Académique Documents

Professionnel Documents

Culture Documents

ConfigurationExample x8 S7 1200 USS v1d0 en 1

Transféré par

tuyetden613Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ConfigurationExample x8 S7 1200 USS v1d0 en 1

Transféré par

tuyetden613Droits d'auteur :

Formats disponibles

Cover sheet

Simple networking and cascading of drives

with S7-1200, SINAMICS G110 and KTP600

Configuration Example X8 y May 2009

Applications & Tools

Answers for industry.

Warranty, liability and support

Note

The application examples are not binding and do not claim to be

complete regarding configuration, equipment and any eventuality. The

application examples do not represent customer-specific solutions. They

are only intended to provide support for typical applications. You are

responsible for ensuring that the described products are used correctly.

These application examples do not relieve you of the responsibility to use

sound practices in application, installation, operation and maintenance.

When using these Application Examples, you recognize that Siemens

cannot be made liable for any damage/claims beyond the liability clause

described. We reserve the right to make changes to these application

examples at any time without prior notice. If there are any deviations

between the recommendations provided in these application examples

and other Siemens publications e.g. Catalogs the contents of the

other documents have priority.

Warranty, liability and support

We do not accept any liability for the information contained in this

document.

Any claims against us based on whatever legal reason resulting from

the use of the examples, information, programs, engineering and

performance data etc., described in this Application Example shall be

excluded. Such an exclusion shall not apply in the case of mandatory

liability, e.g. under the German Product Liability Act

("Produkthaftungsgesetz"), in case of intent, gross negligence, or injury of

life, body or health, guarantee for the quality of a product, fraudulent

concealment of a deficiency or breach of a condition which goes to the root

of the contract ("wesentliche Vertragspflichten"). However, claims arising

from a breach of a condition which goes to the root of the contract shall be

limited to the foreseeable damage which is intrinsic to the contract, unless

caused by intent or gross negligence or based on mandatory liability for

injury of life, body or health. The above provisions do not imply a change of

the burden of proof to your detriment.

Copyright 2009 Siemens I IA/DT. It is not permissible to transfer or

copy these Application Examples or excerpts thereof without the

express authorization from Siemens I IA/DT.

For questions about this document, please use the following e-mail

address:

online-support.automation@siemens.com

Configuration Example X8

V1.0, ID number: 37604154

1 Automation Task

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Table of Contents

1

1.1

1.2

1.3

Automation Task............................................................................................. 4

Application automation task.............................................................................. 4

Control components.......................................................................................... 4

Component list.................................................................................................. 5

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

Automation Solution ...................................................................................... 7

Connection diagram.......................................................................................... 7

Addressing of bus stations and terminating a RS485 bus with USS protocol... 8

Controlling bus stations via RS 485 bus ........................................................... 9

Technological Features .................................................................................. 11

Controlling the pumped amount...................................................................... 12

Balancing of operating hours .......................................................................... 13

Maintenance ................................................................................................... 14

3

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7

3.2

3.3

3.4

3.5

3.6

3.7

Configuration ................................................................................................ 16

Installing and wiring the hardware .................................................................. 16

Connect S7-1200 with PG/PC ........................................................................ 17

Load project in the S7-1200 CPU1214C ........................................................ 18

Load project into the SIMATIC Panel KTP600 ............................................... 19

Connect SIMATIC Panel KTP600 and S7-1200 CPU 1214C ......................... 20

Close off RS 485 bus with terminating resistors ............................................. 20

Parameterization of frequency converters ...................................................... 20

Enabling the pumps ........................................................................................ 25

Change language settings .............................................................................. 26

Moving pump P1 manually ............................................................................. 26

Move pump P1 to P4 automatically on demand ............................................. 28

Procedure with balancing of operating hours ................................................. 30

Procedure for excluding pump P3 due to servicing ........................................ 31

4

4.1

4.2

Code Elements.............................................................................................. 34

Preliminary remarks........................................................................................ 34

Download........................................................................................................ 34

History ........................................................................................................... 35

Configuration Example X8

V1.0, ID number: 37604154

1 Automation Task

Automation Task

1.1

Application automation task

A water user shall be supplied with water on demand via four pumps.

Assuming an output of 100% for each pump, an output of 400% is to be

generated by cascading all four pumps.

By switching pumps on and off an equal load for all pumps shall be ensured

taking into consideration the operating times. The pumping output of a

pump which has been released for maintenance shall be automatically

taken over by a pump with free capacity.

Apart from the above described automatic operation, it shall also be

possible to operate each pump manually.

In order to take into consideration the various pump types, it shall be

possible to operate all pumps in positive and negative direction.

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Figure 1-1

Service

Pump 1

Pump 2

Pump 3

Pump 4

Consumer

Water reservoir

1.2

Control components

Four asynchronous motors are each connected via the communication

module CM1241 (RS485) with the frequency converter SINAMICS G110

and are to be controlled by a S7-1200 controller (CPU1214C).

Communication between control and frequency converter will be performed

by USS protocol.

Operation and visualization takes place via a KTP600 touch panel which is

connected via an Ethernet connection to the S7-1200 controller.

Configuration Example X8

V1.0, ID number: 37604154

1 Automation Task

STEP7 Basic v10.5 is used as configuration tool for the control program

and the HMI.

