Académique Documents

Professionnel Documents

Culture Documents

Sewing Technology: M. S. Ahmadi

Transféré par

dieselakiasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sewing Technology: M. S. Ahmadi

Transféré par

dieselakiasDroits d'auteur :

Formats disponibles

2/1/2014

Yazd University

Textile Engineering Dept.

Sewing Technology

Edited by:

M. S. Ahmadi

Sewing Technology

References:

1- Tyler, D. J. (Reviser) Carr and Lathams Technology of Clothing Manufacture,

Blackwell Publishing Ltd., 2008.

2- Kilgus, R. (Editor) Clothing technology; from fiber to fashion, Verlag EuropaLehrmittel, 2008.

3- Fairhurst, C. Advances in apparel production, Woodhead Publisher,2008.

4- Ukponmwan, J. O. , Mukhopadhyay, A., Chatterjee, K. N. Sewing threads,

Textile Progress, 30: 3, 1-91, 2000.

Sewing Technology

2/1/2014

Swing Thread

Correct selection

of sewing thread requires consideration of its

performance properties during sewing as well as its performance in the

completed garment under conditions of wear and cleaning. It also requires

consideration of its appearance in the sewn seam, which is both its

appearance as sewing thread and the effect it has on the appearance of the

materials being sewn, the latter being also partly connected with thread

performance.

Fiber type

The natural fiber used most frequently is cotton. Cotton threads in general

provide good sewing performance but their strength and abrasion resistance are

inferior to synthetic threads of equal thickness. Cotton threads are more stable

at higher, dry temperatures than are synthetic threads, and are therefore less

affected by hot needles during sewing unless special lubricant precautions are

taken with the synthetic threads.

Soft cotton threads (with no other treatment than bleaching or dyeing and the

application of a low-friction lubricant) generally have a high wet shrinkage,

which may cause pucker in seams after washing. In mercerized cotton threads

the thread is treated under tension in a solution of caustic soda, which causes

the fibers to swell and become rounder in cross-section. The result is a thread

with increased luster and higher tenacity (strength related to thickness).

In recent years there has been a major decline in demand for cotton threads,

and a great upsurge in the use of synthetic or mixture threads which do not rot

and which give greater strength for their size and lower shrinkage.

Sewing Technology

2/1/2014

A limited number of sewing threads are made from viscose. They do not have

the strength or durability of synthetic fibers and they have low elasticity and

low strength when wet, but their great advantage is their high luster for use in

embroidery. Most commonly available in continuous filament form, which has

greater luster than the spun form, their low abrasion resistance and strength is

not a major disadvantage in embroidery machines. Garments incorporating

them should not undergo repeated washing.

Two of the most important types of thread are:

continuous filament polyester

continuous filament nylon 6.6

They are processed to ensure low shrinkage in washing at 100 C (between 0

and 1 per cent) and also in dry heat treatments up to 150 C (generally

between 0 and 2 per cent). Beyond this, special threads may be needed as

polyester and polyamide fibers begin to soften at about 230 C and melt at

about 260 C. Low shrinkage is essential to avoid pucker in the seams on

minimum care garments.

Sewing Technology

Synthetic threads are not significantly affected by rot, mildew or bacteria.

They have high tenacities, especially in continuous filament form, and also

have high resistance to abrasion. Polyester and polyamide possess good

resistance to chemicals in general with polyamide being most resistant to

alkaline conditions and polyester to acid. Both are degraded in strength by

prolonged exposure to sunlight. Polyamide is affected by the visible and the

ultraviolet components of sunlight, as also is cotton, but polyester is only

sensitive to near ultraviolet light. In tropical sunlight, polyamide may

degrade faster than polyester, although it has the higher initial tenacity.

Polyester is considered the best fiber for most sewing thread applications,

having low cost, high strength, good chemical properties, favorable elastic

characteristics and good dye fastness. Polyamide has the high strength to

fineness of polyester but less favorable extension characteristics. Its higher

elasticity makes it unsuitable as a general purpose sewing thread as it tends

to stretch during sewing and relax afterwards, thus causing puckered seams.

Sewing Technology

2/1/2014

Threads made from the aramid or aromatic polyamide fibers such as Nomex are

expensive but have important uses in fire-resistant garments. They have a high

melting point followed by charring rather than dripping like other synthetic

fibers. They are combustible but are self-extinguishing when withdrawn from

the source of heat. This type of performance is not required by the flammability

regulations covering nightwear but in items such as racing drivers suits where

the garment material would also be aramid fiber, such threads are essential so

that the garment remains intact for as long as the fabric withstands the heat.

PTFE sewing threads are also very expensive but they have a few specialist

industrial uses where their complete non-flammability, non-melting property,

and high resistance to chemicals makes them important.

Sewing Technology

Thread constructions

Swing threads structure

Spun threads

Filament threads

Core-spun threads

Spun threads

The twisting process

The twisting process is really the heart of thread manufacture. The twist in the

single yarn consolidates the strength and flexibility provided by the fibers

themselves. In plied threads the direction of the twist should be reversed.

