Académique Documents

Professionnel Documents

Culture Documents

Trial Welding

Transféré par

AnilkumarGopinathanNairDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Trial Welding

Transféré par

AnilkumarGopinathanNairDroits d'auteur :

Formats disponibles

Page 1 of 4

Proposal and Trial for Welding Process Modification for

Circumferential seam welding

Date : 24-06-2016

Objective:

To avoid the GMAW process to weld the root run, by directly applying SAW on

circumferential seam welding of tower sections of more than 25mm thickness.

Current practice:

Joint configuration: Double-V with 60o included angle, Root face 2mm, Root

gap 2-3mm.

60o

2mm

2-3mm

Welding sequence:

1.

2.

3.

4.

5.

6.

Root run with GMAW at inner side.

2 or 3 layers of SAW upon root of it.

Back gauging 2-3 mm deep.

Dye penetrant test on gauged surface.

Fill up 2-3 layers of SAW at outer side.

Ultrasonic testing of entire circumferential seam.

Observations:

1. Defects are found almost at mid thickness of weld joint, mostly planar

defects.

2. Detailed study of defect yet to be carried out, but it may be because of

any of the following

i.

Fit ups not repeatable.

ii.

A broad root face, which does not melt the root face from

either side.

iii.

Back chipping didnt grind through sound weld metal.

iv.

Change in included angle.

v.

Operators skill.

vi.

Machine problem.

Page 2 of 4

Proposed trial:

Trial No: 1

Date: 24-06-2016

Trial test specimen size : 400mm x 300mm x 30mm

Joint configuration: Double-V with 70o included angle, Root face 4mm, Root

gap 0mm,

Plate thickness of 30mm.

70o

Inner side

18m

4mm

0mm

Outer side

Welding sequence:

1.

2.

3.

4.

5.

6.

Root run with SAW at inner side.

3 or 4 layers of SAW upon it.

Back gauging until sound weld metal is visible.

Dye penetrant test on gauged surface.

Fill up 1-2 layers of SAW at outer side.

Ultrasonic testing of entire circumferential seam.

Inference:

1. Slag removal was difficult.

2. UT is ok.

3. Visually not ok.

Further Action:

Repeat the trial with modification in weld edge geometry and welding

electrical parameters.

Page 3 of 4

Trial No: 2

Date: 28-06-2016

Trial test specimen size : 400mm x 300mm x 30mm

Joint configuration: Double-V with 60o included angle, Root face 2mm, Root

gap 0-1 mm.

60o

Inner side

2mm

0-1mm

Outer side

Welding sequence:

1. Root run with GMAW at inner side.

2. 2 or 3 layers of SAW upon it from inner side.

3. Back gauging 2-3 mm deep (Root of GMAW to be removed until we find

sound weld metal).

4. Fill up 2-3 layers of SAW at outer side.

5. Ultrasonic testing of entire circumferential seam.

Inference:

1. After root run using GMAW, it is found that penetration has not reached

the full thickness.

2. Back grinding of the root revealed that the entire length of weld has lack

of penetration to various depths, after completing one side welding.

3. Back grinding to depth upto 4mm required to reveal the sound weld metal.

4. UT is ok.

5. Visually ok.

Further Action:

Repeat the trial with modification in weld edge geometry and welding

electrical parameters.

Page 4 of 4

Trial No: 3

Date: 29-06-2016

Trial test specimen size : 400mm x 300mm x 30mm

Objective amendment: GMAW of root cannot be avoided as this is required for

fit up.

Joint configuration: Double-V with 60o included angle, Root face 2mm, Root

gap 2-3mm.

60o

Inner side

2mm

2-3mm

Outer side

Welding sequence:

1. Root run with GMAW at inner side.

2. 2 or 3 layers of SAW upon it from inner side.

3. Back gauging 2-3 mm deep (Root of GMAW to be removed until we find

sound weld metal).

4. Fill up 2-3 layers of SAW at outer side.

5. Ultrasonic testing of entire circumferential seam.

Vous aimerez peut-être aussi

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Q.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of TwoDocument38 pagesQ.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of Twoquiron2010Pas encore d'évaluation

- Technique # 1. Leftward or Forward Welding:: AdvertisementsDocument2 pagesTechnique # 1. Leftward or Forward Welding:: AdvertisementszombiePas encore d'évaluation

- Weld Defects PresentationDocument80 pagesWeld Defects PresentationRen SalazarPas encore d'évaluation

- Narrow Gap WeldingDocument6 pagesNarrow Gap WeldingRinshad Abdul RahimanPas encore d'évaluation

- Bab 2Document73 pagesBab 2ezad2206Pas encore d'évaluation

- Book 5Document4 pagesBook 5vasuPas encore d'évaluation

- Follow HereDocument18 pagesFollow HereAkram Alhaddad100% (1)