Figure 1-2

3

Ethernet

USS Protokoll via RS485

s

5

J

O

G

F

M

P H6

J

O

G

O

N

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

z0

H5

0

zB

1234567891

U

O

0

S

F

F

1.3

F

M

P H6

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

5

1

J

O

G

F

M

P H6

J

O

G

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

1

Power module PM1207

Communication module CM 1241

Basic Panel KTP600

Frequency converter SINAMICS G110

F

M

P H6

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

SIMATIC S7-1200 CPU

Component list

Products

Table 1-1

Component

No.

MLFB / Order number

S7-1200 CPU1214C

6ES7 214-1AE30-0XB0

RS485 communication

module CM1241

6ES7 241-1CH30-0XB0

DC24V power supply unit

PM 1207

6EP1 332-1SH71

SINAMICS G110 120W

without filter; USS version,

FS A,

6SL3211-0AB11-2UB1

BOP

min. 1

6SL3255-0AA00-4BA1

Asynchronous motors 4pole, aluminum frame,

120W

1LA7060-4AB10

Simulator module for 14

inputs

6ES7 274-1XH30-0XA0

Basic KTP600 panel

(color, PN)

6AV6 647-0AD11-3AX0

Configuration Example X8

V1.0, ID number: 37604154

Note

DC/DC/DC

Optional

1 Automation Task

Accessory

Table 1-2

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Component

No.

Note

PROFIBUS cable:

Length [m]

PB FC Standard

Bus line 2-wire

Shielded

Lot size: Max. 1,000m

Minimum quantity:

20m (sold by the

meter)

6XV1830-0EH10

Profibus connector with

PG port

6ES7972-0BB12-0XA0

Adapter for attachment of

the SINAMICS frequency

converter FS A to the top

hat rail

6SL3261-1BA00-0AA0

Optional

Filter for low leakage

currents

6SE6400-2FL01-0AB0

Optional

Commutation inductor

6SE6400-3CC00-4AB3

Optional

Ethernet connection cables 2

between KTP600, S7-1200

CPU and PC

Note

MLFB / Order number

6XV1870-3QH20

The configuration, as it is, is intended for industrial application. For energy

supply, industrial networks are usually implemented. It is therefore not necessary

to use special filters/inductors with low leakage currents.

If the configuration is used in sensible electricity networks (e.g. PCs on the same

network), filters or inductors should be used.

Programming package

Table 1-3

Component

STEP 7 Basic V10.5

No.

1

MLFB / Order number

Note

6ES7 822-0AA0-0YA0

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Automation Solution

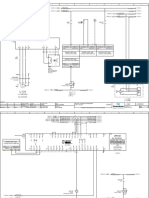

2.1

Connection diagram

Figure 2-1 Wiring

Contactor/

switch

Switch

Fuse

230VAC Fuse

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

KTP600

Inductor

(optional)

Inductor

(optional)

Inductor

(optional)

Inductor

(optional)

Filter

(optional)

Filter

(optional)

Filter

(optional)

Filter

(optional)

PSU 1200 CM1241 +

S7-1200 CPU1214C

Drive 1

Note

Drive 2

Drive 3

Drive 4

The 4-pole asynchronous motors with 400V/230V star/delta winding have

to be connected to the frequency converter in a delta connection

( 230V).

Figure 2-2 Wiring detail for bus connection

RS485 - CM1241

Terminal strip

PROFIBUS

cable

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Attention

What should be done to prevent electromagnetic interference:

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Make sure a good conductive connection between the frequency converter

and the (grounded) metal mounting plate is provided.

Ensure all devices in the cabinet are earthed using short earthing lines with a

large diameter and are connected to a common earthing point or earthing

bar.

Ensure that the S7-1200 CM connected to the frequency converter is

connected to the same earthing or earthing point as the frequency converter

using a short line with a large diameter.

Please use shielded control lines, e.g. a SIEMENS Profibus cable for setting

up the RS485 bus. Ground the shield on the converter side with shield

connections.

Control lines must be installed separately from power cables in separate

installation channels, if possible. Crossings between power and control lines

should be at 90 angle.

Connect the protective conductor of the motor to the earth connection (PE)

of the respective frequency converter.

The line ends should be properly terminated and unshielded lines kept as

short as possible.

Use shielded lines for motor connections, earth the shielding both on the

converter and the motor side using cable clamps.

2.2

Addressing of bus stations and terminating a RS485 bus with

USS protocol

An RS485 bus transmitting data using the USS protocol via a 2-wire

connection between a master (e.g. CPU 1214C) and up to 31 slaves

(e.g. SINAMICS G110). It is necessary here to identify each slave via a

unique address between 1 and 31.

The USS protocol allows only one master which does not require an

assigned address.

In order to avoid reflections at the bus start or end, which may cause a

falsified data signal, the bus must be closed off with terminating resistors as

illustrated in Figure 2-4.

As illustrated in Figure 2-5, in this example it is done on the control side via

the PROFIBUS connector and at SINAMICS G110 of pump 4 by switching

on both assigned DIP switches below the BOP.

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Figure 2-3

B

A

B

A

J

O

G

F

M

P H6

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

1

J

O

G

F

M

P H6

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

1

J

O

G

F

M

P H6

O

N

z0

H5

B

z0

1234567891

U

O

0

S

F

F

1

J

O

G

F

M

P H6

O

N

z0

H5

0

zB

1234567891

U

O

0

S

F

F

1

Pump 1

Pump 2

Pump 3

Pump 4

Address: 1

Address: 2

Address: 3

Address: 4

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Figure 2-4

Switch to ON

2.3

Controlling bus stations via RS 485 bus

USS protocol

The USS protocol was developed in order to exchange process data

between a central controller and bus stations on a RS485 bus. Each bus

station is identified here via a unique bus address.