Without the reverse twist, known as finishing twist, a conventional thread could

not be controlled during sewing.

Sewing Technology

2/1/2014

The individual plies would separate during their

repeated passages through the needle and over

the sewing machine control surfaces. Twist is

defined as the number of turns inserted per

centimeter of yarn or thread produced.

If the twist is too low, the yarns may fray and

break; if too high, the resulting liveliness in the

thread may cause snarling, loop knots or spillage

from the package of thread. There are two

possibilities of twist direction, S and Z.

Sewing Technology

Sewing Technology

10

2/1/2014

For the production of snarl-free sewing threads, a balanced yam structure can

be achieved whereby the doubling twist normally lies between 50 and 60% of

the singles twist. However, the optimum twist factor should be settled after

conducting suitable trials so as to achieve the required quality. The twist level

is often much higher, and it could be set through a twist-deadening process to

avoid snarling. Needle-threads generally require the ply twist to be 90% of the

singles twist, but in the opposite direction. The balancing ply twist in underthreads (again in the opposite direction to the singles twist) may be calculated

by using the following formula, which is applicable to both the imperial and

metric systems:

Thus the balancing twist for a three-ply thread with 800 turns/m in the S

direction in the singles is approximately 460 turns/m in the Z direction. Underthreads generally have a balanced twist structure, with appreciably less twist

than equivalent-count needle-threads.

Sewing Technology

11

The frictional forces acting on a thread during its passage through a sewing

machine also tend to insert some twist, predominantly in one direction. In a

lockstitch machine, during normal straight sewing, the needle and hook tend

to insert some Z twist to the sewing thread. A thread with a correctly

balanced finishing twist reaches equilibrium as it resists further tightening up

of the twist. A thread with an S twist becomes untwisted by the action of the

machine and then frays and breaks. Because the lockstitch machine type is

the most severe in its handling of thread, the majority of threads intended

for use in machine sewing are constructed with a finishing Z twist. There are

only a few machines, such as flatlock, for which this is not suitable and

special threads with S finishing twist are available for these.

Sewing Technology

12

2/1/2014

Filament threads

Monofilament threads

It is harsh on the machine and rather inflexible because the cross-sectional shape

never varies as it would with multifilaments. In addition, the cut ends are harsh

on the wearer. It has virtually no seam grip and stitches tend to unravel easily.

Its great advantage is a translucency that reduces the need for shade

matching. It tends to be used for blind felling and overedging at the lower quality

end of clothing manufacturing and for upholstery and household textiles.

Sewing Technology

13

Multifilament threads

singles or plied or corded

Where flexible threads are required, the filament yarns are twisted, set, dyed and

lubricated only. Where optimum sewing performance and abrasion resistance are

required, the plied threads are treated with synthetic polymer which bonds the

individual filaments and yarns together.

In polyester, they give higher strength with fineness at a lower price than a

similar spun thread, and with good loop-forming properties they give reliable

stitch formation. Their fineness enables larger thread packages to be used, thus

saving operator time changing them, and in particular they enable more thread

to be wound on the bobbin of a lockstitch machine.

Sewing Technology

14

2/1/2014

Textured threads, in fine sizes are useful as needle threads in overedge and

chainstitch machines but their commonest use is in larger sizes where their

soft handle and spreading properties provide good seam cover when used in

the loopers of overedge and covering stitch machines. With appropriate

stitch size and thread tensions, almost complete cover of the fabric can be

achieved, which adds greatly to comfort in garments worn next to the skin

and to appearance in a fabric which frays badly. The degree of stretch in

these threads can also be used when a fabric of moderate stretch must be

sewn with a lockstitch and in this case they are used in the bobbin.

Sewing Technology

15

The locked polyester filaments, also known as air entangled are continuous

filament yarns are treated by means of air jets to have the characteristics and

performance of threads produced by conventional spinning and twisting processes.

The threads have high uniformity and freedom from imperfections and suit a

variety of uses. An advantage of thread such as this which is constructed without

twist is that it has a multi-directional sewing performance and can be used in

sewing with the type of automated stitching jigs.

It was stated earlier that the sewing action in a lockstitch machine can insert or

remove twist from a thread, depending on the twist direction. Z-twist thread is

normally used for forward sewing in a single needle machine but problems can

arise in twin needle machines equipped with two hooks rotating in the same

direction because the thread is pulled off the needles in opposite directions and

one untwists and gives a different appearance from the other. Problems can also

arise with some automatic machines such as those sewing round jigs where sewing

can be in any direction. An untwisted thread would not vary in appearance or

performance with varying sewing direction.

However, for real success these threads must sew well in high speed lockstitch

machines; in particular, they must withstand the high level of abrasion suffered by

threads in this situation.

