Académique Documents

Professionnel Documents

Culture Documents

Layover Inspection Schedule Issue 06

Transféré par

Pankaj KhondgeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Layover Inspection Schedule Issue 06

Transféré par

Pankaj KhondgeDroits d'auteur :

Formats disponibles

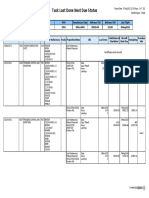

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 1 of 17

A/C REG. ______________ DATE: ______________ STATION: ________________

WORK ORDER NO.______________ STAMP (PLANNING DEPT.) _____________

CHECKED BY:

DIVISION

TECH RECORDS

FORM NO.IGO/E&M/A320/LO/41A

NAME

DATE

SIGNATURE

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 2 of 17

INSTRUCTIONS TO THE CERTIFYING STAFF

1. ENSURE THAT YOU HAVE REQUIRED TOOLS, EQUIPMENT, SPARES AND TECHNICAL LITERATURE PRIOR TO COMMENCEMENT OF

MAINTENANCE TASK.

2. ALL WARNINGS, CAUTIONS DETAILED IN THE REFERENCE TECHNICAL LITERATURE SHALL BE ADHERED TO WHILE PERFORMING

THE RESPECTIVE MAINTENANCE TASK.

3. CARRY OUT FUNCTIONAL TEST OF ALL SYSTEMS THAT WERE DISTURBED DURING THE COURSE OF INSPECTION AND MAINTAIN

RECORDS.

4. RAISE A MAINTENANCE WORK ORDER FOR ANY ABNORMAL FINDINGS OBSERVED WHILE PERFORMING THE INSPECTION

SCHEDULE.

5. WHENEVER AN AREA IS OPENED, INSPECT THE ADJACENT STRUCTURE/COMPONENT ALSO, AND RECORD ABNORMALITY IF

NOTICED, IN A SEPARATE MAINTENANCE WORK ORDER.

6. INSPECTION DATA SHOULD BE RECORDED BY CERTIFYING STAFF AS PER TASK CARD/ WORK ORDER DETAILS (IF APPLICABLE).

7. WHENEVER VALUES ARE TO BE CHECKED THE SAME ARE TO BE RECORDED AGAINST THE CORRESPONDING INSPECTION ITEM.

8. CERTIFY EACH MAINTENANCE STEP IN THE SCHEDULE/WORK ORDER AFTER ITS COMPLETION WITH TIME AND DATE.

9. WHILE CARRYING OUT THE INSPECTION IN OPEN AIR ENSURE THE WEATHER AND ENVIRONMENT IS CONDUCIVE TO CARRY

OUT THE INSPECTION PROPERLY.

10. ALWAYS USE CALIBRATED MEASURING INSTRUMENTS/EQUIPMENTS.

11. ENSURE THAT THE COMPONENT HAS APPROPRIATE SERVICEABLE TAG BEFORE INSTALLING ON THE AIRCRAFT.

12. REVIEW THE AIRCRAFT TECH LOG / CABIN DEFECT LOG FOR ANY PILOT / CABIN CREW DEFECT REPORTS. TAKE APPROPRIATE

RECTIFICATION ACTIONS.

13. REFER ADD/CDD PAGES OF TECH LOG FOR ANY DEFFERED DEFECT AND TAKE APPROPRIATE ACTION.

14. THE TERM INSPECTION/CHECK WHEREVER USED IN THIS SCHEDULE MEANS THAT THE ITEM HAS TO BE CHECKED FOR

SECURITY, CLEANLINESS, CORROSION, DETERIORATION, WEAR, CRACKS, DENTS, SCORES, CUTS, DISTORTION VISUAL EVIDENCE

OF BOWING, OVERHEATING, FREEDOM FROM OBSTRUCTION, LEAKS, LOCKING AND ANY OTHER DAMAGE.

15. THE CMR TASKS ARE MARKED AS (CMR).

16. THE ALS TASKS ARE MARKED AS (ALI).

17. THE CERTIFYING STAFF SIGNING THE CRS SHOULD ENSURE THAT ALL THE TASKS IN THE SCHEDULE ARE SIGNED OFF AND

SHOULD SIGN AND STAMP ON THE COLUMN PROVIDED AT THE BOTTOM OF EACH PAGE OF THE SCHEDULE.

DEFINITIONS:

1. AIRWORTHINESS LIMITATION SECTION (ALS): ALS IS THE REPOSITORY FOR STAND-ALONE DOCUMENTS THAT CONSTITUTES

INSTRUCTIONS FOR CONTINUOUS AIRWORTHINESS. THE TASKS FROM ALS ARE INCLUDED IN THE MAINTENANCE PROGRAM AS

AIRWORTHINESS LIMITATION ITEM (ALI). IT COMPRISES OF DAMAGE TOLERANT AIRWORTHINESS LIMITATION ITEMS (DT ALI),

CERTIFICATION MAINTENANCE REQUIREMENTS (CMR) TASK ARISING FROM SYSTEM SAFETY ASSESSMENT WHICH ARE

ASSOCIATED WITH MOST SIGNIFICANT FAILURE CONDITIONS, AGEING SYSTEMS MAINTENANCE (ASM) & FUEL AIRWORTHINESS

LIMITATIONS (FAL).

2. EXTENDED DIVERSION TIME OPERATIONS (EDTO): THE EXTENDED DIVERSION TIME OPERATIONS (EDTO) IS AN OPERATION BY

AN AIRPLANE WITH TWO OR MORE TURBINE ENGINES WHERE THE DIVERSION TIME TO AN EN-ROUTE ALTERNATE

AERODROME IS GREATER THAN 60 MINUTES.

3. ELECTRICAL WIRING INTERCONNECTION SYSTEM (EWIS): EWIS RELATED TASKS COMPRISE OF THE ATA 20 TASKS, THE

LIGHTNING / HIGH INTENSITY RADIATED FIELDS (L/HIRF) TASKS AND ALL ZONAL INSPECTIONS IDENTIFIED EXCEPT THOSE

ASSOCIATED WITH MAJOR EXTERNAL ZONES (100, 200, 300 ETC). THESE TASKS ARE IDENTIFIED BY (EWIS) IN PARENTHESIS

FOLLOWING THE TASK DESCRIPTION.

