Académique Documents

Professionnel Documents

Culture Documents

Variation

Transféré par

অর্ঘ্য রায়Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Variation

Transféré par

অর্ঘ্য রায়Droits d'auteur :

Formats disponibles

variation. In addition there are skin depth limitations.

Without

saturation, the initial permeability of steel products can range from 50 to over 500. Since

depth of penetration is inversely proportional to the square root of permeability and test

frequency, to obtain equal penetration requires a reduction in frequency by the same factor of

50 to over 500. Unfortunately, lowering frequency will move the operating point to where

there is poor signal separation between lift-off, permeability and resistivity as well as reduced

sensitivity to defects. Therefore magnetic saturation is required to suppress effects of usually

harmless permeability variations, which could be mistaken for or obscure, defect signals.

4.4.1 Vibrations

Vibrations during probe motion can make undesirable signals, or so called probe wobble.

The multi-frequency technique can suppress this effect can by making the amplitude of its

response at the first frequency equal and its phase 180 degrees away from the response at the

second frequency and then adding the two signals together. The resulting sum will result in

cancellation of the responses and thus a zero signal for that particular condition.

When a surface coil is energized and held in air above a conductor the impedance of the coil

has a certain value. As the coil is moved closer to the conductor the initial value will change

when the field of the coil begins to intercept the conductor. Because the field of the coil is

strongest close to the coil, the impedance value will continue to change until the coil is

directly on the conductor. Conversely, once the coil is on the conductor any small variation in

the separation of coil and conductor will change the impedance of the coil. The lift off effect

is so pronounced that small variations in spacing can mask many indications.

The lift off effect is regularly used to measure the thickness of non conductive coatings.

The angle of orientation (tilt) of the probe will also have a significant impact of coupling

efficiency. The use of mechanical guide/holders and spring loaded probes can assist in

reducing the effect of lift off.

4.4.3 Centring, fill factor

In an encircling coil, or an internal coil, fill factor is a measure of how well the conductor (test

specimen) fits the coil. It is necessary to maintain a constant relationship between the

diameter of the coil and the diameter of the conductor. Again, small changes in the diameter

of the conductor can cause changes in the impedance of the coil. This can be useful in

detecting changes in the diameter of the conductor but it can also mask other indications.

For an external coil:

Fill Factor = (D1/D2)2

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ATS Basics - Finning Cat Feb 16 2021Document41 pagesATS Basics - Finning Cat Feb 16 2021ntrkulja@hotmail.comPas encore d'évaluation

- ABS, Diagnostic Trou Ble CodesDocument3 pagesABS, Diagnostic Trou Ble CodesEudis Pineda100% (1)

- CQI 9 Heat Treatment Rev 01Document64 pagesCQI 9 Heat Treatment Rev 01ukavathekar0% (1)

- Wabco Cross Reference PDFDocument360 pagesWabco Cross Reference PDFNEKHIL MATTAAPas encore d'évaluation

- Shyam Enterprises - Unit - Ii Contingency Plan For Abnormal ConditionsDocument4 pagesShyam Enterprises - Unit - Ii Contingency Plan For Abnormal Conditionsঅর্ঘ্য রায়Pas encore d'évaluation

- Samsung Compressor 2020Document70 pagesSamsung Compressor 2020Francisco Seijas100% (3)

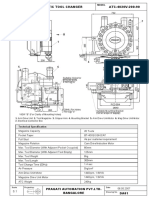

- Atc 4020V 200 90Document1 pageAtc 4020V 200 90Lokesh Loki100% (1)

- (C L, Z L) : Orch RagonDocument1 page(C L, Z L) : Orch Ragonঅর্ঘ্য রায়Pas encore d'évaluation

- NCERT Solution For Cbse Class 9 Maths Chapter 2 Polynomials PDFDocument31 pagesNCERT Solution For Cbse Class 9 Maths Chapter 2 Polynomials PDFঅর্ঘ্য রায়Pas encore d'évaluation

- IAQMDocument1 pageIAQMঅর্ঘ্য রায়Pas encore d'évaluation

- Sting With 70 PDFDocument1 pageSting With 70 PDFঅর্ঘ্য রায়Pas encore d'évaluation

