Académique Documents

Professionnel Documents

Culture Documents

27 PDF

Transféré par

suraj dhulannavarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

27 PDF

Transféré par

suraj dhulannavarDroits d'auteur :

Formats disponibles

Design and Development of Multistage Dumping Trolley

___________________________________________________________________________________________________________

Design and Development of Multistage Dumping Trolley

1

Omkar Bagade, 2Vaibhav Deokar, 3A.H.Pawar

1,2,3,

Vishwakarma Institute of Technology, Pune-37

Email: omkarabagade@gmail.com, 2vaibhavdeokar123@gmail.com, 3ashish.pawar@vit.edu

1

Abstract Conventional dumping trolley operates on

hydraulic system to dump the material on back side only.

The areas where limited space is available, one side

dumping is not feasible. So provision of dumping on either

side is developed through the concept of Multistage

Dumping Trolley (MSDT). This paper presents design and

development of MSDT operates on pneumatic system. The

multistage dumping is accomplished by design of frame

locking mechanism. It consist integrated chassis design for

multi-side dumping. This Multistage Dumping Trolley is in

developing stage.

Index Terms Chassis design, Frame locking mechanism,

Multistage dumping, Pneumatics

I. INTRODUCTION

Dumping trolley is mostly used for agricultural purpose

to carry and dump the material. The conventional

dumping trolley is operated on hydraulic system and

dumps material at backside of trolley only. In case of

narrow lanes and limited spaces, dumping is difficult

with conventional trolley. In MSDT, when high

pressurized air (kinetic energy) is converted to

mechanical linear actuation with the help of actuator, it

is responsible for dumping operation. Three side

dumping is achieved by frames locking mechanism.

This locking mechanism is incorporated in design of

chassis. Thus, the particular stage of dumping is possible

by unlocking respective frame.

B.

Load carriage

This carriage carries load or material to dump.

C.

Locking strips

Three locking strips fitted to all frames excluding base

frame to lock two frames with each other.

D.

Hinges

Five hinges are fitted on frames to tilt the trolley on

desired side.

E.

Dumping shaft

The dumping shaft is fitted within upper frame and

connected to piston rod of dumping actuator.

F.

Actuators

Pneumatic actuators are fitted within frames. Actuators

are used for dumping and locking the frames.

G.

Direction control valve

5/2 direction control valve is used in pneumatic circuit

for directing pressurized fluid to actuators.

III. DESIGN AND CONSTRUCTION

II. PARTS OF TROLLEY

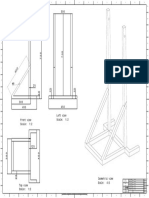

Fig. 2 Assembly drawing in CATIA

Fig.1 shows assembly of dumping trolley consisting

chassis frames, load carriage, locking strips, hinges,

actuators and dumping shaft.

1. Chassis frames

Fig. 1 Model of MSDT

A.

Chassis frames

Chassis is made of four frames namely upper frame,

middle frame, lower frame and base frame.

Frame is the structure of the model, they support and

help in mounting of actuators on it for locking purpose.

A frame is made up of mild steel and hallows square

shape.

___________________________________________________________________________________________________________

Special Issue on International Journal on Theoretical and Applied Research in Mechanical Engineering (IJTARME) V-5 No.2

ISSN (Print): 2319-3182, For National Conference on Advances in Design and Thermal Engineering (NCADTE-2016)

G.H. Raisoni College of Engineering & Management, Chass, Ahmedanagar, Maharashtra 17th to 18th February 2016

5

Design and Development of Multistage Dumping Trolley

___________________________________________________________________________________________________________

Where, FOS=Factor of Safety(Assuming FOS=1.5) We

get, d=5 mm.

4.

Direction control valve

Fig. 3 Chassis frames

There are four frames used in the model as shown in

fig.2:

1.

Upper frame

2.

Middle frame

3.

Lower frame

4.

Base frame

2. Hinges and Locking strips

Hinges are used to connect the frames and are made up

of steel. During dumping stages, hinges accomplish the

purpose of tilting the respective frame. The locking

strips are made up of mild steel used for locking

particular frame when respective cylinder actuates.

Three locking strips are fixed on frames 2, 3 and 4 for

locking the frame 1-2, 2-3 and 3-4 respectively.

Fig. 5 Direction control valve

5/2 direction control valve is used in this model to

execute forward and return strokes of the piston during

dumping stages. Manually lever operated 5/2 direction

control valve is used in pneumatic circuit.

IV. PNEUMATIC CIRCUIT

3. Actuators

Fig. 6 Pneumatic circuit

Fig. 4 Pneumatic actuators

Three locking actuators of 16 x 25 and one dumping

actuator of 25 x 100 are used for locking and dumping

respectively. The thickness of cylinders according to

required pressure and forces are selected using standard

Clavarinos Equation:

Basic circuit of MSDT is pneumatically operated.