4. DETAILED INSPECTION (DI): AN INTENSIVE EXAMINATION OF A SPECIFIC ITEM, INSTALLATION OR ASSEMBLY TO DETECT

DAMAGE, FAILURE OR IRREGULARITY. AVAILABLE LIGHTING IS NORMALLY SUPPLEMENTED WITH A DIRECT SOURCE OF GOOD

LIGHTING AT AN INTENSITY DEEMED APPROPRIATE. INSPECTION AIDS SUCH AS MIRRORS, MAGNIFYING LENSES ETC MAY BE

NECESSARY. SURFACE CLEANING AND ELABORATE ACCESS PROCEDURES MAY BE REQUIRED.

5. GENERAL VISUAL INSPECTION (GVI): A VISUAL EXAMINATION OF AN INTERIOR OR EXTERIOR AREA, INSTALLATION OR

ASSEMBLY TO DETECT OBVIOUS DAMAGE, FAILURE OR IRREGULARITY. THIS LEVEL OF INSPECTION IS MADE FROM WITHIN

TOUCHING DISTANCE UNLESS OTHERWISE SPECIFIED. A MIRROR MAY BE NECESSARY TO ENSURE VISUAL ACCESS TO ALL

SURFACES IN THE INSPECTION AREA. THIS LEVEL OF INSPECTION IS MADE UNDER NORMALLY AVAILABLE LIGHTING

CONDITIONS SUCH AS DAYLIGHT, FLASHLIGHT OR DROP-LIGHT AND MAY REQUIRE REMOVAL OR OPENING OF ACCESS PANELS

OR DOORS. STANDS, LADDERS OR PLATFORMS MAY BE REQUIRED TO GAIN PROXIMITY TO THE AREA BEING CHECKED.

6. VISUAL CHECK (VC): AN OBSERVATION TO DETERMINE THAT AN ITEM IS FULFILLING ITS INTENDED PURPOSE. DOES NOT

REQUIRE QUANTITATIVE TOLERANCES. THIS IS A FAILURE FINDING TASK.

7. OPERATIONAL CHECK (OP): A TASK TO DETERMINE THAT AN ITEM IS FULFILLING ITS INTENDED PURPOSE. DO NOT REQUIRE

QUANTITATIVE TOLERANCES. THIS IS A FAILURE FINDING TASK.

8. FUNCTIONAL TEST (FU): A QUANTITATIVE CHECK TO DETERMINE IF ONE OR MORE FUNCTIONS OF A SYSTEM/SUB-SYSTEM OR

COMPONENT PERFORMS, WITHIN SPECIFIED LIMITS. THIS TASK MAY CALL FOR THE USE OF SPECIAL TEST EQUIPMENT.

FORM NO.IGO/E&M/A320/LO/41A

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 3 of 17

MANPOWER DETAILS

CERTIFYING STAFF

SN

NAME

LIC/APP./AUTH.

STAMP

CAT

SHORT SIGN.

SIGNATURE WITH

DATE

1

2

3

4

5

6

TECHNICIANS

SN

NAME

1

2

3

4

5

6

7

8

FORM NO.IGO/E&M/A320/LO/41A

EMP. ID

SHORT SIGN.

SIGNATURE WITH

DATE

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 4 of 17

A/C REG.: ______________ DATE: _______________ STATION: _______________

TOTAL NUMBER OF WORK ORDERS PERFORMED (SCHEDULED & UNSCHEDULED)

FLIGHT REPORT

SECTOR FLOWN

DATE OF FLIGHT

FLIGHT NO.

FROM

TIME IN AIR

TO

AIRBORNE

TOUCH DOWN

IN AIR

NO. OF

LDGS.

OIL UPLIFT (QTS.)

ENG 1

ENG 2

APU

TOTAL

PREVIOUS DAY RECORD

CURRENT DAY RECORD

TOTAL

NOTE: THIS FLIGHT TIME LOG IS TO BE FILLED AND CERTIFIED BY THE APPROVED/AUTHORISED PERSON

A/C FLIGHT HRS.

A/C LANDINGS

FORM NO.IGO/E&M/A320/LO/41A

DATE

TIME

SIGN

(CERTIFYING STAFF)

APP. / AUTH. STAMP

CAT

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 5 of 17

LIST OF REQUIRED TOOLS/EQUIPMENTS/CONSUMABLES

SN

NOMENCLATURE

PART NUMBER /

SPECIFICATION

QTY

1.

Warning Notices

Not Specific

As Required

2.

Suitable Access Platforms

Not Specific

As Required

3.

Tyre Pressure Gauge

Not Specific

01

4.

Low Pressure Dry Nitrogen Gas source and

Charging Equipment.

Not Specific

01

5.

Ground Safety lock of NLG Downlock

D23080000

01

6.

Ground Lock Sleeve of MLG Downlock

460007280

02

7.

Engine Oil

MIL PRF 23699

As Required

8.

Hydraulic Fluid

Skydrol LD4

CML Ref : 02-003D or

02-506

As Required

9.

Mineral Hydraulic Fluid

MIL PRF 5606H

As Required

Fuel Tank Draining Kit

a) Adapting Pipe Water draining from fuel

tank.

98A28101000000

or

98D28104000000

01

b) Purger Water drain for wing tanks.

98A28104000000

01

c) Water Drain purger for centre tank.

98A28104000002

01

01

10.

11.

One liter Glass Jar for fuel sample

Not Specific

01

12.

Fuel drain Container (metallic)

10 liters

01

13.

Fuel sampling kit.

Aquadis Detector

(HYDROKIT)

As Required

14.

Pin-Safety (Towing Pin)

D23156000

15.

Cover-Total Temperature Sensor

98A10001013000

16.

Cover-Pitot Probe

98A10001005000

17.

Cover-Slip On Angle Of Attack Sensor

98A10001500000

18.

Cover-Static Probe

98D10103500042

98D10103500043

FORM NO.IGO/E&M/A320/LO/41A

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 6 of 17

THIS SCHEDULE CONSISTS 33 TASKS

SN

SKILL

CODE

DESCRIPTION

ARRIVAL

1

Install the wheel chocks.

REF: AMM TASK 10-11-00-555-015

AF

Install the nose landing gear and the main landing gear ground lock safety

devices (as necessary). REF: AMM TASK 32-00-00-481-001

AF

If aircraft towing is required, place the towing lever in the "towing position"

and install pin.

