Académique Documents

Professionnel Documents

Culture Documents

EDS 06-0014 Secondary Substation Earthing Design PDF

Transféré par

Rajendra Prasad ShuklaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EDS 06-0014 Secondary Substation Earthing Design PDF

Transféré par

Rajendra Prasad ShuklaDroits d'auteur :

Formats disponibles

Document Number: EDS 06-0014

Date: 28/07/2014

ENGINEERING DESIGN STANDARD

EDS 06-0014

SECONDARY SUBSTATION EARTHING DESIGN

Network(s):

EPN, LPN, SPN

Summary:

This standard details the earthing design requirements for secondary distribution

substations.

Owner:

Stephen Tucker

Date:

28/07/2014

Approved By:

Steve Mockford

Approved Date:

04/08/2014

This document forms part of the Companys Integrated Business System and its requirements are mandatory throughout UK

Power Networks. Departure from these requirements may only be taken with the written approval of the Director of Asset

Management. If you have any queries about this document please contact the author or owner of the current issue.

Circulation

UK Power Networks

External

All UK Power Networks

G81 Website

Asset Management

Contractors

Capital Programme

ICPs/IDNOs

Connections

Meter Operators

HSS&TT

Network Operations

UK Power Networks Services

Other

THIS IS AN UNCONTROLLED DOCUMENT, THE READER MUST CONFIRM ITS VALIDITY BEFORE USE

Version: 3.0

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Revision Record

Version

3.0

Review Date

28/07/2019

Date

28/07/2014

Author

Stephen Tucker

Updated to ensure consistency with EDS 07-0102 and ECS 06-0023.

Design flowchart revised (Section 7.1).

Lower rebar connection removed from all earthing arrangements (Section 8.1).

Integral and basement substation design with embedded mesh introduced (Section 8.5).

Use of network contribution (Section 7.5), explanation of ground return current (Appendix H) and

worked example from ICP addendum incorporated (Appendix F).

Pipelines (Section 10.11) and fuel filling stations (Section 10.12) added to special situations.

Standard arrangement resistances (Table A-2) and touch/step voltage percentages (Table A-4)

revised, typical ground return current values added (Table A-3), touch/step voltage limits updated

to include tarmac and longer fault clearance times (Table A-5) and typical network contribution

values included (Table A-7).

Simple rod and conductor electrode options added (Appendix B).

Design form revised (Appendix C).

Use of vertical steel piles (Section 7.5) and surface current density calculation added (Appendix I).

Version

2.0

Review Date

18/03/2018

Date

01/03/2013

Author

Stephen Tucker

Document completely revised

Version

1.2

Review Date

28/07/2019

Date

03/08/2011

Author

Stephen Tucker

Reclassification of document from Earthing Design Manual Section 4

Version

1.1

Review Date

31/12/2011

Date

11/01/2011

Author

Stephen Tucker

Version 1 (previously Earthing Manual Section 5) withdrawn and interim guidance provided

Version

1.0

Review Date

31/03/2011

Date

31/03/2008

Author

Stephen Tucker/

Rob Weller

Original

UK Power Networks 2014 All rights reserved

2 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Contents

1

Introduction ............................................................................................................. 7

Scope ....................................................................................................................... 8

Abbreviations .......................................................................................................... 8

Definitions ................................................................................................................ 9

Design Requirements ............................................................................................ 10

Preliminary Earthing Design Assessment ........................................................... 11

Earthing Design Procedure .................................................................................. 12

7.1

Overview ................................................................................................................. 12

7.2

Information Requirements ....................................................................................... 12

7.3

EPR Calculation ...................................................................................................... 14

7.4

Touch and Step Voltage Calculation ........................................................................ 15

7.5

Combined HV/LV Earths and Network Contribution ................................................. 17

7.6

Transfer Voltage Calculation ................................................................................... 18

7.7

HOT Site Assessment ............................................................................................. 18

Standard Earthing Arrangements ........................................................................ 19

8.1

Overview ................................................................................................................. 19

8.2

GRP and Brick-Built Substations (Combined HV/LV Earths) ................................... 20

8.3

GRP and Brick-Built Substations (Separate HV/LV Earths) ..................................... 21

8.4

Compact (including Micro and Padmount) Substations ............................................ 22

8.5

Integral, Basement and Raft Substations ................................................................. 23

8.6

Customer HV Supplies and Associated Substations ................................................ 25

8.7

Outdoor Substations ................................................................................................ 28

8.8

Asset Replacement ................................................................................................. 28

Installation Requirements ..................................................................................... 30

9.1

General ................................................................................................................... 30

9.2

Electrode System .................................................................................................... 30

9.2.1

Earth Bar ................................................................................................................. 31

9.3

Bonding ................................................................................................................... 31

9.3.1

Equipment Bonding ................................................................................................. 31

9.3.2

Metallic Fences, Gates and Doors ........................................................................... 32

9.3.3

Ancillary Metalwork.................................................................................................. 34

9.3.4

Ducting and Ventilation Shafts ................................................................................. 34

9.4

Cables ..................................................................................................................... 34

9.5

Combined HV/LV Earths ......................................................................................... 35

9.6

Separate HV/LV Earths Additional Requirements .................................................... 35

UK Power Networks 2014 All rights reserved

3 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

9.6.1

LV Earth .................................................................................................................. 35

9.6.2

Neutral-Earth Link ................................................................................................... 35

9.6.3

Warning Notices for Separated Earths..................................................................... 35

9.6.4

Lighting and Socket Supplies .................................................................................. 35

9.6.5

Street Lighting Columns .......................................................................................... 36

10

Special Situations.................................................................................................. 37

10.1

General ................................................................................................................... 37

10.2

Substation Refurbishment and Asset Replacement/Enhancement .......................... 37

10.3

Secondary Substations within Grid or Primary Substations ..................................... 37

10.4

Supplies to Higher Voltage (Grid and Primary) Substations, National Grid and

HOT Sites................................................................................................................ 38

10.5

Supplies from Grid or Primary Substations with a High EPR ................................... 38

10.6

Substations near Livestock/Horses or other High Risk Locations ............................ 39

10.7

Mobile Phone Base Stations Associated with Transmission Towers ........................ 39

10.8

Substations Located Near Tower Lines ................................................................... 39

10.9

Substations Located Near Railways ........................................................................ 39

10.10 Substations Located Near Telephone Exchanges ................................................... 40

10.11 Substations Located near Pipelines ......................................................................... 40

10.12 Substations Located near Fuel Filling Stations ........................................................ 40

10.13 IDNO Substations .................................................................................................... 40

10.14 HV Generator Connections (including Solar Farms) ................................................ 41

10.15 Customers Lightning Protection .............................................................................. 41

11

Earthing Design Assessment ............................................................................... 42

11.1

External Connection Providers ................................................................................ 42

11.1.1 Overview ................................................................................................................. 42

11.1.2 Earthing Drawing ..................................................................................................... 42

11.1.3 Earthing Report ....................................................................................................... 42

11.1.4 Further Information .................................................................................................. 42

11.2

UK Power Networks ................................................................................................ 42

12

References ............................................................................................................. 43