Even if PROFIBUS uses the same physical RS485 technology, PROFIBUS

and USS protocol differ considerably.

Communication of the S7-1200 controller is performed via the

communication module with the bus station by integrating the STEP7 Basic

library included in delivery.

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Communication with bus stations

For a command to be sent from control to the bus station, a function is

necessary that controls communication between CPU and the bus stations.

This is achieved using the "USS_PORT" block.

During each call of the block, the communication with a bus station is

processed. Communication with the bus stations is asynchronous. This

means that the S7-1200 controller runs several cycles before the data

exchange with a bus station is completed. This is why the block is usually

called from a delay alarm OB in a defined interval. However, it can also be

called up cyclically, which does not increase the number of transactions.

The "port" block parameter specifies the communication module via which

the bus is connected. The "USS_DB" parameter defines the

"USS_DRV_DB" instance data block in which the send and receive data is

called up or stored (Figure 2-5). The instance data block is a buffer which

all USS_Operations can access.

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Note

An extensive description of the blocks and a calculation of the call

intervals of "USS_PORT", depending on the transmission rate can be

found in the S7-1200 system manual, chapter 6.3.

Transferring and reading data to bus stations

The "USS_DRV" block exchanges data with the bus station by creating

request messages and evaluating answer messages. The instance data

block is used as storage. For each bus station an own "USS_DRV" block

has to be used.

Up to 16 called "USS_DRV" blocks share an instance data block. Up to

16 bus stations can be managed with a "USS_DRV" block.

Using the parameters on the left side of the "USS_DRV" block the switchon signal (RUN), for example, or the desired speed is sent to the assigned

bus station.

The status signals of the bus station are provided by block "USS_DRV" on

the right block side. The current speed of the bus station is indicated by the

parameter "Speed" (Figure 2-5).

10

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Figure 2-5

USS_DRV_DB

Reserved

1

Data Drive 1

State

2

3

Communication via RS485

4

5

Control

6

7

8

9

s

s

10

11

12

13

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

14

15

16

2.4

J

O

G

F

M 6

P

H

O

N

z0

H5

B

z0

1234567891

U

O

0

S

F

F

1

Address 1

Technological Features

As mapped out in Figure 2-6, the control program takes into consideration

that activated and cascaded pumps must have an identical flow rate. This

prevents the throttle check valves from reducing the water flow rate.

Figure 2-6

Throttle check valve

Consumer

Pump 4

Water reservoir

Configuration Example X8

V1.0, ID number: 37604154

11

2 Automation Solution

The delivery head H of each pump depends on the conveying current Q.

Figure 2-7 shows how the delivery head is increased for a quadrupled

conveying current when cascading 4 pumps.

Figure 2-7

Systems duty point

Delivery head H

Characteristic

1 Pump

Characteristic

2 Pumps

Characteristic

3 Pumps

Characteristic

4 Pumps

Btot.

Bthree

Btwo

System characteristic

Bindividual

Qindividual

Q2P parallel

Q3P parallel

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Q4P parallel

100%

200%

300%

400%

Conveying current Q

2.5

Controlling the pumped amount

The control algorithm shall be explained using the following graphic.

12

The algorithm controls pump P1 when demand <100%

If the demand increases to >100% and remains below 200%, the load is

distributed between pump P1 and P2. For a load of 200% both pumps

are used at 100% load each.

If the demand increases to >200% and remains below 300%, the load is

distributed between pump P1, P2 and P3. For a load of 300% all

3 pumps are used at 100% load each.

If the demand increases to >300% and remains below 400%, the load is

distributed between pump P1, P2, P3 and P4. For a load of 400% all

4 pumps are used at 100% load each.

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

Figure 2-8

400%

Setpoint

2/3

1

3/4

P1

1/2

0

2/3

2/3

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

2.6

15

20

P2

1

3/4

10

15

P3

1/2

10

1

3/4

P4

1/2

Note

10

1/2

0

2/3

1

3/4

The used algorithm assumes that all used pumps have the same

characteristics!

Balancing of operating hours

Recording the pump operating hours

The control program records the operating hours of each pump. As soon as

a pump is running (even if only slowly) it is considered as switched on.

The speed of the pumps does not enter the calculation of the operating

hours. Only the effective runtimes are calculated.

Switch-on priorities of the frequency converters

Each pump is assigned a priority, which controls which pump will be

switched on next when required. The pump with the lowest operating time

receives the highest priority. This means that this pump is the next to be

switched on if required.

The control algorithm shall be explained using the following graphic Figure

2-9.

The algorithm controls pump P4 if the demand is <100%, since with

5 hours it has the lowest amount of operating hours.

If the demand increases to >100% and remains below 200%, the load is

distributed between pump P4 and P3. Pump P3 is selected as with

10 hours it has the lowest number of operating hours. For a load of

200% both pumps are used at 100% load each.

Configuration Example X8

V1.0, ID number: 37604154

13

2 Automation Solution

If the demand increases to >200% and remains below 300%, the load is

distributed between pump P4, P3 and P2. Pump P2 is selected as with

15 hours it has the lowest number of operating hours. For a load of

300% all 3 pumps are used at 100% load each.

