Académique Documents

Professionnel Documents

Culture Documents

E5924 ws08w01

Transféré par

Inkanata SacTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E5924 ws08w01

Transféré par

Inkanata SacDroits d'auteur :

Formats disponibles

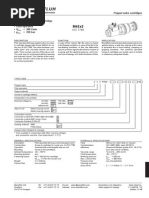

2/2 Solenoid Directional Valve

Poppet Type, Direct-Acting

Normally Closed

SAE-08 Cartridge 250 bar

WS08W-01

19 l/min

250 bar

FUNCTION

FEATURES

zz External surfaces zinc-plated and corrosion-proof

zz Hardened and ground internal valve components to ensure minimal wear and

extended service life

zz Coil seals protect the solenoid system

zz Wide variety of connectors available

zz Excellent switching performance by high power HYDAC solenoid

zz Low pressure drop due to CFD optimized flow path

SPECIFICATIONS

Operating pressure:

Nominal flow:

Leakage:

Media operating temperature range:

Ambient temperature range:

Operating fluid:

Viscosity range:

Filtration:

MTTFd:

Installation:

Materials:

Cavity:

Weight:

Electrical data:

Response time:

Type of voltage:

E 5.924.4/09.13

Current draw at 20 C:

370

In the de-energized mode, the valve

blocks flow in both directions.

When energized the valve allows flow in

both directions.

Coil duty rating:

Coil type:

max. 250 bar

max. 19 l/min

Leakage-free

(max. 5 drops 0,25 cm/min at 250 bar)

min. -30 C to max. +100 C

min. -20 C to max. + 60 C

Hydraulic oil to DIN 51524 Part 1 and 2

min. 7.4 mm/s to max. 420 mm/s

Class 21/19/16 according to ISO 4406 or

cleaner

150 years (see "Conditions and

instructions for valves" in brochure 5.300)

No orientation restrictions

Valve body:

free-cutting steel

Poppet:

hardened and

ground steel

Seals:

NBR (standard)

FKM (optional, media

temperature range

-20 C to +120 C)

Back-up rings: PTFE

Coil:

steel / polyamide

FC08-2

Valve complete 0.33 kg

Coil only

0.19 kg

Energized:

approx. 35 ms

De-energized: approx. 50 ms

DC solenoid, AC voltage is rectified

using a bridge rectifier built into the coil

1.5 A at 12 V DC

0.8 A at 24 V DC

Continuous up to max. 115%

of the nominal voltage at

60 C ambient temperature

Coil-40-1836

DIMENSIONS

After loosening mounting nut,

coil can be rotated through 360

and removed.

hex. 7/8"

torque 25+5 Nm

Manual override, with

HNBR-rubber cap

without man.

override

torque 4+1 Nm

MODEL CODE

WS08W 01 M C N 24 DG

Basic model

Directional poppet valve UNF

Type

01 = standard

Manual override

no details = without manual override

M = manual override

Body and Ports*

C = cartridge only

SB3 = G3/8 ports, steel body

AB3 = G3/8 ports, aluminium body

Seals

N = NBR (standard)

V = FKM

Coil voltage

DC voltages

12 = 12 V DC

24 = 24 V DC

AC voltages (bridge rectifier built into the coil)

115 = 115 V AC

230 = 230 V AC

Other voltages on request

Coil connectors (type 40-1836)

DC: DG = DIN connector to EN 175301-803

DK = KOSTAL threaded connection M27x1

DL = 2 flying leads, 457 mm long, 0.75 mm

DN = Deutsch connector, 2-pole, axial

DT = AMP Junior Timer, 2-pole, radial

AC: AG = DIN connector to EN 175301-803

Other connectors on request

Standard models

thick

millimeter (inch)

subject to technical modifications

CAVITY

FC08-2

Model code

Part No.

WS08W-01-C-N-24DG

3011913

WS08W-01-C-N-230AG

Other models on request

3043358

*Standard in-line bodies

Code

Part No.