12.1

Internal Standards ................................................................................................... 43

12.2

External Standards .................................................................................................. 44

Appendix A UK Power Networks Supporting Data ...................................................... 45

Appendix B Typical Electrode Systems ....................................................................... 49

Appendix C Earthing Design Form ............................................................................... 51

Appendix D Earthing Design Assessment Form ......................................................... 51

Appendix E Secondary Substation Earthing Design Tool .......................................... 51

UK Power Networks 2014 All rights reserved

4 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Appendix F Earthing Design Example .......................................................................... 51

Appendix G Standard Secondary Substation Arrangement Voltage Profiles ............ 51

Appendix H Calculation of Ground Return Current ..................................................... 52

Appendix I Electrode Surface Area Current Density ................................................... 55

Figures

Figure 6-1 Preliminary Earthing Design Assessment........................................................ 11

Figure 7-1 Earthing Design Procedure Flowchart ............................................................. 13

Figure 7-2 Transfer Voltage ............................................................................................. 18

Figure 8-1 Combined HV/LV Earth Substation Earthing Arrangement ............................. 20

Figure 8-2 Separated HV/LV Earth Substation Earthing Arrangement ............................. 21

Figure 8-3 Compact/Micro Earthing Arrangement ............................................................ 22

Figure 8-4 Standard Design Approach for Integral and Basement Substation .................. 24

Figure 8-5 Typical HV Supply and Customer Substation Arrangement for a COLD Site ... 26

Figure 8-6 Typical HV Supply and Customer Substation Arrangement for a HOT Site ..... 27

Figure 8-7 Typical Earthing associated with Asset Replacement...................................... 29

Figure 10-1 Options for Supplies to Higher Voltage Substations ...................................... 38

Figure 10-2 LV Supply from a Grid or Primary Substation with a High EPR ..................... 39

Figure H-1 Cable Ground Return Current......................................................................... 52

Figure H-2 Nomogram Ground Return Current Calculation from ENA ER S34 (showing

RA+RB/l = 1.1)..................................................................................................... 53

Figure H-3 Simple Cable Ground Return Current and EPR Calculator ............................. 53

Figure H-4 BS 7354 Ground Current Calculation ............................................................. 54

Tables

Table 8-1 Standard Secondary Substation Drawings ....................................................... 19

Table 9-1 Earth Electrodes............................................................................................... 30

Table 9-2 Bonding Conductors ......................................................................................... 31

Table A-1 Data Sources for Earthing Design Calculations................................................ 45

Table A-2 Resistances Values for Standard Secondary Substation Earthing

Arrangements .................................................................................................... 45

Table A-3 Ground Return Current Values for Typical UK Power Networks 11kV Cables

(based on a 0.1 source resistance [RPrimSub or RA] and 1 secondary

resistance [RSecSub or RB]) .................................................................................... 46

Table A-4 Touch and Step Voltages for Standard Secondary Substation Earthing

Arrangements .................................................................................................... 47

Table A-5 Maximum Acceptable Touch and Step Voltages (based on ENA TS 41-24

Figure 2) ............................................................................................................ 47

Table A-6 Protection Operation Time ............................................................................... 48

UK Power Networks 2014 All rights reserved

5 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Table A-7 Estimated Network Contribution (based on interconnected substations and

PILC cable) ........................................................................................................ 48

Table B-1 1, 10 and 20 Earth Electrode Options ...................................................... 49

Table B-2 Earth Rod Resistance based on Soil Resistivity ............................................... 50

Table B-3 Earth Conductor and Lattice Earth Mat Resistance based on Soil Resistivity .. 50

UK Power Networks 2014 All rights reserved

6 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Introduction

This standard (previously Section 4 of the Earthing Design Manual) details the earthing

design requirements for secondary distribution substations. It is intended to provide

guidance for UK Power Networks designers/planning engineers and external connection

providers to ensure that designs satisfy the requirements of the latest standards.

The construction of the earthing for secondary substations is detailed ECS 06-0023.

The earthing arrangements have been developed to cover a range of standard substation

designs and are supported by a standard design procedure to allow optimal earthing designs

to be produced. There will be some situations where standard arrangements are not

suitable, and it is the responsibility of the designer/planning engineer to exercise a degree of

judgement, and to seek help from an earthing specialist (refer to EDS 06-0001) if the

appropriateness of a standard arrangement is in doubt.

The legacy approach to secondary substation earthing design was based on one or two

earth rods and combining HV and LV earths if the measured earth resistance was less than

1 ohm. These rules relied on metallic sheathed cables providing a grading effect (hence

controlling touch and step potentials) and reducing the overall substation earth resistance

(hence reducing the earth potential rise) together with low values of earth fault current.

However many parts of UK Power Networks have high earth fault levels that require

additional earthing measures. Furthermore, plastic sheathed cables have been in use for

many years and therefore the composition of the cable network is changing; the previous

grading benefit provided by metallic sheath cables can no longer be exploited at new and

refurbished sites. Although more robust earthing arrangements can overcome some of these

limitations the magnitude of the earth fault levels remains, therefore the legacy approach can

no longer be justified and more detailed attention to earthing design is required.

This standard is based on the principles of BS EN 505221 and seeks to achieve an earthing

design with acceptable touch and step voltages and a low earth potential rise to allow the HV

and LV earths to be combined if required. The main requirements include:

A buried ring electrode around the site or an embedded mesh to control the touch and

step voltages.

Calculation of a site specific earth resistance to achieve acceptable touch and step

voltages and allow the HV and LV earths to be combined (this value may be higher or

lower than 1).

In some situations additional electrode consisting of buried conductor and/or rods may

be required to achieve the calculated earth resistance.

The contribution of the wider network and/or vertical steel piles may be used to

supplement the main earthing system if appropriate; however the touch and step

voltages shall be safe before any network contribution is considered.

The earthing systems for substations supplied from directly from the overhead line

network may require additional precautions (e.g. additional ring electrode and/or a

concrete or tarmac surround) to achieve acceptable touch and step voltages.

Conductor sizing is based on a common approach to all three network areas.

The earthing arrangements are included in the civil substation construction drawings.

Although this standard is based on BS EN 50522, the touch and step voltage limits and the values for

combining HV and LV earthing are currently taken from ENA TS 41-24 Issue 1. Once ENA TS 41-24 has been

revised by the ENA the new limits will be adopted by UK Power Networks.

UK Power Networks 2014 All rights reserved

7 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Scope

This standard applies to the earthing design for all new secondary substations and existing

secondary substations where a material alteration is to take place, e.g. switchgear

replacement, fencing replacement etc.

Secondary substation earthing construction is covered in ECS 06-0023.

The earthing design for pole-mounted equipment, LV networks (including LV overhead

networks) and customer installations are covered respectively in EDS 06-0015,

EDS 06-0016 and EDS 06-0017 (refer to Section 12).

