Académique Documents

Professionnel Documents

Culture Documents

Ship Initial Inspection Checklist Port State Control

Transféré par

vdevivTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ship Initial Inspection Checklist Port State Control

Transféré par

vdevivDroits d'auteur :

Formats disponibles

Australian Government

Australian Maritime Safety Authority

SHIP INITIAL INSPECTION

CHECKLIST

Port State Control

Ship name

Port of inspection

Date

/20

Inspector

Signature

AMSA 36 (4/14)

SHIPSYS MOBILE USERS ONLY

INSPECTION TIMES

Initial inspection

Date

Time

Detailed inspection

Date

Commenced initial inspection

/20

Commenced detailed inspection

/20

Completed initial inspection

/20

Completed detailed inspection

/20

Time

GENERAL DETAILS

Owner (record owners name from ships registration papers or C.S.R)

Charterer

IMO registered owner number

P&I club

Last special survey (dd/mm/yyyy)

Port of registry

Master advises that all equipment is operating

satisfactorily and that the vessel is seaworthy

Country

Agent

Type of cargo

YES / NO

Masters signature

Comments

Scheduled departure date

/

/20

Time

Next port

ETA next port

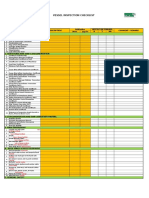

CREW QUALIFICATIONS

(Place a against the applicable certificates)

Rank

Valid CoC

The Certificate of

Competency (CoC)

kept on board, must

be an original with an

English translation

included

Valid Flag

Endorsement

The flag State must

recognise any certificate

issued by another party

to any officer serving

under its flag

Tanker Endorsement

Tanker endorsements or certificates

are required for officers and

certificates for ratings assigned

specific duties related to cargo

operations to show compliance with

(Reg V/1-1 and V/1-2)

The minimum requirement

for a vessel operating in

sea area A3, is for one

navigating officer to hold

a valid GMDSS GOC and

all others to hold valid

GMDSS ROC certificates

Master >500 GT

II/2

V1

GOC/ROC

Chief Officer >500 GT

II/2

V1

GOC/ROC

Officer NW

II/1

GOC/ROC

Ratings NW

II/4

C/Engineer >3000 kW

III/2

V1

2/Engineer

III/2

V1

Officer EW

III/1

Rating EW

III/4

1

Masters, Chief Engineers, Chief Officers and Second Engineers and any other person with immediate responsibility for loading, discharge and care

in transit and handling of cargo require a tanker endorsement to show compliance with Reg V/1-1 and V/1-2.

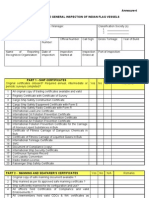

DOCUMENTATION

(Place a against the applicable items inspected)

Appropriate cargo documentation

International Civil Liability Insurance Certificate (Bunkers/oil pollution)

Appropriate cargo publications

Last PSC report

Approved stability information

LRIT conformance test report

Cargo Gear Record Book

MASTREP Book

Cargo Record Book

Official log book entries, records of drills etc

Cargo securing manual

Oil Record Book(s)

Continuous Synopsis Record

P&A Manual (Chemical Tankers)

Document of Authorisation (Grain)

P&I Insurance (Certificate of Entry)

Document of Compliance (Dangerous Goods)

REEFVTS Users Guide

Documented Safety Management System

Ship type appropriate for the cargo

Enhanced survey report

Shore based radio equipment maintenance agreement

Evidence of annual test of 406 EPIRB/VDR/AIS

SOPEP / SMPEP / SEEMP

Garbage management plan/record book

Survey report file

AREA 1 - EXTERNAL HULL & PRE-BOARDING

1.1

1.2

1.3

Hull Condition

Port/Starboard* Side Alongside

Hull Markings

Accommodation Ladder & Side Netting

AREA 2 - HOURS OF REST AND FATIGUE

2.1

2.2

2.3

2.4

2.5

Watchkeeping schedule posted (in an easily accessiblearea)