- Defects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Document4 pagesDefects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Aris WicaksonoPas encore d'évaluation

- Method of Statement For Hollowness RepairDocument3 pagesMethod of Statement For Hollowness RepairSumedhaSampath0% (1)

- 1.0 Title: Shield Metal Arc Welding (SMAW)Document13 pages1.0 Title: Shield Metal Arc Welding (SMAW)Exo NadiPas encore d'évaluation

- Effect of Welding Parameters On The Mechanical Properties and Microstructure of BQ Plateastm SA 516 - 60 GradeDocument4 pagesEffect of Welding Parameters On The Mechanical Properties and Microstructure of BQ Plateastm SA 516 - 60 GradeEditor IJRITCCPas encore d'évaluation

- ASTM A-358 With ClassDocument2 pagesASTM A-358 With Classsateesh chand100% (1)

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenPas encore d'évaluation

- With World Class Quality: GasketsDocument12 pagesWith World Class Quality: GasketsblahblahPas encore d'évaluation

- Welded Connections: Chapter Twenty OneDocument14 pagesWelded Connections: Chapter Twenty OnePaul RoquePas encore d'évaluation

- CWB Procedure and RulesDocument4 pagesCWB Procedure and Rulesippon_osoto100% (1)

- Weld DefectsDocument80 pagesWeld Defectsakhilsyam21100% (1)

- Design and Performance Studies of The Scanning Magnetron in Terms of V-I Characteristics, Dependence of V-I Characteristics On Scanning Speed, Deposition Rate and Substrate TemperatureDocument5 pagesDesign and Performance Studies of The Scanning Magnetron in Terms of V-I Characteristics, Dependence of V-I Characteristics On Scanning Speed, Deposition Rate and Substrate TemperatureIjsrnet EditorialPas encore d'évaluation

- Cracked Bogie FrameDocument15 pagesCracked Bogie Framedattu33Pas encore d'évaluation

- Repair Procedure Lens RingDocument3 pagesRepair Procedure Lens Ringqaisarabbas9002Pas encore d'évaluation

- Weld Defects Incomplete Root PenetrationDocument4 pagesWeld Defects Incomplete Root PenetrationMuhammed SulfeekPas encore d'évaluation

- Specifications Bruney Tandem 3 Seater With Cushion (Set of 3 Chairs) 1. Tubular Steel FrameDocument2 pagesSpecifications Bruney Tandem 3 Seater With Cushion (Set of 3 Chairs) 1. Tubular Steel Framesai kumarPas encore d'évaluation

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDocument16 pagesManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukdarouichPas encore d'évaluation

- Dual Film RT Article PDFDocument7 pagesDual Film RT Article PDFRaja Muaz Ahmad KhanPas encore d'évaluation

- Bend TestDocument14 pagesBend TesttengkustrengthPas encore d'évaluation

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDPas encore d'évaluation

- Cswip 3 (1) .1 Bridge Examination QuestionDocument4 pagesCswip 3 (1) .1 Bridge Examination Questionmunna100% (2)

- Research Proposal WeldingDocument10 pagesResearch Proposal WeldingKreshaMorenoLluismaPas encore d'évaluation

- Weld Cracks in An Ammonia Converter: James D. CampbellDocument6 pagesWeld Cracks in An Ammonia Converter: James D. Campbellvaratharajan g rPas encore d'évaluation

- W 16 TIG Full Parer HE ICDocument8 pagesW 16 TIG Full Parer HE ICNarasimha DvlPas encore d'évaluation

- Friction Stir Welding of Magnesium Alloy ZM21: Transactions of The Indian Institute of MetalsDocument5 pagesFriction Stir Welding of Magnesium Alloy ZM21: Transactions of The Indian Institute of Metalsagilan89Pas encore d'évaluation

- Weld DefectDocument4 pagesWeld DefectAzzah NazPas encore d'évaluation

- Crack Depth Evaluation For Boiler Tubes Using X-Ray Image AnalysisDocument5 pagesCrack Depth Evaluation For Boiler Tubes Using X-Ray Image AnalysisMohsin IamPas encore d'évaluation

- TCVN 4395-1986Document11 pagesTCVN 4395-1986huytai8613Pas encore d'évaluation

- Quiz MCP1Document5 pagesQuiz MCP1Rob WillestonePas encore d'évaluation

- Mechanical Testing of Welded JointsDocument41 pagesMechanical Testing of Welded JointsSanadPas encore d'évaluation

- Incomplete Root Fusion & PenetrationDocument3 pagesIncomplete Root Fusion & PenetrationFsPas encore d'évaluation