Abbreviations

Term

Definition

CNE

Combined neutral earth (refer to Section 4 for definition)

Ellipse

UK Power Networks asset register

EPR

Earth potential rise (refer to Section 4 for definition)

IDNO

Independent Distribution Network Operator

NetMap

UK Power Networks graphical information system (GIS)

RCD

Residual Current Device

SNE

Separate neutral earth (refer to Section 4 for definition)

UK Power Networks 2014 All rights reserved

8 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Definitions

This section defines the main terms used in this standard (refer to EDS 06-0012 for a full list

of earthing terms and definitions).

Cable - Combined Neutral Earth (CNE)

A CNE cable has a combined neutral and earth metallic outer sheath with a covering and is

most commonly used in a PME (protective multiple earthing) LV earthing system.

Cable - Separate Neutral Earth (SNE)

An SNE cable has separate neutral and earth conductors. Generally the neutral conductor is

a fourth core and the earth conductor forms a protective sheath.

COLD Site

A COLD site is a grid, primary or secondary substation where the earth potential rise (EPR)

is less than 430V or 650V (for high reliability protection with a fault clearance time less than

200ms).

HOT Site

A HOT site is a grid, primary or secondary substation where the earth potential rise (EPR) is

greater than 430V or 650V (for high reliability protection with a fault clearance time less than

200ms).

Earth Potential Rise (EPR)

EPR is the potential (voltage) rise that occurs on any metalwork due to the current that flows

through the ground when an earth fault occurs on the HV or LV network. Note: Some current

will flow through the cable sheath back to the source and some will flow through the ground,

it is only the current that flows through the ground that causes the earth potential rise (refer

to Figure H-1). Historically this has also been called Rise of Earth Potential (ROEP).

Step, Touch and Transfer Voltages

The step voltage is the potential difference between a persons feet assumed to be 1m

apart. The touch voltage is the potential difference between a persons hands and feet

when standing up to 1m away from any earthed metalwork they are touching. The transfer

voltage is the potential transferred by means of a conductor between an area with a

significant earth potential rise and an area with little or no earth potential rise, and results in

a potential difference between the conductor and earth in both locations.

Substation Earthing Database

The substation earthing database contains the classification (HOT or COLD) of all grid and

primary substations together with the details of the earth potential rise (EPR) and other

relevant earthing information. Refer to EDS 06-0002 for further details.

UK Power Networks 2014 All rights reserved

9 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Design Requirements

Substation earthing provides the following function:

To pass the fault current during an earth fault back to the system neutral and operate the

source protection.

To prevent dangerous potentials appearing at the substation and causing danger to staff

or the public.

To prevent dangerous potentials appearing on the customers LV neutral/earth.

To comply with the requirements for substation LV earthing for PME systems.

To satisfy these requirements the following design criteria shall be satisfied for secondary

substation earthing design:

A maximum HV electrode earth resistance of 10 to operate the HV protection.

A ring electrode enclosing and bonded to all equipment and rebar bonding to ensure the

touch and step potentials are within acceptable limits.

Earth electrode sizes based on source earth fault levels.

The earth potential rise limited to 430V as far as reasonably practicable (provided the HV

protection operates within 1 second for faults at the substation),to allow the HV/LV earths

to be combined and prevent dangerous voltages appearing on the LV system; if this limit

cannot be satisfied the HV/LV earths shall be separated and a maximum EPR of 2kV

applies.

A maximum LV earth resistance of 20 (in accordance with ENA ER G12) where a

separate LV earth is required.

Touch voltage within the acceptable limits using the installed electrode system alone and

not rely on any parallel contribution from network.

The proposed earthing system can be achieved on-site to avoid re-design at the time of

installation.

Refer to EDS 06-0012 for a more detailed explanation of earth potential rise, the voltage

limits and the associated calculations.

UK Power Networks 2014 All rights reserved

10 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Preliminary Earthing Design Assessment

A preliminary earthing design assessment for a secondary substation should be carried out

using the flowchart in Figure 6-1 to determine if there are any external factors that are likely

to affect the earthing design.

START

Yes

Overhead site?

Refer to

EDS 06-0015

No

Existing

Yes

secondary substation or fence

replacement?

Refer to Section 10 then

carry out earthing design

No

Yes

Special situation?

Refer to Section 10 then

carry out earthing design

No

Located

within grid or primary

site?

Yes

Grid or primary site HOT?

No

Use combined HV/LV earth

connected to site earth

Yes

No

Use combined HV/LV earth

connected to site earth

(not suitable for providing

external supplies)

Consider use of earthing

specialist to carry out

detailed design

Joint site with customer?

No

Non-standard/bespoke

earthing arrangement?

Yes

Employ earthing specialist

to carry out detailed design

No

Carry out earthing design in

accordance with Section 7

Figure 6-1 Preliminary Earthing Design Assessment

UK Power Networks 2014 All rights reserved

11 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Earthing Design Procedure

7.1

Overview

The secondary substation earthing design procedure is shown in Figure 7-1. The flowchart

includes references to the sections that follow and the appendices, where relevant, to

provide further detail on each of the steps in the flowchart.

The earthing design tool (Appendix E) should be used by UK Power Networks staff to carry

out the earthing design to ensure that it complies with this standard and the design is

correctly documented.

Complete the earthing design form in Appendix C or provide the information detailed in

Section 11.

UK Power Networks designers and planning engineers shall provide the following for all

secondary substation projects:

A completed earthing design and construction form (Appendix C) for the project file.

A completed earthing construction form (Appendix C) and a copy of the relevant earthing

arrangement drawing from EDS 07-0102 for the delivery team and/or customer.

External connection providers shall provide the information detailed in Section 11 to allow

UK Power Networks to assess the design.

Note: If a non-standard design is required an earthing specialist shall be employed to carry

out the appropriate design and calculations. The report and drawings produced from this

may be used in lieu of the above documentation requirements.

7.2

Information Requirements

The following information is required to design a secondary substation earthing system:

Source grid/primary substation earth fault level and earth resistance value (if available).

Earth fault level at the new secondary substation.

Source substation classification (HOT/COLD) and the associated earth potential rise for

HOT sites.

Details of the cable or overhead line network between the source and the new secondary

substation including lengths, types, and the cable sheath cross-section and material

(where appropriate) etc.

Distance of the secondary substation from the source substation.

Soil resistivity at secondary substation location.

Fault clearance time for an earth fault at the new substation (detailed design only).

Refer to Appendix A for UK Power Networks data sources.

Where required UK Power Networks will provide the network specific data to enable an

external connection provider to design a suitable secondary substation earthing system.

UK Power Networks 2014 All rights reserved

12 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

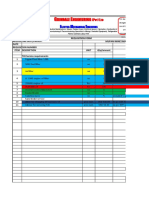

7.2

Section, Table, Appendix #

Obtain data

8.1

Select substation earthing

arrangement

No

Standard substation

arrangement suitable?

Yes

Employ earthing specialist

to carry out design

Table

A-2

Determine secondary

substation earth resistance

7.3 &

App H

Determine ground return

current

Table

A-5

Recalculate earth resistance

7.3

Determine touch voltage limit

for fault clearance time

7.4

Install additional earth

electrode to reduce earth

resistance or consider

different design

Calculate EPR

7.4

No

EPR < 2x touch

voltage limit?

Calculate touch voltage

Yes

Yes

Is design

achievable

on-site?