Rest periods comply with STCW requirements

Rest periods reflect actual hours worked

Watchkeepers on first and subsequent watch sufficiently rested

No issues with thenavigation plan/equipment that may

compromise watchkeepers ability to perform effectively

AREA 3 - ISM CODE

3.1

3.2

3.3

3.4

Designated Person Ashore Dened

Masters Review of ISM System

Manuals. Audit Reports and Document Control

Documented Emergency Procedures

AREA 4 WHEELHOUSE

4.1

4.2

4.3

4.4

4.5

4.6

Voyage Plan and Publications

Navigational Aids

Compass and Compass Deviation Records

Fire Detection Panel

Navigation Light Panel

BNWAS

AREA 5 - RADIO

5.1

5.2

5.3

5.4

Correct MSI Reception

MF / HF DSC Radiotelephony

GMDSS equipment tested on batteries Yes/No*

SART Inspection

Portable VHF Inspection

AREA 6 - MONKEY ISLAND

6.1

6.2

6.3

6.4

Masts & Attachments

Vent Closures

Standard Compass

Antenna Inspection

AREA 7 - EXTERNAL SUPERSTRUCTURE & DECK

7.1 Accommodation Vent Closures

7.2 Battery Room

7.3 EPIRB

7.4 Battery Inspection

7.5 Weather Doors/Frames

7.6 Hydrants/Hoses/Nozzles

7.7 Engine Room Dampers

Identify which (if any) dampers were inspected

and/or tested (e.g. port forward, stbd aft etc)

7.8 External Accommodation Ladders

7.9 Emergency Power Source

Source - Batteries/Emergency Generator*

(no blackout) - sequence test carried out Yes/No*

7.10 Funnel Damper Operation

Identify funnel dampers/closures which were inspected and/or

tested (if any) (e.g. aft funnel, funnel top trapdoor etc)

7.11 Man-Overboard Light/Smoke

7.12 Fire Control Plan outside accommodation

7.13 Lifebuoy/Lines/Lights

7.14 Paint Locker

*Delete as appropriate

INSPECTED ITEMS DETAILS/NOTES

AREA 8 - BOAT DECK

8.1

8.2

8.3

Boat Preparation & Overside Lights

Launching Instructions

Embarkation Ladder

AREA 9 - SURVIVAL CRAFT

9.1

9.2

9.3

9.4

9.5

9.6

Stowage Release & Launching Arrangements

Identify which (if any) boats inspected (port/starboard/free-fall)

Lifeboat/Rescue Boat Hull/Attachments

Lifeboat/Rescue Boat Equipment

Lifeboat/Rescue Boat Engine

Identify which (if any) boats (e.g. port, starboard, free-fall) and

indicate if engine and clutch tests carried out on each

Operational Readiness

Life Rafts & Liferaft Securing Arrangement

AREA 10 - MAIN DECKS

10.1 Load Line Closing Devices

Identify which (if any) devices inspected/tested

10.2 Crew Protection

10.3 Deck Structures & Machinery

10.4 Mooring Arrangement (winches/ropes/wires)

10.5 Pilot Boarding Arrangements

10.6 Fire Main Condition

AREA 11 - FIXED FIRE EXTINGUISHING SYSTEM

11.1 Type of System Fitted CO2 / Foam / Dry - Powder / Hypermist*

11.1 Operating Instructions

11.2 Overall Condition

AREA 12 - EMERGENCY FIRE PUMPS

12.1 Emergency Fire Pump

If tested - method of test

12.2 Engine Room Fire Main Isolating Valve

AREA 13 - STEERING GEAR FLAT

13.1

13.2

13.3

13.4

Change Over Instructions

Emergency Steering

Overall Condition

Communications to Wheelhouse

AREA 14 - ENGINE ROOM

14.1

14.2

14.3

14.4

14.5

14.6

14.7

Valves, Piping and Fittings

Engine Room Doors

Fire Appliances

Means of Escape (EEBD)

Electrical Safety

Bilges/Tank Top Cleanliness

Self Closing Cocks/Valves

AREA 15 - POLLUTION PREVENTION

15.1

15.2

15.3

15.4

Oil Filtering & Associated Equipment

Garbage Arrangements

Sewage Pollution Prevention

Air Pollution Prevention

AREA 16 - ACCOMMODATION/CATERING

16.1

16.2

16.3

16.4

16.5

16.6

16.7

Cleanliness/Hygiene

Sanitary Arrangements

Mess & Recreation Facilities

Food & Food Storage

Fire Fighting Arrangements

Overall Condition

Fire Dampers

*Delete as appropriate

INSPECTED ITEMS DETAILS/NOTES

AREA17 - FIRE CONTROL STATION

17.1 Firemans Outt

17.2 Remote Stops/Fuel Shutoffs

Identify which (if any) tested (individual or group)