Material

Ports

Pressure

FH082-SB3

560919

Steel, zinc-plated

G3/8

420 bar

FH082-AB3

3011423

Aluminium, clear anodized

G3/8

210 bar

Other housings on request

Seal kits

Code

Material

Part No.

FS082-N SEAL KIT

NBR

3033920

FS082-V SEAL KIT

FKM

3051756

PERFORMANCE

Pressure drop

Measured at = 34 mm/s, Toil = 46 C

Form tools

Tool

Countersink FC08-2

Reamer FC08-2

Part No.

175473

175474

NOTE

millimeter (inch)

subject to technical modifications

The information in this brochure relates to the

operating conditions and applications described.

For applications or operating conditions not

described, please contact the relevant

technical department.

Subject to technical modifications.

HYDAC Fluidtechnik GmbH

Justus-von-Liebig-Str.

D-66280 Sulzbach/Saar

Tel: 0 68 97 /509-01

Fax: 0 68 97 /509-598

E-Mail: flutec@hydac.com

E 5.924.4/09.13

Flow rate

371

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Solenoid Bidirectional ValveDocument2 pagesSolenoid Bidirectional Valveman_y2kPas encore d'évaluation

- E5907 ws08z01-1Document2 pagesE5907 ws08z01-1raul20132013Pas encore d'évaluation

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierPas encore d'évaluation

- Solenoid ValveDocument9 pagesSolenoid ValveNitish DhawanPas encore d'évaluation

- 2/2 Cartridge Seat Valve, Size 5: 1 DescriptionDocument6 pages2/2 Cartridge Seat Valve, Size 5: 1 DescriptionSimen EllingsenPas encore d'évaluation

- 30 22 7 012 0010-Finder-Datasheet-548493Document2 pages30 22 7 012 0010-Finder-Datasheet-548493Tony RodriguezPas encore d'évaluation

- 2/2-Way Valves DN 20 To DN 50Document4 pages2/2-Way Valves DN 20 To DN 50Oscar CurimanyaPas encore d'évaluation

- Position Switches FR Series: Selection DiagramDocument12 pagesPosition Switches FR Series: Selection DiagramMehmetLeventÖzsinanPas encore d'évaluation

- s270 MCB CatalogueDocument1 pages270 MCB CatalogueManu PillaiPas encore d'évaluation

- En733 PDFDocument2 pagesEn733 PDFachuthkumarPas encore d'évaluation

- H25 Incremental EncoderDocument4 pagesH25 Incremental EncoderEdgar AllamPas encore d'évaluation

- Actuator LA36: FeaturesDocument8 pagesActuator LA36: FeaturesNikhil Babu PPas encore d'évaluation

- BV309A Bullet ValveDocument2 pagesBV309A Bullet ValveAnthony PecorinoPas encore d'évaluation

- Brochure Mercotac PDFDocument8 pagesBrochure Mercotac PDFRoderikus Rendy MPas encore d'évaluation

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58Pas encore d'évaluation

- Coils 10 SeriesDocument4 pagesCoils 10 SeriesMr CrossplanePas encore d'évaluation

- K01 TypeDocument10 pagesK01 TypeHenry PalPas encore d'évaluation

- Solinoid Popet ValveDocument3 pagesSolinoid Popet ValvesaqureshPas encore d'évaluation

- ZVP4525GDocument8 pagesZVP4525GAlexander AnotherSituation MartinsonPas encore d'évaluation

- Pressure Transmitter For General Industrial Applications Model A-10Document7 pagesPressure Transmitter For General Industrial Applications Model A-10brunotavernaPas encore d'évaluation

- G2RSDocument14 pagesG2RSMisaelRodriguezPas encore d'évaluation

- s-392-t 2 Vias LatchDocument2 pagess-392-t 2 Vias LatchBruno AlbuquerquePas encore d'évaluation

- Final de Carrera XCKJDocument2 pagesFinal de Carrera XCKJmpicaPas encore d'évaluation