No

Touch voltage

< touch voltage limit?

Re-evaluate design or

consider use of earthing

specialist to carry out

detailed design

No

Yes

Table

A-6

No

EPR < 430?

7.5

Evaluate network

contribution

Re-calculate EPR

Yes

Yes

EPR < 430?

No

Source

substation EPR > 430 and Yes

supplied via continuous

cable?

7.6

Calculate transfer voltage

EPR < 2kV?

No

Yes

Use combined HV/LV earth

with calculated HV

resistance

COLD Site

No

No

Transfer voltage > 430V?

Document design and

determine electrode and

other earthing requirements

Yes

Use separated HV/LV

earths, calculated HV

resistance and 20 ohm LV

earth resistance

7.7

HOT Site

Figure 7-1 Earthing Design Procedure Flowchart

UK Power Networks 2014 All rights reserved

13 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

7.3

EPR Calculation

The following process should be used to calculate the EPR:

1. Determine the source (primary or grid) substation earth resistance (or assume 0.1 if not

available).

Grid and primary substation earthing data is available from the Substation Earthing

Database2. Refer to EDS 06-0002 for further information.

2. Select a standard earthing arrangement based on the type of secondary substation (e.g.

GRP, brick-built, integral etc) from Section 8.

3. Estimate the substation HV electrode resistance (RSecSub) using Table A-2 (for the UK

Power Networks standard substation arrangements) and the soil resistivity.

Soil resistivity data is available in the Earthing Design Tool or NetMap3 (refer to

EDS 06-0018 for further information).

4. Determine the earth fault current at the secondary substation (If). If the earth fault level at

the secondary substation is not available the earth fault level at the source substation will

provide a good (but pessimistic) approximation.

Refer to EDS 08-0134 for further Information on obtaining earth fault levels.

5. Calculate the percentage of fault current (%Igr) that will flow through the ground.

For overhead supplied sites, or sites with any overhead line in the supply circuit, the

ground return current can be taken as 100%.

For entirely cable supplied sites a ground return current of 40% of the total earth fault

current can be assumed as a first estimate or a more accurate value can be

calculated (refer to Appendix H and Table A-3).

Note: It is likely that there are several cable types between the secondary substation and

the source substation. The initial calculation should be based on the smallest size cable;

however modelling each cable separately will provide a more accurate value and a lower

value of EPR.

6. Use this percentage (%Igr) to calculate the value of the ground return current Igr:

Igr = %Igr If

7. Use the calculated value of Igr and the value of RSecSub to calculate the EPR for the site:

EPR = Igr RSecSub

UK Power Networks maintains a Substation Earthing Database which is available from the UK Power Networks

Intranet (Applications > Reporting Centre > Substation Earthing Database).

3

UK Power Networks GIS system.

UK Power Networks 2014 All rights reserved

14 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

7.4

Touch and Step Voltage Calculation

Touch and step voltages for each of the UK Power Networks standard earthing

arrangements expressed as a percentage of the EPR are given in Table A-4 (Appendix A).

Furthermore a set of acceptable touch and step voltage limits, based on fault clearance

times and substation surface type, are given in Table A-5 (Appendix A).

Note: If the design does not use a UK Power Networks standard earthing arrangement then

the earthing electrode system shall be modelled by an earthing specialist to determine the

touch and step voltage.

1. To calculate the touch voltage and determine whether it is acceptable the following

information is required:

Proposed earthing arrangement for the secondary substation.

Substation surface type.

Calculated value of EPR.

Fault clearance time.

What fault clearance time to use?

The fault clearance time is the sum of the protection relay (source or upstream) and the

circuit-breaker operating times. A value of 1s can be used for 11kV circuits but is likely to

be pessimistic and provide onerous touch voltage limits.

Alternatively the actual protection clearance time can be calculated using Table A-6

(Appendix A) and the circuit-breaker operating time of either 100ms (oil) or 50ms (SF6 or

vacuum).

Note: For overhead line supplied substations it is permissible to use the pole-mounted

recloser protection to achieve acceptable touch voltages.

2. Calculate the touch voltage using the following formula:

VTouch = EPR %Touch

VStep = EPR %Step

where %Touch and %Step are the percentage of the EPR at which the maximum touch and

step voltage can occur. Values for the UK Power Networks standard substation

arrangements are detailed in Table A-4 (Appendix A) otherwise they can be calculated

using computer simulation software.

3. Check whether the touch voltage (VTouch) is greater than the acceptable limits (VTouchLimit)

in Table A-5 (Appendix A).

4. Check whether the step voltage (VStep) is greater than the acceptable limits (VStepLimit) in

Table A-5 (Appendix A).

UK Power Networks 2014 All rights reserved

15 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

5. If the touch or step voltage exceeds the limits further work is required to reduce the

substation resistance and the EPR. The value of RSecSub can be calculated using the

equation below. However as the value of resistance will change the proportion of current

returning through earth it will be necessary to repeat the steps in Section 7.3 to calculate

the final EPR. Note: It may be necessary to repeat this several times to determine actual

values of resistance and EPR.

If the substation is supplied directly from the overhead line network additional

precautions may be required (e.g. additional ring electrode and/or a concrete or tarmac

surround) to achieve acceptable touch voltages.

RSecSub = VTouchLimit Igr

6. Using the results of the calculations above determine the additional earth electrode

(conductor, rods etc) requirements using Appendix B.

The earthing systems for substations supplied directly from the overhead line network may

require additional precautions (e.g. additional ring electrode and/or a concrete or tarmac

surround) to achieve acceptable touch and step voltages.

Note: A design cannot be accepted or approved if the touch and step voltages exceed the

applicable limits.

UK Power Networks 2014 All rights reserved

16 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

7.5

Combined HV/LV Earths and Network Contribution

If the EPR value is less than 430V the HV and LV earths may be combined, however to

achieve this it may be necessary to further reduce the overall earth resistance of the

substation.

An underground cable network consisting of interconnected substations and metallic sheath

cables can provide a low earth resistance that will be in parallel with resistance of the

installed earthing system. Provided the substation earth resistance is below 10 ohms and the

touch and step voltages are within the limits the network contribution may be used to

achieve a low overall earth resistance and an EPR value below 430V to allow the HV and LV

earths to be combined.

A conservative contribution can be determined through inspection of the network to

understand the number of interconnected substations and the lengths/types of cable. A

range of typical values is given in Table A-7 (Appendix A). Alternatively, measurements or

engineering experience can be used to determine a more accurate value.

The EPR can be recalculated as follows:

1. Assess the network contribution through inspection or measurement.

2. Recalculate the EPR using the substation earth resistance in parallel with the network

earth resistance (RSecSub // RNetwork):

EPR = Igr (RSecSub // RNetwork)

If it is not considered realistic to achieve a low enough earth resistance to limit the EPR to

430V the design shall be based on reasonably practical installation with a low resistance to

minimise the EPR. Separated HV and LV earthing shall be installed and the site shall be

classified as HOT.

The resistance (electrode) contribution from vertical steel piles may also be used to

supplement the main earthing system provided they are bonded via a welded connection

and the rest of the electrode system satisfies the surface area requirements of Appendix I.