If the demand increases to >300% and remains below 400%, the load is

distributed between pump P4, P3, P2 and P1. For a load of 400% all

4 pumps are used at 100% load each.

Figure 2-9

400%

Setpoint

2/3

1

3/4

1/2

20

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

2/3

25

15

15

20

25

P1

P2

1

3/4

P3

1/2

10

15

20

25

1

3/4

P4

1/2

2.7

20

1/2

10

2/3

20

1

3/4

15

2/3

20

10

15

20

25

Maintenance

The plant also offers the possibility of excluding individual pumps from the

process, e.g. during failure or if a pump needs to be serviced (as shown in

Figure 2-10).

As long as the requested water consumption is lower or equal 300%, and

an active pump is taken out of the group for servicing, its task is taken over

by a pump which is inactive at that time.

The control algorithm shall be explained using the following graphic.

14

The algorithm controls pump P1 when demand <100%

If the demand increases to >100% and remains below 200%, the load is

distributed between pump P1 and P2. For a load of 200% both pumps

are used at 100% load each.

If the demand increases to >200% and remains below 300%, the load is

distributed between pump P1, P2 and P4. Since pump P3 is not

available due to maintenance works, the task is taken on by pump P4.

For a load of 300% all 3 pumps are used at 100% load each.

Configuration Example X8

V1.0, ID number: 37604154

2 Automation Solution

After terminating the maintenance works and enabling the maintained

pump, it is reintegrated into the process according to the above rules.

Figure 2-10

400%

300%

2/3

Setpoint

1

3/4

1/2

0

2/3

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

2/3

2/3

10

15

20

P1

1

3/4

1/2

P2

10

3/4

10

15

10

15

P3

1/2

1

3/4

P4

1/2

Configuration Example X8

V1.0, ID number: 37604154

15

3 Configuration

Configuration

3.1.1

Installing and wiring the hardware

Table 3-1

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

No.

Instruction

Note/picture

1.

Mount

the fuse

the PM 1207 power supply unit

the S7-1200 CPU 1214C

the CM1241

and the frequency converters

on a top hat rail.

2.

Mount the motors onto a suitable fixture.

3.

Connect the controller to the 24 V DC

supply voltage of the PM 1207

See Figure 2-1

4.

Connect the frequency converters with

the motors.

See Figure 2-1

5.

Connect the PROFIBUS cable with the

S7-1200 CM1241 and the frequency

converters

See Figure 2-2

6.

Connect all ground connections to earth.

Note

For simulating the release of all frequency converters (status I0.0 to I0.3

= "1") we recommend using the simulator module (1214C - 14 E/A).

At this point it is assumed that the necessary software has been installed

on your computer and that you are familiar with handling the software.

Furthermore it is assumed, that STEP7 Basic V10.5 has been installed

on the standard Windows PC for operator control.

16

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

!

WARNING

3.1.2

Please carefully read all safety and warning notices given in the

operating instructions on the frequency converter and all warning

labels attached to the device before doing any installation and

commissioning procedures. Please maintain warning labels in a

legible condition and do not remove them from the device.

Connect S7-1200 with PG/PC

Table 3-2

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

No.

Function

1.

Connect your development system (PG/PC) to the S71200 CPU, using an Ethernet cable.

2.

Open the network connection in the control panel of the

PG/PC.

3.

Open the properties of the network connection.

4.

Open the Internet Protocol (TCP/IP) Properties

5.

In "General", select "Use the following IP address" and

set the address:

IP address: 192.168.1.10

Subnet: 255.255.255.0

6.

Confirm with OK to close all windows

Configuration Example X8

V1.0, ID number: 37604154

Remarks

17

3 Configuration

3.1.3

Load project in the S7-1200 CPU1214C

Table 3-3

No.

1.

Function

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Extract the included project (*.zip) onto your hard disk

drive.

Open the extracted S7-1200 project (*.ap10 file)

using STEP7 Basic V10.5

2.

Change from the portal view to the project view.

3.

Click project navigation on PLC_1 [CPU 124C

DC/DC/DC] with the right mouse button

4.

Select "Dowload to device" "All"

5.

Set the checkmark in the "Instruction" column and click

"Load"

6.

The hardware configuration and the program are loaded

into the CPU.

7.

After loading confirm that the CPU is set to RUN.

18

Remarks

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

3.1.4

Load project into the SIMATIC Panel KTP600

Table 3-4

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

No.

Instruction

1.

2.

Select the "Transfer" button after the "bootloader"

sequence.

The panel is now ready for loading the project.

3.

Click HMI_1 [KTP600] with the right mouse in the project

navigation

4.

Select "Download to device" "All"

5.

Set the checkmark in the "Instruction" column and click

"Download"

6.

The HMI project is loaded. The panel starts automatically

after completion.

Remarks

Connect KTP600 with a DC 24V power supply

Connect your development system (PG/PC) with the

KTP600 using an Ethernet cable

Configuration Example X8

V1.0, ID number: 37604154

19

3 Configuration

3.1.5

Connect SIMATIC Panel KTP600 and S7-1200 CPU 1214C

Table 3-5

No.

Function

Remarks

Once the S7-1200 project was successfully loaded,

connect the KTP600 with the S7-1200 CPU1214C, using

an Ethernet cable.