REF: AMM TASK 09-10-00-860-092

AF

AF

Install Pitot, Static covers and other blanks.

REF: AMM TASK 10-11-00-555-069

Review the aircraft technical log and start corrective actions as necessary.

NOTE: If the aircraft electrical network is not energized, perform items 6 and

7 otherwise continue with item 8

Do a safety check of the flight compartment for proper position of the

controls.

Energize the aircraft electrical network.

REF: AMM TASK 24-41-00-861-002

ENGINE OIL

(MPD 791000-I1-1-IGO) REF: AMM TASK 12-13-79-610-011

Check oil level and replenish.

WARNING:

IF NECESSARY TO REMOVE THE OIL TANK CAP, YOU MUST

WAIT A MINIMUM OF 5 MINUTES AFTER ENGINE SHUTDOWN TO ALLOW PRESSURE IN OIL TANK TO DECREASE.

WARNING:

OIL IS DANGEROUS IF IT IS ALLOWED TO BE ABSORBED

THROUGH THE SKIN AND INTO THE BODY. IMMEDIATELY

FLUSH THE OIL WITH WATER.

CAUTION:

DO NOT PUT OIL THAT HAS BEEN DRAINED FROM THE

ENGINE BACK TO THE OIL TANK.

CAUTION:

IF THE ENGINE WAS STOPPED FOR MORE THAN ONE HOUR,

DO SPECIFIC MAINTENANCE ACTION (REFER SUBTASK 12-1379-869-051) TO MAKE SURE THAT OIL LEVEL IS CORRECT. THIS

WILL PREVENT OVERSERVICING IF OIL IS ADDED.

i.

For NON-EDTO A/C:

Do a check of engine oil level as per AMM 12-13-79-610-011

and replenish, if required. Record the uplift in the aircraft

technical log.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AF

AF

AF

AF

AUTH. STAMP

EN

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 7 of 17

SN

SKILL

CODE

DESCRIPTION

ii.

For EDTO certified A/C:

a) Do a check of the engine oil level on the tank sight gauge

within a period of 5 to 60 minutes after engine shutdown.

If the oil tank sight glass shows less than FULL, replenish

the oil tank to FULL level. Compute oil consumption since

last uplift and record in the aircraft technical log.

b) Check no oil filter CLOG indication on ECAM ENG Page.

Record Oil uplift:

Engine No. 1 ........... Qts

Engine No. 2 ...Qts

Also record the oil uplift in Tech Log and on page no.4 of this schedule.

9

EN

APU OIL

REF: AMM TASK 12-13-49-612-001

CAUTION:

i.

ii.

IF POSSIBLE, WAIT AT LEAST 1 HOUR AFTER THE APU SHUT

DOWN TO ALLOW THE OIL TO BECOME COOL BEFORE YOU

SERVICE THE SYSTEM. THIS WILL MAKE SURE THE SIGHT

GLASS READING IS ACCURATE.

For NON-EDTO A/C:

If ECAM APU page shows LOW OIL LEVEL message,

replenish APU oil tank to FULL level and record uplift in the

aircraft technical log.

For EDTO certified A/C:

a) If ECAM APU page shows LOW OIL LEVEL message,

replenish APU oil tank to FULL level. Compute oil

consumption since last uplift and record in the aircraft

technical log.

b) Check no Oil filter clog (APU Maintenance status on

ECAM.) Follow the TSM procedure if Class 2 message

indicates discrepancy with APU system including oil filter

clog.

EN

Record Oil uplift .Qts.

Record following: APU S/N .. APU HRS .. APU CYC .

Also record the oil uplift in Tech Log and on page no.4 of this schedule.

10

HYDRAULIC RESERVOIR QUANTITY CHECK

WARNING: DO NOT GET HYDRAULIC FLUID ON THE SKIN OR EYES. FLUSH

WITH CLEAN WATER AND GET MEDICAL AID.

Do a fluid level check of the Green, Blue and Yellow hydraulic reservoirs

(On ECAM LOWER DISPLAY, HYD page).

Add hydraulic fluid to the reservoirs as necessary. Record uplift(s)

Green ..Qts.

Blue Qts

Yellow .. Qts

Also record the hydraulic uplift in Tech Log

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 8 of 17

SN

SKILL

CODE

DESCRIPTION

EXTERNAL WALK AROUND (AIRFRAME)

11

INTEGRATED DRIVE GENERATOR

(MPD 242100-07-1) Ref. AMM 24-21-51-200-010

(NOTE: TO BE PERFORMED ON EDTO CERTIFIED AIRCRAFT ONLY).

CHECK IDG OIL LEVEL AND DIFFERENTIAL PRESSURE INDICATOR

EN

Record Oil uplift:

IDG No. 1 ..... Qts

Also record the oil uplift in Tech log.

12

IDG No. 2 ....Qts

LOWER HALF OF FUSELAGE

(MPD ZL-100-01-1-IGO) REF: AMM TASK: 05-21-00-200-001

Do a general visual inspection of the lower half of the fuselage from ground as

far as visible, including:

Pitot probes, static ports and AOA sensors: No obstruction

(Inspection with protective covers removed)

Avionics equipment ventilation: Air inlet and air outlet valves

Batteries ventilation outlet (Venturi): No obstruction

Waste water drain mast

Antennas: No damage

Wing and engine scan lights: Cleanliness

Wing-to-fuselage fairings and belly fairing

Anti-collision beacon light: Cleanliness

Radome: No damage, latches engaged and locked

Crew oxygen cylinder overpressure indicator: Green disc in place

(Near access door 812).

LP/HP GRD connection panels CLOSED

Ram air inlet flap

Ram air intakes and outlets: No obstruction

Inspect the belly fairing access panels for missing fasteners.

Ensure that there are no signs of corrosion, cracks or damage.

13

AF

UPPER HALF OF THE FUSELAGE

(MPD ZL-200-01-1-IGO) REF: AMM TASK:05-22-00-200-001

Do a general visual inspection of upper half of fuselage from ground as far as

possible for signs of corrosion, cracks or damage, including:

Cockpit & cabin windows: adjoining structure

Emergency exits

Anti-collision beacon light: Cleanliness

Antennas: No damage

Ensure that there are no signs of corrosion, cracks or damage.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 9 of 17

SN

14

SKILL

CODE

DESCRIPTION

STABILIZERS AND CONE/REAR FUSELAGE

(MPD ZL-300-01-1-IGO) REF: AMM TASK: 05-23-00-200-001

Do a general visual inspection of the rear fuselage with cone and stabilizers

from ground as far as visible, including:

THS and elevators: Damage, evidence of fluid leakage

Fin and rudder: Damage, evidence of fluid leakage

Static dischargers

Tail cone strobe light

Waste water drain mast

Outflow valve

Fuselage tail damage due to ground contact

AF

Ensure that there is no sign of corrosion, cracks or damage.