Sewing Technology

16

2/1/2014

Core-spun threads

In these threads a continuous multifilament core is wrapped around with a

sheath of spun fibers, two or three of these yarns then being plied together. This

is the construction of the threads referred to earlier that can be a mixture of

natural and synthetic fibers, the majority of these corespun threads consisting of

a polyester core and a cotton cover. The continuous filament core produces high

tenacities and excellent loop-forming characteristics through the sewing machine

needle. The thread lubricant is retained well by the surface fibers and, combined

with the effect of air carried to the needle during sewing, results in good sewing

performance

(i) Spun and (ii) corespun threads.

Sewing Technology

17

A major objective was to create a thread did not suffer damage on contact with

a needle heated by friction the fabric and the cotton cover fulfils this function

extremely well. A difficulty with the polyester and cotton combination is that the

thread must be dyed twice; this adds to cost.

Developments in thread lubricants in recent years have allowed totally synthetic

threads to achieve much greater heat resistance than before, and fewer

problems need now be experienced with hot needles against synthetic thread.

Accordingly, many of the advantages of the corespun construction are now being

achieved in threads that are poly poly corespun, i.e. a polyester filament core

with a spun polyester covering; these do not need the double dyeing process.

There is also a strength contribution from the polyester sheath, which is not

obtained with cotton, although with the type of high tenacity polyester used for

the cores of these threads, strength is already very high. Sewability remains at

least as important as strength and the cotton cover may continue to give this

more successfully. Corespun in general enable clothing manufacturers to sew

with finer threads and still achieve adequate seam strength. This is an important

advantage with fine fabrics because the finer the thread, the less it will tend to

cause pucker in the fabric. This also matches up with the use of finer needles to

reduce needle damage.

Sewing Technology

18

2/1/2014

From a situation where cotton threads formed a large part of the market a

couple of decades ago, the synthetics and corespuns have made great inroads.

Polyester/cotton corespun now has over 50 per cent of the market in Britain,

especially in high-volume, quality conscious manufacture where the demands

of thread performance in sewing and wearing are great. Spun polyester is the

dominant thread in the high volume area of underwear production where

large quantities of white are used and it is also used in fashion manufacturing.

Sewing Technology

19

Thread finishes

The final aspect of thread construction to be studied is that of surface

finish, the most important type of finish being lubrication. The

requirement of a lubricating finish applied to a sewing thread is that it

should produce a regular level of friction and that, for synthetic threads

in particular, it should provide protection from needle heat.

In a lockstitch machine, for example, each portion of thread may travel at

least forty times through the eye of the needle, in repeated cycles of fl

exing and abrasion, before receiving a last impact from the needle eye as

it becomes a stitch. A series of tension peaks occurs as a lockstitch

machine goes through its stitch cycle. These occur as the stitch balance is

set, as the needle punches the thread through the fabric, as the rotary

hook picks up the loop of the needle thread and as the thread is pulled

off the rotary hook at its lowest position. Thread must withstand these

stresses and, even in fi ne sizes, retain enough of its initial strength

during stitching to give adequate seam strength.

Sewing Technology

20

10

2/1/2014

The nature of the lubricating finish is the result of considerable research by

the thread companies to fulfill a number of requirements. A lubricant must

not clog the needle eye nor cause staining; it must allow the thread to

unwind evenly from the package, and it must reduce friction with machine

surfaces but without creating too much slippage. It must reduce fiber-to-fiber

slippage in spun threads which could lead to loss of strength; it must not

react adversely to high temperatures, and it must be relatively inexpensive

and easy to apply to the thread during manufacture. Different threads need

different amounts of lubricant according to their end use. Corespun and spun

polyester threads must often withstand high temperatures when used as

needle threads and thus need a high level of lubricant.

Sewing Technology

21

A continuous filament thread would not generally need so much to

perform well. The type of lubricant would vary between natural and

synthetic fibers. Occasionally, where there are still stitching problems with

excessive needle heating despite the use of a suitable thread, it may be

necessary to add extra lubricant. In certain circumstances, the thread may

be run between two felt pads soaked in the correct lubricant in a specially

designed box which confines the lubricant to the thread and keeps it from

soiling the rest of the machine.

This should only be done on the advice of the thread maker as in many

cases the problem can be overcome by correct choice of needle and

thread, by further investigation of the fabric itself which may be poorly

lubricated, and by checks on thread storage in case this is unsuitable and

the natural moisture and the lubricant on the thread is becoming dried

out. Spraying or soaking the thread package is generally messy and

unsuccessful and should be avoided, as should the use of incorrect

lubricants such as sewing machine oil.

Sewing Technology

22

11

2/1/2014

it should be stated that it is by no means as serious a problem today as it was

when synthetic fibers were first used in any quantity. There was a time when

many factories had needle coolers, in the form of jets of compressed air,

attached to virtually all their sewing machines but their use now is far less

common. Progress in fabric and thread lubricants, and the use of finer

needles, have combined to reduce the problem to more manageable

proportions.