17.3 International Shore Connection

17.4 Fixed Fire Suppression System Controls

AREA 18 - ADDITIONAL FOR PASSENGER SHIPS

18.1

18.2

18.3

18.4

18.5

Emergency Plans

Zone Isolation Operation

Sprinkler Auto Pump Cut-In

Sprinkler Station Alarms

Lifeboats

Identify which (if any) boats inspected

18.6 Passenger Cabin Emergency Information

18.7 Evacuation Direction Signs

18.8 Emergency Lighting

18.9 Watertight Doors Local & Remote

Identify which (if any) doors tested

18.10 Rescue & Fast Rescue Boat

18.11 Emergency Drills Demonstration

18.12 Procedures & responsibilities for incident response

AREA 19 - ADDITIONAL FOR BULK CARRIERS

19.1

19.2

19.3

19.4

19.5

Shippers declaration on board

Loading instruments/Loading Booklet

Masters Report

Monitoring equipment: Oxygen, Gas, pH and Temperature

Adequacy of hold closing arrangements and ventilators

Give details of inspection and condition found

19.6 Electrical equipment and cabling/gas sampling points

19.7 Compliance with the IMSBC Code

19.8 Inspection of main deck

19.9 Cargo Hold(s) inspection

Holds inspected internally Yes / No*

If yes give details

19.10 Internal inspection of Ballast Tanks

Tanks inspected internally Yes / No*

If yes give details

19.11 Enhanced Survey Records

Yes / No / N/A*

19.12 Procedures and responsibilities for cargo operations

19.13 Water Ingress Alarm System

19.14 De-Watering Arrangement

AREA 20 - ADDITIONAL FOR RO-ROS

20.1 Shell Doors Locking and Sealing Arrangements

If carried out identify which doors inspected/tested

20.2 Vehicle Deck Drainage

If carried out identify which drainage arrangements were tested

20.3 Ramp/Bulwarks/Guard Rails

20.4 Cargo Securing Arrangements

20.5 Fire Fighting Arrangements

20.6 Fire Protection Arrangements

20.7 General Structural Inspections

20.8 Water Fog and Foam Applicators

*Delete as appropriate

INSPECTED ITEMS DETAILS/NOTES

AREA 21 - ADDITIONAL FOR GAS/CHEM/OIL TANKERS

21.1 Procedures & responsibilities for cargo

handling operations

21.2 I.G. System

System sighted in operation Yes/No*

21.3 Pumproom and pumproom ventilation system

21.4 Venting, purging, gas-freeing & ventilation

21.5 Fire protection for cargo tanks deck area

21.6 Portable oxygen/gas measuring instruments

21.7 Emergency towing arrangement

21.8 Oil discharge monitor

AREA 22 - ADDITIONAL FOR SHIPS CARRYING

CONTAINERS AND GENERAL CARGOES

22.1 Cargo Securing Arrangements

22.2 Dangerous Goods

22.3 Navigation bridge visibility

AREA 23 - AUSTRALIAN VESSELS FSC

ADDITIONAL REQUIREMENTS

23.1 Medical Locker Certificate (MO 11)

23.2 Fire Fighting Appliance Certificate/s (MO15)

23.3 Portable extinguishers comply with AS and MO 15

23.4 Certificates of Medical Fitness (MO9)

23.5 Lift certificate (MO 12)

23.6 Liferaft Certificates (MO 25)

23.7 For Refrigeration licences the following must be in place:

A vacuum pump

record the serial number here: ........................

A receptacle to pump-down the system gas

CFC gas leakage device available

All CFC bottles to be suitably marked and

inspection/tests in date

23.8 Fixed oxy/acetylene installation (MO 12)

AREA 24 MARITIME LABOUR CONVENTION 2006

MDI: YES

NO

MLC elements inspected during MDI:

24.0 Certification

24.1 Minimum Age

24.2 Medical Certificates

24.3 Training and Qualifications

24.4 Recruitment and Placement

24.5 Seafarers Employment Agreements (SEA)

24.6 Wages

24.7 Hours of work and hours of rest

24.8 Entitlement to leave

24.9 Repatriation

24.10 Manning levels

24.11 Accommodation and recreational facilities

24.12 Food and Catering

24.13 Medical Care on board ship and ashore

24.14 Ship owners liability

24.15 Health and Safety Protection

24.16 Social Security

24.17 On Board Complaint procedure

*Delete as appropriate

INSPECTED ITEMS DETAILS/NOTES

ADDITIONAL COMMENTS

Vous aimerez peut-être aussi

- Ship Initial Inspection Checklist: Port State ControlDocument34 pagesShip Initial Inspection Checklist: Port State ControlBHASKAR HALDAR100% (1)

- AMSA36Document66 pagesAMSA36Btwins123100% (2)

- Australian Government Ship Inspection ChecklistDocument34 pagesAustralian Government Ship Inspection ChecklistConrad ManacapPas encore d'évaluation

- Amsa PSC ChecklistDocument11 pagesAmsa PSC Checklistdassi99100% (1)

- AMSA 전용 필수 점검표Document3 pagesAMSA 전용 필수 점검표RiskyMaulanaPas encore d'évaluation

- AMSA Ship Initial Inspection ChecklistDocument13 pagesAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- Checklist Inspecao Naval-ModeloDocument72 pagesChecklist Inspecao Naval-ModeloManuel RibeiroPas encore d'évaluation

- пркерghDocument13 pagesпркерghВячеслав ЮрченкоPas encore d'évaluation

- Full Condition Survey ReportDocument44 pagesFull Condition Survey ReportManish Kumar Singh100% (3)

- Existing Vessel Take Over ChecklistDocument6 pagesExisting Vessel Take Over ChecklistTamaro Raja Pahala MahaPas encore d'évaluation

- Questions For Interview - ANSWEREDDocument4 pagesQuestions For Interview - ANSWEREDalbaraka.shippingPas encore d'évaluation

- Taking Over ChecklistDocument2 pagesTaking Over ChecklistDinesh Singh Sheoran100% (1)

- PSC Compliance ChecklistDocument12 pagesPSC Compliance Checklistreda hmr100% (1)

- FSI Inspection FormDocument16 pagesFSI Inspection FormDenosisPas encore d'évaluation

- Master's Checklist for Ship MaintenanceDocument4 pagesMaster's Checklist for Ship MaintenanceValentin Jonov100% (2)

- Report on Certificate Status for MV OOCL KaohsiungDocument8 pagesReport on Certificate Status for MV OOCL KaohsiungYuvaraj0% (1)

- Vessel Inspection Checklist: Description Validation Start ExpireDocument5 pagesVessel Inspection Checklist: Description Validation Start ExpireDodik ParulianPas encore d'évaluation

- SURvillance ChecklistDocument9 pagesSURvillance ChecklistPRASADPas encore d'évaluation

- Annexes MAIBInvReport-18 2015 PT BranzaDocument27 pagesAnnexes MAIBInvReport-18 2015 PT BranzaRaluca Maxim MunteanuPas encore d'évaluation

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- Port State Control Checklist for Vessel Certification and EquipmentDocument26 pagesPort State Control Checklist for Vessel Certification and Equipmentmajdirossross100% (1)

- Checklist For Dumper/Sand Truck: A. ParticularsDocument2 pagesChecklist For Dumper/Sand Truck: A. ParticularsikponmwonsaPas encore d'évaluation

- SIRE Inspection Preparation Document BLANKDocument5 pagesSIRE Inspection Preparation Document BLANKhmmbacon100% (1)

- !SIRE Inspection Preparation DocumentDocument4 pages!SIRE Inspection Preparation DocumentKarim Paquiao100% (1)

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliPas encore d'évaluation

- ANNEX I PORT INSPECTIONYes/NoYes/NoDocument7 pagesANNEX I PORT INSPECTIONYes/NoYes/No송성훈Pas encore d'évaluation

- Minimum Requirements To Leave Shipyard For Sea TrialDocument3 pagesMinimum Requirements To Leave Shipyard For Sea TrialHUNG NIKKOPas encore d'évaluation

- FSI Checklist (May 2011)Document13 pagesFSI Checklist (May 2011)Arun Mishra67% (3)

- Lloyd - Maintenance Guide Checklist Rev3Document22 pagesLloyd - Maintenance Guide Checklist Rev3Amit Kumar Sen100% (1)

- Port State Control Quick Guide: Achieving ComplianceDocument19 pagesPort State Control Quick Guide: Achieving Compliancefredy2212100% (1)