- Characterization of Material Properties by UltrasonicsDocument14 pagesCharacterization of Material Properties by UltrasonicsHendi AfriyanPas encore d'évaluation

- Sting WithDocument1 pageSting Withঅর্ঘ্য রায়Pas encore d'évaluation

- Discovery and Reasoning in Mathematics'Document10 pagesDiscovery and Reasoning in Mathematics'অর্ঘ্য রায়Pas encore d'évaluation

- BABS UNSW Australia Protocols 1MNa2CO3Document1 pageBABS UNSW Australia Protocols 1MNa2CO3অর্ঘ্য রায়Pas encore d'évaluation

- On Their EducationDocument2 pagesOn Their Educationঅর্ঘ্য রায়Pas encore d'évaluation

- Discovery and Reasoning in Mathematics'Document10 pagesDiscovery and Reasoning in Mathematics'অর্ঘ্য রায়Pas encore d'évaluation

- Ive Aion RportDocument4 pagesIve Aion Rportঅর্ঘ্য রায়Pas encore d'évaluation

- Characterization of Material Properties by UltrasonicsDocument14 pagesCharacterization of Material Properties by UltrasonicsHendi AfriyanPas encore d'évaluation

- 11 (1) 1Document24 pages11 (1) 1অর্ঘ্য রায়Pas encore d'évaluation

- Measurement of C A S E Depth: Bydale J.Wright, General Superinlendent Heat Treatdiv., Caterpillartractorco. Peoria, IllDocument3 pagesMeasurement of C A S E Depth: Bydale J.Wright, General Superinlendent Heat Treatdiv., Caterpillartractorco. Peoria, IllRitikPas encore d'évaluation

- Process and Product Audit Plan For Cup-Cone For The Year of 2018Document11 pagesProcess and Product Audit Plan For Cup-Cone For The Year of 2018অর্ঘ্য রায়Pas encore d'évaluation

- Wa0007Document2 pagesWa0007অর্ঘ্য রায়Pas encore d'évaluation

- Reduce FrictionDocument2 pagesReduce Frictionঅর্ঘ্য রায়Pas encore d'évaluation

- Part - Ii Examination Fees: Rs.2000/-: (For Office Use Only) Receipt No.: Date: Examination FeesDocument1 pagePart - Ii Examination Fees: Rs.2000/-: (For Office Use Only) Receipt No.: Date: Examination Feesঅর্ঘ্য রায়Pas encore d'évaluation

- IntrodfjgjgDocument32 pagesIntrodfjgjgঅর্ঘ্য রায়Pas encore d'évaluation

- HT Plan 17th To 28thDocument8 pagesHT Plan 17th To 28thঅর্ঘ্য রায়Pas encore d'évaluation

- Permty So Tat Annot EsDocument4 pagesPermty So Tat Annot Esঅর্ঘ্য রায়Pas encore d'évaluation

- The Bed of The HearthDocument1 pageThe Bed of The Hearthঅর্ঘ্য রায়Pas encore d'évaluation

- The SeverityDocument1 pageThe Severityঅর্ঘ্য রায়Pas encore d'évaluation

- Precipitation Because The Is Very SlowDocument1 pagePrecipitation Because The Is Very Slowঅর্ঘ্য রায়Pas encore d'évaluation

- Laue PhotographDocument1 pageLaue Photographঅর্ঘ্য রায়Pas encore d'évaluation

- Recovery Stage ofDocument1 pageRecovery Stage ofঅর্ঘ্য রায়Pas encore d'évaluation

- Reduce FrictionDocument2 pagesReduce Frictionঅর্ঘ্য রায়Pas encore d'évaluation

- 352 32115 EC331 2013 1 1 1 EC331.Lecture.4Document50 pages352 32115 EC331 2013 1 1 1 EC331.Lecture.4Tamirat SilashPas encore d'évaluation

- Pchs-I - 3mn-E1 Ring Force Load CellsDocument3 pagesPchs-I - 3mn-E1 Ring Force Load CellsMIGUEL LOPEZPas encore d'évaluation

- Sharp AR-M207, AR-M165, AR-M162 Parts & ServiceDocument178 pagesSharp AR-M207, AR-M165, AR-M162 Parts & Service4555556100% (2)