15

WING

(MPD ZL-500-01-1-IGO)

WARNING:

REF: AMM TASK:05-25-00-200-001

DO NOT EXTEND THE SLATS AND FLAPS WHEN THE THRUST

REVERSER COWLS ARE DEPLOYED IN THE 45 UNIT POSITION

Do a general inspection of LH and RH wings from ground as far as visible.

(A) RIGHT/LEFT WING LEADING EDGE

Do a general visual inspection of the wing leading edge from ground as far as

visible, including:

Slats

Leading edge access panels(pressure relief panels in place)

Surge tank NACA air intake: No obstruction

Surge tank overpressure protector: White cross visible

Ensure that there are no signs of corrosion, cracks or damage.

(B) RIGHT/LEFT WING TIP AND TRAILING EDGE

Do a general visual inspection of the wing tip and trailing edge from ground as

far as visible, including:

Navigation and strobe lights for condition

Static dischargers missing or damaged

Control surfaces, flaps and flap track fairings: Damage, evidence of

fluid leakage

Lower wing surface: Damage, evidence of fuel leakage

Wing tank overpressure protector: Burst disk in place (White cross

visible

Landing light: No damage, cleanliness

Ensure that there are no signs of corrosion, cracks or damage.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 10 of 17

SKILL

CODE

SN

DESCRIPTION

16

LANDING GEAR AND LANDING GEAR DOORS

(MPD ZL-700-01-1-IGO) REF: AMM TASK: 05-27-00-200-001

Do a general visual inspection of the main and nose landing gears and landing

gear doors from ground as far as visible, including:

Doors and wheel well

Gear assembly structure: Damage, evidence of leakage

Shock absorber: Signs of leakage and normal extension

Shock absorber sliding tube: Scoring/damage, cleanliness,

(if necessary, make a clean cloth moist with mineral hydraulic fluid

(Mat. No. 02-001), clean tube and dry with a clean cloth)

Proximity detectors: Security, cleanliness

Brake units: Evidence of leakage or overheating

AF

Ensure that there are no signs of corrosion, cracks or damage.

17

18

DOORS

(MPD ZL-800-01-1-IGO) REF: AMM TASK: 05-28-00-200-001

Do a general visual inspection of all pax, service and cargo doors from ground

for signs of corrosion, cracks or damage.

4 Passenger/Crew doors

3 cargo compartment doors

4 overwing emergency exits

Service panel doors, avionic compartment access doors,

AF

TANKS

(MPD 281100-01-2) REF: AMM TASK: 12-32-28-281-001

WARNING:

1. OBEY THE FUEL SAFETY PROCEDURES. GROUND THE AIRCRAFT CORRECTLY.

2. HEADSET SHOULD NOT BE WORN. CABLES/LINES CONNECTED TO THE

AIRCRAFT SHOULD NOT BE TOUCHED.

3. FUELLING SHOULD NOT BE DONE DURING BAD WEATHER CONDITION.

4. LIGHTENING IS DANGEROUS WHILE WORKING ON FUEL TANKS.

5. ALWAYS CONNECT THE GROUND CABLE TO THE PARKING GROUND POINT

BEFORE CONNECTING TO THE AIRCRAFT. DO NOT ATTACH THE GROUND

CABLE TO AIRCRAFT FIRST AS THERE IS A RISK OF ELECTRIC SHOCK.

NOTE:

1. IF POSSIBLE, DO THE WATER DRAIN PROCEDURE BEFORE A REFUEL.

ALTERNATIVELY, YOU MUST WAIT FOR ONE HOUR AFTER A REFUEL HAS

BEEN COMPLETED BEFORE YOU DO THE WATER DRAIN PROCEDURE.

2. USE THE GRAVITY PROCEDURE ONLY IF THERE IS MORE THAN 10%

CONTENT OF FUEL IN EACH TANK

3. USE SUCTION PROCEDURE IF THERE IS LESS THAN 10% CONTENT OF FUEL

IN EACH TANK.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 11 of 17

SN

SKILL

CODE

DESCRIPTION

Drain water from wing tanks and center tank at water drain valves

Take fuel samples from all tanks. Check for any contamination. Check water

contents in the samples with Aquadis detector (HYDROKIT).

After drainage, make sure that the drain valves are correctly closed and not

leaking.

19

WHEELS

(MPD 324100-01-1)

AF

REF: AMM TASK: 32-41-00-210-003

Inspect Nose, RH / LH Main Landing Gear Wheels and Tyres for satisfactory

condition (Wear & Damage) including:

Wheels: Rim damage, sheared/missing tie bolts

Tyres: Wear, damage and signs of under inflation/over inflation.

NOTE: For tyre damage, cuts, chord breakage etc refer to AMM Task

32-41-00-210-002.

CAUTION:

1. TYRE PRESSURE MUST BE CHECKED WHEN THE TYRES ARE NOT HOT.

2. SERVICE TYRES WITH NITROGEN ONLY.

3. ON ANY DAY IF LOW TYRE PRESSURE IS SUSPECTED ON ANY WHEEL

DURING INSPECTION THEN CHECK THE TYRE PRESSURE OF THE

SUSPECTED WHEEL/S AND INFLATE TO MAXIMUM TYRE PRESSURE.

4. AT LINE STATION IF DRY NITROGEN GAS IS NOT AVAILABLE THEN AIR

MAY BE USED. BUT BEFORE USE IT MUST BE ENSURED THAT THE AIR

BEING USED HAS OXYGEN NOT MORE THAN 5% BY VOLUME.

HOWEVER IF AIR WITH UNKNOWN OXYGEN CONTENT IS USED THEN

THIS AIR SHOULD BE REMOVED FROM TYRES WITHIN 15 HOURS AND

THE TYRES CHARGED WITH DRY NITROGEN. ACCORDINGLY A

NOTING SHOULD BE REFLECTED IN DEFERRED MAINTENANCE AND

WORKORDER.