1.

3.1.6

Close off RS 485 bus with terminating resistors

Table 3-6

No.

1.

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Function

2.

Remarks

Remove the BOP of the frequency converter (last bus

station) of pump P4

For activating the terminating resistor you change the

DIP switch as follows:

50Hz: 1=OFF, 2=ON, 3=ON

60Hz: 1=ON, 2=ON, 3=ON

Snatch the BOP back to the frequency converter

In order to activate the terminating resistor at the

controller (first bus station) please bring the switch to

position "ON"

3.1.7

Parameterization of frequency converters

Parameterizing the frequency converter of pump P1 (address 1)

Table 3-7

Step

Instruction

Remarks

1.

Set the BOP to the SINAMICS G110 frequency

converter to whom address 1 is to be assigned

2.

In order to change a parameter proceed as follows:

Switch to parameterization mode: P

Select parameter with cursor:

20

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Step

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

3.

Instruction

Select parameter: P

Select value with cursor:

Accept value: P

Remarks

To set the traversing parameter proceed as follows:

Function

Parameters

Value

Resetting the frequency converter to delivery

status

P0010

30

P0970

P0010

Start the quick startup

Check the parameter setting to suit the

DIP switch:

Europe 50Hz, power in kW 1

Rated motor voltage

P0100

P0304

230 V

Rated motor output

P0307

0.12 kW

Rated motor frequency

P0310

50 Hz

Rated motor speed

P0311

1350 r/min

Command source (USS)

P0700

Frequency setpoint

P1000

Minimum motor frequency

P1080

0.0 Hz

Maximum motor frequency

P1082

50.0 Hz

Startup ramp

P1120

10.0 s

Delay ramp

P1121

10.0 s

End of the quick start

P3900

Activate Expert mode

P0003

Reference frequency

P2000

50.0 Hz

Data transmission speed 57,600 b/s

P2010

Address (Slave)

P2011

USS PZD length

P2012

USS PKW length

P2013

Communication monitoring:

Value 0 without monitoring

P2014

Save data in EPROM

P0971

These values are preset depending on the position of the DIP switch at the front of the

SINAMICS G110 (except for parameter value 2). Details on interaction of P0100 and position of

the DIP switch are given in the parameter list of SINAMICS G110. Parameter value and

position of the DIP switch must be related to parameter value 0 and 1!

Configuration Example X8

V1.0, ID number: 37604154

21

3 Configuration

Step

4.

5.

Instruction

Remarks

To secure the parameters in BOP proceed as follows:

Function

Parameters

Value

Activate Expert mode

P0003

Activate Parameterization mode

P0010

30

Transfer parameters from G110 to BOP

P0802

In order to depict the current frequency during

runtime, select the parameter P0000 and press

the P button

Parameterizing the frequency converter of pump P2 (address 2)

Table 3-8

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Step

Instruction

Remarks

1.

Unplug the BOP from the frequency converter

of pump P1 and plug it to the second

SINAMICS G110 (for pump 2).

2.

In order to change a parameter proceed as follows:

Switch to parameterization mode: P

Select parameter with cursor:

Select parameter: P

Select value with cursor:

Accept value: P

3.

4.

22

To adopt the settings of the second frequency converter and adjust the address

proceed as follows:

Function

Parameters

Value

Activate Expert mode

P0003

Activate Parameterization mode

P0010

30

Transfer parameters from BOP to G110

P0803

Change the address to 2

P2011

Save data in EPROM

P0971

In order to depict the current frequency during

runtime, select the parameter P0000 and press

the P button

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Parameterizing the frequency converter of pump P3 (address 3)

Table 3-9

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Step

Instruction

Remarks

1.

Unplug the BOP from the frequency converter

of pump P2 and plug it to the third SINAMICS

G110 (for pump 3).

2.

In order to change a parameter proceed as follows:

Switch to parameterization mode: P

Select parameter with cursor:

Select parameter: P

Select value with cursor:

Accept value: P

3.

4.

To adopt the settings of the third frequency converter and adjust the address

proceed as follows:

Function

Parameters

Value

Activate Expert mode

P0003

Activate Parameterization mode

P0010

30

Transfer parameters from BOP to G110

P0803

Change the address to 3

P2011

Save data in EPROM

P0971

In order to depict the current frequency during

runtime, select the parameter P0000 and press

the P button

Configuration Example X8

V1.0, ID number: 37604154

23

3 Configuration

Parameterizing the frequency converter of pump P4 (address 4)

Table 3-10

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Step

Instruction

Remarks

1.

Unplug the BOP from the frequency converter

of pump P3 and plug it to the fourth SINAMICS

G110 (for pump 4).

2.

In order to change a parameter proceed as follows:

Switch to parameterization mode: P

Select parameter with cursor:

Select parameter: P

Select value with cursor:

Accept value: P

3.

4.

Note

24

To adopt the settings of the fourth frequency converter and adjust the address

proceed as follows:

Function

Parameters

Value

Activate Expert mode

P0003

Activate Parameterization mode

P0010

30

Transfer parameters from BOP to G110

P0803

Change the address to 4

P2011

Save data in EPROM

P0971

In order to depict the current frequency during

runtime, select the parameter P0000 and press

the P button

Ensure that a blinking light is visible at the SINAMICS G110. If this is not the

case, it is in operation and a configuration is not possible.

