Académique Documents

Professionnel Documents

Culture Documents

Stickup

Transféré par

Samsul Imran BahromCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stickup

Transféré par

Samsul Imran BahromDroits d'auteur :

Formats disponibles

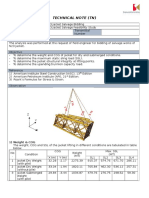

Date: 11 Jul 16

Pile/Conductor stick-up calculations (API RP2A WSD specifications)

LARAK PILE STICK-UP

P1+P2

Select hammer model,

Hammer total static weight,

Hammer static weight on pile top,

CG of hammer above pile top,

Pile true batter,

Pile material yield stress,

Pile modulus of elasticity,

Maximum pile driving dynamic stress,

Effective length factor,

Coefficient Cm,

Stick-up length analysed,

% horizontal load at top of pile/conductor,

Pile Segment

section length

(mm)

0

P3

17500

P3

3500

Length

from pile top

(mm)

Top of pile

0

0

0

0

0

0

0

17,500

17,500

21,000

Top of jacket leg

=

=

=

=

1:

=

=

=

=

=

=

=

MHU400T

20

60.2

60.2

3,260

4.5

345.0

210,000

218.0

2.1

1.0

21.00

2.0

MT

MT

mm

12.605

MPa

MPa

MPa

(API RP2A recommendation)

(API RP2A recommendation)

m

=

68.90

%

ft

Pile

Pile weight

Moment

Moment

Total moment

OD

Wall thk above section due to pile wt due to hammer at pile section

(mm)

(mm)

(kN)

(kNm)

(kNm)

(kNm)

2000

2000

2000

2000

2000

2000

1067

1067

1067

1067

10

10

10

10

10

10

40

40

40

40

0.0

0.0

0.0

0.0

0.0

0.0

0.0

173.9

173.9

208.7

0.0

0.0

0.0

0.0

0.0

0.0

0.0

332.1

332.1

478.2

Total maximum static + dynamic pile stress =

344.7

MPa

*** Total static + dynamic stress Fy, Ok ***

Version: 18 May 2005

Dr Sam MT

deg

0.0

420.1

420.1

420.1

420.1

420.1

420.1

2,882.1

2,882.1

3,374.5

0.0

420.1

420.1

420.1

420.1

420.1

420.1

3,214.2

3,214.2

3,852.8

Static bending stress

Actual

Allowable

(N/mm2)

(N/mm2)

0.00

13.58

13.58

13.58

13.58

13.58

13.15

100.63

100.63

120.62

182.65

182.65

182.65

182.65

182.65

182.65

258.75

258.75

258.75

258.75

Static axial stress

Actual

Allowable

(N/mm2)

(N/mm2)

9.22

9.22

9.22

9.22

9.22

9.22

4.47

5.78

5.78

6.04

73.24

73.24

73.24

73.24

73.24

73.24

73.24

73.24

73.24

73.24

Combined

stress check

(unity ratio)

0.13

0.21

0.21

0.21

0.21

0.21

0.12

0.50

0.50

0.59

*** UC 1.0, Ok ***

Page:

Vous aimerez peut-être aussi

- Pile/Conductor Stick-Up Calculations (API RP2A WSD SpecificationsDocument5 pagesPile/Conductor Stick-Up Calculations (API RP2A WSD SpecificationsSamsul Imran BahromPas encore d'évaluation

- Attachment 1Document2 pagesAttachment 1Samsul Imran BahromPas encore d'évaluation

- Coleman Xtreme 5 Days Wheeled Cooler Box - Blue (50qt) - Shopee MalaysiaDocument3 pagesColeman Xtreme 5 Days Wheeled Cooler Box - Blue (50qt) - Shopee MalaysiaSamsul Imran BahromPas encore d'évaluation

- XfemDocument29 pagesXfemSamsul Imran BahromPas encore d'évaluation

- DANA-Technical Note (TN)Document8 pagesDANA-Technical Note (TN)Samsul Imran BahromPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Untitled DocumentDocument6 pagesUntitled DocumentrameezshyamaleePas encore d'évaluation

- Supergene High Yield Introgressed Hybrid Oil Palm MalaysiaDocument16 pagesSupergene High Yield Introgressed Hybrid Oil Palm MalaysiaYangSern Lim100% (13)