The resistance of the vertical piles is included in the calculations in a similar way to the

Network Contribution above.

Note: Further design work may be required if HV/LV earth segregation is not possible due to

presence of HV/LV PILC cables.

UK Power Networks 2014 All rights reserved

17 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

7.6

Transfer Voltage Calculation

If the secondary substation is entirely cable fed from a HOT source substation (i.e. the EPR

at the source substation is greater than 430V or 650V for high reliability protection) it is

necessary to calculate the transfer voltage from the source substation as illustrated in Figure

7-2. Previously, the rule of thumb was that the first substation out from a HOT site should

be treated as HOT however this methodology is not valid in all cases.

Note: The transfer potential calculation is not necessary if an overhead line section is

included in the circuit.

If the new substation is not the first substation on the circuit it is not valid to assume that the

transfer potential from the source will be of no significance. However, accurate calculation is

complex, therefore it is sufficient to simply disregard intermediate substations and to use the

total circuit length.

Primary 33/11kV

Substation

Secondary 11kV/LV

Substation

ZCircuit

EPRSourceSub

ZSecSub

VTransfer

Figure 7-2 Transfer Voltage

1. Calculate the transfer voltage using the following formula.

(

2. If the transfer voltage is greater than 430V separate HV and LV earths shall be installed.

7.7

HOT Site Assessment

If the EPR is greater than 430V the secondary substation shall be classified as a HOT site.

The details of any HOT site shall be sent to UK Power Networks Asset Management

(earthingenquiries@ukpowernetworks.co.uk) so that they can be recorded in the Substation

Earthing Database. BT (or another telecommunication company) may also need to be

notified refer to Section 10.10 further details.

UK Power Networks 2014 All rights reserved

18 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Standard Earthing Arrangements

8.1

Overview

This section details the earthing arrangements for the standard secondary substation

designs. The arrangements include HV and LV (if required) earthing for the following types

of ground-mounted substation:

New COLD site design for GRP, brick-built and outdoor substations (Section 8.2).

New HOT site design for GRP brick-built and outdoor substations (Section 8.3).

Compact or micro pad-mounted substations without an enclosure (Section 8.4).

Integral and basement substations (Section 8.5).

Customer substations (Sections 8.6).

Existing outdoor substations (Section 8.7).

These earthing arrangements have been incorporated into the standard substation design

drawings contained in EDS 07-0102. A full list of the available drawings is given in Table 8-1.

Table 8-1 Standard Secondary Substation Drawings

Description

Drawing No

GRP Unit/Package Substation with Standard Plinth

EDS 07-0102.01

GRP Unit/Package Substation with Fully-bunded Plinth

EDS 07-0102.02

GRP Elevated Substation with Fully-bunded Plinth

EDS 07-0102.21

GRP Micro Substation with Standard Plinth

EDS 07-0102.03

GRP Compact Substation with Standard Plinth

EDS 07-0102.04

GRP Metering Substation with Standard Plinth

EDS 07-0102.16

Freestanding Brick-built Unit/Package Substation (3.6m x 3.6m)

EDS 07-0102.18

Freestanding Brick-built Substation for a Single Transformer without/with

ACB and LV Board (4m x 5m)

EDS 07-0102.05-06

Integral Substation for a Single Transformer without/with ACB and LV Board

EDS 07-0102.07-08

Basement Substation

EDS 07-0102.09

Micro Substation

EDS 07-0102.10

Compact Substation

EDS 07-0102.11

Fenced Outdoor Substation with Micro and Ring Main Unit

EDS 07-0102.12

Fenced Outdoor Substation with Micro and Extensible Switchgear

EDS 07-0102.13

The electrode resistance of the standard arrangements (with 2.4m rods) in a range of

uniform soil conditions can be found in Table A-2 (Appendix A). Note: In most cases

additional (or deeper) electrodes will be required to provide the desired value of earth

resistance.

Plots showing the touch and step voltages across the sites with standard earthing

arrangements are included in Appendix G.

Only for use in Areas of Outstanding Natural Beauty (AONB).

UK Power Networks 2014 All rights reserved

19 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.2

GRP and Brick-Built Substations (Combined HV/LV Earths)

The general earthing arrangement for GRP, brick-built and outdoor5 substations with a

combined HV/LV earth (COLD site) is shown below. Refer to EDS 07-0102.01-04,16 (GRP),

EDS 07-0102.05-06,18 (brick-built) and EDS 07-0102.12-13 (outdoor) for specific designs.

1

1

Combined HV/LV Earths

Neutral/Earth Link In

Transformer

Main Earth Bar/Terminal

To LV Cable

Neutral

5

LV

RMU

6

3

Additional HV Earth

Electrode/Rods

(as required to achieve

earth resistance)

To HV

Earth

2

Note: Not all equipment

bonding is shown

LV CNE Cable

HV Earth Electrode

Primary Fault Level

Bare Copper Conductor

Bare Copper Tape

Up to 8kA

70mm2

25mm x 3mm

Up to 12kA

120mm2 (or 2 x 70mm2)

25mm x 4mm

Up to 15kA

2 x 70mm2

25mm x 6mm

1 - 2.4m earth rods at rear corners

2 - Alternative internal 2.4m earth rods in place of external ones for brick-built substations

3 - HV electrode around the outer edge of foundation buried at a depth of 500-600mm

4 - HV electrode connecting each side of outer loop to main earth terminal

5 - Connection to reinforcement rebar/mesh

6 - Neutral/Earth link in place

Figure 8-1 Combined HV/LV Earth Substation Earthing Arrangement

Outdoor secondary substations are not generally used for new build, however they may be used in specific

situations, e.g. Areas of Outstanding Natural Beauty, when GRP and brick-built designs are not suitable.

UK Power Networks 2014 All rights reserved

20 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.3

GRP and Brick-Built Substations (Separate HV/LV Earths)

The general earthing arrangement for GRP, brick-built and outdoor6 substations with a

separate HV/LV earth (HOT site) is shown below. Refer to EDS 07-0102.01-04,16, 21

(GRP), EDS 07-0102.18 (brick-built) and EDS 07-0102.12-13 (outdoor) for specific designs.

1

1

Separate HV/LV Earths

Neutral/Earth Link Out

Transformer

Main Earth Bar/Terminal

To LV Cable

Neutral

5

LV

RMU

6

3

To HV

Earth

To LV

Earth

4

7

Additional HV Earth

Electrode/Rods

(as required to achieve

earth resistance)

2

Note: Not all equipment

bonding is shown

HV/LV Separation

(8m minimum)

LV Earth Connection (Insulated)

LV Earth Electrode/Rods

(max resistance 20)

LV CNE Cable

HV Earth Electrode

LV Earth

Primary Fault Level

Bare Copper Conductor

Bare Copper Tape

Up to 8kA

70mm2

25mm x 3mm

Up to 12kA

120mm2 (or 2 x 70mm2)

Up to 15kA

2 x 70mm

25mm x 4mm

25mm x 6mm

LV earth connection 70mm2 PVC

covered stranded copper conductor

LV earth electrode 70mm2 bare

stranded copper conductor

1 - 2.4m earth rods at rear corners

2 - Alternative internal 2.4m earth rods in place of external ones for brick-built substations

3 - HV electrode around the outer edge of foundation buried at a depth of 500-600mm

4 - HV electrode connecting each side of outer loop to main earth terminal

5 - Connection to reinforcement rebar/mesh

6 - Neutral/Earth link removed

7 - Warning labels

Figure 8-2 Separated HV/LV Earth Substation Earthing Arrangement

Outdoor secondary substations are not generally used for new build; however they may be used in specific

situations, e.g. Areas of Outstanding Natural Beauty, when GRP and brick-built designs are not suitable.

