Académique Documents

Professionnel Documents

Culture Documents

20150916130056460

Transféré par

Blasko Nikiforov0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues4 pagesaaa

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentaaa

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues4 pages20150916130056460

Transféré par

Blasko Nikiforovaaa

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Session 4: Material Requirements Planning

Wrap-Up and Homework

Vocabulary Check

Match the vocabulary words to the correct definition.

L D_ The raw material, part, or subassembly that goes into a higher level assembly,

|, compound, or other item

2 \__ The function of determining what material is needed and when, and maintaining

proper due dates for required materials

3. GL. Atechnique used in MRP where a planned order receipt in one time period will

require the release of that order in an earlier time period based on the lead time

for the item:

A set of techniques that uses BOM dat

requirements for materials

inventory data, and the MPS to calculate

‘The item produced from one or more components

‘An artificial grouping of items or events in BOM format used to facilitate master

scheduling and material planning.

*~

&

£

7. X& Open order that has an assigned due date,

_Ht Using the BOM to calculate component quantities

bh

‘The total of independent and dependent demand for a component before the

netting of on-hand inventory and scheduled recespts

10. In MRP and MPS, the capability to identify for a given item the sources of its

gross requirements or allocations.

11. In MRP, are derived as a result of applying gross requirements and

allocations against inventory on hand, scheduled receipts, and safety stock,

12, The quantity planned to be received at a future date as a result of a planned

order release.

Word bank:

4a MRP ~ g. lead-time offset

gb. gross requirement 2-1 priority planning

‘5 =<. parent B-h. exploding

‘\ -d. component \{ + i. net requirements

planning BOM =i scheduled receipt

pegging \2—1 planned order receipt

4

©2045 AICS a6t Participant Workbook Version 4.3,

‘Session 4: Material Requirements Planning

Performance Check

Select the best answer to each of the following questions.

4, Inthe diagram below, which Is the independent demand item?

Pee eee

i 2 3 4

1X

boi

a 2

da 3

Which of the following is an objective of MRP? MG OwIETves

a. Keep the factory busy. LDeTEe Mw MATERIALS REQUIRE

Keep priorities current. 2s Keer Pecenies CUReOVT

. Determine the forecast. 4-s

4d. Minimize inventory investment.

3, Whatis the name ofthe set of priority planning techniques for planning

component items below the end-item level?

a. master scheduling

5) MRP cp nwswee Uncen MRETE SHERING EXPL

c, capacity planning aici

4. production control

4, Which of the following sa major input to an MRP system?

PraboR Weers TO HAT

a. the production plan oles [nmeme rR, PROoUTIC Benem)

b. the capacity plan TERUG srevcuee Fite

q ~yeeey eeccee Fe

c. shop floor activity planning and control Te aaree, Re

@ the mrs a

5, What is the name of the document that shows the component paris and the

wrimtber of parts needed to make one of an assembly or subassembly?

a. route sheet

b. material requirements plan

-@& BOM

d,_ material requisition

S201 APICS wT Parlisipant Workbook Version 4.3

y

fe

)

y

,

'

’

i

’

’

i

é

’

5

5

a

,

,

5

,

j

i

5

i

,

‘

5

5

,

’

’

i

»

y

i

,

,

é

>

a

,

*

a

o

‘Session 4: Material Requirements Planning

6 Which of the following statements is true?

a. The same part number can be used to identify similar products.