Sewing Technology

23

Other finishes for sewing threads

water-resistant finish

Wicking is the crucial factor in keeping rainwear seams dry, and waterrepellent

threads are available which reduce the problem.

soil release finish

Flame retardant finish

Sewing Technology

24

12

2/1/2014

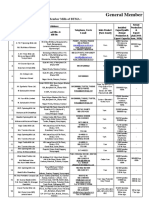

Numbering sewing threads

The commonest system and the one used for synthetic and corespun threads is

the metric ticket number system. It is derived from the number metric (Nm) yarn

count system, which refers to the number of 1-m lengths that weigh 1 g.

The metric ticket number system for sewing threads is based on a threefold

equivalent of the number metric system and relates its number to the finished

thread rather than to the single yarns from which it is made. The ticket number

is calculated via the resultant count, recalculated into threefold terms whatever

the number of plies of yarn twisted together to form the thread. The thread

could be made from a single yarn or from two, three or more plied yarns. Other

examples are: a thread of Nm 80/2 is Tkt. 120; Nm 30/3 is Tkt. 30; Nm 20/1 is

Tkt. 60; Nm 60/3 is Tkt. 60; Nm 40/2 is Tkt. 60, etc.

Sewing Technology

25

Cotton sewing threads are sized on the cotton ticket number system, which

works on the same principle. The basis of it is the cotton count, which is

written as, for example, 3/60 Ne, meaning that the thread has three single

yarns, each of which would need 60 hanks of 840 yards to weigh 1 lb.

The cotton ticket number is the threefold equivalent of the cotton count. A

six-cord construction of cotton yarns of count 60 Ne has a total resultant

count of 10 and therefore a Tkt. No. 30 (equals 3 10).

Ne = 0.59 Nm

The only other system used for sewing threads is the denier system. In sewing

threads it is generally only applied to polyamide, particularly to

monofilaments.

Sewing Technology

26

13

2/1/2014

Sewing Technology

27

Sewing Technology

28

Yarn properties

14

2/1/2014

Sewing Technology

29

Factors to consider when choosing the right thread are:

sewability of the seam;

thread loop strength;

linear strength;

elongation;

shrinkage;

abrasion resistance;

colour fastness;

resistance to chemicals, heat, light, etc.

In addition, when sewing the garment together in production, other factors to

consider are:

the required seam strength;

type of seam;

stitch type;

stitch density (stitches per centimetre);

type of material being sewn;

type of sewing machine and related equipment;

conditions under which the product must perform;

normal life of product;

cost effectiveness.

Sewing Technology

30

15

2/1/2014

Thread characteristics:

1. Tensile strength. This is the force applied to breaking point. The value is

commonly expressed in kilograms.

2. Elongation. This is the amount by which the thread is extended before

breaking and is expressed as a percentage of its original length. The

consistency of this characteristic is crucial for the threads sewing

properties and its behaviour in the seam.

3. Abrasion resistance. This is the ability of a thread to withstand

seam abrasion in wear but the thread must also possess good abrasion

resistance during sewing.

4. Sewability. Only an optimum combination of the above thread

characteristics will give good sewing performance.

Sewing Technology

31

Thread packages

In order that thread should sew well, it must be presented to the machine in a

satisfactory way. It must be possible to purchase it in economically large or

small quantities, while still having the right number of separate packages

available for use on multi-thread machines. It is sold by length rather than by

weight, and is available in a variety of types of package appropriate to the

thread type and its end use.

Sewing Technology

32

16

2/1/2014

Spools are the smallest packages and are flanged bobbins, once made in wood

but now always made in plastic. Although used to a small extent on slower

industrial machines, especially in footwear and leather goods manufacture,

they are largely used for domestic sewing. A relatively short length of thread,

usually 100 or 500 m, is parallel wound on to the bobbin. Spools are not

suitable for delivering thread to high-speed industrial machines, nor for

textured threads.

Sewing Technology

33

Cops are small, cylindrical, flangeless tubes on to which thread is crosswound

for stability. The lack of flanges facilitates regular offwinding from the top on

industrial sewing machines, mainly lockstitch, their small diameter making

them less well suited to the faster thread offtake of machines such as

overedgers. They usually contain lengths of 10002500 m of thread and are a

popular size in fashion manufacturing where production runs in any one

colour are short. They are suitable for cotton, spun polyester, spun nylon or

corespun threads, but not for glac finish of fine filament threads where

spillage from the package would be a problem.

Sewing Technology

34

17

2/1/2014

Cones contain 5000 m or more of soft or mercerized cotton, spun polyester or

corespun thread, crosswound for stability and good offwinding performance.

They give trouble-free thread delivery at intermittent or continuous high

speeds and this, combined with their long length capacity, makes them ideal

for use on class 400, 500, 600 and combination stitch machines where stops

for rethreading need to be minimized. Cones are the ideal package for

conventional sewing threads in situations where thread consumption is high

and production runs are long with limited shade changes. They are also well

suited to automatic machines.