- MT-II LabDocument7 pagesMT-II LabAjay Vikram0% (1)

- Laser Assisted MicrogrindingDocument19 pagesLaser Assisted MicrogrindingSanooj NasarudeenPas encore d'évaluation

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyPas encore d'évaluation

- Operating Instructions For Eclipse Refractometer - 2013 - EnglishDocument16 pagesOperating Instructions For Eclipse Refractometer - 2013 - Englisharavindan100% (1)

- Report MetallographyDocument6 pagesReport MetallographyOsama Bin Anwar0% (1)

- Anchorage DesignDocument47 pagesAnchorage DesignbeePas encore d'évaluation

- Bolted Conn. With Hot-Dip Galv. Steel Memb.Document14 pagesBolted Conn. With Hot-Dip Galv. Steel Memb.PaulPas encore d'évaluation

- Welding Defects (Copy and Paste Je)Document9 pagesWelding Defects (Copy and Paste Je)Hamimi AkmalPas encore d'évaluation

- Presencacion Norma SMS DIN 1Document12 pagesPresencacion Norma SMS DIN 1wili_ab8040Pas encore d'évaluation

- FEM Modelling of Weld Damage in Continuous Cold RoDocument11 pagesFEM Modelling of Weld Damage in Continuous Cold RoAimen AouniPas encore d'évaluation

- GR 11 ReportDocument14 pagesGR 11 ReportVanessa HadJeanxPas encore d'évaluation

- SDDocument MGCGBF6002Document2 pagesSDDocument MGCGBF6002j.saiyathPas encore d'évaluation

- Drywall Partition-Fire Resistant BoardDocument14 pagesDrywall Partition-Fire Resistant BoardsanthoshkumarPas encore d'évaluation

- Fiberstrong Piping System Above Ground Installation ManualDocument32 pagesFiberstrong Piping System Above Ground Installation ManualIbrahim Habiba100% (1)

- General Guidelines InsulationDocument56 pagesGeneral Guidelines InsulationPadmanaban SoundirarajanPas encore d'évaluation

- Analysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsDocument13 pagesAnalysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsLiu YangtzePas encore d'évaluation

- 111 WeldDocument13 pages111 Weldpavlosmakridakis2525Pas encore d'évaluation

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IID'EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiPas encore d'évaluation

- Spot Welding Interview Success: An Introduction to Spot WeldingD'EverandSpot Welding Interview Success: An Introduction to Spot WeldingPas encore d'évaluation

- Trading Book - DSDocument9 pagesTrading Book - DSAnilkumarGopinathanNairPas encore d'évaluation

- Item Approx Price ActualDocument2 pagesItem Approx Price ActualAnilkumarGopinathanNairPas encore d'évaluation

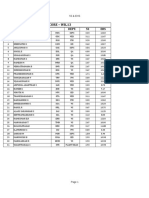

- SL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossDocument27 pagesSL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossAnilkumarGopinathanNairPas encore d'évaluation

- Daily ExpenseDocument33 pagesDaily ExpenseAnilkumarGopinathanNairPas encore d'évaluation

- Trading Book - AGDocument7 pagesTrading Book - AGAnilkumarGopinathanNairPas encore d'évaluation

- WEEK 22 LS Repair TrendDocument2 pagesWEEK 22 LS Repair TrendAnilkumarGopinathanNairPas encore d'évaluation

- EuclidDocument15 pagesEuclidAnilkumarGopinathanNairPas encore d'évaluation

- Deputy Manager - Ied SGM - IedDocument2 pagesDeputy Manager - Ied SGM - IedAnilkumarGopinathanNairPas encore d'évaluation

- Unit-1 5S & EHS ScoreDocument2 pagesUnit-1 5S & EHS ScoreAnilkumarGopinathanNairPas encore d'évaluation

- Supplier Kpi From Ved - Purc, Stores & LogDocument18 pagesSupplier Kpi From Ved - Purc, Stores & LogAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 24-04-2018Document13 pagesUT Performance 24-04-2018AnilkumarGopinathanNairPas encore d'évaluation

- Bay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorDocument1 pageBay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorAnilkumarGopinathanNairPas encore d'évaluation

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairPas encore d'évaluation

- Joint Part Number WPS Number Base Flange Template Fish Plate Thickness (MM) Process InvolvedDocument2 pagesJoint Part Number WPS Number Base Flange Template Fish Plate Thickness (MM) Process InvolvedAnilkumarGopinathanNairPas encore d'évaluation

- Daily Attendance Report Jan 2018Document2 pagesDaily Attendance Report Jan 2018AnilkumarGopinathanNairPas encore d'évaluation

- Copy of Copy of Copy of Copy of WEEK 29 COMPLETEDDocument58 pagesCopy of Copy of Copy of Copy of WEEK 29 COMPLETEDAnilkumarGopinathanNairPas encore d'évaluation