5. THE CHEMICAL REACTION BETWEEN THE OXYGEN IN THE TYRES AND

GASES FROM THE INNER LINER OF THE TYRE MAY CAUSE A TYRE

EXPLOSION.

Check and record tyre pressure and inflate to maximum specified tyre

pressure, if necessary

(TO BE DONE DURING NIGHT HALT ON SUNDAY, TUESDAY & THURSDAY)

NOTE:

MLG Tyre Pressure - Min : 210 psi

NLG Tyre Pressure - Min : 178 psi

Max: 220 psi

Max: 187 psi

CAUTION: IN CASE TYRE PRESSURE IS FOUND BELOW 170 PSI FOR NLG OR

BELOW 190 PSI FOR MLG REFER AMM TASK 32-41-00-210-059 FOR FURTHER

ACTION.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 12 of 17

SN

SKILL

CODE

DESCRIPTION

INITIAL TYRE PRESSURE:

Main Wheels

#1

#2

#3

#4

Nose Wheels

#1

#2

Tyre Pr.

(PSI)

FINAL TYRE PRESSURE:

AF

Main Wheels

#1

#2

Nose Wheels

#3

#4

#1

#2

Tyre Pr.

(PSI)

Record the following Data:

TP Gauge Serial No. ..

20

Gauge Calibration date: . Next due on

MAIN LANDING GEAR BRAKES

(MPD 324227-01-1)

REF: AMM TASK:32-42-27-210-003

WARNING:

PUT SAFETY DEVICES AND WARNING NOTICES IN POSITION

BEFORE STARTING INSPECTION NEAR MLG AND THE RELATED

DOORS.

Functional check of brake heat pack for wear by use of the wear indicator

(parking brake applied)

Ensure that there are no leaks from brake assemblies and hydraulic lines.

AF

WASTE/WATER SERVICING

NOTE:

In freezing conditions, drain the potable water system and the toilet

waste tank. Service before aircraft departure.

Obey the cold weather maintenance procedure (Ref. TASK 12-31-38660-001).

If the temperature in the aircraft is below 4 DEG.C (39.20 DEG.F) do

the pre-conditioning procedure (Ref. TASK 12-33-21-618-001).

AF

Ensure that the potable water system is serviced as required.

To fill the potable water system with electrical power (Ref. AMM TASK 12-1538-613-001).

To fill the potable water system without electrical power (Ref. AMM TASK 1215-38-613-002).

AF

NOTE:

NOTE:

21

22

Ensure that the toilet waste tank is serviced as required (Ref. AMM TASK 1216-38-613-001).

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 13 of 17

SN

SKILL

CODE

DESCRIPTION

FLIGHT COMPARTMENT

23

CREW OXYGEN SYSTEM

On the DOOR/OXY page (lower ECAM DU), ensure that the oxygen pressure is

indicated in Green

24

AF

AIRCRAFT DOCUMENTS

Check for the presence and validity (where applicable) of the following

documents. Torn/mutilated/missing/invalid documents must be replaced.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

25

Certificate of Registration

Certificate of Airworthiness

Aircraft Station License

Noise Certificate

Permit to Operate

Certificate of Insurance

Weight Schedule

Airworthiness Review Certificate (ARC)

Emergency Equipment Location Chart

LOPA

MEL Vol 1 and Vol 2

Flight Report Book (FRB)

Dent & Buckle Chart

Cabin Defect Log Book (CDLB) in passenger compartment.

AF

EMERGENCY EQUIPMENT:

Check the emergency equipment for presence, correct stowage & validity

(where applicable).

Refer Emergency Equipment Location Chart in Documents on-board file for

location and quantity of the equipment.

1.

2.

3.

4.

5.

6.

7.

AF

Crash Axe

Fire proof gloves

Life vest for crew

Portable fire extinguisher

Portable Breathing Equipment

Flash light

Escape Rope

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 14 of 17

SN

SKILL

CODE

DESCRIPTION

PASSENGER COMPARTMENT

26

EMERGENCY EQUIPMENT

Check the emergency equipment for presence, correct stowage & validity

(where applicable).

Refer Emergency Equipment Location Chart in Documents on-board file for

location and quantity of the equipment.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

First Aid Kit

Medical Kit

Universal Precaution Kit

Megaphone

Life vest for cabin crew

Life vest for infants

Portable fire extinguisher

Portable oxygen bottle & masks

Portable Breathing Equipment

Manual Release Tools

Portable ELT

Flash lights

PAX Life Vests

Automated External Defibrillators (AED)

Ensure that the Green Ready light is blinking.

NOTE:

- If the Ready light is steady: The AED is in use or running a

self-test.

- If the Ready light is off, the AED is chirping, and the ibutton is flashing: The following may be the probable

causes:

a) A self-test error has occurred,

b) there is a problem with the pads,

c)

the Infant/Child Key has been left installed,

d) the battery power is low.

Press the i-button for instructions.

- If the Ready light is off but the AED is not chirping and the

i-button is not flashing: The following may be the probable

causes:

a) there is no battery inserted,

b) the battery is depleted,

c)

the defibrillator needs repair.

15. Additional Emergency Equipment on EDTO certified A/C:

a) Survival Kit

b) Over-wing Escape Life Lines

c)

Supplemental Life Raft

d) Portable ELT

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

AF

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 15 of 17

SN

27

DEMO KIT CONTENTS:

Check the FWD and AFT Demo Kits contents as mentioned below:

SN

28

SKILL

CODE

DESCRIPTION

Description

FWD Demo Kit

AFT Demo Kit

DEMO MASK

DEMO BELT

EXTENSION BELT

PAX INFO CARD

DEMO LIFE VEST

General visual check of the left and right wing upper surface and control

surfaces, through cabin windows.

AF

AF

AIRCRAFT CLEANING

29

30

31

COCKPIT AREA

Check and clean the cockpit area including windshield & windows, crew and

observer seats, floor area and cockpit door.

AF

CABIN

Check passenger compartment for general cleanliness including PSU, Stowage

compartments in galleys, toilets, doors, ceiling and side wall panels.

Passenger seat upholstery, carpets and passenger windows.

AF

EXTERIOR CLEANING

REF: AMM TASK 12-21-11-615-002

External surface of fuselage, wing control surfaces, landing gear doors. Check

that fuselage exterior is free from streaks and deposits.