- 1MRK502029-UEN en Installation Commissioning Manual REG670 1.2Document258 pages1MRK502029-UEN en Installation Commissioning Manual REG670 1.2Anonymous bSpP1m8j0nPas encore d'évaluation

- IEEE AP-S - DL Brochure - SASTRA PDFDocument2 pagesIEEE AP-S - DL Brochure - SASTRA PDFTroll BwoiPas encore d'évaluation

- Read and Understand Electronic Radar 1920s: SignalsDocument14 pagesRead and Understand Electronic Radar 1920s: SignalsAdrian TerrazasPas encore d'évaluation

- Bar Bending Schedule (BBS) : Penulangan Horizontal Tie Beam As-ADocument4 pagesBar Bending Schedule (BBS) : Penulangan Horizontal Tie Beam As-AWilly PriambudiPas encore d'évaluation

- Schneider - Electric GVAD0110 DatasheetDocument2 pagesSchneider - Electric GVAD0110 DatasheetNilton SAPas encore d'évaluation

- FlowCon FN02 02-BUS 04 InstructionDocument8 pagesFlowCon FN02 02-BUS 04 InstructionSalah ArafehPas encore d'évaluation

- Symbols of Transmission Lines: (Electrical Distribution)Document2 pagesSymbols of Transmission Lines: (Electrical Distribution)mhs madiunPas encore d'évaluation

- Desktop and Charge-Only Dual Base Compliance Insert: For Users in English-Speaking Regions (En)Document12 pagesDesktop and Charge-Only Dual Base Compliance Insert: For Users in English-Speaking Regions (En)Mitko MihaylovPas encore d'évaluation

- ZVS-ZCS Bidirectional Full-Bridge DC-DC ConverterDocument6 pagesZVS-ZCS Bidirectional Full-Bridge DC-DC ConverterVenkatesan SwamyPas encore d'évaluation

- Blue LedDocument3 pagesBlue LedKrishnaPas encore d'évaluation

- Adetunji Timilehin Eee191334Document4 pagesAdetunji Timilehin Eee191334somoyetobi8Pas encore d'évaluation

- Radiodetection RD4000: The World's Most Advanced Cable and Pipe Locating SystemDocument6 pagesRadiodetection RD4000: The World's Most Advanced Cable and Pipe Locating SystemRidha Ben AbdelwahedPas encore d'évaluation

- IM-T-9A and IM-T-11A Interface Modules: DatasheetDocument11 pagesIM-T-9A and IM-T-11A Interface Modules: DatasheetJuanEmmanuelCarlosAttwellPas encore d'évaluation

- Iec 77a-532-Np (2006) PDFDocument6 pagesIec 77a-532-Np (2006) PDFJulián C. PachónPas encore d'évaluation

- Final Copy LDRDocument9 pagesFinal Copy LDRUday100% (1)

- Narrow BPF and BRF - Record PartDocument9 pagesNarrow BPF and BRF - Record PartAlfred D'SouzaPas encore d'évaluation

- Instruction Vertyanov JIG Ver3 PDFDocument26 pagesInstruction Vertyanov JIG Ver3 PDFJoao GentilePas encore d'évaluation

- Page 1 of 4 Buy Behringer PMP5000-B212XL PA Package - Live Sound Packages - Musician's FriendDocument4 pagesPage 1 of 4 Buy Behringer PMP5000-B212XL PA Package - Live Sound Packages - Musician's FriendCarlos Ediver Arias RestrepoPas encore d'évaluation

- Radio Receiver: Malahit-Dsp1 Malahit-Dsp2 Malahit-Dsp3Document56 pagesRadio Receiver: Malahit-Dsp1 Malahit-Dsp2 Malahit-Dsp3ol ok100% (1)

- D 3820Document41 pagesD 3820teja tejaPas encore d'évaluation

- 1T01128Document1 page1T01128Mahesh KhiwalPas encore d'évaluation

- K1Fo 12 Element 144/147 MHZ YagiDocument11 pagesK1Fo 12 Element 144/147 MHZ YagiAndhi AerosupplyPas encore d'évaluation