- FINDER Catalogue 2014-15Document564 pagesFINDER Catalogue 2014-15Yiannis MinoglouPas encore d'évaluation

- B 3 Ga 012 ZDocument10 pagesB 3 Ga 012 Zgigel1980Pas encore d'évaluation

- TX Relays: Features Typical ApplicationsDocument7 pagesTX Relays: Features Typical ApplicationszakioPas encore d'évaluation

- Electro Válvula Del CompresorDocument4 pagesElectro Válvula Del CompresorneumaticoPas encore d'évaluation

- Pizzato Elettrica Position Switches FR Series - Catalog 2011-2012Document12 pagesPizzato Elettrica Position Switches FR Series - Catalog 2011-2012IBJSC.comPas encore d'évaluation

- M2 Series - Miniature Plug-In Power Relays: ContactDocument5 pagesM2 Series - Miniature Plug-In Power Relays: ContactbansalrPas encore d'évaluation

- C4 R30datasheetDocument2 pagesC4 R30datasheetsimbugowriPas encore d'évaluation

- Data Sheet... : DRM Series DRM270012L/2CO/12V DCDocument3 pagesData Sheet... : DRM Series DRM270012L/2CO/12V DClucian_matei_2Pas encore d'évaluation

- Globe Motor Spec SheetDocument4 pagesGlobe Motor Spec Sheetargh112Pas encore d'évaluation

- Wika Level IndicatorDocument24 pagesWika Level Indicatormatteo2009Pas encore d'évaluation

- VK3000Document11 pagesVK3000wintermacPas encore d'évaluation

- 03 Bushing-Cedaspa Type FDocument7 pages03 Bushing-Cedaspa Type FKatherine SmithPas encore d'évaluation

- Standard Coils and Proportional Valve CoilsDocument8 pagesStandard Coils and Proportional Valve CoilsElias Oliveira DomingosPas encore d'évaluation

- TamanhoDocument3 pagesTamanhoRogeriogodoyPas encore d'évaluation

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziPas encore d'évaluation

- IR Sol 985 3W BBDocument2 pagesIR Sol 985 3W BBStill SurvivingPas encore d'évaluation

- High-Speed DC Circuit-Breaker PDFDocument8 pagesHigh-Speed DC Circuit-Breaker PDFfassina01Pas encore d'évaluation

- G9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsDocument2 pagesG9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsNandam SrinivasPas encore d'évaluation

- TQ-SMD Relays: Low-Profile Surface-Mount RelayDocument5 pagesTQ-SMD Relays: Low-Profile Surface-Mount RelayTomas Perez GPas encore d'évaluation

- Datasheet G RelaysDocument10 pagesDatasheet G RelaysthomaswangkoroPas encore d'évaluation

- DatasheetDocument5 pagesDatasheetSaramet BogdanPas encore d'évaluation

- VCADocument11 pagesVCAMi LuPas encore d'évaluation

- OsiSense XC Standard - XCKM102Document7 pagesOsiSense XC Standard - XCKM102Marisol InfantePas encore d'évaluation

- m115 PDFDocument12 pagesm115 PDFladytibia_94899958Pas encore d'évaluation

- Salmson Light Commercial SCX-DCX - SXM-DXM PDFDocument8 pagesSalmson Light Commercial SCX-DCX - SXM-DXM PDFLuPas encore d'évaluation

- Size 25: Series Trda-25NaDocument7 pagesSize 25: Series Trda-25NaMarina Pascal100% (1)

- Moeller Datasheet MCS4 019711Document5 pagesMoeller Datasheet MCS4 019711mihai37Pas encore d'évaluation

- 500 Pressure SensorDocument5 pages500 Pressure SensorMabel Lorena Ochoa ContrerasPas encore d'évaluation