Sewing Technology

35

Vicones are parallel tubes or low-angled cones with an additional base in the

form of a raised flange which may incorporate a small lip. They contain

polished or continuous filament thread and are designed to contain any

spillage that may occur in offwinding these smooth threads with no snagging

or trapping when the slack thread is taken up.

Sewing Technology

36

18

2/1/2014

Large packages for use on overedge and coverstitch machines can hold in

excess of 20 000 m of spun or corespun thread wound on large cones or

tubes.

Containers are constructed to handle lively monofilament threads that

would be difficult to control on standard packages. An exceptionally large

spool of thread is held within the container which can incorporate an extra

lubricant applicator at the thread draw-off point.

Sewing Technology

37

Cocoons are self-supporting, i.e. centreless, thread packages, specially

designed for insertion in the shuttle of multi-needle quilting machines and

some types of embroidery machines.

Prewound bobbins are precision-wound thread packages which can replace

metal bobbins on a variety of lockstitch machines. Conventional bobbins in

these machines are inconvenient and inefficient as time is lost in starting up

an empty bobbin on its winder after removing a full one, thread tensions and

lengths are variable and faulty build-up of thread on the bobbin may cause

jamming in the bobbin case. They also inhibit overspin during stitching, a

particular problem on zig-zag machines. Prewound bobbins generally contain

more thread and the length is guaranteed. Thus in cases where bobbin

runout must be avoided, the number of seams that can be sewn with each

bobbin can be determined and the almost empty bobbin changed in time.

Bobbin changing time is considerably reduced and smoother unwinding

results from the initial precision winding. This improves efficiency and quality

of production. A variety of thread types are available prewound and in a

variety of sizes to fit most lockstitch machines. From some manufacturers,

these packages are selfsupporting and have no metal, wood or paper

support.

Sewing Technology

38

19

2/1/2014

Sewing Technology

39

Sewing Machinery

It is possible to categorize industrial sewing machine units into four types:

A- basic sewing machines.

B- mechanized (short and long cycle) machines.

C- semi-automatic machines.

D- automatic transfer lines.

A- Basic sewing machine unit

In general, a sewing machine consists of:

a sewing head;

a machine bed;

a work-top;

a machine stand;

a drive motor;

a treadle.

Sewing Technology

40

20

2/1/2014

Construction of a sewing machine

Sewing Technology

41

Sewing head

This forms the main mechanical element of the Integral Sewing Unit (ISU). The

horizontal component of the casting (horizontal arm) houses the top shaft

(excluding over edge machines); this is often the main drive shaft. The top shaft

is usually driven by a V-belt connected to the drive motor pulley wheel and the

balance or hand wheel of the top shaft. However, this is not always the case and

some direct current (DC) motors mount directly to the top shaft.

The top shaft is supported at both ends of the horizontal arm on bearings, which

are lubricated by gravity or a splash feed oil system on standard machines and by

a pressure-fed system on high-speed seamers. The top shaft imparts movement

upon all other driven mechanisms within the sewing head by way of a toothed

(timing) belt or rigid drive shaft and gears to the bottom shaft which drives all

the mechanisms below the bed including feed and stitch forming elements. The

top shaft generates the needle bar movement and the action of the needle

thread take-up mechanism.

Sewing Technology

42

21

2/1/2014

The rotary motion of the top shaft is transformed into a reciprocating vertical

movement by means of loose pin connections to a balanced cam on the end

of the top shaft; this constitutes the needle bar drive assembly.

Let us look more closely at the components that make up the sewing head of

a standard lockstitch machine. As with the standard machine, the needle

thread take-up is driven by an eccentric cam and pivot coupling on the top

shaft. It is the bottom shaft that drives the fabric feed mechanism via ancillary

shafts often referred to as rocker bars. These impart the forward and

backward motion onto the feed dog along with the rise and fall of the device.

It is the bottom shaft that drives the stitch-forming mechanisms, which

operate below and/or around the fabric plies. A sewing machine head will

usually only offer one stitch type. However, a stitch type exists a

combination stitch that is made up of a chainstitch and an overedge stitch,

which can be used together or as separate stitch types by the omission of one

or more threads.

Sewing Technology

43

Moving parts of a sewing machine

Sewing Technology

44

22

2/1/2014

Machine bed

The shape of the machine bed is principally governed by the nature of the sewing

operation. The volume of fabric that passes beneath and around the needle and

the amount of movement required on this fabric, determines this.

The simplest form of sewing machine is the flat bed type with the following basic

components:

Sewing Technology

45

Sewing Technology

46

23

2/1/2014

Sewing Technology

47

Work-top

Large fabric pieces must be supported by the work-top surface or suspended

by an elevated arm (extremely large work surfaces can be seen in curtain or

bed linen manufacturing units). It is important not to allow the size of the

worktop to inhibit factory layout. Some work surfaces may be split-level in

order to reduce overall dimensions but maintain surface area. The science of

ergonomics is often brought into play by workspace designers.