- Gateway Review - OdsDocument1 pageGateway Review - OdsAnilkumarGopinathanNairPas encore d'évaluation

- Demaic Plan Actual Define Measure Analyze Improve Control Gateway Review (Plan) Gateway Review (Actual)Document1 pageDemaic Plan Actual Define Measure Analyze Improve Control Gateway Review (Plan) Gateway Review (Actual)AnilkumarGopinathanNairPas encore d'évaluation

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairPas encore d'évaluation

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairPas encore d'évaluation

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairPas encore d'évaluation

- Welder Training ManualDocument2 pagesWelder Training ManualAnilkumarGopinathanNair67% (3)

- 2201 IntGCSE (9-1) Subject Grade Boundaries V1Document4 pages2201 IntGCSE (9-1) Subject Grade Boundaries V1Fariha RahmanPas encore d'évaluation

- Leadership and Management in Different Arts FieldsDocument10 pagesLeadership and Management in Different Arts Fieldsjay jayPas encore d'évaluation

- CG Photo Editing2Document3 pagesCG Photo Editing2Mylene55% (11)

- Active Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023Document119 pagesActive Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023jagdeepchkPas encore d'évaluation

- Simon Ardhi Yudanto UpdateDocument3 pagesSimon Ardhi Yudanto UpdateojksunarmanPas encore d'évaluation

- Test 2-Module 1 12-10-2017: VocabularyDocument2 pagesTest 2-Module 1 12-10-2017: VocabularySzabolcs Kelemen100% (1)

- PDFDocument40 pagesPDFAndi NursinarPas encore d'évaluation

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 pagesThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanPas encore d'évaluation

- Immunity Question Paper For A Level BiologyDocument2 pagesImmunity Question Paper For A Level BiologyJansi Angel100% (1)

- Yale Revision WorksheetDocument3 pagesYale Revision WorksheetYASHI AGRAWALPas encore d'évaluation

- ST Arduino Labs CombinedDocument80 pagesST Arduino Labs CombineddevProPas encore d'évaluation

- Tese Beatbox - Florida PDFDocument110 pagesTese Beatbox - Florida PDFSaraSilvaPas encore d'évaluation

- Very Narrow Aisle MTC Turret TruckDocument6 pagesVery Narrow Aisle MTC Turret Truckfirdaushalam96Pas encore d'évaluation

- Module 5 What Is Matter PDFDocument28 pagesModule 5 What Is Matter PDFFLORA MAY VILLANUEVAPas encore d'évaluation

- Dialectical Relationship Between Translation Theory and PracticeDocument5 pagesDialectical Relationship Between Translation Theory and PracticeEverything Under the sunPas encore d'évaluation

- Generation III Sonic Feeder Control System Manual 20576Document32 pagesGeneration III Sonic Feeder Control System Manual 20576julianmataPas encore d'évaluation

- 220245-MSBTE-22412-Java (Unit 1)Document40 pages220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhPas encore d'évaluation

- Day6 7Document11 pagesDay6 7Abu Al-FarouqPas encore d'évaluation

- Test Bank For Psychology 6th Edition Don HockenburyDocument18 pagesTest Bank For Psychology 6th Edition Don HockenburyKaitlynMorganarwp100% (42)

- Assessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy AnDocument11 pagesAssessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy Any4smaniPas encore d'évaluation

- Sla At&tDocument2 pagesSla At&tCésar Lainez Lozada TorattoPas encore d'évaluation

- Claim of FactDocument11 pagesClaim of FactXeb UlritzPas encore d'évaluation

- SPC FD 00 G00 Part 03 of 12 Division 06 07Document236 pagesSPC FD 00 G00 Part 03 of 12 Division 06 07marco.w.orascomPas encore d'évaluation

- Instant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdDocument17 pagesInstant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdLance CorreaPas encore d'évaluation

- Praise and Worship Songs Volume 2 PDFDocument92 pagesPraise and Worship Songs Volume 2 PDFDaniel AnayaPas encore d'évaluation

- Perdarahan Uterus AbnormalDocument15 pagesPerdarahan Uterus Abnormalarfiah100% (1)

- Mcdaniel Tanilla Civilian Resume Complete v1Document3 pagesMcdaniel Tanilla Civilian Resume Complete v1api-246751844Pas encore d'évaluation

- Ej. 1 Fin CorpDocument3 pagesEj. 1 Fin CorpChantal AvilesPas encore d'évaluation

- Sample CVFormat 1Document2 pagesSample CVFormat 1subham.sharmaPas encore d'évaluation

- Origin ManualDocument186 pagesOrigin ManualmariaPas encore d'évaluation