During forward stroke by DCV the compressed air is

directed by Y type valve to dumping actuator as well as

locking actuators. For locking actuator, the locking

operation is controlled individually by shut-off valves.

During return stroke the second position of DCV

executes return of dumping actuator and unlocking of

frames respectively. Maximum operating pressure of

circuit is up to 4-5 bars.

V. STAGES OF MSDT

1. Back side dumping:

Material of piston is Aluminum, t=200N/mm2 Assume,

p = 3 bar =0.3 N/mm2, = 0.36, ri = 25mm Substituting

above values,

we get, t= 0.031mm.

The piston rod is designed by standard Rankins

formula:

t = (u/FOS)

Fig. 7 Back side dumping

___________________________________________________________________________________________________________

Special Issue on International Journal on Theoretical and Applied Research in Mechanical Engineering (IJTARME) V-5 No.2

ISSN (Print): 2319-3182, For National Conference on Advances in Design and Thermal Engineering (NCADTE-2016)

G.H. Raisoni College of Engineering & Management, Chass, Ahmedanagar, Maharashtra 17th to 18th February 2016

6

Design and Development of Multistage Dumping Trolley

___________________________________________________________________________________________________________

During backside dumping, first locking actuator kept

unlocked by shut-off valve and remaining two becomes

locked during operation. Thus in forward stroke first

frame is tilted towards backside by actuating dumping

actuator.

2. Left side dumping:

VI. CONCLUSION

The developed prototype model of multistage dumping

trolley can be used to dump the material at any required

side. Thus, the limitations of conventional tractordumping trolley can be overcome. Development of

multistage dumping trolley is achieved by integrated

chassis design which includes locking mechanism of

frames. The frame locking mechanism operates on

pneumatic system gives easy and effective locking of

frames to accomplish multistage. Thus it saves energy as

well as time required for dumping with efficient

working of trolley.

REFERENCES

[1]

P.Jagadamba., and Mr. Hari Sankar Vanka.,

Design and Optimization of Three Stages

Hydraulic Cylinder Used In Dump Trucks.

Fig. 8 Left side dumping

[2]

During left side dumping, second locking actuator kept

unlocked by respective shut-off valve and remaining two

becomes locked during operation. Thus first and second

frame in locked condition are tilted towards left side by

actuation of dumping actuator.

Ganesh Shinde., P. Tawele., and L. Raut.

Design and Development of 3-Way Dropping

Dumper

[3]

Design of machine elements - R.S.Kurmi

[4]

R.K.Bansal, Pascal, Fluid Mechanic, Laxmi

Publication LDT.

[5]

Khurmi Gupta,2008,Degree of freedom, Theory

of machine, S chand & Company Ltd; (2008)

[6]

www.tractorbynet.com

Transportation.

[7]

www.northpointauto.com/np/LinkClick.aspx?file

ticket...tabid=40

[8]

www.shanafelt.com/material-handlingcontainers.html

[9]

K.Mahadevan, K balaveera Reddy Design data

hand book-CBS Publication 2008.

[10]

Manufacturing Technology - M.Haslehurst.

[11]

www.lislesurplus.com/.../8-x-14-x-2-bumperpull-dump-traile r-drop-sides-7-ton/

3. Right side dumping:

During right side dumping, third locking actuator kept

unlocked by respective shut-off valve and remaining two

becomes locked during operation. Thus first, second and

third frame in locked condition are tilted towards right

side by actuation of dumping actuator.

...

Trailers

&

Fig. 9 Right side dumping

___________________________________________________________________________________________________________

Special Issue on International Journal on Theoretical and Applied Research in Mechanical Engineering (IJTARME) V-5 No.2

ISSN (Print): 2319-3182, For National Conference on Advances in Design and Thermal Engineering (NCADTE-2016)

G.H. Raisoni College of Engineering & Management, Chass, Ahmedanagar, Maharashtra 17th to 18th February 2016

7

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Wind Driven Mobile Charging of Automobile BatteryDocument7 pagesWind Driven Mobile Charging of Automobile Batterysuraj dhulannavarPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Visvesvaraya Technological University BelgaumDocument2 pagesVisvesvaraya Technological University Belgaumsuraj dhulannavarPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Left View Scale: 1:2: 1:1 XXX A0Document1 pageLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- 1:1 XXX A1: Toshavi PCDocument1 page1:1 XXX A1: Toshavi PCsuraj dhulannavarPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- FrameDocument1 pageFramesuraj dhulannavarPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- M.H.Saboo Siddik PolytechnicDocument5 pagesM.H.Saboo Siddik Polytechnicsuraj dhulannavarPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDocument13 pagesD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 1:1 XXX A1: Toshavi 5/3/2016Document1 page1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 1:1 XXX A4: Designed By: DateDocument1 page1:1 XXX A4: Designed By: Datesuraj dhulannavarPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- FrameDocument1 pageFramesuraj dhulannavarPas encore d'évaluation

