyanshu GuptaPas encore d'évaluation

- Delay Codes1 3Document10 pagesDelay Codes1 3AhmedPas encore d'évaluation

- Implementasi Sistem Pengenalan Candi Kecil Di Yogyakarta Menggunakan BerbasisDocument7 pagesImplementasi Sistem Pengenalan Candi Kecil Di Yogyakarta Menggunakan BerbasisRivan AuliaPas encore d'évaluation

- Unit 2 Talents: Phrasal Verbs: TurnDocument5 pagesUnit 2 Talents: Phrasal Verbs: TurnwhysignupagainPas encore d'évaluation

- ElectricityDocument196 pagesElectricityjingcong liuPas encore d'évaluation

- Eps 400 New Notes Dec 15-1Document47 pagesEps 400 New Notes Dec 15-1BRIAN MWANGIPas encore d'évaluation

- A Review of Automatic License Plate Recognition System in Mobile-Based PlatformDocument6 pagesA Review of Automatic License Plate Recognition System in Mobile-Based PlatformadiaPas encore d'évaluation

- How Plants SurviveDocument16 pagesHow Plants SurviveGilbertPas encore d'évaluation

- Heat and Mass Chapter 2Document49 pagesHeat and Mass Chapter 2Mvelo PhungulaPas encore d'évaluation

- Worship Aid - May Crowning 2020Document5 pagesWorship Aid - May Crowning 2020Kevin RyanPas encore d'évaluation

- Kyoto Seika UniversityDocument27 pagesKyoto Seika UniversityMalvinPas encore d'évaluation

- Nursing Care Plan Diabetes Mellitus Type 1Document2 pagesNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- MHD Exam 6 MaterialDocument179 pagesMHD Exam 6 Materialnaexuis5467100% (1)