- Bruce Lyon - Occult CosmologyDocument55 pagesBruce Lyon - Occult Cosmologyeponymos100% (1)

- Provisional Restorations in Fixed ProsthodonticsDocument4 pagesProvisional Restorations in Fixed ProsthodonticsPhoebe David100% (1)

- Truss Design GuidDocument3 pagesTruss Design GuidRafi HasanPas encore d'évaluation

- HP Compaq 6531s Inventec Zzi MV Rev A03 (6820s)Document54 pagesHP Compaq 6531s Inventec Zzi MV Rev A03 (6820s)y2k_yah7758Pas encore d'évaluation

- Properties of Equality PDFDocument1 pageProperties of Equality PDFR. I. P.Pas encore d'évaluation

- CHAPTER 48 - Skin Integrity & Wound CareDocument3 pagesCHAPTER 48 - Skin Integrity & Wound CareAPas encore d'évaluation

- Coffee Vibes: Here Is Where Your Presentation BeginsDocument86 pagesCoffee Vibes: Here Is Where Your Presentation Beginssyeda salmaPas encore d'évaluation

- LP 1st ObservationDocument6 pagesLP 1st ObservationMichael AnoraPas encore d'évaluation

- Catalogue Pièces Moteur R984Document150 pagesCatalogue Pièces Moteur R984Eza IR100% (1)

- Ken Russell Revealed:: Still Images 1954 - 1957Document4 pagesKen Russell Revealed:: Still Images 1954 - 1957Adriana ScarpinPas encore d'évaluation

- ISO 13920 - Tolerâncias para Juntas SoldadasDocument7 pagesISO 13920 - Tolerâncias para Juntas SoldadasRicardo RicardoPas encore d'évaluation

- NCERT Class 7 English Part 1 PDFDocument157 pagesNCERT Class 7 English Part 1 PDFVvs SadanPas encore d'évaluation

- HOconsDocument14 pagesHOconsMax PradoPas encore d'évaluation

- Lisca - Lingerie Catalog II Autumn Winter 2013Document76 pagesLisca - Lingerie Catalog II Autumn Winter 2013OvidiuPas encore d'évaluation

- Formula 1638 Collagen Eye CreamDocument2 pagesFormula 1638 Collagen Eye CreamLinh Sa LaPas encore d'évaluation

- Anna Kingsford, Edward Maitland - The Perfect Way, or The Finding of Christ (1909)Document484 pagesAnna Kingsford, Edward Maitland - The Perfect Way, or The Finding of Christ (1909)Momir Miric100% (1)

- 09.3090 USTR2433b T Series Cassettes Omega IFU enDocument51 pages09.3090 USTR2433b T Series Cassettes Omega IFU enAdi SaputraPas encore d'évaluation

- Ground Investigation ReportDocument49 pagesGround Investigation Reportjoemacx6624Pas encore d'évaluation

- Practice Test 1 + 2Document19 pagesPractice Test 1 + 2yếnPas encore d'évaluation

- Comprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationDocument66 pagesComprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationJorge Talavera AnayaPas encore d'évaluation

- Carbohydrate-Related Diseases Term PaperDocument5 pagesCarbohydrate-Related Diseases Term Paperheiress comiaPas encore d'évaluation

- Atomic Structure RevisionDocument4 pagesAtomic Structure RevisioncvPas encore d'évaluation

- Exam Materials ScienceDocument10 pagesExam Materials ScienceChimzoe CatalanPas encore d'évaluation

- Septage Management Guide 1Document43 pagesSeptage Management Guide 1Ria Tiglao FortugalizaPas encore d'évaluation

- Rog Strix Z390-E Gaming: DDR4 4266 Qualified Vendors List (QVL)Document13 pagesRog Strix Z390-E Gaming: DDR4 4266 Qualified Vendors List (QVL)ALAN ANDRES ZAVALA LLANOSPas encore d'évaluation

- Standard Evaluation System For RiceDocument62 pagesStandard Evaluation System For RiceIRRI_resources90% (10)

- Namma Kalvi 12th English Slow Learners Study MaterialDocument28 pagesNamma Kalvi 12th English Slow Learners Study MaterialSTANLEY RAYEN100% (1)

- 02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingDocument47 pages02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingHattar MPas encore d'évaluation