- SEO Condition Survey ReportDocument4 pagesSEO Condition Survey Reportpgupta71Pas encore d'évaluation

- On Off Hire SurveyDocument7 pagesOn Off Hire Surveyio75100% (2)

- VSL Inspection Form 300611Document6 pagesVSL Inspection Form 300611Kunal SinghPas encore d'évaluation

- Guide For Vetting InspectionsDocument6 pagesGuide For Vetting InspectionsAnonymous b68EQR100% (1)

- MARPOL Annex I Survey ChecklistDocument5 pagesMARPOL Annex I Survey Checklistitavsa100% (3)

- Tanker Inspection Report SummaryDocument15 pagesTanker Inspection Report SummaryMalik Badi Uz Zaman100% (1)

- Annex - II: Application For Towing PermissionDocument2 pagesAnnex - II: Application For Towing PermissionAjay SinghPas encore d'évaluation

- Bangladesh Shipping Corporation Cargo / Container /tanker Vessel Safety Management SystemDocument1 pageBangladesh Shipping Corporation Cargo / Container /tanker Vessel Safety Management Systemmehedi2636Pas encore d'évaluation

- LIFT INSPECTION CHECKLISTDocument2 pagesLIFT INSPECTION CHECKLISTjillianix100% (1)

- Vessel InspectionDocument19 pagesVessel Inspectionmega10612014100% (1)

- Full Condition Survey ReportDocument48 pagesFull Condition Survey ReportJorge Ruiz100% (4)

- Survey Report Summary of KMP Selat Madura IIDocument13 pagesSurvey Report Summary of KMP Selat Madura IIApras TyoPas encore d'évaluation

- Medi Lisbon q88Document8 pagesMedi Lisbon q88levent364Pas encore d'évaluation

- BR 02 - LIST 01 - Rev 1 JUL 08Document1 pageBR 02 - LIST 01 - Rev 1 JUL 08sailor21316Pas encore d'évaluation

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichPas encore d'évaluation

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaDimosPas encore d'évaluation

- Coast Guard Port State Control Job AidDocument24 pagesCoast Guard Port State Control Job AidOm Prakash RajPas encore d'évaluation

- Oral Examination Checklist: Page 1 of 2Document2 pagesOral Examination Checklist: Page 1 of 2circoleco100% (1)

- SeaDocument18 pagesSeaRattapong PlaituanPas encore d'évaluation

- CertificatesDocument3 pagesCertificatesP Venkata SureshPas encore d'évaluation

- CL 4Document1 pageCL 4mehedi2636Pas encore d'évaluation

- Ship Inspections and Vetting GuidelinesDocument7 pagesShip Inspections and Vetting Guidelinesmark john batingal100% (1)

- Ships arrival checklistDocument2 pagesShips arrival checklistNi CkPas encore d'évaluation

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsD'EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Radar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersD'EverandRadar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- VFR and IFR Flight Training: Need to Know AcronymsD'EverandVFR and IFR Flight Training: Need to Know AcronymsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Marine and Offshore Pumping and Piping SystemsD'EverandMarine and Offshore Pumping and Piping SystemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Ship and Mobile Offshore Unit Automation: A Practical GuideD'EverandShip and Mobile Offshore Unit Automation: A Practical GuidePas encore d'évaluation

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsD'EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Future IMO and ILO Legislation: Autumn 2020Document54 pagesFuture IMO and ILO Legislation: Autumn 2020Morten SzilasPas encore d'évaluation

- 10 Simple Things That Make Seafarers Happy On Board ShipsDocument17 pages10 Simple Things That Make Seafarers Happy On Board ShipsvdevivPas encore d'évaluation

- Free-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosaDocument2 pagesFree-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosavdevivPas encore d'évaluation

- Rec 85 Rev1 Dec 2018 UlDocument14 pagesRec 85 Rev1 Dec 2018 UlvdevivPas encore d'évaluation

- HEALTHY SHIP FOODDocument8 pagesHEALTHY SHIP FOODvdevivPas encore d'évaluation

- Operational Safety Criteria For Receiving Pilot by HelicopterDocument6 pagesOperational Safety Criteria For Receiving Pilot by HelicoptervdevivPas encore d'évaluation

- MEG4 Mooring Line Base Design CertificateDocument4 pagesMEG4 Mooring Line Base Design CertificatevdevivPas encore d'évaluation