UK Power Networks 2014 All rights reserved

21 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.4

Compact (including Micro and Padmount) Substations

The earthing arrangement for a compact/micro substation without an enclosure is shown

below. These are generally installed on the overhead network and therefore the HV and LV

earths shall be separated as shown. However if the EPR is less than 430V, the HV and LV

earths may be combined.

Refer to EDS 07-0102.10, 11 and 15 for specific designs. Note: If the compact substation is

installed in a GRP enclosure the standard arrangements shown in Sections 8.2 and 8.3 shall

be used.

1

Separated

HV/LV Earths

Separate HV/LV Earths

Neutral/Earth Link Out

7

LV

Neutral

9

6

HV

Earth

9

3

To HV Earth

Electrode

To LV Earth

Electrode

To LV Cable

Neutral and Sheath

Additional HV Earth

Electrode/Rods

(as specified )

HV/LV Separation

(8m minimum)

LV Earth Electrode/Rods

(max resistance 20)

LV Earth Connection

LV CNE Cable

Combined

HV/LV Earths

Combined HV/LV Earths

Neutral/Earth Link In

8

6

LV

Neutral

HV

Earth

To HV Earth

Electrode

4

5

5

Additional HV Earth

Electrode/Rods

(as specified )

HV Earth Electrode

LV Earth

Primary Fault Level

Bare Copper Conductor

Bare Copper Tape

Up to 8kA

70mm2

25mm x 3mm

Up to 12kA

120mm2 (or 2 x 70mm2)

25mm x 4mm

Up to 15kA

2 x 70mm2

25mm x 6mm

LV earth connection 70mm2 PVC

covered stranded copper conductor

LV earth electrode 70mm2 bare

stranded copper conductor

1 - 2.4m earth rods at rear corners 500mm behind plinth

2 - 2.4m earth rods at front corners 500mm in front of the plinth

3 - HV electrode in a ring around the substation, extending 500mm on all sides, buried at a depth of 500mm and

connected to the earth rods

4 - HV electrode connecting each side of outer loop to the main earth terminal

5 - HV electrode in two places between the earthing ring and the earth terminal, passing directly underneath the

positions where an operator is required to stand to open the front cover and carry out operations

6 - Connection to reinforcement rebar/mesh

7 - Neutral/Earth link removed

8 - Neutral/Earth link in place

9 - Warning labels

Figure 8-3 Compact/Micro Earthing Arrangement

UK Power Networks 2014 All rights reserved

22 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.5

Integral, Basement and Raft Substations

The standard arrangements shown Section 8.2 and 8.3 should be used wherever possible.

However where the substation is situated within a building or on a raft, it is usually

impracticable to install one of these arrangements. In these situations a standard approach

shall be applied using earth rods installed through the substation floor or in the basement,

external electrodes underneath the HV cable, vertical piles and an embedded mesh within

the floor screed (to control the touch and step potentials).

It is not usually possible to separate the HV and LV earths, so it is important to achieve an

EPR value of less than 430V (COLD site) so that they can be combined. If the EPR is

greater than 430V or if the building or its electrical supply will interact with Network Rail,

London Underground or other electrified travel infrastructure, a bespoke design is

necessary, involving an earthing specialist.

The earthing design should include the following elements which are illustrated in Figure 84 (a):

2 to 4 vertical earth rods through the substation floor (Figure 8-4 (b)) or the basement

(Figure 8-4 (c)) directly into natural soil, to achieve a sufficiently low earth resistance for

a low EPR.

An embedded mesh in a thin layer of concrete (Figure 8-4 (d)) to control the touch

voltages around the equipment.

The following options, where practical, may be used to supplement the above:

Install at least 20-50m of bare copper electrode underneath the HV cable, directly into

natural soil.

Install bare copper electrode in the soil at a depth of approximately 500mm, adjacent or

up to 1m away from the outer walls of as many sides of the UK Power Networks part of

the building as possible. Wherever practicable, this shall include the wall adjacent to the

HV switchgear.

Incorporate the steel in vertical piles near the substation into the design these shall be

of welded type and only the electrically continuous length should be included in the

calculation.

The standard approach outlined above should cover the majority of integral, basement and

raft substations; however advice from an earthing specialist should be sought at an early

stage for more complex installations.

UK Power Networks 2014 All rights reserved

23 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

1b

1a

Substation

Transformer

(b) Earth Rod Installation through

Substation Floor into Soil

Main Earth Terminal

5

LV

RMU

Substation

3

Basement

1c

2

1b

1a

(c) Earth Rod Installation through

Basement into Soil

(a) Overall Earthing Arrangement

1a - Main earth rods (length to be determined by calculation based on

target resistance value and soil resistivity)

1b - Optional additional earth rods to help achieve overall low resistance

1c - Optional bare earth electrode laid with incoming HV cables to help

achieve overall low resistance

2 - Connections to mesh embedded within concrete floor screed - two per

each sheet of mesh

3 - Main earth bar

4 - Wall-mounted earth ring above floor level/below door tread to aid

connections

5 - Main equipment bond (not all equipment shown)

6 - Doorframe and door bonding

(d) Embedded Mesh within Floor

Screed

Figure 8-4 Standard Design Approach for Integral and Basement Substation

UK Power Networks 2014 All rights reserved

24 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.6

Customer HV Supplies and Associated Substations

The earthing system for an HV supply and any associated customer substation will usually

consist of parts provided by the customer and parts provided by UK Power Networks. The

objective is to design an earthing system that satisfies the safety requirements with an

acceptable degree of redundancy and, wherever possible, an EPR less than 430V to allow

the customer to combine the HV and LV earths if required. Note: UK Power Networks is not

responsible for a HV customers LV earthing arrangements but has a duty of care to ensure

that the customers LV system will not become dangerous in the event of a HV fault.

The customer shall provide an HV earthing system for their installation, that is adequate to

ensure safety of their installation, irrespective of the earthing provided by UK Power

Networks. The earthing system should normally consist of copper earth electrodes (tapes

and rods) and steel reinforcement piles or rebar in the vicinity of the substation. In the

majority of cases the earthing systems can be interconnected, especially when the resulting

earth resistance is low enough to achieve an EPR below 430V. In this case it may also be

possible to use the same earthing system to provide the LV earth. This is illustrated in Figure

8-5. The aim of the design is to ensure that UK Power Networks and customer earthing

systems shall each be adequate to ensure safety in the absence of the other system. The

customer system shall not be reliant on UK Power Networks earth terminal for safety (and

vice-versa) since the integrity of either system can be subject to external influences.