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111Pas encore d'évaluation

- Ug7Ocr Rg7Ocr: - 0,6/1 KV - 0,6/1 KV (Wire Fraud)Document2 pagesUg7Ocr Rg7Ocr: - 0,6/1 KV - 0,6/1 KV (Wire Fraud)MihaelaPas encore d'évaluation

- Hydraforce Valve sv08-24 - 06jul2023 - 18-00Document5 pagesHydraforce Valve sv08-24 - 06jul2023 - 18-00Edwin RamirezPas encore d'évaluation

- DSG ValvesDocument17 pagesDSG ValvesChris RoederPas encore d'évaluation

- RE18136Document4 pagesRE18136Ahmed Abd ElhakeemPas encore d'évaluation

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesD'EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- SPM 4210 Wetkret Concrete Spraying Machine SpecificationsDocument6 pagesSPM 4210 Wetkret Concrete Spraying Machine SpecificationsInkanata SacPas encore d'évaluation

- Perkins 1103 Valve InstallDocument10 pagesPerkins 1103 Valve InstallInkanata SacPas encore d'évaluation

- School Bus ClassificationsDocument6 pagesSchool Bus ClassificationsInkanata SacPas encore d'évaluation

- Baldwin Filters Product CatalogDocument1 307 pagesBaldwin Filters Product CatalogInkanata SacPas encore d'évaluation

- Engineparts: BF Engine Parts For HeavyweightsDocument4 pagesEngineparts: BF Engine Parts For HeavyweightsInkanata SacPas encore d'évaluation

- 2000W Metal Halide Ballast Data SheetDocument1 page2000W Metal Halide Ballast Data SheetInkanata SacPas encore d'évaluation

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPDocument1 pageMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPInkanata SacPas encore d'évaluation

- BOSCHDocument3 pagesBOSCHDiego Pacheco VelaPas encore d'évaluation

- Winnovative PDF Tools Demo: Global Stage Literacy Book 1Document4 pagesWinnovative PDF Tools Demo: Global Stage Literacy Book 1Inkanata SacPas encore d'évaluation

- FIG 101 Cylinder Head: Year / MonthDocument24 pagesFIG 101 Cylinder Head: Year / MonthInkanata Sac100% (1)

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramInkanata SacPas encore d'évaluation

- Underground ProductsDocument6 pagesUnderground ProductsInkanata SacPas encore d'évaluation

- HYW-35 T5: Generating RatesDocument6 pagesHYW-35 T5: Generating RatesInkanata SacPas encore d'évaluation

- HX80 PDFDocument2 pagesHX80 PDFInkanata SacPas encore d'évaluation

- TEMA/ Theme: Likes and Dislikes PrimaryDocument3 pagesTEMA/ Theme: Likes and Dislikes PrimaryInkanata SacPas encore d'évaluation

- Rev. Change Details by DateDocument1 pageRev. Change Details by DateInkanata SacPas encore d'évaluation

- Valve Assembly, Main Relief (lp22v00001f1 & Lp22v00001f2)Document2 pagesValve Assembly, Main Relief (lp22v00001f1 & Lp22v00001f2)Inkanata SacPas encore d'évaluation

- ITM Drilling Machines WebDocument6 pagesITM Drilling Machines WebInkanata SacPas encore d'évaluation

- 5800 2 Ecomax t4 93kw Ipu LRDocument4 pages5800 2 Ecomax t4 93kw Ipu LRInkanata SacPas encore d'évaluation

- Denso Common Rail Injector Test DataDocument28 pagesDenso Common Rail Injector Test DataInkanata Sac94% (16)

- Winkie Parts 1Document9 pagesWinkie Parts 1Inkanata SacPas encore d'évaluation

- QNTC Dellsvr01 Inetpub - D PartsLiterature F 720 033 Rev. B Metal Face SealsDocument2 pagesQNTC Dellsvr01 Inetpub - D PartsLiterature F 720 033 Rev. B Metal Face SealsInkanata Sac100% (1)