AF

EXTERNAL WALK AROUND (APU)

AUXILLARY POWER UNIT

32

Visual check of the APU area from ground for general condition:

Air intake

Doors: Closed and secured

Drain mast, drains and vents

Exhaust

Fire extinguisher overpressure discharge indicator: Red disc in place

Ensure that there are no signs of corrosion, cracks or damage.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

EN

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 16 of 17

SN

SKILL

CODE

DESCRIPTION

EXTERNAL WALK AROUND (ENGINES)

33

POWER PLANT, NACELLES AND PYLON

(MPD ZL-400-01-1-IGO) Ref: AMM Task: 05-24-00-200-001

Visual inspection of power plant, nacelles and pylon from ground as far as

visible(cowl doors closed) including:

Pylon fairing and fillets: No damage, pressure relief doors closed

Engine air inlet: lip and outer and inner skin, riveting, acoustic

panels, and visible probes and sensors (P2/T2)

Fan blades, annulus fillers and spinner: No damage

Fan rotor path, splitter fairing, inlet guide vanes, fan outlet guide

vanes and fan duct. Check Fan free rotation by hand.

External surface of the fan cowl doors and thrust reverser doors,

Doors closed and correctly latched. Access doors and pressure

relief doors in place, closed and secured.

Air inlets/outlets: No obstruction.

Translating sleeves correctly stowed.

CNA (Common Nozzle Assembly) and exhaust: Last stage LPT

blades, struts, nozzle and plug (for damage and metal deposit)

Drain mast and pylon drains: No obstruction, evidence of leakage.

Fan Exhaust: Acoustic lining, exit vanes, struts and thrust reverser

blocker doors.

Ensure that there are no signs of corrosion, cracks or damage.

SIGNATURE

(CERTIFYING STAFF)

FORM NO.IGO/E&M/A320/LO/41ARE

AUTH. STAMP

EN

TECH

CERTIFYING

STAFF

LAYOVER INSPECTION SCHEDULE

(AIRBUS A320 AIRCRAFT WITH V2527-A5 ENGINES)

APPROVAL

IGO/E&M/Approval/Insp.Sch/22 dated: 15.06.2015

INTERVAL

To be performed once every 36 calendar hours

EFFECTIVITY: IGO ALL

ISSUE: 06

Dated: 15.06.2015

PAGE: 17 of 17

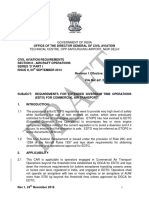

CERTIFICATE OF RELEASE TO SERVICE

ORGANIZATION NAME

INTERGLOBE AVIATION LIMITED (INDIGO)

ORGANIZATION APPROVAL

REFERENCE

DAW, DELHI REGION LETTER NO. INDIGO/F APP/1034 DATED 31/07/2006

CERTIFICATE OF RELEASE TO SERVICE IN ACCORDANCE WITH CAR 145

AIRCRAFT

AIRBUS A320-232

MSN

REGISTRATION

HAS BEEN MAINTAINED AS SPECIFIED IN THE WORK ORDER

TAH

TAC

WORK ORDER

NO.

RECORD WORKORDER & TASKCARD NUMBERS (AS APPLICABLE), INCLUDING A BRIEF DESCRIPTION OF WORK

PERFORMED*

CERTIFIES THAT THE WORK SPECIFIED EXCEPT AS OTHERWISE SPECIFIED WAS CARRIED OUT IN ACCORDANCE WITH

CAR-145 AND IN RESPECT TO THAT WORK THE AIRCRAFT/AIRCRAFT COMPONENT IS CONSIDERED READY FOR

RELEASE TO SERVICE.

CERTIFYING

STAFF (NAME)

SIGNATURE

LIC/APP./AUTH.

STAMP

LOCATION**

DATE

TIME

* REFERENCE TO APPROVED DATA USED TO PERFORM THE WORK

** LOCATION WHERE THE WORK WAS PERFORMED

FORM NO. IGO/E&M/CRS/No. 7

FORM NO.IGO/E&M/A320/LO/41A

Issue 1

Vous aimerez peut-être aussi

- B737-300F Aircraft Daily ChecklistDocument10 pagesB737-300F Aircraft Daily ChecklistUmer JavedPas encore d'évaluation

- The Grid 2: Blueprint for a New Computing InfrastructureD'EverandThe Grid 2: Blueprint for a New Computing InfrastructurePas encore d'évaluation

- 8 Day Inspection Schedule Issue 12 Rev 00 (A320-232) PDFDocument22 pages8 Day Inspection Schedule Issue 12 Rev 00 (A320-232) PDFRoshith Krishnan100% (1)

- A320 maintenance checklistDocument5 pagesA320 maintenance checklistLandy FebriansyahPas encore d'évaluation

- Airframe Level 1rDocument185 pagesAirframe Level 1rAbil Gilang -Pas encore d'évaluation

- ATA 06decoded PDFDocument52 pagesATA 06decoded PDFraiday840% (1)

- The 737 APUDocument1 pageThe 737 APUAhmad AlshiekhPas encore d'évaluation

- M03 - Other MPD SourcesDocument18 pagesM03 - Other MPD SourcesA WongPas encore d'évaluation

- HKA Cabin Cleaning Standard and Procedures - CCSP - Rev4 PDFDocument303 pagesHKA Cabin Cleaning Standard and Procedures - CCSP - Rev4 PDFTeow Chee MengPas encore d'évaluation

- 1A+2A+4A 11aug2007Document39 pages1A+2A+4A 11aug2007RaviSinghPas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument20 pagesA318/A319/A320/A321: Service BulletinPradeep K sPas encore d'évaluation

- 737-800 ExtnDocument6 pages737-800 ExtnIshmum Monjur NilockPas encore d'évaluation

- Continuing Airworthiness Management Excedure (CAMOEDocument27 pagesContinuing Airworthiness Management Excedure (CAMOEDipendra SenPas encore d'évaluation

- Boeing 737 Classic Aircraft Type Rating CourseDocument4 pagesBoeing 737 Classic Aircraft Type Rating CourseGuntur EkoPas encore d'évaluation

- Powerplant Level 1rDocument220 pagesPowerplant Level 1rAbil Gilang -Pas encore d'évaluation

- Aircraft System GMFDocument147 pagesAircraft System GMFKrasakKrusuk Si MaulPas encore d'évaluation