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

3.2

Enabling the pumps

Table 3-11

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Step

Instruction

1.

To enable pumps P1 to P4 you change the

status of the following inputs "1":

I0.6

I0.7

These two inputs switch the OFF2 and OFF3

inputs at the "USS_DRV" block.

They are wire-break safe and have to be set

before the pumps are released

2.

To enable pumps P1 to P4 you change the

status of the following inputs "1":

I0.0

I0.1

I0.2

I0.3

These four inputs enable a pump each. They

enable the RUN input at the "USS_DRV" block.

The block is enabled when the OFF2 and OFF3

inputs are set to "1" first.

Configuration Example X8

V1.0, ID number: 37604154

Figure/short note

25

3 Configuration

3.3

Change language settings

Table 3-12

Step

Instruction

1.

Press the "Sys" button in order to access the

Control Panel.

2.

Press the "German" button in order to be

able to control the plant in German

language.

Press the "English" button in order to be

able to control the plant in English

language.

Alternatively you can swap between the

languages in each operator display via

softkey F1.

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

3.4

Figure/short note

Moving pump P1 manually

In manual operation the setpoint speed value for each motor is given

individually.

Table 3-13

Step

1.

Instruction

2.

26

Figure/short note

In order to select the manual mode press

the "Manual Mode" button

The label of this button will subsequently

display "Auto Mode"

Change to the operator screen of pump P1,

by pressing the "P1" button.

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Step

3.

Instruction

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Figure/short note

Press the selected button until the left bar

shows a setpoint speed value of 100%.

Due to the ramp of 10 sec configured in

the frequency converter, the actual speed

value is delayed. This ramp causes a

delayed rise of the actual speed value in

form of the right-hand bar.

4.

Change the rotation direction by pressing

button I0.4

The rotational speed actual value will

drop to standstill

The rotation direction of the motor is

changed

The actual speed value will increase

again to 100%

5.

Turn off pump P1 via switch I0.6 (with break)

or I0.7 (without break) through the hardware.

This function is the same as an emergency

stop.

6.

To enable pump P 1 again, turn switch I0.6 or

I0.7 back on again.

Furthermore turn switch I0.0 off and on again,

so that the edge for the release is performed

again at the "USS_DRV" block.

7.

The pump starts running again.

8.

Switch off pump P1 by pressing the STOP

button.

Configuration Example X8

V1.0, ID number: 37604154

27

3 Configuration

3.5

Move pump P1 to P4 automatically on demand

In automatic operation one setpoint value is assigned for all pumps. The

startup program automatically calculates the setpoint value for the

individual pumps.

Table 3-14

Step

1.

Instruction

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

2.

3.

4.

28

Figure/short note

In order to select the automatic mode

press the "Auto Mode" button

The label of this button will subsequently

display "Manual Mode"

Increase the setpoint value to 100%.

The speed of pump P1 increases with a

delay also to 100% of the maximum value

The BOP of the frequency converter of

pump P1 shows 50 Hz

Increase the setpoint value to 120%.

Since pump P1 cannot handle this load

by itself, it is now distributed to pump P1

and P2. Both pumps P1 and P2 are now

respectively operated with a speed of

60% of the maximum value

The BOP of the frequency converter of

pump P1 and P2 now shows 30 Hz

Increase the setpoint value to 200%.

The speed of pumps P1 and P2

increases with a delay to 100% of the

maximum value respectively

The BOP of the frequency converter of

pump P1 and P2 now shows 50 Hz

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Step

5.

Instruction

6.

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

7.

8.

9.

Figure/short note

Increase the setpoint value of the pumps

to 220%.

Since the pumps P1 and P2 cannot

handle this load alone, it is now

distributed between pump P1, P2 and P2.

All three pumps P1, P2 and P3 are now

respectively operated with a speed of

73% of the maximum value

The BOP of the frequency converter of

pump P1, P2 and P3 now shows

36.67 Hz

Increase the setpoint value of the pumps

to 300%.

The speed of pumps P1, P2 and P3

increases with a delay to 100% of the

maximum value respectively

The BOP of the frequency converter of

pump P1, P2 and P3 now shows 50 Hz

Now increase the setpoint value of the

pumps to 320%.

Since the pumps P1, P2 and P3 cannot

handle this load alone, it is now

distributed between pump P1, P2, P3 and

P4. The four pumps P1, P2, P3 and P4

are now respectively operated with a

speed of 80% of the maximum value

The BOP of the frequency converter of

pump P1, P2, P3 and P4 now shows

40 Hz

Increase the setpoint value of the pumps

to 400%.

The speed of pumps P1, P2, P3 and P4

increases with a delay to 100% of the

maximum value respectively

The BOP of the frequency converter of

pump P1, P2, P3 and P4 now shows

50 Hz

Stop the pumps by pressing the STOP button.

Configuration Example X8

V1.0, ID number: 37604154

29

3 Configuration

3.6

Procedure with balancing of operating hours

Operating the plant with balancing of operating hours causes the pump with

the least operating hours being added upon addition of a further pump.

Table 3-15

Step

1.

Instruction

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

2.

3.

4.