Machine stand

The frame upon which all of the sewing machine system elements are

mounted the stand is designed to allow optimum space at the front, to

allow access to the sewing head, while supporting the drive unit in a stable

position at the rear. In fact, there is some evidence (from America) that sitting

too close to the sewing machine motor can lead to cancer in the lower

abdomen. Stands for use in team-working environments (where operators

move freely from machine to machine and work in a standing position) are

quickly adjustable in height to accommodate variations in operator stature.

Sewing Technology

48

24

2/1/2014

Drive motor

Sewing Technology

49

Sewing Technology

50

25

2/1/2014

Sewing Technology

51

Sewing Technology

52

26

2/1/2014

Sewing Technology

53

Sewing Technology

54

27

2/1/2014

Sewing Technology

55

Sewing Technology

56

28

2/1/2014

Sewing Technology

57

29

Vous aimerez peut-être aussi

- Sewing ThreadDocument11 pagesSewing Threadmoorthy-sweetyPas encore d'évaluation

- What Is A Sewing ThreadDocument8 pagesWhat Is A Sewing ThreadtomPas encore d'évaluation

- Fabric Science AssginmentDocument6 pagesFabric Science AssginmentAyesha SumreenPas encore d'évaluation

- Selecting The Correct Sewing ThreadDocument5 pagesSelecting The Correct Sewing ThreaddieselakiasPas encore d'évaluation

- All About Sewing ThreadsDocument6 pagesAll About Sewing ThreadsAshraf Ali0% (1)

- Cotton Fabric SewabilityDocument9 pagesCotton Fabric SewabilityTuan Nguyen MinhPas encore d'évaluation

- Com-4 and Elite Yarns - Compact SpinningDocument10 pagesCom-4 and Elite Yarns - Compact SpinningParesh HadkarPas encore d'évaluation

- By - Kamble Zunjarrao B. Final Year B.Textile (Textile Technology) Roll No. 14Document26 pagesBy - Kamble Zunjarrao B. Final Year B.Textile (Textile Technology) Roll No. 14Dyeing DyeingPas encore d'évaluation

- Yarns From EpgpathshalaDocument22 pagesYarns From EpgpathshalakabuPas encore d'évaluation

- Knitted Spacer Fabric - Manufacturing Techniques and ApplicationDocument8 pagesKnitted Spacer Fabric - Manufacturing Techniques and ApplicationomiPas encore d'évaluation

- Sourcing & Costing of Apparel Products: National Institute of Fashion and TechnologyDocument7 pagesSourcing & Costing of Apparel Products: National Institute of Fashion and TechnologyRabi KantPas encore d'évaluation

- Sourcing and CostingDocument7 pagesSourcing and CostingRabi KantPas encore d'évaluation

- Characteristics of Sewing ThreadDocument14 pagesCharacteristics of Sewing ThreadTuan Nguyen Minh50% (2)

- Understanding ThreadDocument9 pagesUnderstanding ThreadEdwin CastañedaPas encore d'évaluation

- Conversion of Fibre Into A YarnDocument32 pagesConversion of Fibre Into A YarnMohammed Atiqul Hoque ChowdhuryPas encore d'évaluation

- Development in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghDocument24 pagesDevelopment in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghAnonymous Pt7NHkat9Pas encore d'évaluation

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDPas encore d'évaluation

- Approximate Thread Consumption For MenDocument7 pagesApproximate Thread Consumption For MenGopalakrishnan PalaniappanPas encore d'évaluation

- Compact SpinningDocument15 pagesCompact SpinningCẩm TúPas encore d'évaluation

- Latest Technologies and Developments in Spinning, Weaving, and ProcessingDocument8 pagesLatest Technologies and Developments in Spinning, Weaving, and Processingkhushi savlaPas encore d'évaluation

- Oe & RS YarnDocument16 pagesOe & RS YarnrabiulfPas encore d'évaluation

- Sewing Threads From Polyester Staple FibreDocument13 pagesSewing Threads From Polyester Staple FibreganeshaniitdPas encore d'évaluation

- Defects and Quality Optimisation of Core-Spun Yarn Containing SpandexDocument9 pagesDefects and Quality Optimisation of Core-Spun Yarn Containing SpandexMohammed Atiqul Hoque Chowdhury100% (1)

- TestingDocument36 pagesTestingMd.Milon HossainPas encore d'évaluation

- Southeast University: AssighnmentDocument11 pagesSoutheast University: AssighnmentTamanna TasnimPas encore d'évaluation

- Winding 1Document16 pagesWinding 1Siddhesh Pradhan67% (3)

- ProjectDocument12 pagesProjectJoshi ParthPas encore d'évaluation

- Presented By: Elfa RajaDocument32 pagesPresented By: Elfa RajaSreenithiRavichandranPas encore d'évaluation

- Sewing Thread Spinning: MD Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Department Batch 08Document9 pagesSewing Thread Spinning: MD Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Department Batch 08Rupesh Kumar PrajapatiPas encore d'évaluation