In some situations, it may be necessary to rely on combined systems to ensure safety of

both systems (i.e. where safety of each system in isolation cannot economically and/or

practically be achieved). In such cases, the systems shall be combined with duplicate links,

and the customer system shall be constructed to UK Power Networks standards (in terms of

conductor sizing, method of installation and touch/step considerations). However care is

needed if the customer system should become decommissioned or compromised; clear

labelling and test facilities will enable UK Power Networks to assess whether any customer

contribution has been lost.

The situation is more complex if the EPR exceeds 430V the following design options shall be

considered:

Extend the HV earth or reduce the earth fault current to reduce the EPR below 430V, if

this is possible at a reasonable cost. One option for substations on new networks (such

as in London) is to interconnect the earthing with existing 11kV sites that have metallic

sheathed cables or connect onto abandoned sheathed cables.

Interconnect the HV and LV earths and operate with the necessary measures in place.

This is only really practical at an isolated location such as a standalone factory or office,

a wind or solar farm, generating station or National Grid site.

Separate the HV and LV earthing systems at all points by a minimum of 8m and ensure

that they cannot be interconnected. Precautions will also be required to ensure that a

person cannot contact both earth systems simultaneously (refer to Figure 8-6).

Segregate the UK Power Networks HV earth from both of the customer earths. This is

difficult to achieve, is not a desirable solution and generally requires a special design.

Options to achieve it include introduction of a span of unearthed overhead line or cable

sheath insulation joints between the site and the UK Power Networks system. However

the working practices (such as isolation and earthing for work on the HV system) need

careful consideration in this situation.

Note: If the EPR is greater than 430V the transfer voltage requires special consideration

especially if there are metallic boundary fences or metallic buildings in the vicinity.

UK Power Networks 2014 All rights reserved

25 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Combined HV/LV Earths

UK Power Networks

Substation

Customer

Substation

8

1

3

Note:

Equipment

bonding not

shown

1

Additional

electrode/rods

(if required )

5

7

RMU

MU

HV

LV

TX

6

Additional

electrode/rods

(if required )

3

1

Customer LV SNE Cables

UK Power Networks

Substation

Customer

Substation

1

3

Note:

Equipment

bonding not

shown

RMU

MU

HV

TX

LV

6

Additional

electrode/rods

(if required )

4

4

3

1

2

Customer LV SNE Cables

1 - 2.4 m earth rods at 2 corners of substation (alternatively they can be installed internally)

2 - HV electrode around the outer edge of foundation buried at a depth of 500-600mm

3 - HV electrode connecting outer loop to switchgear/transformer earth terminal

4 - Connection to reinforcement rebar/mesh

5 - Interconnection via a link between UK Power Networks and Customer substations

6 - Neutral-earth link in place

7 - HV cable screen insulated from earth

8 - Warning labels

Figure 8-5 Typical HV Supply and Customer Substation Arrangement for a COLD Site

UK Power Networks 2014 All rights reserved

26 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Separated HV/LV Earths

UK Power Networks

Substation

Customer

Substation

8

1

3

Note:

Equipment

bonding not

shown

1

3

5

7

RMU

MU

HV

LV

TX

6

Additional

electrode/rods

(if required )

3

1

HV/LV

Separation

(8m minimum)

LV Earth Cable (Insulated)

Customer LV SNE Cables

UK Power Networks

Substation

Customer

Substation

1

3

Note:

Equipment

bonding not

shown

RMU

MU

HV

TX

LV

6

Additional

electrode/rods

(if required )

4

4

3

1

HV/LV

Separation

(8m minimum)

LV Earth Cable (Insulated)

Customer LV SNE Cables

1 - 2.4 m earth rods at 2 corners of substation (alternatively they can be installed internally)

2 - HV electrode around the outer edge of foundation buried at a depth of 500-600mm

3 - HV electrode connecting outer loop to switchgear/transformer earth terminal

4 - Connection to reinforcement rebar/mesh

5 - Interconnection via a link between UK Power Networks and Customer substations

6 - Neutral-earth link removed

7 - HV cable screen insulated from earth

8 - Warning labels

Figure 8-6 Typical HV Supply and Customer Substation Arrangement for a HOT Site

UK Power Networks 2014 All rights reserved

27 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

8.7

Outdoor Substations

Outdoor (open compound) secondary substations are no longer constructed except in Areas

of Outstanding Natural Beauty. For these a close boarded fence is required. Refer to

EDS 07-0102.12-13 for specific designs.

8.8

Asset Replacement

Earthing needs to be considered during asset replacement work at existing sites. The

installation of a complete earthing system based on a standard arrangement is rarely

practical. However the opportunity to enhance the earthing should be taken and the earthing

installed should seek to achieve as much of the following as possible, using the excavations

that are necessary for the remedial work:

Buried bare electrode around the equipment at a depth of around 0.5m and connected to

the main earth bar. Note: It is especially important to ensure that there is bare electrode

under the operators standing position especially if metallic sheathed cables are

replaced with plastic cables (even short lengths) during a switchgear change.

An embedded and bonded mesh or surface grate under the operators standing position

if buried electrode is not practical.

One or two substantial earth rods connected to the buried earth electrode or the main

earth bar.

Bonding of all equipment to the main earth bar.

If a metallic fence and/or gates are present the requirements of Section 9.3.2 shall also

be applied.

If just the LV pillar is being replaced the installation of a buried electrode system is unlikely to

be practical but the pillar shall be bonded to the main earth bar. The more equipment

alterations and associated excavations that are taking place, the more the earthing can be

improved until a stage is reached where it is close to one of the standard arrangements

shown in the previous sections.

For basement and integral substations the standard approach outlined in Section 8.5 should

be used and is likely to provide a more practical solution.

For emergency asset replacement or where the installation of buried electrode is not

practical a steel grate plate should be installed in front of the switchgear where the operator

would stand and connected to the main earth terminal using duplicate connections. The

grate should be securely embedded in the shingle or bolted to the concrete floor.

Some typical examples are shown in Figure 8-7.

UK Power Networks 2014 All rights reserved

28 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

HV

Switchgear

Transformer

2

3

RMU

(a) Switchgear Replacement Only

(b) Switchgear and Transformer Replacement

Transformer

LV

RMU

LV Pillar

LV Pillar

Transformer

1 - 1.2 m earth rods connected to the

buried electrode

2 - Buried bare copper earth electrode

ring around and the switchgear and any

other equipment

3 - Buried bare copper earth electrode

in front of the switchgear where an

operator stands when using the

switchgear

4 - Connection to equipment earth

terminal

HV Earth Electrode

(c) Switchgear, Transformer and LV Replacement

Fault Level

Bare Copper Bare Copper

Conductor

Tape

Up to 8kA

70mm2

Up to 12kA

2 x 70mm2

25mm x 4mm

Up to 15kA

25mm x 6mm

25mm x 3mm

2 x 70mm

Transformer

LV

RMU

Steel Grate under

Operator Position

(d) Use of Steel Grate

Figure 8-7 Typical Earthing associated with Asset Replacement

UK Power Networks 2014 All rights reserved

29 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

Installation Requirements

This section details the general earthing requirements for all new and modified earthing

installations.