30

Figure/short note

In order to select the automatic mode

press the "Auto Mode" button

The label of this button will subsequently

display "Manual Mode"

For the current operating hours of pump

P1 to P4 you set the following values:

P1: 20

P2: 15

P3: 10

P4: 05

To do this you select the marked field,

enter the desired value and acknowledge

the input by pressing the Return key

20

15

10

P1

P2

P3

20

15

10

20

15

10

12

P4

Press the selected buttons in order to

recalculate the pump priority and to

activate the counting of operating hours.

Increase the setpoint value to 100%.

The speed of pump P4 increases with a

delay also to 100% of the maximum value

The BOP of the frequency converter of

pump P4 shows 50 Hz

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Step

5.

Instruction

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

6.

7.

Increase the setpoint value to 120%.

Since pump P4 cannot handle this load

by itself, it is now distributed to pump P4

and P3. Both pumps P4 and P3 are now

respectively operated with a speed of

60% of the maximum value

The BOP of the frequency converter of

pump P4 and P3 now shows 30 Hz

Now press the "Recalc Balance" button.

The pump priorities are then recalculated.

If at this time the operating hours of pump

P3 and P4 are higher than that of pump

P1 and P2, pump P1 and P2 take on the

tasks of pump P3 and P4. Both pumps P3

and P4 are then switched off.

Figure/short note

20

15

21

16

20

15

21

16

20

15

21

16

In order to terminate this scenario you press

the STOP button.

3.7

Procedure for excluding pump P3 due to servicing

In the case of servicing, it shall be possible to directly deactivate a pump for

maintenance works, and its tasks shall be automatically taken on by

another pump

Table 3-16

Step

1.

Instruction

For the current operating hours of pump

P1 to P4 you set the following values:

P1: 0

P2: 0

P3: 0

P4: 0

To do this you select the marked field,

enter the desired value and acknowledge

the input by pressing the Return key

Configuration Example X8

V1.0, ID number: 37604154

Figure/short note

P1

P2

P3

P4

31

3 Configuration

Step

2.

Instruction

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Activate the counting of operating hours

by pressing the "Count up seconds"

button

Update the pump priority by pressing the

"Recalc Balance" button.

3.

Change into automatic operation of the plant

by pressing the "Auto Mode" button.

4.

5.

6.

Figure/short note

Increase the setpoint value of the pumps

to 220%.

All three pumps P1, P2 and P3 are now

respectively operated with a speed of

73% of the maximum value

The BOP of the frequency converter of

pump P1, P2 and P3 now shows 36.67

Hz

Withdraw the release for pump P3 by

switching off input I0.2.

The right image shows how the load of

pump P3 was taken over by pump P4.

Increase the setpoint value of the pumps

further to 300%.

300,0

32

Configuration Example X8

V1.0, ID number: 37604154

3 Configuration

Step

7.

Instruction

Increase the setpoint value to over 300%.

A demand of over 300%, however,

cannot be managed, since only 3 pumps

are available. A respective message

informs of this condition.

Acknowledge the message box by

pressing the "!" icon ".

Close the dialog box by pressing "x"

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

Figure/short note

Configuration Example X8

V1.0, ID number: 37604154

33

4 Code Elements

Code Elements

4.1

Preliminary remarks

We offer you software examples with test code and test parameters as a

download. These software examples support you in the first steps and tests

with the configuration examples.

The software examples are always assigned to the components used in the

Configuration Example and show their basic interaction. However, they are

not real applications in the sense of technological problem solving with

definable properties.

4.2

Download

The software examples are available on the HTML page from which you

downloaded this document.

Table 4-1

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

File name

2009.06.05_CE_x8_V1d0.zip

34

Contents

STEP 7 Basic project for S7-1200

CPU1214C and KTP600

Configuration Example X8

V1.0, ID number: 37604154

5 History

History

Table 5-1

Version

20.05.2009

Modifications

First version

Copyright Siemens AG 2009 All rights reserved

ConfigurationExample_x8_S7-1200_USS_v1d0_en.doc

V1.0

Date

Configuration Example X8

V1.0, ID number: 37604154

35

Vous aimerez peut-être aussi

- 214 Bo Thu Trong Tieng TrungDocument2 pages214 Bo Thu Trong Tieng TrungVũ ĐanPas encore d'évaluation

- Vacon 100 INDUSTRIAL Application Manual DPD00927J UKDocument360 pagesVacon 100 INDUSTRIAL Application Manual DPD00927J UKSayam SawanyakulPas encore d'évaluation

- Pinyin - Chinese Pinyin Table (Horizontal)Document1 pagePinyin - Chinese Pinyin Table (Horizontal)JennelynPas encore d'évaluation

- FM Fire Pump Inspection Checklist and FormDocument4 pagesFM Fire Pump Inspection Checklist and Formkrunalb@inPas encore d'évaluation

- Vacon NX All in One Application Manual DPD00903F UK PDFDocument398 pagesVacon NX All in One Application Manual DPD00903F UK PDFtuyetden613Pas encore d'évaluation

- Sieps80000015d 8 1 PDFDocument578 pagesSieps80000015d 8 1 PDFZjmmy JonhPas encore d'évaluation

- Electric Generator GSW1120M NewDocument7 pagesElectric Generator GSW1120M Newtuyetden613Pas encore d'évaluation

- Modular. Powerful. Easy To Use. Innovations - With Firmware V2.0 & V3.0Document2 pagesModular. Powerful. Easy To Use. Innovations - With Firmware V2.0 & V3.0tuyetden613Pas encore d'évaluation