® Apart has one and only one part number,

Vous aimerez peut-être aussi

- 1 How To Hide Links PDFDocument6 pages1 How To Hide Links PDFBlasko NikiforovPas encore d'évaluation

- Fast Food Restaurant Business Plan19Document52 pagesFast Food Restaurant Business Plan19Blasko NikiforovPas encore d'évaluation

- Diy - Popular Woodworking PlansDocument108 pagesDiy - Popular Woodworking Plansrlfd14183% (6)

- Objekti I Oprema Za ŽivinuDocument32 pagesObjekti I Oprema Za ŽivinuAnonymous mKdAfWifPas encore d'évaluation

- Biznis Plan PlastenikDocument8 pagesBiznis Plan PlastenikSelma RosicPas encore d'évaluation

- A Y5169eDocument120 pagesA Y5169ebolaaajiiiPas encore d'évaluation

- Прашања и одговори октомври ИпардDocument6 pagesПрашања и одговори октомври ИпардBlasko NikiforovPas encore d'évaluation

- The Fragmented Warehouse: Location Assignment For Multi-Item PickingDocument7 pagesThe Fragmented Warehouse: Location Assignment For Multi-Item PickingBlasko NikiforovPas encore d'évaluation

- Potential Muscular StrengthDocument6 pagesPotential Muscular StrengthBlasko NikiforovPas encore d'évaluation

- Прашања и одговори октомври ИпардDocument6 pagesПрашања и одговори октомври ИпардBlasko NikiforovPas encore d'évaluation

- Obrazec Za DozvolaDocument2 pagesObrazec Za DozvolaBlasko NikiforovPas encore d'évaluation

- Прашања и одговори октомври ИпардDocument6 pagesПрашања и одговори октомври ИпардBlasko NikiforovPas encore d'évaluation

- Denis Kuljis - Majmuni, Gangsteri I Heroji 37Document375 pagesDenis Kuljis - Majmuni, Gangsteri I Heroji 37hrundi75% (4)

- BBS - Translation ITDocument37 pagesBBS - Translation ITBlasko NikiforovPas encore d'évaluation

- Прашања и одговори октомври ИпардDocument6 pagesПрашања и одговори октомври ИпардBlasko NikiforovPas encore d'évaluation

- TO DO List ExcelDocument5 pagesTO DO List ExcelGary PearsPas encore d'évaluation

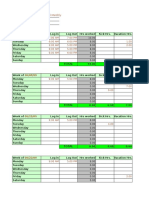

- 03.1BasicMonthly Sick VacationDocument6 pages03.1BasicMonthly Sick VacationBlasko NikiforovPas encore d'évaluation

- Ponedelnik Vtornik Sreda Cetvrtok Chest & Back AB Ripper X Yoga X AB Ripper X Shoulders & Arms AB Ripper X X Stretch AB Ripper X Core SynergisticsDocument2 pagesPonedelnik Vtornik Sreda Cetvrtok Chest & Back AB Ripper X Yoga X AB Ripper X Shoulders & Arms AB Ripper X X Stretch AB Ripper X Core SynergisticsBlasko NikiforovPas encore d'évaluation

- 13 Malite I Srednite Pretpr Vo MakedonijaDocument8 pages13 Malite I Srednite Pretpr Vo Makedonijasanja_miteva_1Pas encore d'évaluation

- MThomas KinesiologyDocument80 pagesMThomas KinesiologyBlasko NikiforovPas encore d'évaluation

- The 242 Method by Anthony Mychal PDFDocument80 pagesThe 242 Method by Anthony Mychal PDFYuldash100% (6)

- AUTOLIMARDocument16 pagesAUTOLIMARMilan AntovicPas encore d'évaluation

- Neuro FactorsDocument3 pagesNeuro FactorsBlasko NikiforovPas encore d'évaluation

- Bodyweight and Dumbbell ExercisesDocument79 pagesBodyweight and Dumbbell Exercisessureshr_42Pas encore d'évaluation

- 20150916130141518Document7 pages20150916130141518Blasko NikiforovPas encore d'évaluation

- High Frequency Training Workout Mass1Document28 pagesHigh Frequency Training Workout Mass1Blasko NikiforovPas encore d'évaluation

- PuskinDocument1 pagePuskinBlasko NikiforovPas encore d'évaluation

- Tro SociDocument5 pagesTro SociBlasko NikiforovPas encore d'évaluation

- Hazmat Shipping GuideDocument150 pagesHazmat Shipping GuideZied Hemaier100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)