- Lechler Airnozzles Series 600 383 35Document2 pagesLechler Airnozzles Series 600 383 35eka jimmyPas encore d'évaluation

- IndicatorsDocument4 pagesIndicatorsLuis Alejandro Mariño - RamguzPas encore d'évaluation

- Honda E-StormDocument104 pagesHonda E-StormJaimeDiazDiazPas encore d'évaluation

- Sekačka TORO 53 ADS - Katalog Dílů-3350-665Document24 pagesSekačka TORO 53 ADS - Katalog Dílů-3350-665Vladimír KřížPas encore d'évaluation

- A4vg125hwdl232r-Nzf02f021s-S R902189541 StaraDocument34 pagesA4vg125hwdl232r-Nzf02f021s-S R902189541 StaraRodrigues de OliveiraPas encore d'évaluation

- Front Axle ShaftsDocument12 pagesFront Axle ShaftsKammoePas encore d'évaluation

- Br. No. PierDocument33 pagesBr. No. PierAnish ThakurPas encore d'évaluation

- Vol 5 Issue 10 M 13Document4 pagesVol 5 Issue 10 M 13G venkateshPas encore d'évaluation

- Inertial Navigation SystemsDocument8 pagesInertial Navigation SystemsRadunPas encore d'évaluation

- Watt Drive Project Datasheets 3Document3 pagesWatt Drive Project Datasheets 3Janpol JavilloPas encore d'évaluation

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them100% (6)

- Ethane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0127Document64 pagesEthane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0127sarangpunePas encore d'évaluation

- Electric Actuated Butterfly Valves: FeaturesDocument7 pagesElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluPas encore d'évaluation

- SadfasdfasdfdasdfdasDocument15 pagesSadfasdfasdfdasdfdasRoni AmaralPas encore d'évaluation

- Connecting Rod Force Analysis and Weight OptimizationDocument18 pagesConnecting Rod Force Analysis and Weight OptimizationSukhamMichaelPas encore d'évaluation

- SGP SyllabusDocument2 pagesSGP SyllabusPrathap VuyyuruPas encore d'évaluation

- Question Bank-EE 401 Type 1 - Multiple Choice Questions: Page 1 of 13Document43 pagesQuestion Bank-EE 401 Type 1 - Multiple Choice Questions: Page 1 of 13Rishabh KaliaPas encore d'évaluation

- Barton 242 User ManualDocument36 pagesBarton 242 User Manualjohnnylim456100% (1)

- CFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageDocument7 pagesCFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageAlireza Ab100% (1)

- Robotics and Vision SystemDocument64 pagesRobotics and Vision Systemasuras1234Pas encore d'évaluation

- GE Codigos Error Estufas, Lavavajillas, Microondas PDFDocument5 pagesGE Codigos Error Estufas, Lavavajillas, Microondas PDFElvis Jesus Landa ReyesPas encore d'évaluation

- Uniflo Fog Reduction ModuleDocument8 pagesUniflo Fog Reduction Modulecristi_molinsPas encore d'évaluation

- Documentacion 5549393Document4 pagesDocumentacion 5549393Marcelo San MartinPas encore d'évaluation

- Case Study Failure of Boiler Feed Water Pump-ADocument13 pagesCase Study Failure of Boiler Feed Water Pump-Akirany58Pas encore d'évaluation

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxPas encore d'évaluation

- Seismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2Document35 pagesSeismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2jakeer7100% (2)

- Module 3: Mass Transfer Coefficients: Lecture No. 5Document3 pagesModule 3: Mass Transfer Coefficients: Lecture No. 5Anonymous Clbs7UkPas encore d'évaluation

- Mechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedDocument1 pageMechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedJovani G. BallonPas encore d'évaluation

- Datasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignDocument10 pagesDatasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignImpel IntralogisticsPas encore d'évaluation

- Senarai Harga Barang Ganti Proton Waja IIDocument6 pagesSenarai Harga Barang Ganti Proton Waja IIzul kifliePas encore d'évaluation