- Garment MFGDocument7 pagesGarment MFGBalaso MalagavePas encore d'évaluation

- Course Title: Weaving Technology Lab Course Code: TEX 206Document6 pagesCourse Title: Weaving Technology Lab Course Code: TEX 206MahinPas encore d'évaluation

- Compact SpinnigDocument17 pagesCompact Spinnigshahadat hossainPas encore d'évaluation

- WarpingDocument13 pagesWarpingBhaskar MitraPas encore d'évaluation

- Learning Outcome of TextDocument14 pagesLearning Outcome of TextAman DeepPas encore d'évaluation

- LLearning Outcome of TextDocument14 pagesLLearning Outcome of TextAman DeepPas encore d'évaluation

- Fibre: Manufacture of Fibre FabricDocument4 pagesFibre: Manufacture of Fibre FabricSurenderMalanPas encore d'évaluation

- Threads: Training & Development/Od Shahi Exports PVT LTDDocument30 pagesThreads: Training & Development/Od Shahi Exports PVT LTDVarun MehrotraPas encore d'évaluation

- Fokus2 Kap1 enDocument10 pagesFokus2 Kap1 endilanhjPas encore d'évaluation

- Knitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Document5 pagesKnitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Pradeep AhirePas encore d'évaluation

- Knitted Fabric - Application and ScopeDocument16 pagesKnitted Fabric - Application and ScopeHaqiqat Ali83% (6)

- Best Practices in WeavingDocument12 pagesBest Practices in WeavingRajesh RamanPas encore d'évaluation

- Sewing ThreadsDocument39 pagesSewing ThreadsAnkit ChandorkarPas encore d'évaluation

- Vortex Spinning 2Document6 pagesVortex Spinning 2Salome KyatuheirePas encore d'évaluation

- Wool 482 582 12 T 12Document26 pagesWool 482 582 12 T 12AJIT KUMARPas encore d'évaluation

- Air Jet Spinning of Cotton YarnsDocument9 pagesAir Jet Spinning of Cotton YarnsUsman GillPas encore d'évaluation

- Seam EngineeringDocument6 pagesSeam EngineeringHasan AbuPas encore d'évaluation

- Special YarnDocument42 pagesSpecial YarnMd. Nasir UddinPas encore d'évaluation

- Compact SpinningDocument16 pagesCompact SpinningShankar V IyerPas encore d'évaluation

- Amsterdam Reflow Booklet - Chapter 10Document7 pagesAmsterdam Reflow Booklet - Chapter 10rim3lPas encore d'évaluation

- Yarn Clearing SystemsDocument11 pagesYarn Clearing SystemsLohit MohapatraPas encore d'évaluation

- Rotor SpinningDocument13 pagesRotor Spinningvamsi krishnaPas encore d'évaluation

- Modular SystemDocument13 pagesModular Systemvamsi krishnaPas encore d'évaluation

- Stitch TypesDocument57 pagesStitch TypesOjasvi Agarwal100% (1)

- Common Yarn Faults in Manmade FibresDocument2 pagesCommon Yarn Faults in Manmade FibressuhaibqaisarPas encore d'évaluation

- Mono Vs MultiDocument1 pageMono Vs MultiVaruna PereraPas encore d'évaluation

- The Knotting & Braiding Bible: The Complete Guide to Creative Knotting including Kumihimo, Macramé, and PlaitingD'EverandThe Knotting & Braiding Bible: The Complete Guide to Creative Knotting including Kumihimo, Macramé, and PlaitingÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Net Making Made Simple - A Guide to Making Nets for Sport and HomeD'EverandNet Making Made Simple - A Guide to Making Nets for Sport and HomePas encore d'évaluation

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerD'EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerÉvaluation : 4 sur 5 étoiles4/5 (3)

- 00761patina - 2016 EN PDFDocument3 pages00761patina - 2016 EN PDFdieselakiasPas encore d'évaluation

- 00034top Latex e 2014 EN - (EN) PDFDocument3 pages00034top Latex e 2014 EN - (EN) PDFdieselakiasPas encore d'évaluation

- 00783wallcrete - 2015 EN - (EN)Document1 page00783wallcrete - 2015 EN - (EN)dieselakiasPas encore d'évaluation

- Ellikon PMS Colour Chart WEBDocument24 pagesEllikon PMS Colour Chart WEBdieselakiasPas encore d'évaluation

- CatalogDocument43 pagesCatalogdieselakiasPas encore d'évaluation

- International Abbreviations (Composition Chart)Document2 pagesInternational Abbreviations (Composition Chart)dieselakiasPas encore d'évaluation

- 4-H 224 Clothing - Level 2 3Document1 page4-H 224 Clothing - Level 2 3dieselakiasPas encore d'évaluation

- 4-H 223 Clothing - Level I 2Document1 page4-H 223 Clothing - Level I 2dieselakiasPas encore d'évaluation