- Ata25 AirbusDocument308 pagesAta25 AirbusOliver BarrientosPas encore d'évaluation

- Airbus Commercial Aircraft AC A350 900 1000Document411 pagesAirbus Commercial Aircraft AC A350 900 1000librada diazPas encore d'évaluation

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldPas encore d'évaluation

- MLG - Removal InstallationDocument14 pagesMLG - Removal InstallationKeilaeFrancisco ArcePas encore d'évaluation

- Afm PDFDocument26 pagesAfm PDFcf34Pas encore d'évaluation

- Aircraft Classifications - RfsDocument69 pagesAircraft Classifications - RfsPaulo SouzaPas encore d'évaluation

- A320 LG ServicingDocument59 pagesA320 LG ServicingSergej RepenkovPas encore d'évaluation

- Aircraft Economic Life WhitepaperDocument9 pagesAircraft Economic Life WhitepaperFlankerSparrowPas encore d'évaluation

- AddictionV2 ManualDocument20 pagesAddictionV2 ManualLORVMAXXXL100% (1)

- Level III Ata 49 ApuDocument60 pagesLevel III Ata 49 ApuGuyPas encore d'évaluation

- Sep Question Bank For Crew - Recurrent Training Chapter 1: PolicyDocument197 pagesSep Question Bank For Crew - Recurrent Training Chapter 1: PolicyHoàng Việt TrungPas encore d'évaluation

- LAST DONE WLB - 07aug2022 - 122946Document292 pagesLAST DONE WLB - 07aug2022 - 122946EssamPas encore d'évaluation

- Requirements for Air Operator Certificate RenewalDocument21 pagesRequirements for Air Operator Certificate RenewalHussainAhmedPas encore d'évaluation

- Embraer ERJ-190 Series (GE CF34) : T1+T2 Combined / Theoretical & Practical ElementsDocument4 pagesEmbraer ERJ-190 Series (GE CF34) : T1+T2 Combined / Theoretical & Practical Elementsေအာင္ ရွင္း သန္ ့Pas encore d'évaluation

- Teardowns and End-Of-Life Solutions - Aircraft CommerceDocument8 pagesTeardowns and End-Of-Life Solutions - Aircraft CommerceadelPas encore d'évaluation

- Ea 767 31-002 Eicas Upgrade Ops6 PDFDocument5 pagesEa 767 31-002 Eicas Upgrade Ops6 PDFjuanf490Pas encore d'évaluation

- 2520 M1F00 01 00 Iss 11Document1 page2520 M1F00 01 00 Iss 11Christina GrayPas encore d'évaluation

- Level III Ata 52 DoorsDocument72 pagesLevel III Ata 52 DoorsGuyPas encore d'évaluation

- A318/A319/A320/A321 Aircraft Pressure Refuel ProcedureDocument7 pagesA318/A319/A320/A321 Aircraft Pressure Refuel Procedureraiday84Pas encore d'évaluation

- B 737 - CL - Ata 38 - B1.1Document47 pagesB 737 - CL - Ata 38 - B1.1Vasili RafaelyanPas encore d'évaluation

- GeneralDocument48 pagesGeneralParag Alamyan100% (1)

- Mega Ac25Document93 pagesMega Ac25Nariaki SumiPas encore d'évaluation

- Defueling Procedure Erj 190Document4 pagesDefueling Procedure Erj 190jucamallaPas encore d'évaluation

- 1c-Check Inspection Schedule..............Document36 pages1c-Check Inspection Schedule..............Jeffrey DavisPas encore d'évaluation

- (Indigo) Freshers Ame Job Guidance by Aviator-ArifDocument55 pages(Indigo) Freshers Ame Job Guidance by Aviator-ArifShivan AadithyaPas encore d'évaluation

- Mil HDBK 516Document183 pagesMil HDBK 516juanblas86Pas encore d'évaluation

- Ata 71 - B1 - Iae V2500Document61 pagesAta 71 - B1 - Iae V2500Abil Gilang -Pas encore d'évaluation

- A Seminar on the Airbus A380Document22 pagesA Seminar on the Airbus A380Chandrashekar HiremathPas encore d'évaluation

- 8 Repair BasicsDocument66 pages8 Repair BasicsedvynwillisturbanosPas encore d'évaluation

- Rolls Royce TrentDocument11 pagesRolls Royce Trentmakumba1972Pas encore d'évaluation

- 2009-Final Report B707 - ST-AKW - Report 10 2009Document96 pages2009-Final Report B707 - ST-AKW - Report 10 2009AlexShearPas encore d'évaluation

- SB F2000ex - 386 R3Document20 pagesSB F2000ex - 386 R3Rudro Kumar100% (1)

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Document20 pagesCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05Pas encore d'évaluation

- On The Design and Structural Analysis o Fjet Engine Fan Blade StructuresDocument11 pagesOn The Design and Structural Analysis o Fjet Engine Fan Blade StructuresNico ScheggiaPas encore d'évaluation

- 3 Application ARCDocument9 pages3 Application ARCHemantkumar TungPas encore d'évaluation

- Dy CHK - 400 2015 New 737 BOOK NG 00 103Document23 pagesDy CHK - 400 2015 New 737 BOOK NG 00 103Syed Salman UddinPas encore d'évaluation

- Aircraft Anti-Icing SystemDocument3 pagesAircraft Anti-Icing SystemVejay RamPas encore d'évaluation

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanPas encore d'évaluation

- Boeing 717Document7 pagesBoeing 717s3m3staPas encore d'évaluation

- Weekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFDocument10 pagesWeekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFSabeeka BatoulPas encore d'évaluation

- Airbus FAST Magazine 44 p8 p16Document9 pagesAirbus FAST Magazine 44 p8 p16Subha SahaPas encore d'évaluation

- DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015Document20 pagesDFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015KamalVirkPas encore d'évaluation

- DCAM PART 66 CAT B1.1 MODULE 4 ELECTRONIC FUNDAMENTALS SEMICONDUCTORSDocument114 pagesDCAM PART 66 CAT B1.1 MODULE 4 ELECTRONIC FUNDAMENTALS SEMICONDUCTORSwmfadzli7265100% (2)

- Upk Instructions ManualDocument1 pageUpk Instructions ManualPankaj KhondgePas encore d'évaluation

- Fak After Use FormDocument1 pageFak After Use FormPankaj KhondgePas encore d'évaluation