If combined HV/LV earthing is installed then the requirements in Sections 9.1 to 9.5 shall

apply. The HV and LV earthing should be bonded together as described in Section 9.5.

If it has been determined that separated HV and LV earthing is to be installed then the

requirements of Section 9.6 shall also apply in addition to section 9.1 to 9.5.

9.1

General

The theft of copper earthing continues to be a significant national problem. Therefore the

earthing system shall be designed and constructed to ensure that it is secure and not

vulnerable to theft. To aid this aluminium conductor or tape shall be used for all above

ground earthing wherever appropriate and practicable.

9.2

Electrode System

The earth electrode system shall provide the basic functional earthing for the site so that it is

SAFE without any contribution from the network to which it is to be connected. The earth

electrode system shall therefore consist of the following:

Bare copper clad earth electrodes using the minimum sizes specified in Table 9-1.

A ring of earth electrode buried around the perimeter of the substation (or alternatively

buried around the inside perimeter of the substation) at a depth of 500-600mm (except at

integral and basement substations where this is not achievable).

A minimum of two earth rods installed on two corners of the substation (or alternatively

internally) and connected to the outer ring.

Two connections from the outer ring onto the main transformer/switchgear earth terminal

or dedicated substation earth bar.

An earth electrode passing underneath any switchgear or LV operating position and

connected to the outer electrode. This may be omitted if it can be shown that rebar (or

equivalent) or an insulated or earthed operator platform is providing this function.

Connections to the rebar or reinforcement mesh. Note: The rebar shall not extend where

it might be within 2m of LV metalwork or other earthed metalwork if the substation is

HOT.

Additional electrode and rods, as necessary, to enable the required earth resistance to

be achieved.

Table 9-1 Earth Electrodes

Function

Source

Fault Level

Bare Copper Stranded

Conductor

HV Earth Electrode

Up to 8kA

70mm

Earth Rod Electrode

Bare Copper Tape

25mm x 3mm

Up to 12kA

120mm (or 2 x 70mm )

Up to 15kA

2 x 70mm

Any

1m or 1.2m Copper Clad Rods (16mm or 19mm diameter)

UK Power Networks 2014 All rights reserved

25mm x 4mm

25mm x 6mm

30 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

9.2.1

Earth Bar

All earth connections shall be labelled and connected via separate connections to a

dedicated earth bar (GRP/brick-built designs) or marshalling bar or tape (integral/basement

designs) which in turn shall be connected to the main transformer/switchgear earth terminal

to allow:

Operational personnel to determine if the earthing is intact when entering the substation.

The earthing to be easily identified.

The earth resistance to be measured using a clamp meter.

Note: At new enclosed substations the HV earth bar within the LV cabinet/pillar shall not be

used to marshal the earthing connections as access, particularly at IDNO substations, to the

LV cabinet/pillar is not always available. However it is acceptable to use the HV earth bar

within the LV cabinet/pillar at existing outdoor sites for all earth connections to prevent theft.

9.3

Bonding

9.3.1

Equipment Bonding

All current carrying items of equipment including the HV switchgear, LV pillar/cabinet/board

and LV ACB shall be bonded to the transformer (or switchgear) earth terminal using an

independent connection. The minimum size of the bonding conductors is detailed in Table 92.

Table 9-2 Bonding Conductors

Function

Source

Fault Level

Covered Stranded Cable

Any

Up to 8kA

70mm Copper

Up to 12kA

Up to 15kA

Above Ground

Bonding

Up to 8kA

Up to 15kA

25mm x 3mm Copper

2

120mm (or 2 x 70mm ) Copper

2

2 x 70mm Copper

Tape

25mm x 4mm Copper

25mm x 6mm Copper

25mm x 6mm Aluminium

40mm x 6mm Aluminium

120mm Aluminium

240mm Aluminium

All other non-current carrying items of equipment (e.g. control units, RTUs, battery chargers

etc.) shall be bonded to the main earth terminal using a minimum of 35mm2 covered

aluminium cable, 16mm2 covered stranded copper cable or equivalent7.

Minimum conductor sizes taken from BS EN 50522 while ENA TS 41-24 is being revised.

UK Power Networks 2014 All rights reserved

31 of 55

Secondary Substation Earthing Design

Document Number: EDS 06-0014

Version: 3.0

Date: 28/07/2014

9.3.2

Metallic Fences, Gates and Doors

The general rule for metallic substation fences, gates and doors is that they shall be bonded

to the HV earth at all times, unless:

The fence, gate or door is situated more than 2m from any item of equipment or other

earthed metalwork bonded to the HV earth, or

A barrier exists sufficient to prevent simultaneous contact between the fence/gate/door

and the other earthed metalwork.

The site is HOT, in which case the fences, gates and doors can be a shock risk to those

outside the substation. Grading electrodes or independent earthing is required in such

situations as described below. Alternatively the fence could be replaced with a nonmetallic one.

Note: Due to the small size of most secondary substations, metallic fences, gates and doors

will nearly always be within 2m of the equipment and this approach (bonding to HV) should

be adopted in most cases. Additional measures may be required to prevent danger to those

outside the substation, as described below.

If a fence, gate or door is not bonded to the HV earth for the reasons described above, it

shall be provided with an electrode system sufficient to eliminate stray voltages. This should

consist of one or more rod electrodes, adjacent to the fence, gate or door.

9.3.2.1 Metallic Fences

If a metallic fence is installed within 2m of accessible earthed equipment (whether the site is

HOT or otherwise):

It shall be connected to the HV earth; and

A grading electrode of 70mm2 bare copper cable or 25mm x 4mm bare copper tape shall

as a minimum be installed under the fence line, or just inside (or outside), ideally at a

depth of 500mm (300mm minimum) and connected to the fence; this is to protect staff

and the public from dangerous touch potentials. Ideally, and if practicable the grading

electrode should be installed outside the fence at a distance of 300-500mm away from

the fence (in some situations the designer will specify an outside grading electrode, in

which case an electrode underneath or inside the fence line is unacceptable).

Each metallic gate shall be bonded to the gatepost using flexible 35mm2 covered

stranded aluminium cable or 16mm2 covered stranded copper cable or tinned copper

braid.

Each pair of gateposts shall be bonded together using flexible 35mm2 covered stranded

aluminium or 16mm2 covered stranded copper cable.

If metallic fencing is installed more than 2m away from the equipment or other earthed

metalwork, or the metalwork is completely contained in GRP or brick enclosure (and

therefore not accessible8), the fencing shall not be connected to the HV earth. Instead a

single earth rod shall be installed at each corner fence/gate post and connected to the fence

to eliminate stray voltages. At larger sites additional earth rods shall be installed at 5m

intervals, 1m either side of any overhead line crossing and connected to the fence.

In assessing this requirement, thought should be given to metalwork that is accessible when the substation

doors are open; if a 2m separation cannot be maintained on the door side of the GRP/brick enclosure then it will

be necessary to bond the fence to HV steelwork to prevent dangerous hand-hand touch voltages.