- PR 40 Rev1 Apr 2019 UlDocument12 pagesPR 40 Rev1 Apr 2019 UlvdevivPas encore d'évaluation

- PR 40 Rev1 Apr 2019 UlDocument12 pagesPR 40 Rev1 Apr 2019 UlvdevivPas encore d'évaluation

- Navigation Safety Assessment in The Restricted Area With The Use of ECDIS PDFDocument7 pagesNavigation Safety Assessment in The Restricted Area With The Use of ECDIS PDFvdevivPas encore d'évaluation

- 2019 Anchoring Guidelines A Risk-Based-Approach PDFDocument57 pages2019 Anchoring Guidelines A Risk-Based-Approach PDFvdeviv100% (3)

- c2Document30 pagesc2vdevivPas encore d'évaluation

- What Are CATZOC and How To Use It For Passage Planning - MySeaTime PDFDocument25 pagesWhat Are CATZOC and How To Use It For Passage Planning - MySeaTime PDFvdeviv100% (2)

- S-101 Info Paper Jun12 enDocument13 pagesS-101 Info Paper Jun12 envdevivPas encore d'évaluation

- Position Cross-Checking On ECDIS in View of International Regulations Requirements and OCIMF RecommendationsDocument9 pagesPosition Cross-Checking On ECDIS in View of International Regulations Requirements and OCIMF RecommendationsKen Shin100% (1)

- Drug Abuse at SeaDocument40 pagesDrug Abuse at SeavdevivPas encore d'évaluation

- LNG VESSEL APPROVAL PROCEDURE - DESFA LNG TERMINAL Rev.2 - 2015 1 PDFDocument11 pagesLNG VESSEL APPROVAL PROCEDURE - DESFA LNG TERMINAL Rev.2 - 2015 1 PDFvdevivPas encore d'évaluation

- Digital Technology and Seafarers Mental Wellbeing PDFDocument7 pagesDigital Technology and Seafarers Mental Wellbeing PDFvdevivPas encore d'évaluation

- MEPC.1-Circ.810 - Adequate Port Reception Facilities For Cargoes Declared As Harmful To The Marine Environme... (Secretariat)Document2 pagesMEPC.1-Circ.810 - Adequate Port Reception Facilities For Cargoes Declared As Harmful To The Marine Environme... (Secretariat)vdevivPas encore d'évaluation

- Hatzigrigoris - New Operating Con.2008.SYMPDocument8 pagesHatzigrigoris - New Operating Con.2008.SYMPvdevivPas encore d'évaluation

- Guide On Shipping Industry 22122015Document31 pagesGuide On Shipping Industry 22122015vdevivPas encore d'évaluation

- Factors Influencing Occupational Stress in SeafarersDocument8 pagesFactors Influencing Occupational Stress in SeafarersvdevivPas encore d'évaluation

- OVVP OffshoreVesselVettingProcess Tcm14-41400Document52 pagesOVVP OffshoreVesselVettingProcess Tcm14-41400vdeviv100% (1)

- 229-77039 FINAL - GMP FAQs - V3 tcm155-246541 PDFDocument10 pages229-77039 FINAL - GMP FAQs - V3 tcm155-246541 PDFvdevivPas encore d'évaluation

- Mooring Winch Brake Capacity Calculation PDFDocument1 pageMooring Winch Brake Capacity Calculation PDFvdeviv100% (1)

- 96 98 EC - EN ConsolidatedText - 2015 04 30 - tcm8 26027Document96 pages96 98 EC - EN ConsolidatedText - 2015 04 30 - tcm8 26027vdevivPas encore d'évaluation

- Single Drum Winch Design Chapter 10Document54 pagesSingle Drum Winch Design Chapter 10kelvinyeoh100% (3)

- Pipe Flow Calculations PDFDocument12 pagesPipe Flow Calculations PDFharrypop418Pas encore d'évaluation

- Calculating Reel Capacity for Wire RopeDocument1 pageCalculating Reel Capacity for Wire RopevdevivPas encore d'évaluation

- 20 January 2017 Standard Europe Circular Ballast Water Management ConventionDocument5 pages20 January 2017 Standard Europe Circular Ballast Water Management ConventionvdevivPas encore d'évaluation

- Heather Horton ResumeDocument1 pageHeather Horton ResumeHeather HortonPas encore d'évaluation