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDocument17 pagesWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- 1:1 XXX A4: Toshavi 4/8/2016Document1 page1:1 XXX A4: Toshavi 4/8/2016suraj dhulannavarPas encore d'évaluation

- 1:1 XXX A1: Designed By: DateDocument1 page1:1 XXX A1: Designed By: Datesuraj dhulannavarPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Iqmin A Jktinv0087205 Jktyulia 20230408071006Document1 pageIqmin A Jktinv0087205 Jktyulia 20230408071006Rahayu UmarPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Sloba Dragovic - ResumeDocument3 pagesSloba Dragovic - ResumeSloba DragovicPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Reference Letter of DR Zaka EmadDocument2 pagesReference Letter of DR Zaka EmadRMRE UETPas encore d'évaluation

- Hyster H 60 XL SHOP MANUALDocument273 pagesHyster H 60 XL SHOP MANUALjacksonholland833583% (6)

- Huawei RTN 980-950 QoS ActivationDocument7 pagesHuawei RTN 980-950 QoS ActivationVenkatesh t.k100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 7.4.1.2 Packet Tracer - Skills Integration Challenge InstructionsDocument3 pages7.4.1.2 Packet Tracer - Skills Integration Challenge InstructionsJerry FullerPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Msamb Rules and Japan GuidelinesDocument3 pagesMsamb Rules and Japan GuidelineslawrgeoPas encore d'évaluation

- What Is A SAP LockDocument3 pagesWhat Is A SAP LockKishore KumarPas encore d'évaluation

- Ma 500TRDocument3 pagesMa 500TRBoban ButrićPas encore d'évaluation

- 010 Frank Sealing Systems 700BR01Document28 pages010 Frank Sealing Systems 700BR01Handy Han QuanPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 2520 995 RevBDocument52 pages2520 995 RevBgovindarulPas encore d'évaluation

- Wilf Book FlyerDocument4 pagesWilf Book FlyerEduardo Manuel Chávarry VelaPas encore d'évaluation

- Taking Off - RC Works (Complete)Document4 pagesTaking Off - RC Works (Complete)Wai LapPas encore d'évaluation

- CSB GP1234 - Hoja de DatosDocument2 pagesCSB GP1234 - Hoja de DatosGermanYPPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Brochure Otis Gen360 enDocument32 pagesBrochure Otis Gen360 enshimanshkPas encore d'évaluation

- FPFH Standar InstallationDocument13 pagesFPFH Standar InstallationYulius IrawanPas encore d'évaluation

- Arduino Water Flow Sensor CodeDocument6 pagesArduino Water Flow Sensor CodeNasruddin AVPas encore d'évaluation

- Fisher Imprints: Inter-Disciplinary PressDocument8 pagesFisher Imprints: Inter-Disciplinary PressUndi GunawanPas encore d'évaluation

- DeltaBox Catalogue UK 2021Document37 pagesDeltaBox Catalogue UK 2021Philip G. SantiagoPas encore d'évaluation

- OsiriX JPEG2000Document10 pagesOsiriX JPEG2000Camilo Dario Botero CruzPas encore d'évaluation

- Oyo Busines ModelDocument1 pageOyo Busines ModelVikash KumarPas encore d'évaluation

- Rosemount 2120 Vibrating Fork Liquid Level SwitchDocument16 pagesRosemount 2120 Vibrating Fork Liquid Level SwitchTariqMalikPas encore d'évaluation

- Boeing 757 Normal Checklist: Power Up & Preliminary PreflightDocument4 pagesBoeing 757 Normal Checklist: Power Up & Preliminary PreflightАлексей ЯрлыковPas encore d'évaluation

- Ieeeee13caf2 935f 20150515073915Document9 pagesIeeeee13caf2 935f 20150515073915Jennifer YoungPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mercruiser GearcasecomponentsDocument42 pagesMercruiser GearcasecomponentswguenonPas encore d'évaluation

- Priska (Full)Document4 pagesPriska (Full)Eka MurdaniPas encore d'évaluation

- Siva QADocument6 pagesSiva QAsivakanth mPas encore d'évaluation

- Revit LookupDocument6 pagesRevit Lookupjuand_121Pas encore d'évaluation

- Culpeper County Water & Sewer Master Plan Compiled 2016-12-06 PDFDocument238 pagesCulpeper County Water & Sewer Master Plan Compiled 2016-12-06 PDFSuddhasattwa BandyopadhyayPas encore d'évaluation

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Document20 pagesProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediPas encore d'évaluation