- 0632059516Document233 pages0632059516Jose Alberto Castellano100% (15)

- Is June 2012Document3 pagesIs June 2012Aviation WorldPas encore d'évaluation

- IlsDocument22 pagesIlsHemantkumar TungPas encore d'évaluation

- Instrument System Paper 2013 June.Document13 pagesInstrument System Paper 2013 June.Pankaj KhondgePas encore d'évaluation

- D8S-S1 (R1 - Nov2016) EDTODocument29 pagesD8S-S1 (R1 - Nov2016) EDTOPankaj KhondgePas encore d'évaluation

- JAA InstrumentsDocument4 pagesJAA InstrumentsPankaj KhondgePas encore d'évaluation

- Aircraft Instruments Essay QuestionsDocument91 pagesAircraft Instruments Essay QuestionsPankaj KhondgePas encore d'évaluation

- Refer Chart No. 2Document4 pagesRefer Chart No. 2ramcm024Pas encore d'évaluation

- Lgciu Ts GuideDocument34 pagesLgciu Ts GuidePankaj KhondgePas encore d'évaluation

- Radio Telephony BookDocument97 pagesRadio Telephony BookPankaj KhondgePas encore d'évaluation

- RTR - A (Part 1 Questions)Document77 pagesRTR - A (Part 1 Questions)sujatanathv29% (7)

- UntitledDocument2 pagesUntitledKavin MadhaniPas encore d'évaluation

- D8S-S1 (R1 - Nov2016) EDTODocument29 pagesD8S-S1 (R1 - Nov2016) EDTOPankaj KhondgePas encore d'évaluation

- 2010 QuestionDocument110 pages2010 QuestionsudhirvatsaPas encore d'évaluation

- Correct Fan Cowl Door Opening ProcedureDocument2 pagesCorrect Fan Cowl Door Opening ProcedurePankaj KhondgePas encore d'évaluation

- GIC 05 of 2012 - MW Inspection and Jacking PrecautionsDocument2 pagesGIC 05 of 2012 - MW Inspection and Jacking PrecautionsPankaj KhondgePas encore d'évaluation

- Obtaining fuel figuresDocument2 pagesObtaining fuel figuresPankaj KhondgePas encore d'évaluation

- Guidelines for airlines on Ebola screening of passengersDocument1 pageGuidelines for airlines on Ebola screening of passengersPankaj KhondgePas encore d'évaluation

- GIC 09 of 2012 - Connecting GPUDocument2 pagesGIC 09 of 2012 - Connecting GPUPankaj KhondgePas encore d'évaluation

- Product Data: Airstream™ 42BHC, BVC System Fan CoilsDocument40 pagesProduct Data: Airstream™ 42BHC, BVC System Fan CoilsMaxmore KarumamupiyoPas encore d'évaluation

- JRC Wind Energy Status Report 2016 EditionDocument62 pagesJRC Wind Energy Status Report 2016 EditionByambaa BattulgaPas encore d'évaluation

- Parasim CADENCEDocument166 pagesParasim CADENCEvpsampathPas encore d'évaluation

- Managing operations service problemsDocument2 pagesManaging operations service problemsJoel Christian Mascariña0% (1)

- Storage Reservior and Balancing ReservoirDocument19 pagesStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- InvoiceDocument1 pageInvoiceAnurag SharmaPas encore d'évaluation

- Keynes Presentation - FINALDocument62 pagesKeynes Presentation - FINALFaith LuberasPas encore d'évaluation

- Illustrator CourseDocument101 pagesIllustrator CourseGreivanPas encore d'évaluation

- MSDS Metafuron 20 WPDocument10 pagesMSDS Metafuron 20 WPAndi DarmawanPas encore d'évaluation

- Memento Mori: March/April 2020Document109 pagesMemento Mori: March/April 2020ICCFA StaffPas encore d'évaluation

- 20220720-MODIG-Supply Chain Manager (ENG)Document2 pages20220720-MODIG-Supply Chain Manager (ENG)abhilPas encore d'évaluation

- 2014 March CaravanDocument48 pages2014 March CaravanbahiashrinePas encore d'évaluation

- Lenex 3.0 Technical DocumentationDocument31 pagesLenex 3.0 Technical DocumentationGalina DPas encore d'évaluation

- Embedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDocument27 pagesEmbedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDhirenKumarGoleyPas encore d'évaluation

- M Series CylindersDocument61 pagesM Series CylindersAndres SantanaPas encore d'évaluation

- Duct Design ChartDocument7 pagesDuct Design ChartMohsen HassanPas encore d'évaluation

- Examination: Subject CT5 - Contingencies Core TechnicalDocument7 pagesExamination: Subject CT5 - Contingencies Core TechnicalMadonnaPas encore d'évaluation

- Research Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormDocument13 pagesResearch Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormBikaZee100% (1)

- IT support tips for non-tech colleaguesDocument7 pagesIT support tips for non-tech colleaguesLeo KrekPas encore d'évaluation

- Stellar Competent CellsDocument1 pageStellar Competent CellsSergio LaynesPas encore d'évaluation

- Modulus of Subgrade Reaction KsDocument1 pageModulus of Subgrade Reaction KsmohamedabdelalPas encore d'évaluation

- CLC Customer Info Update Form v3Document1 pageCLC Customer Info Update Form v3John Philip Repol LoberianoPas encore d'évaluation

- Coa - Ofx-8040a (H078K5G018)Document2 pagesCoa - Ofx-8040a (H078K5G018)Jaleel AhmedPas encore d'évaluation

- Factory Hygiene ProcedureDocument5 pagesFactory Hygiene ProcedureGsr MurthyPas encore d'évaluation

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinPas encore d'évaluation

- Hindustan Coca ColaDocument63 pagesHindustan Coca ColaAksMastPas encore d'évaluation

- Request Letter To EDC Used PE PipesDocument1 pageRequest Letter To EDC Used PE PipesBLGU Lake DanaoPas encore d'évaluation

- NH School Employee Criminal Record Check FormDocument2 pagesNH School Employee Criminal Record Check FormEmily LescatrePas encore d'évaluation

- Advanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFDocument103 pagesAdvanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFtudor11111Pas encore d'évaluation

- Sap Ewm - Erp Initial SetupDocument3 pagesSap Ewm - Erp Initial SetupVAIBHAV PARAB80% (5)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)