- Kryptonite Chords by 3 Doors Downtabs at Ultimate Guitar ArchiveDocument2 pagesKryptonite Chords by 3 Doors Downtabs at Ultimate Guitar ArchiveDaryl BadajosPas encore d'évaluation

- Frequently Asked Questions: SectionsDocument15 pagesFrequently Asked Questions: SectionsRobson LopesPas encore d'évaluation

- Analysis With An Introduction To Proof 5th Edition Lay Solutions ManualDocument36 pagesAnalysis With An Introduction To Proof 5th Edition Lay Solutions Manualcalymene.perdurel7my100% (29)

- Three Brass Cats-ScoreDocument20 pagesThree Brass Cats-ScoreFlávio BolrãoPas encore d'évaluation

- Secondary Radar Concepts (New) 2019Document209 pagesSecondary Radar Concepts (New) 2019Pradeep Seemala100% (1)

- PLC-XW200-250 0809-44880180Document1 pagePLC-XW200-250 0809-44880180ماستر للتوريداتPas encore d'évaluation

- Frank Zappa - Peaches en RegaliaDocument8 pagesFrank Zappa - Peaches en RegaliabaianosalvadorPas encore d'évaluation

- Wireless Battery ChargerDocument22 pagesWireless Battery ChargerAvinashreddy 9490665077100% (1)

- Whispering Eyes: Yuriko Nakamura 108 90Document3 pagesWhispering Eyes: Yuriko Nakamura 108 90TanPas encore d'évaluation

- TETRAPOL TPH700 Handportable RadioDocument4 pagesTETRAPOL TPH700 Handportable RadioFavre Alvarez VillagranPas encore d'évaluation

- Sinugbuanong Binisaya Teacher's Guide Q1-4 PDFDocument291 pagesSinugbuanong Binisaya Teacher's Guide Q1-4 PDF엘라엘라95% (20)

- OPT B1 U10 Grammar HigherDocument1 pageOPT B1 U10 Grammar HigherShorena KhubunaiaPas encore d'évaluation

- Jasmine Johnson Resume1Document3 pagesJasmine Johnson Resume1api-357417433Pas encore d'évaluation

- Performance of Gesture Controlled DroneDocument11 pagesPerformance of Gesture Controlled DroneKrishna SivaPas encore d'évaluation

- Not Perfect by Tim MinchinDocument5 pagesNot Perfect by Tim MinchinWilliam AckernleyPas encore d'évaluation

- Homework SolutionsCh3DSPFirst 1Document7 pagesHomework SolutionsCh3DSPFirst 1haiderPas encore d'évaluation

- Studio ScriptDocument3 pagesStudio Scriptapi-423589311Pas encore d'évaluation

- Chasing GraceDocument2 pagesChasing Graceefp31Pas encore d'évaluation

- Notas y Letras (NO BORRAR)Document205 pagesNotas y Letras (NO BORRAR)NicolasBacaCastexPas encore d'évaluation

- ADC - Sound Shaper Tree - Manul ServicioDocument41 pagesADC - Sound Shaper Tree - Manul ServicioCarol Eduardo Apitz DíazPas encore d'évaluation

- Electromagnetic Spectrum GuideDocument3 pagesElectromagnetic Spectrum GuideJeff GanterPas encore d'évaluation

- Wights Waits For Weights - Drum SetDocument1 pageWights Waits For Weights - Drum SetAnonymous f5WvZf1y6gPas encore d'évaluation

- Cifra Club - Spandau Ballet - TrueDocument4 pagesCifra Club - Spandau Ballet - TruefePas encore d'évaluation

- Abducted To Oz by Dulabone, ChrisDocument68 pagesAbducted To Oz by Dulabone, ChrisGutenberg.orgPas encore d'évaluation

- WiproDocument41 pagesWiprosuganya004Pas encore d'évaluation

- DSL-2730U User ManualDocument87 pagesDSL-2730U User Manualdeepak1438Pas encore d'évaluation

- Competition: The Fuel For GreatnessDocument46 pagesCompetition: The Fuel For Greatness111Pas encore d'évaluation

- Odeon Tab GuitarDocument5 pagesOdeon Tab Guitara3l2g1i0100% (1)

- L'Atelier Sungha Jung Tabs PDFDocument8 pagesL'Atelier Sungha Jung Tabs PDFjustinbui85Pas encore d'évaluation