- 4-H 223 Clothing - Level I 11Document1 page4-H 223 Clothing - Level I 11dieselakiasPas encore d'évaluation

- 4-H 223 Clothing - Level I 3Document1 page4-H 223 Clothing - Level I 3dieselakiasPas encore d'évaluation

- 4-H 223 Clothing - Level I 1Document1 page4-H 223 Clothing - Level I 1dieselakiasPas encore d'évaluation

- Season Spanning CardiganDocument2 pagesSeason Spanning CardiganandiscrbdPas encore d'évaluation

- Owl Granny Square PatternDocument1 pageOwl Granny Square PatternDa BomshizPas encore d'évaluation

- Color and Weave Relationship in Woven FabricsDocument14 pagesColor and Weave Relationship in Woven FabricsAnonymous UoRu4sPas encore d'évaluation

- L601 Pyjamas Assembly InstructionDocument16 pagesL601 Pyjamas Assembly InstructionDolly StevenPas encore d'évaluation

- Quilts For Kids Four-Patch Quilt &&Document2 pagesQuilts For Kids Four-Patch Quilt &&uzed2beeyaPas encore d'évaluation

- Open For Christmas!, DROPS Extra 0-1058 by DROPS DesignDocument5 pagesOpen For Christmas!, DROPS Extra 0-1058 by DROPS DesignRaquel Kaffee100% (1)

- April Scarf: Heidi Robinson FlorriemarieDocument2 pagesApril Scarf: Heidi Robinson FlorriemarieVesna TrpkovskaPas encore d'évaluation

- Alfa Next 11 Sewing Machine Instruction ManualDocument68 pagesAlfa Next 11 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Granny Square Tote in Paintbox Yarns Downloadable PDF - 2Document4 pagesGranny Square Tote in Paintbox Yarns Downloadable PDF - 2Vivi Vivon100% (1)

- YarnCount To GSMDocument3 pagesYarnCount To GSMAsad ZamanPas encore d'évaluation

- DSN mojitoENDocument2 pagesDSN mojitoENLoretto Elizz100% (1)

- Craft Documentation Gota PattiDocument28 pagesCraft Documentation Gota PattiKriti KumariPas encore d'évaluation

- Students Notes - AFD - I Year - 02 - Tools & Equipment Used in Garment MakingDocument8 pagesStudents Notes - AFD - I Year - 02 - Tools & Equipment Used in Garment Makingmaya_muthPas encore d'évaluation

- Finisterre Sweater UsDocument11 pagesFinisterre Sweater UsHadPas encore d'évaluation

- LEARNING MODULE in Technology and Livelihood Education 10Document20 pagesLEARNING MODULE in Technology and Livelihood Education 10Faye Leria100% (2)

- BW June July 08 TocDocument2 pagesBW June July 08 TocInterweave57% (7)

- DefinitionsDocument15 pagesDefinitionsTherescuer RescuedPas encore d'évaluation

- English Crochet Pattern "Lamb" (Pajama Holder)Document38 pagesEnglish Crochet Pattern "Lamb" (Pajama Holder)Mónika Csillik100% (4)

- Ayala Museum WorksheetDocument4 pagesAyala Museum WorksheetKat LinPas encore d'évaluation

- Spinning MillsDocument29 pagesSpinning MillsBDU - GrihayanPas encore d'évaluation

- Shed GeometryDocument55 pagesShed Geometryusmante90% (10)

- Worksheet No: 3 With Answers: A) Yarn B) Thread D) FabricDocument5 pagesWorksheet No: 3 With Answers: A) Yarn B) Thread D) FabricRemya PrakashPas encore d'évaluation

- 6 Petal African Flower TriangleDocument5 pages6 Petal African Flower TriangleMonica GuarnieriPas encore d'évaluation

- Alfa 233 236 333 336 Sewing Machine Instruction ManualDocument40 pagesAlfa 233 236 333 336 Sewing Machine Instruction ManualJohan KristerssonPas encore d'évaluation

- White Gardenia: Instructions: Yarn: Cotton Thread Colour A White, Colour B Dark Yellow, Colour CDocument5 pagesWhite Gardenia: Instructions: Yarn: Cotton Thread Colour A White, Colour B Dark Yellow, Colour CmaijobPas encore d'évaluation

- History of The Vonwiller Com-Pany and Its Sample Books: Mehr Information &Document1 pageHistory of The Vonwiller Com-Pany and Its Sample Books: Mehr Information &carloszavalaPas encore d'évaluation

- Thread Guide: To Professional SeamsDocument24 pagesThread Guide: To Professional SeamsMarko SanchezPas encore d'évaluation

- Cactus AmoreDocument5 pagesCactus AmoretamaraiivanaPas encore d'évaluation

- Queen of Heirlooms PAITHANIDocument23 pagesQueen of Heirlooms PAITHANISIDDHARTH KOTHARIPas encore d'évaluation

- Dress Me Bunny PDFDocument5 pagesDress Me Bunny PDFAditi PatelPas encore d'évaluation