- DS PRK46BEx en 50109200Document4 pagesDS PRK46BEx en 50109200tuyetden613Pas encore d'évaluation

- A0905 00 9520 G4Document119 pagesA0905 00 9520 G4tuyetden613100% (1)

- Standard Electrical SymbolsDocument40 pagesStandard Electrical Symbolssilviamenegazzo100% (13)

- Distance SensorDocument5 pagesDistance Sensortuyetden613Pas encore d'évaluation

- Why Did Windows Crash. A Troubleshooting GuideDocument15 pagesWhy Did Windows Crash. A Troubleshooting Guidetuyetden613Pas encore d'évaluation

- PLC ExamplesDocument78 pagesPLC ExamplesMuhammad Mahfud RosyidiPas encore d'évaluation

- Customer Documentation Extinguisher Type E-HRDDocument18 pagesCustomer Documentation Extinguisher Type E-HRDtuyetden613100% (1)

- Maxxflow HTC ManualDocument24 pagesMaxxflow HTC Manualtuyetden613Pas encore d'évaluation

- Intouch 9Document19 pagesIntouch 9VICTORSJPas encore d'évaluation

- Circuit Diagrams P160110 Rev.0Document24 pagesCircuit Diagrams P160110 Rev.0tuyetden613Pas encore d'évaluation

- Program Comments Network Title Network CommentDocument10 pagesProgram Comments Network Title Network Commenttuyetden613Pas encore d'évaluation

- Adaptive ControlDocument1 pageAdaptive Controltuyetden613Pas encore d'évaluation

- 03PLC ModelDocument1 page03PLC Modeltuyetden613Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 78-SAFETY - QUESTIO in PDFDocument21 pages78-SAFETY - QUESTIO in PDFIndermohan MehtaPas encore d'évaluation

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Document38 pagesMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسPas encore d'évaluation

- Belbin's Team ModelDocument2 pagesBelbin's Team Modelsonu_saisPas encore d'évaluation

- 63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebDocument2 pages63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebAradhana AradhanaPas encore d'évaluation

- ROV Inspection and Intervention VesselDocument2 pagesROV Inspection and Intervention VesselAhmad Reza AtefPas encore d'évaluation

- 027 03 Dec13 CseDocument647 pages027 03 Dec13 CseParth NagarPas encore d'évaluation

- A-W and A-F Oil SeparatorsDocument1 pageA-W and A-F Oil SeparatorstribleprincePas encore d'évaluation

- IB Biology Lab Report TemplateDocument6 pagesIB Biology Lab Report TemplatebigbuddhazPas encore d'évaluation

- Soft Sculpture EventsDocument28 pagesSoft Sculpture EventsAlabala BalaaPas encore d'évaluation

- 4 MFL67658602 00 160519 1Document329 pages4 MFL67658602 00 160519 1Cédric MorisotPas encore d'évaluation

- Pepperdine Resume Ico William Kong Updated BDocument1 pagePepperdine Resume Ico William Kong Updated Bapi-278946246Pas encore d'évaluation

- 01-Toy Product DesignDocument54 pages01-Toy Product DesignJuanPas encore d'évaluation

- SOS Children's Village: by Bekim RamkuDocument21 pagesSOS Children's Village: by Bekim RamkuAbdulKerim AyubPas encore d'évaluation

- 4 Chacon Et Al 2004Document7 pages4 Chacon Et Al 2004Luis Serrano CortezPas encore d'évaluation

- Pdlgfu15: PDLGFU15 User's GuideDocument327 pagesPdlgfu15: PDLGFU15 User's Guidejose antonio carazoPas encore d'évaluation

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ADocument11 pagesPurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalPas encore d'évaluation

- Indian Council of Medical ResearchDocument6 pagesIndian Council of Medical Researchram_naik_1Pas encore d'évaluation

- 4naa7 4eeDocument2 pages4naa7 4eeDorottya HózsaPas encore d'évaluation

- Hotel Organizational StructureDocument3 pagesHotel Organizational StructureChi LinhPas encore d'évaluation

- Important Questions - BlockchainDocument1 pageImportant Questions - BlockchainHarsh Varshney100% (1)

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Document23 pagesReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- Avenger 220 Cruise Street BS IVDocument79 pagesAvenger 220 Cruise Street BS IVShubham AatopartsPas encore d'évaluation

- CSR of Pidilite PDFDocument2 pagesCSR of Pidilite PDFtarang keraiPas encore d'évaluation

- One Word SubstitutionDocument5 pagesOne Word SubstitutionPranaykant Singh PanwarPas encore d'évaluation

- Amiel Houser - LévinasDocument8 pagesAmiel Houser - Lévinaschristyh3Pas encore d'évaluation

- Mcs Text BookDocument309 pagesMcs Text Bookkancha_basu2447100% (1)

- Refraction Through A Lens PDFDocument3 pagesRefraction Through A Lens PDFPrudhvi JoshiPas encore d'évaluation

- TEST Unit 5Document5 pagesTEST Unit 5Giang Nguyen Thi ThuPas encore d'évaluation

- 20-12-11 Ericsson V, Samsung EDTX ComplaintDocument22 pages20-12-11 Ericsson V, Samsung EDTX ComplaintFlorian MuellerPas encore d'évaluation

- Intro Ducci OnDocument38 pagesIntro Ducci OnCARLOS EDUARDO AGUIRRE LEONPas encore d'évaluation